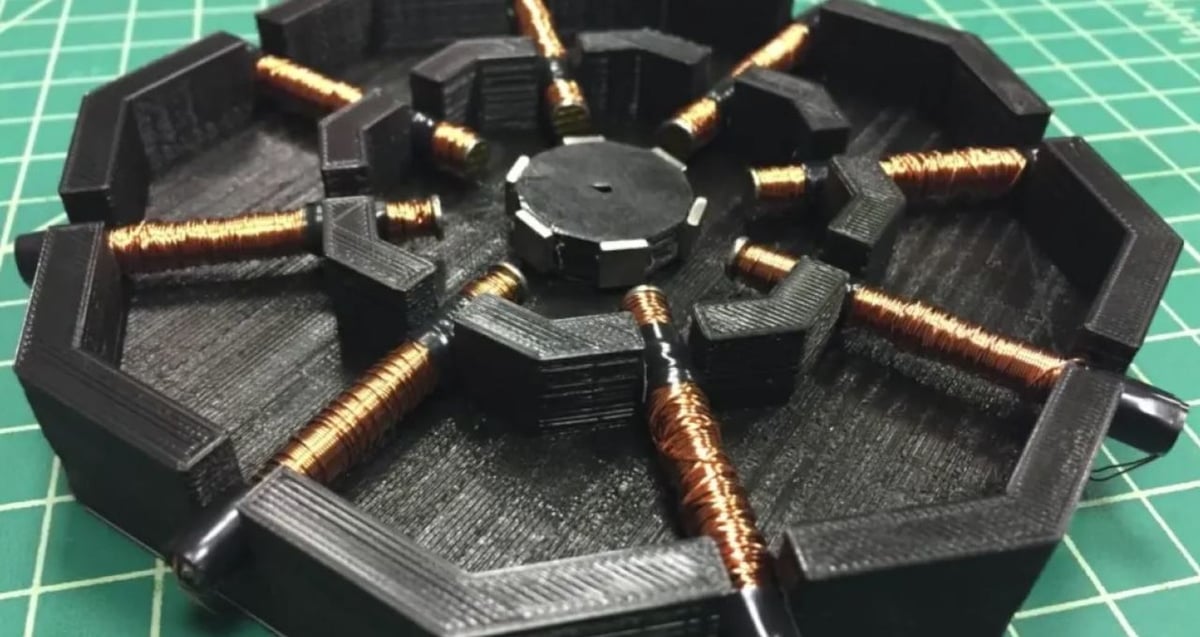

If you have a 3D printer, you may have noticed those boxy and heavy motors that control motion along the axes of your printer. 3D printers typically function using this specific type of motor, known as a stepper motor.

Stepper motors are used on 3D printers, CNC machines, laser engravers, and other machines for their immense accuracy. Stepper motors rely on a current supplied by the machine to rotate a certain amount; this specific rotation is known as one step for the motor.

The smaller the available step, the more capable the printer is of being precise. That’s why on some machines, you’re advised to use a layer height divisible by 0.04 because the stepper motor has a full step of 0.04 mm. However, moving in single, whole steps isn’t the only option for 3D printers because of something called microstepping.

In this article, we’ll go over the basics of microstepping and what it is. We’ll discuss how it relates to 3D printing, reviewing what controls it, and how it can be used.

What Is It?

Microstepping is the division of a singular step into smaller steps. These smaller, “micro” steps are typically a fraction with a denominator that’s a multiple of 2, such as 1/16, 1/32, or 1/64. As we mentioned, microstepping allows the motor to rotate a distance smaller than that of a single, whole step. But how does it work?

The Mechanics

Inside the motor, there are electromagnetic coils. When a coil receives power, a magnet spins toward it, which spins the core of the motor. Say the motor magnet is pointing towards a coil ‘A’. When the right-hand coil ‘B’ receives power, the magnet spins to face coil ‘B’. This process represents how a motor moves one full step.

For microstepping, the magnet needs to end facing an area in between two coils. This happens when both coils receive power, but they receive a fraction (the microstepping value) of the power they would normally receive for whole steps. To get the magnet to face a direction closer to coil ‘A’, coil ‘B’ would get less power than coil ‘A’.

What Controls It?

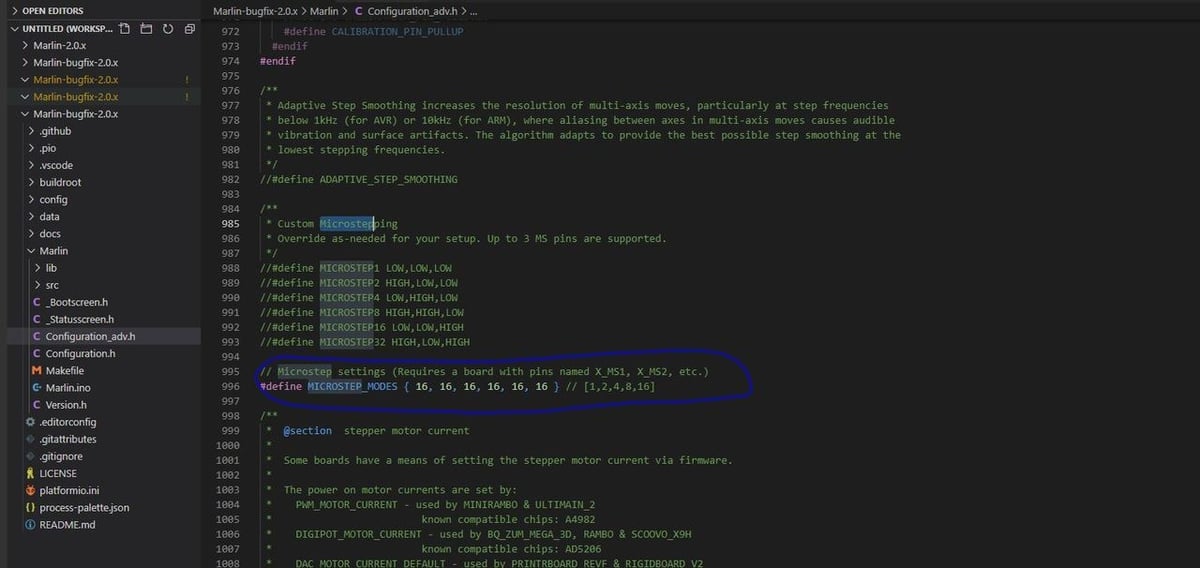

The microstepping fraction for stepper motors is actually set through the firmware on your machine. At the same time, your mainboard has to be able to handle the value or else it won’t work (or could break something). Typically, your mainboard will be the limiting factor because you can always adjust or find new firmware that enables smaller microsteps.

Mainboards are equipped with stepper motor drivers that have a limit for microstepping. Some mainboards have physically movable jumper pins so you can manually set a new mainboard microstepping value, but remember to change your firmware to match! You can’t use firmware permitting 1/256 microsteps on a board with drivers only capable of handling 1/128 microsteps, and the same goes for the reverse.

Consider if you had a stepper motor with a whole step of 0.2 mm, and you wanted to perform a move of 0.00625 mm. If your firmware only allows for 1/32 microstepping, your printer won’t be able to perform such a precise motion. Instead, it’ll move as close as it can using the smallest permitted microsteps. Essentially the smaller (or larger the denominator of) the microstepping value, the more accurate your printer is.

If you want to adjust your firmware to use a different microstepping value, Marlin firmware is a good choice. You may be able to change your microstepping value on other firmware programs too, but check first before adjusting your mainboard.

Downsides

So if smaller microsteps equals better prints, why not immediately upgrade your printer to the maximum microstepping mainboard and firmware? Well, the smaller the step, the lower the current the motor receives.

In other words, when a stepper motor rotates one full step, it receives a certain pulse of power to move. However, when it’s microstepping, it receives a fraction of the normal pulse (the amount of the microstep).

While this allows for more precise moves, it also means less torque for microstepping because the pulse is less powerful. Because of this, the motor has to continuously receive a pulse to maintain its precise position, which means more current is being used.

Accuracy & Performance

Microstepping can be very helpful at times; however, full steps are generally a better option when you can use them. That’s because they are more accepted and compatible, and they have more torque than microsteps. In theory, while full steps aren’t any more precise, they can hold their positions stronger than microsteps.

Also, keep in mind that just because you’re instructing your motors to perform precise moves, it doesn’t mean they are. If a microstep doesn’t allow enough motor torque to withstand other forces from moving the motor’s fine position, the motor won’t be able to perform the precise microstep. That’s why it’s always nice not to have to use microstepping, especially on the Z-axis of a 3D printer, because there can be considerable weight (from the extruder, etc.) pushing down on this axis.

Real World Examples

Microstepping has advanced significantly over time, and now, 1/256 microsteps are possible if the firmware and mainboard permit it. For reference and comparison, below we’ve listed three popular 3D printers and their microstepping capabilities:

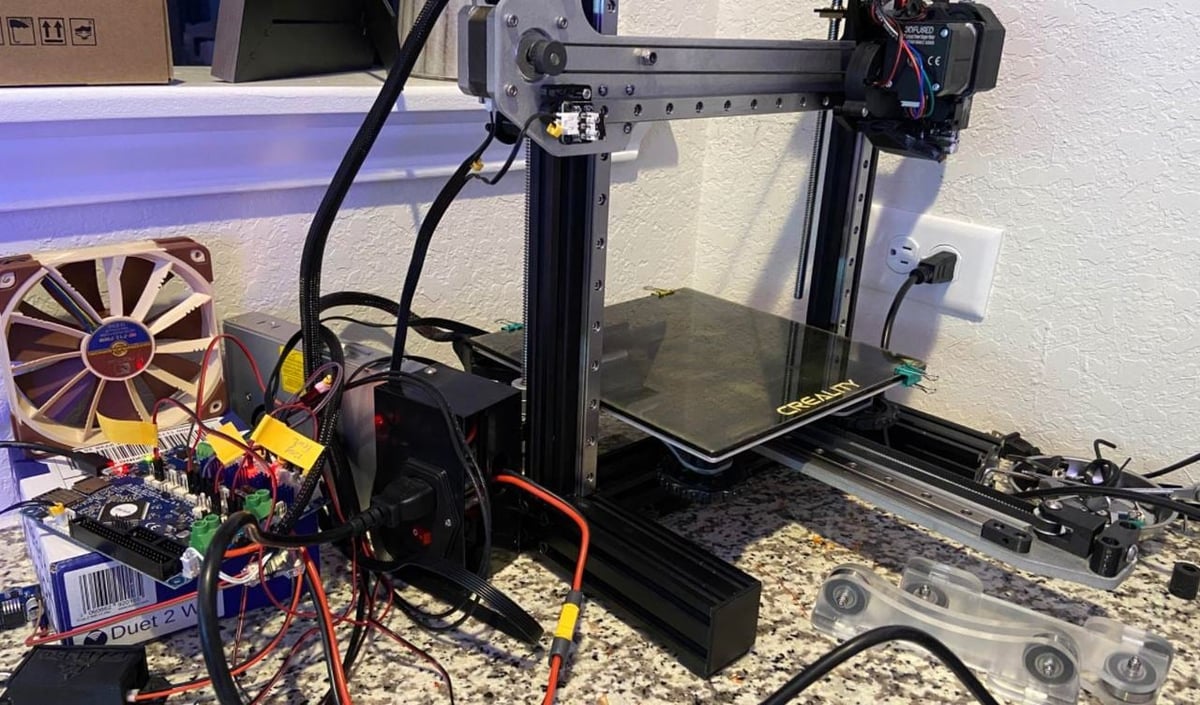

- The Creality Ender 3 (Pro and V2), equipped with a 32-bit V4.2.7 mainboard and Marlin 2.0, uses 1/16 microsteps by default.

- The Prusa i3 MK3S+, with a 8-bit Einsy Rambo mainboard and Prusa Marlin firmware, is capable of 1/256 microsteps.

- The Anet A8, with its stock mainboard and original Marlin-based firmware, is capable of 1/16 microsteps.

Below are three additional mainboards and their maximum microstepping values:

- Smoothieboard V2: 1/256

- Duet 2 Wifi: 1/256

- MKS Gen L: Manually adjustable up to 1/32, depending on drivers

Overall, microstepping can be very useful to make precise moves on your 3D printer for more dimensionally-accurate prints. However, the smaller the microstepping value, the less torque the steps will produce, and they could fail. So, for this reason, you should try to limit how much microstepping is used in prints and use full steps if your design permits it.

Lead image source: MatterHackers

License: The text of "What Is Microstepping? – Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.