Types of Laser Marking Machines

Whether marking metal machinery or personalized gifts, laser engraving is your go-to technology. Laser engraving machines come in different types: Fiber lasers, CO2 lasers, and laser diodes.

The CO2 laser is the most common, with relatively cheaper machine prices, and where the technology depends on a gas medium to amplify the power of the laser source. One limitation of CO2 lasers is the types of materials that can be engraved. While covering most basic materials, such as wood, acrylic, cardboard and fabric, this type of laser is not convenient for most metals. Consequently any application that uses sliver, gold or aluminium will not work with a CO2 laser.

Instead, you’ll need to turn to a fiber laser, which uses an earth medium to amplify laser power. An example of earth mediums used is Neodymium, a metal used in the manufacturing of very strong magnets. A fiber laser works more efficiently for industrial uses, whether for plastic or metal materials. Engraving on machine blades, creating metal name tags from coated aluminum, or permanent marking on plastic are all common applications of the fiber laser. Some brands offer machines with a dual laser source — a CO2 and a fiber source — where prices are significantly higher.

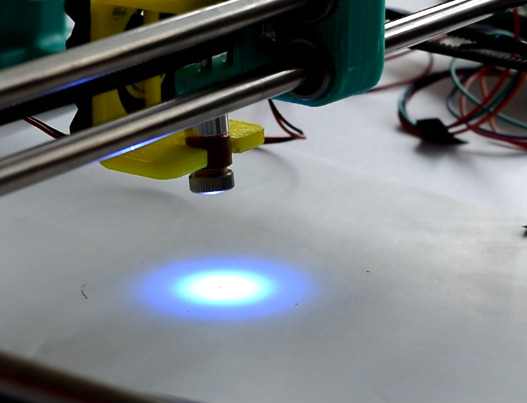

Finally, lasers that use diodes as a source are ideal for light material applications, such as fabrics and different types of cardboard. In this case, there is no amplification of laser power, only a diode (similar to an LED). Diode laser machines mostly come in small sizes, are relatively slower and significantly cheaper.

Laser Marking on Soft Materials

CO2 or diode laser sources are ideal for soft materials, such as leather, cardboard and different fabrics. With this type of engraving, the heat from the laser source burns the initial surface layer, causing a change in color and texture. For example, in the case of leather, when the initial layer is burned, a dark or light marking is produced, depending on the type of leather. Natural leather would result in a dark mark, while faux leather would have only its plastic coating burned, resulting in a mark that has the same color of the fabric underneath.

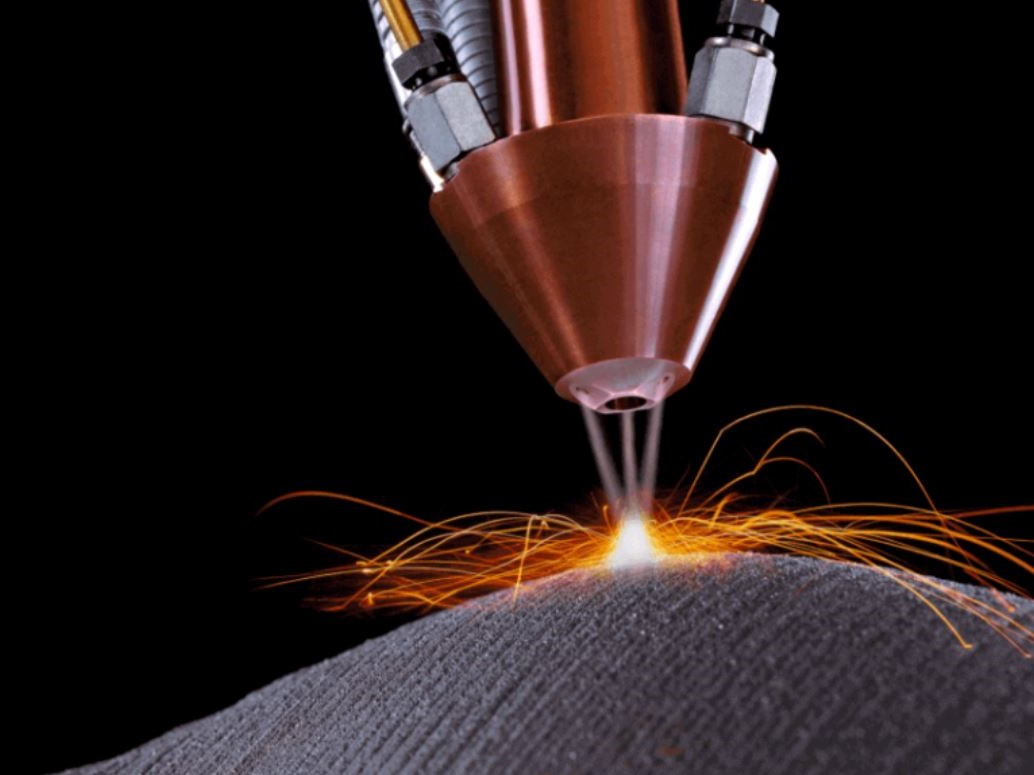

Laser Marking on Hard Materials

Ranging from jewellery to machine parts to electronic components, fiber lasers can make customizable laser marking solutions for variety of materials. With this technology, different processes correspond to different materials.

One such process is annealing, where heat from the laser oxidizes the initial metal layer. The selected area changes color, but it is not removed. This is also referred to as black surface marking, since it produces a tan or dark color. Laser marking on knife blades, for example, is done using annealing.

White surface marking is another process — mostly used on metals or coated metals — where the laser removes a very fine layer from the surface. Similar to white surface marking is frosting, which is used for reflective or highly polished surfaces.

Finally, plastics also benefit from fiber laser marking. Through a process called foaming, they change color due to the laser’s heat.

All these processes are surface lasers marking, which leaves no or slight change in surface texture. Another option is deep engraving, where the final mark is embossed with a different texture.

Laser Marking Services

Related Articles