PLA is the most commonly used filament in 3D printing today. There are many reasons for this, but mostly, it’s a combination of its low extrusion temperature, price, and ease of use. All of these reasons combine to make PLA incredibly versatile, and some of the desired parts to be printed will inevitably come into contact with food. It can be used for 3D printing everything from cookie cutters to chopstick rests, even dog bowls! Searching STL file repositories reveals just how many food-related accessories are out there for you to print!

If you’ve ever thought about using 3D prints around food, it’s important to know what you’re getting yourself into. For example, if you try and use a stirrer printed from PLA in a hot coffee, the spoon will bend and possibly melt! Even more of a concern is the bacteria that could be lurking trapped between the layers of the print.

Food safety is a complex issue, filled with acronyms. If you’re not a microbiologist, this article will help you get a handle on food safety when working with PLA, what the risks are, and how you can improve the food safety of your PLA prints.

The Ingredients

The basic building block of PLA is a chemical called lactic acid. Lactic acid is produced by the body naturally and is the chemical responsible for the burning feeling in your legs after a sprint. Poly(lactic) acid, PLA, is multiple units of lactic acid joined together in a chain.

PLA for 3D printing is often derived from leftover sugarcane or corn crops, which is why it’s often described as a bioplastic. However, just because it’s made from food doesn’t mean it’s food safe!

During the manufacturing process of a spool of filament, there may be cross-contamination with other polymers or from catalysts used during PLA production. Manufacturers first need to turn the lactic acid into a long chain of molecules. This requires a lot of energy, so catalysts are added to aid the process. Extruding the raw PLA into filament through machinery may also introduce residues from other thermoplastics left over from previous production runs. Furthermore, manufacturers often use additives to enhance the properties of PLA to make it easier to work with. This is particularly common in PLA+ filaments, where sometimes even ABS is used!

Overall, although many PLA brands are recognized as food safe by key authorities like the EFSA and FDA, you should be wary when you know a part will come into contact with food. Don’t make the mistake of assuming a filament is food safe just because it’s PLA, and check out manufacturer’s websites to see if they’re displaying any certification.

When Leftovers Aren't Tasty

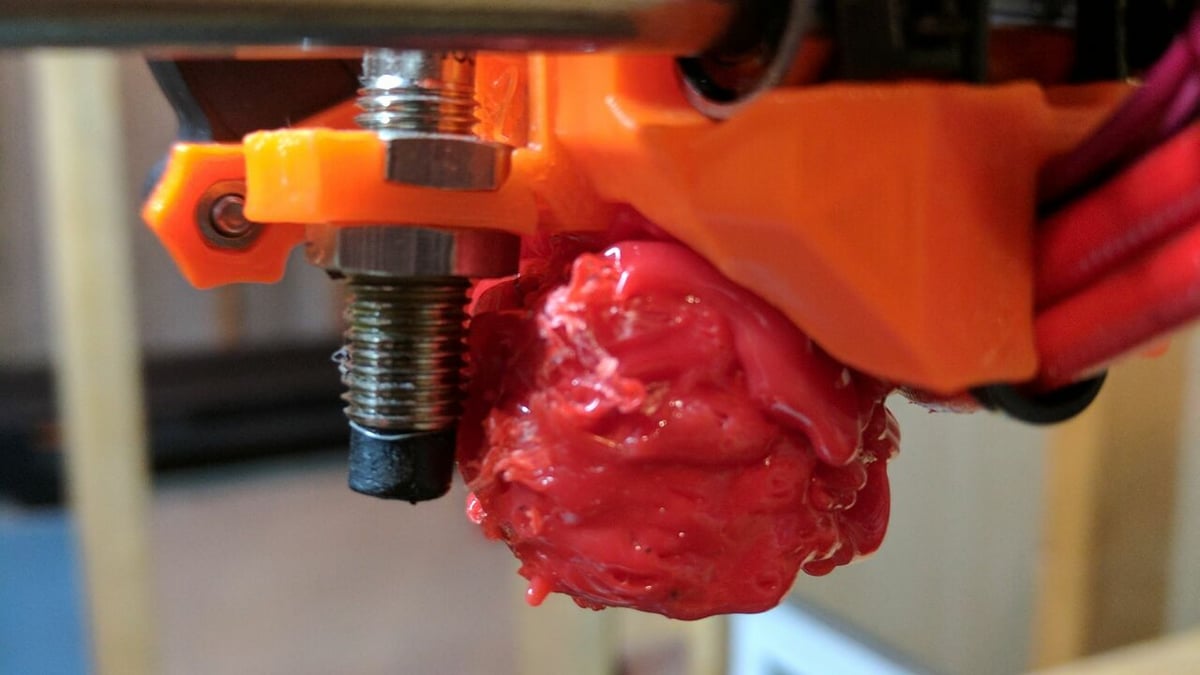

Even if the material you’re working with has been certified as food safe, there are still a lot of ways this could be compromised. All filaments that you print with will deposit small amounts of material inside your printer’s hot end. For example, when you change from colored to white filament, you’re likely to see streaks of color in the extruded filament. The same thing happens with different materials, too.

If you’ve ever printed with a higher temperature filament, like PETG, and forgotten to purge the hot end before switching to PLA, you’ll know how much filament can end up stuck in the hot end. So, while your filament itself might be food-safe, there may be unsafe residues in your hot end contaminating it.

One way to prevent cross-contamination is to use a specific food-safe hot end. This doesn’t need to be anything too fancy, just a separate hot end you know you only use for food-safe filaments. Another consideration is that the hot end should ideally be all metal and made of stainless steel – that also goes for the nozzle. This avoids the risk of any lead present in brass alloys contaminating your food-safe prints.

Additionally, an all-metal hot end has no PTFE liner, which avoids the risk of thermal decomposition of PTFE, as PTFE and related chemicals are known to be toxic. As a bonus, an all-metal hot end is also easier to clean.

A final thought is to remember that temperature control is vital to avoid thermal decomposition of the PLA itself. Printing too hot may well produce unsafe compounds from even a food-safe filament.

The One with All the Letters

When researching food safety and 3D printing, you’ll often find lots of technical language. Chief among these are the bureaucrat’s best friend – acronyms! Two of the most important bodies to be aware of are the FDA (Food and Drug Administration) and the EFSA (European Food Safety Authority), both of which we’ve already mentioned. These are the organizations that determine whether something can be officially classed as safe to use with food in the US and EU, respectively.

Other important acronyms to understand include the following:

- VOCs (volatile organic compounds): Easily evaporated chemicals (think of the smell of opening a solvent) that are produced by 3D printing.

- UFPs (ultrafine particles): Microscopic plastic particles produced by FDM printers. These aren’t great to inhale or ingest. They adhere to surfaces like the hot end and bed of the printer, leading them to stick to prints, which can lead to cross-contamination.

- MSDS (material safety data sheet): A document produced by manufacturers containing information about a product’s safety. The key thing to check in relation to food safety is that a material is just PLA without any additives (Section 1 of the MSDS).

- GRAS (generally recognized as safe): A certification by the FDA that a product is generally safe to be in contact with food.

Layer Lines: A Home for Bacteria

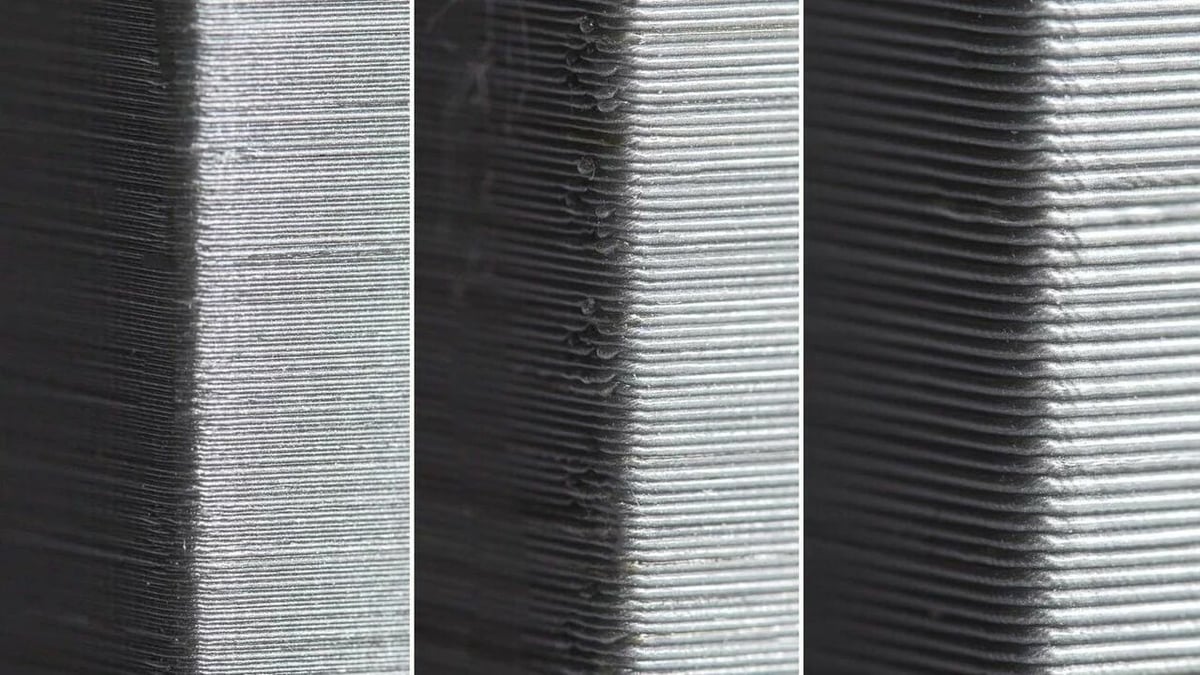

FDM, by the nature of the manufacturing process, introduces lines between the layers and tiny pores in the surfaces of printed parts. These nooks and crannies provide an ideal nesting ground for bacteria to breed. Regardless of how perfectly tuned your settings are, parts produced on FDM machines will unavoidably feature layer lines. This is true even if you can’t see them at minuscule layer heights.

These microscopic imperfections make it very difficult to truly clean a 3D printed object that is in contact with food. Small particles of food can be trapped in these gaps, providing sustenance for bacteria. This can lead to a higher chance of food poisoning when using 3D printed items. And due to the comparatively low glass transition temperature of PLA, disinfecting a part by boiling isn’t an option, as it will likely deform your part.

How to Improve Food Safety

One way to make PLA parts safer to use with food is by sealing the surface with food-safe epoxy. The epoxy resin fills in layer lines and pores, preventing bacterial growth and making parts easier to wash. If you weren’t already convinced, epoxy also reduces the likelihood of non-food safe material coming in contact with food by providing a barrier between the 3D printed part and food. However, if you want to go down this route, it’s vital your epoxy resin is food safe!

Remember not to put PLA parts in the dishwasher or use them for hot food or drink. PLA has a low glass transition temperature of around 65℃. This means the PLA will soften in the dishwasher or in contact with hot food. If you’re looking for food-safe filaments that are heat resistant, there are some other options. Otherwise, stick to a non-abrasive soap and lukewarm water when cleaning PLA prints.

Finally, and most importantly, do your research! You’ve made an excellent start by reading this article. You can learn more about food safety from the FDA’s Code of Federal Regulations (CFR) 21 and the EFSA’s EU Commission Regulation No. 10/2011. If you’re selling your work, you should definitely familiarize yourself with the food safety regulations in your country.

In conclusion, be wary when printing PLA parts for use with food. While the material itself is technically food safe, and there are ways to limit potential contamination from the printing process, there are always risks involved. Consider the end-use of what you want to print: If the food contact will be brief, like using a cookie cutter, the risk is likely to be lower than, for example, drinking from a 3D printed cup. It’s always better to be safe than sorry!

License: The text of "Is PLA Food Safe?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.