This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Anti-Extrusion Material

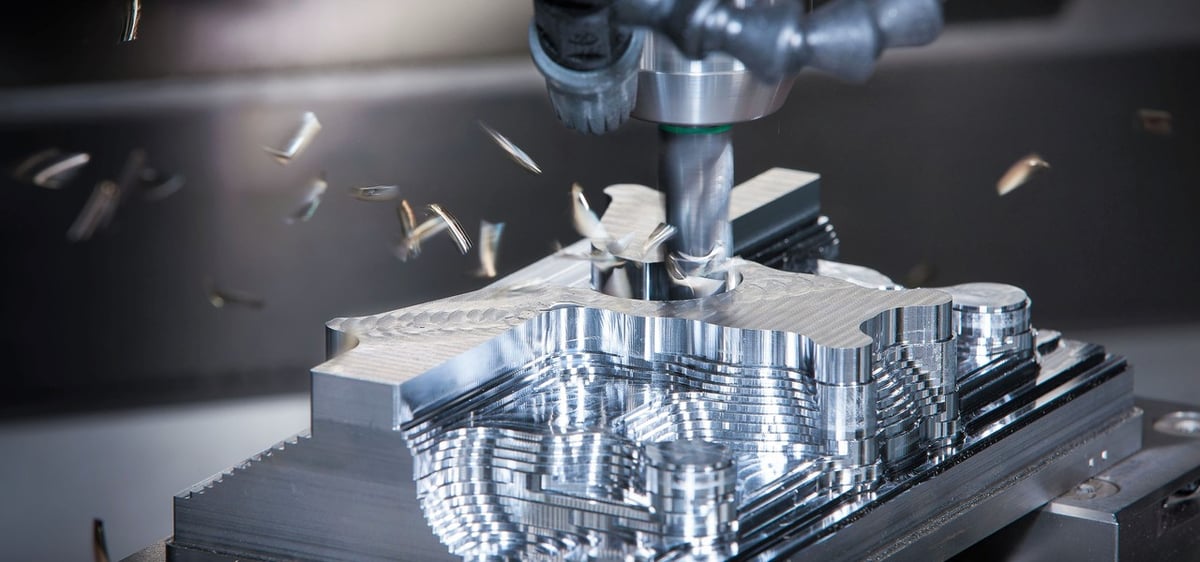

How to Choose the Correct CNC Material

CNC is a computer controlled fabrication technique and about 30 years older than 3D printing. Fast, accurate, and versatile, it belongs in the advanced maker's toolkit.

Advertisement

Advertisement