These two leading computer-aided design (CAD) software platforms, SolidWorks and Fusion 360, are often compared. They are both used by designers and engineers for creating 3D models and they share a wide menu of functions and tools. But each has its strengths.

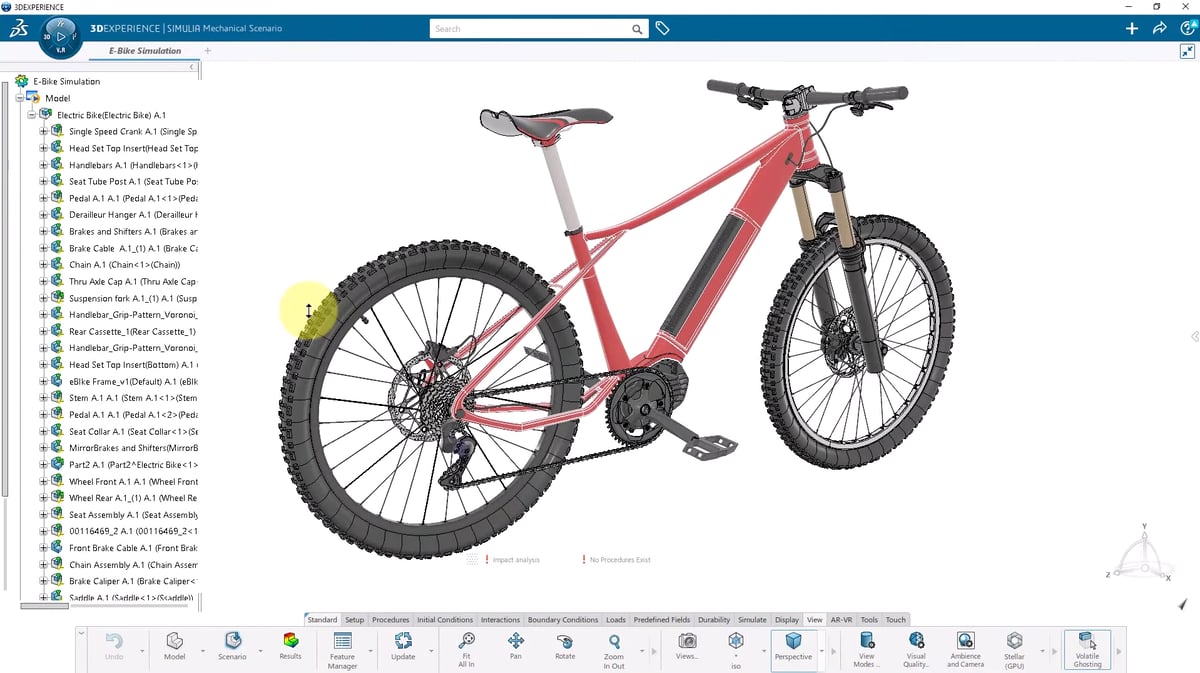

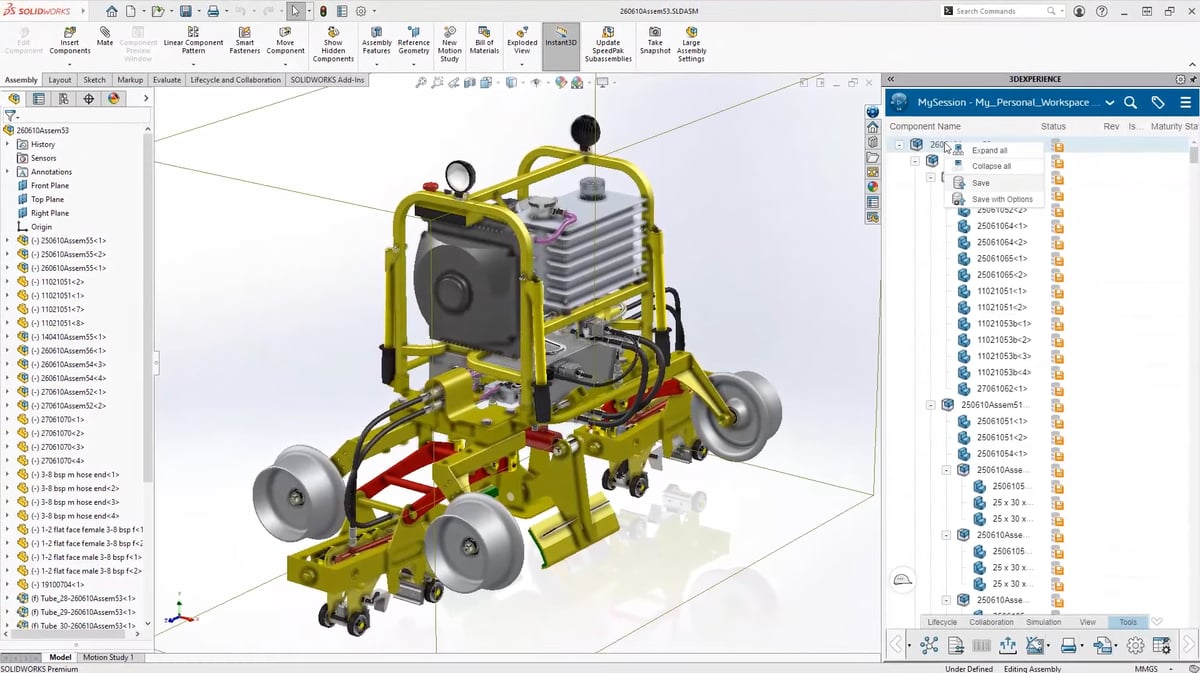

Overall, SolidWorks, developed by Dassault Systemes, is renowned for its robustness in mechanical design and engineering. It’s favored for creating complex assemblies, simulations, and generating detailed manufacturing drawings. It is widely used in automotive, aerospace, and manufacturing.

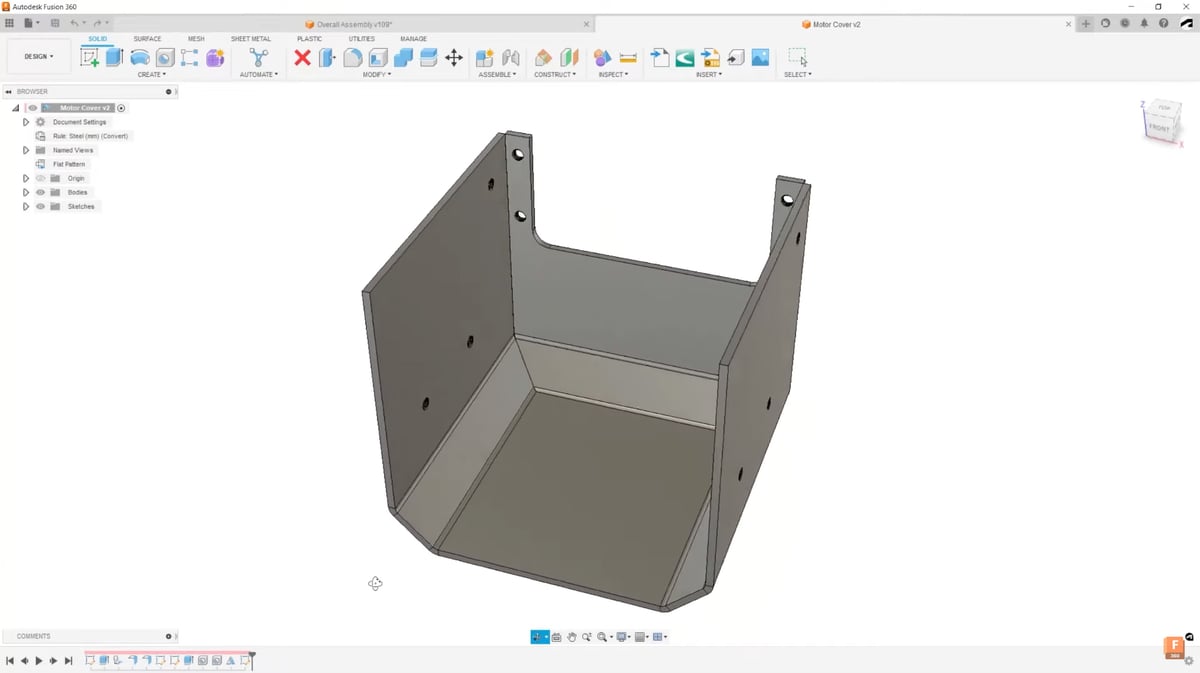

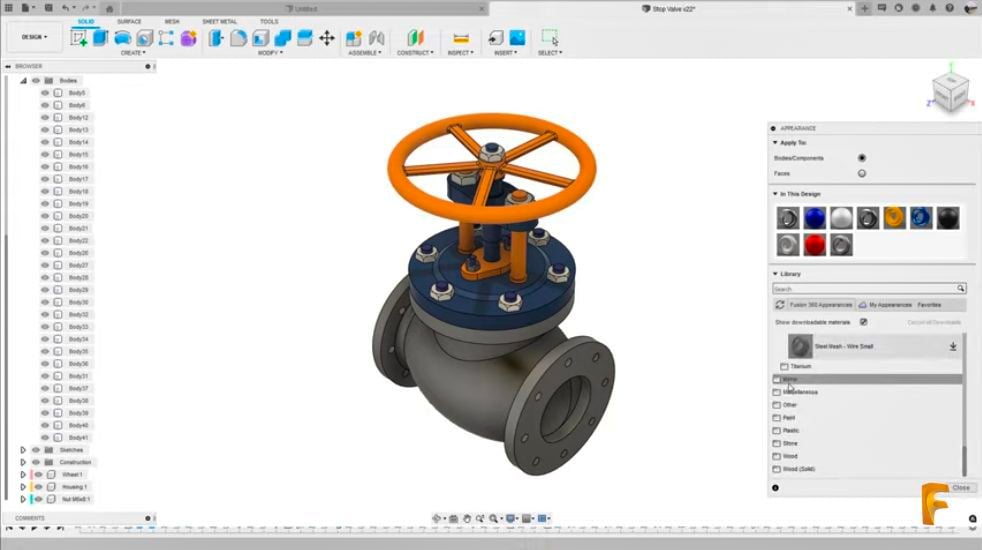

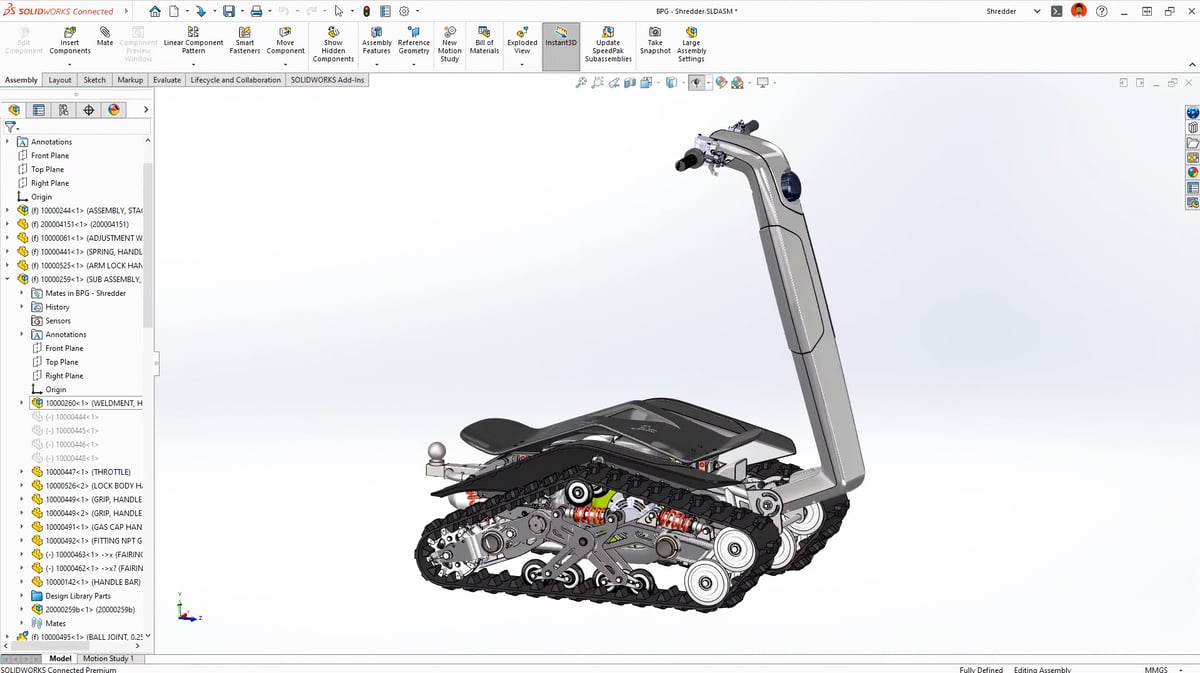

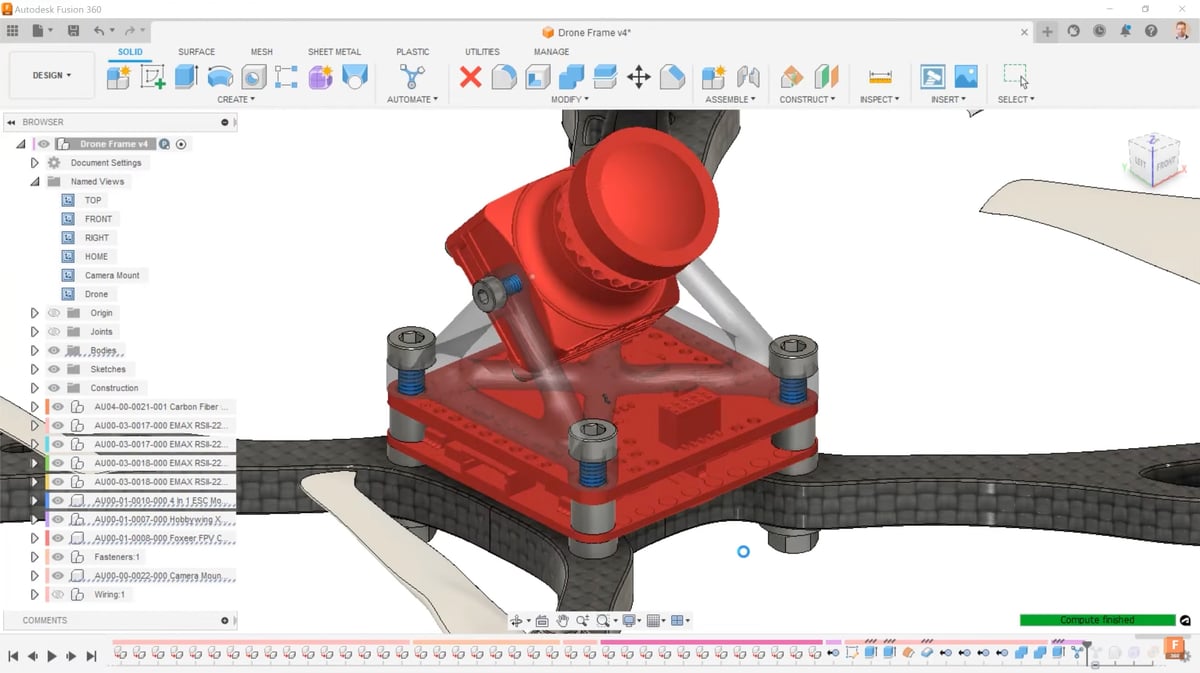

On the other hand, Fusion 360 (now called just Fusion), developed by Autodesk, is known for its flexible 3D modeling, simulation, and rendering capabilities. It’s popular with startups, hobbyists, and small businesses due to its ease-of-use, collaborative features, and integrated CAM functionality. It can be super-charged with a range of sophisticated extensions, expanding it reach to virtually any industry.

In a nutshell, it’s traditional versus versatile. And with that said, let’s jump right into what specifically makes and separates these two top-tier CAD programs.

Feature Comparison

Let’s take a quick look at the major features of these two CAD program comparing the most robust versions, which are SolidWorks Premium vs. Fusion 360, plus all available add-ons and extensions from the parent publishers. This enables you to see the full depth of each one’s features.

Both of these CAD programs are available in versions that do not offer the full feature set, such as the Standard SolidWorks and the student-version of Fusion.

User Interface

The user interfaces (UI) of SolidWorks and Fusion reflect their respective design philosophies and target user bases so it’s generally not easy to switch from one to the other.

SolidWorks features a traditional, window-based interface with a ribbon toolbar at the top, similar to many other professional CAD software applications. The ribbon toolbar organizes commands and tools into tabs and groups, making them easily accessible. On the left side of the screen, there’s a feature manager design tree, which provides a hierarchical view of the model’s features and components. Users can easily navigate through the design history and make changes to individual features.

For SolidWorks specifically, the UI might feel a little overwhelming, with many smaller icons and buttons. One huge advantage of SolidWorks over Fusion is the possibility to customize mouse buttons and keyboard shortcuts, making life much easier for those following the same workflow on a daily basis.

SolidWorks utilizes a context-sensitive PropertyManager that displays relevant options and parameters based on the selected feature or entity. This streamlined approach reduces clutter and helps users focus on the task at hand.

There’s also a strong focus on customizing your UI in SolidWorks by rearranging toolbars, adding or removing buttons, and creating custom keyboard shortcuts.

Fusion 360, on the other hand recently went through a modernization of its US. As a browser-based interface, it combines design, simulation, and manufacturing tools into a unified environment. The UI is organized into “workspaces”, such as Model, Sculpt, Patch, Render, and CAM, so you can transition between different stages of the design process.

Fusion 360’s UI incorporates collaborative features, such as commenting, markups, and shared project folders, facilitating teamwork and communication. Plus there’s the timeline and browser panel at the bottom of the screen, providing a chronological history of the design’s construction. Users can easily modify and reorder features and components directly from the timeline, promoting a non-linear and iterative design approach.

Fusion 360 integrates data management capabilities directly into the UI, allowing users to organize, track, and access project files, components, and revisions seamlessly. This centralized approach simplifies file management and ensures data consistency across projects.

Features & Functionalities

What’s challenging about comparing SolidWorks to Fusion is uncovering exactly which features on in the which version and which are reserved for additional-fee add-ons.

Autodesk doesn’t even like to call its Fusion extensions add-on, but rather they are features in the program that you “unlock” by paying for them. You’ll inevitably see something in Fusion 360 that you’d like to do but you need an extension subscription. On the one hand it seems sort of sneaky and revenue-driven, but on the other hand, there’s a good chance most users won’t need all of the possible features so why clutter with program with things you don’t need. Autodesk offers a robust CAD experience for a very reasonable price.

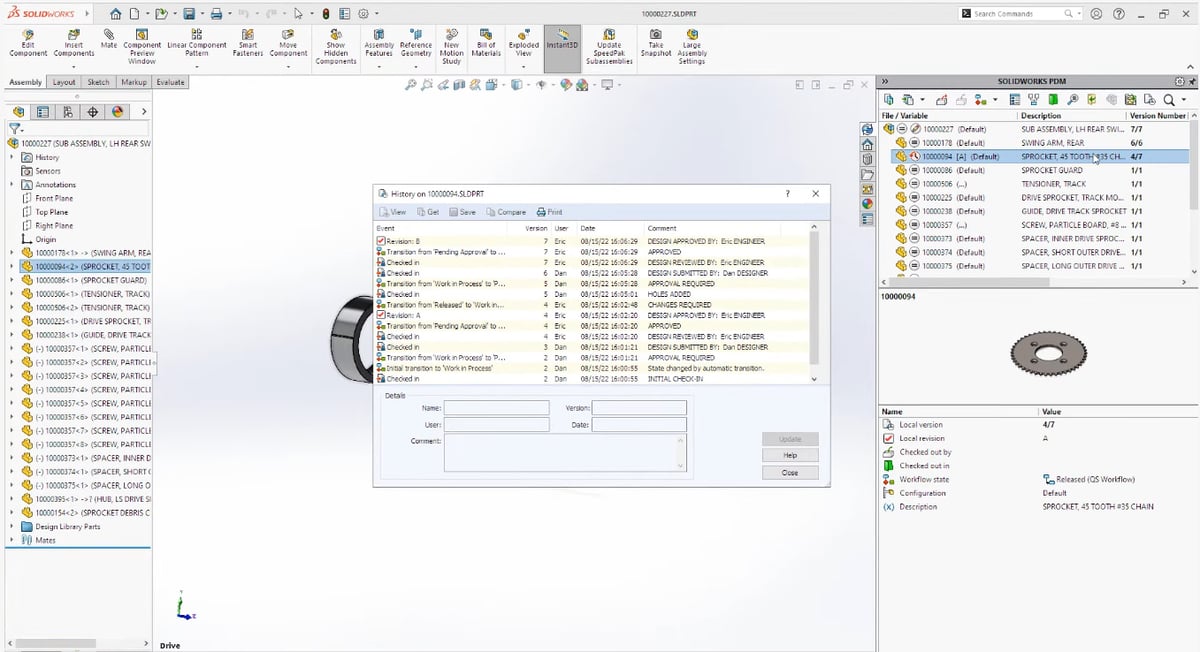

SolidWorks is more upfront with exactly what you’ll get in each of its three tiers: Standard, Professional, and Premium. It also offers a few other very niche add-ons, like the one for piping and tubing. In fact, you can see every SolidWorks feature on this page of its Help Documents.

Still, the way parts are created and assembled is where these two programs are the most fundamentally different. Lets take a look at three core functions and how they differ.

Parts & Assembly

SolidWorks and Fusion 360 are both capable of handling assembly design tasks, allowing users to create complex assemblies composed of multiple components and parts. However, SolidWorks is renowned for its more robust assembly design capabilities offering a comprehensive set of tools for creating, managing, and analyzing assemblies.

Among the SolidWorks assembly tools you’ll find a wide range of mate relationships; support for creating assembly-level features, such as cuts, holes, and patterns, which can be applied across multiple components simultaneously; and collision detection tools that identify and resolve problem interferences between components within an assembly.

Fusion also offers robust assembly design capabilities that let you define relationships between components, such as mates, joints, and motion constraints. You can also interactively assemble and disassemble, which is a handy tool for design iteration and collaborating with teams.

Like SolidWorks, Fusion includes a component library, but its is cloud-based so you can share access multiple projects.

Although both SolidWorks and Fusion offer robust assembly design capabilities, SolidWorks may have a slight edge in terms of its extensive experience and maturity in assembly design, offering a broader range of features and capabilities tailored specifically for mechanical engineering and product design.

On the other hand, Fusion’s integration with cloud-based collaboration features and its unified CAD/CAM/CAE environment may appeal if you’re looking for a more efficient approach to assembly design and engineering workflows.

SolidWorks is an assembly-oriented program, meaning that parts are created and saved individually before being assembled in a separate file. This is advantageous when the same parts are used in different assemblies, and it makes documentation easier.

In contrast, Fusion opts for a multi-component part system, where components of an assembly are created and assembled in the same file. This makes it easier for users to reference and create new components within an assembly.

In addition, Fusion supports mesh modeling, allowing the user to import polygon meshes such as STL files and instantly start sculpting in its user-friendly interface. SolidWorks offers a similar feature through its surfacing features, but it can be quite challenging to set up and execute.

Rendering

In terms of rendering capability, Fusion may have a slight edge over SolidWorks due to Autodesk’s more modern rendering engine and comprehensive feature set. Fusion’s rendering tools offer a broader range of options for creating realistic and visually appealing renderings, including advanced materials, lighting effects, and post-processing filters. Plus the cloud rendering capabilities enables you to offload rendering tasks to remote servers for, theoretically, faster processing.

Yet, SolidWorks 2024 introduced a host of new real-life rendering capabilities. You can now select appearance types and optimize their parameters more easily with a simplified interface, adjust textures and texture maps for parameters with greater control and fidelity, the company says.

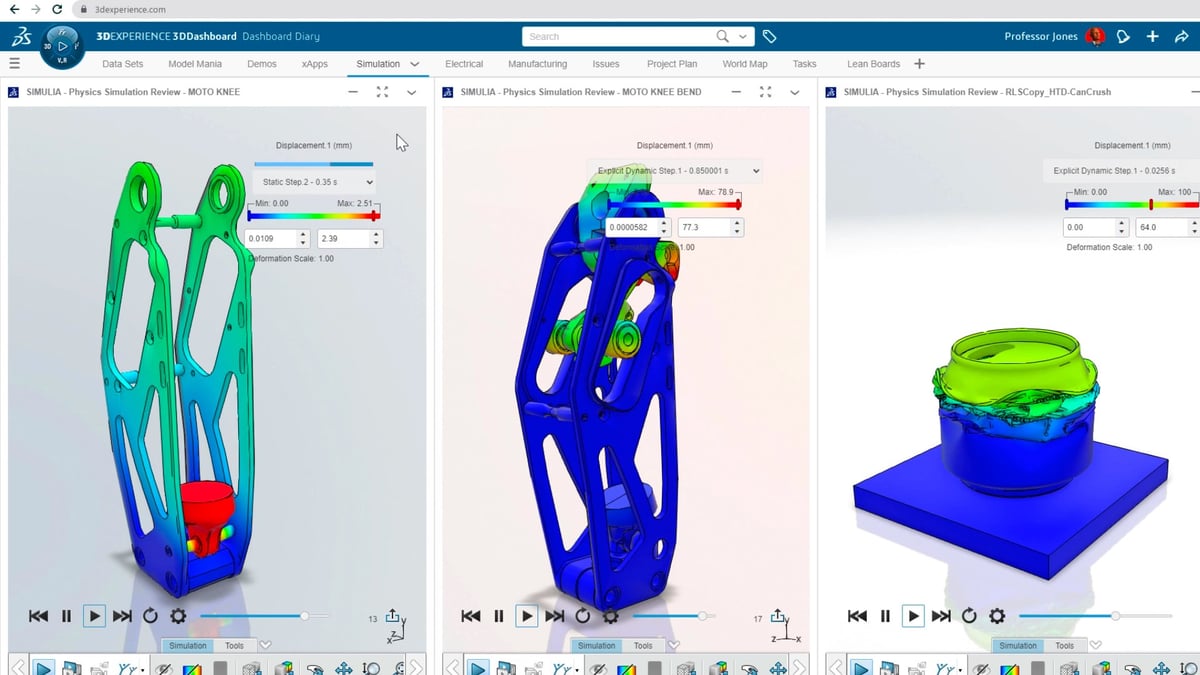

Simulation

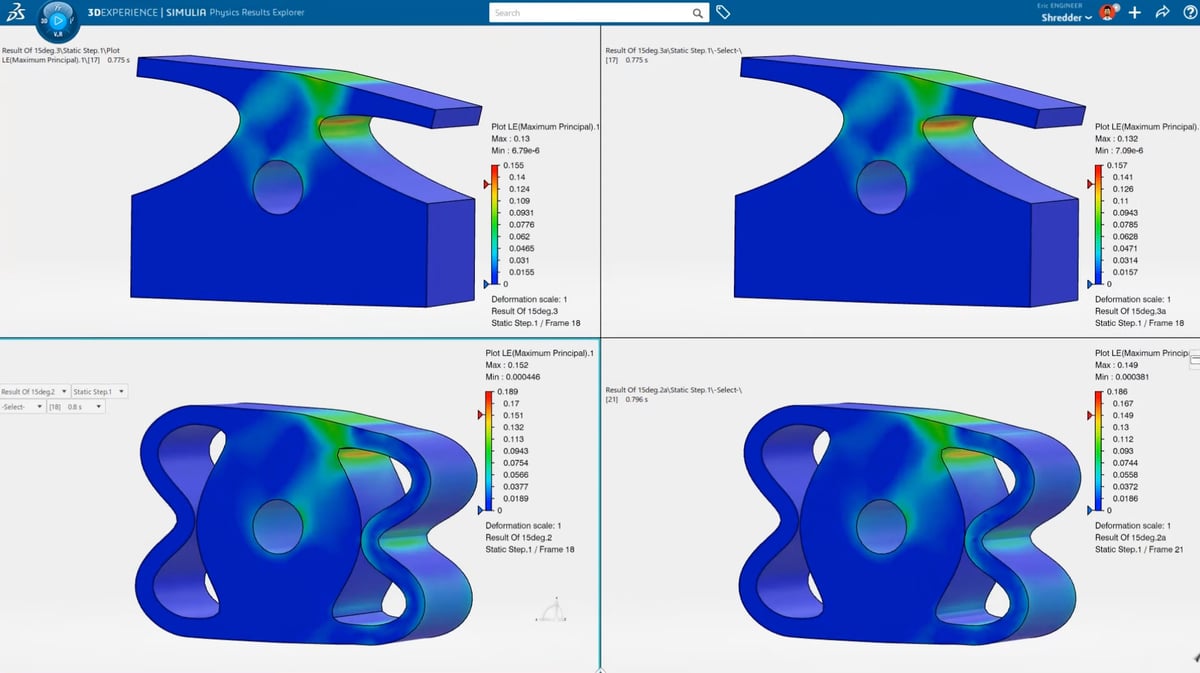

When it comes to simulations, both programs offer some baked-in tools to analyze and validate designs for mechanical performance, structural integrity, and other engineering criteria, plus more robust capabilities found in optional extensions.

SolidWorks provides a range of simulation tools under the umbrella of SolidWorks Simulation, including finite element analysis (FEA) capabilities for simulating structural behavior, thermal performance, and motion analysis. It allows users to apply various loads, constraints, and boundary conditions to analyze how a design will perform under real-world conditions.

Flow Simulation is a computational fluid dynamics (CFD) tool integrated into SolidWorks that covers fluid flow, heat transfer, and airflow around objects. There’s also a plastics simulation tool specifically designed for analyzing the injection molding process.

Fusion includes simulation capabilities through its Simulation workspace, which offers finite element analysis (FEA) and thermal analysis tools. Just like in SolidWorks, you can apply forces, constraints, and material properties to simulate how a design will behave under mechanical stress.

Modal analysis in Fusion helps you understand the natural frequencies and mode shapes of a design, which is crucial for avoiding resonance and vibration issues in mechanical systems. There are also some tools for simulating heat transfer and thermal performance of designs.

Purchase the Simulation Extension ($1,465/year) for Fusion and you can boost your simulations options significantly. Not only are there more robust versions of the simulations in the standard platform but you now have access to generative design (formerly a separate Fusion extension) as well as event simulation, injection molding simulation, electronic cooling, and more.

Price & System Requirements

Almost all CAD software is sold on a yearly subscription basis, and that’s somewhat the case for both SolidWorks and Fusion.

- SolidWorks is a one-time purchase with a yearly subscription on top for updates and around-the-clock professional support. For example, the premium version is around $8,000 for the perpetual license and then another $2,000 per year on top. The standard version is about $4,000 for the perpetual software license plus $1,295/year for an annual subscription.

- Fusion is much lighter on the pocket at first. The full version can be used with either yearly or monthly payments, ranging from $85 per month or $680 per year. This subscription grants full access to all workspaces that include CAM and CAE functionalities. Keep in mind that extensions are required for many advanced functions. For example, advance design for additive manufacturing requires a Fusion with Netfabb Premium subscription at $5,300/year. Advanced simulation is another $1,400 on top of your Fusion subscription per year.

Free Trials, Student, & Other Licenses

Both CAD programs offer alternative licenses. Fusion is free for students and educators and qualifying start-ups, while the educational version of SolidWorks costs from $60 – $99 per year. A limited-feature version of Fusion is free for personal use, which is why it’s so popular for hobbyists.

For many, the system and hardware requirements may be the deciding factor. Once again, they differ greatly between these two programs. SolidWorks will not run natively on a Mac, whereas Fusion 360 is optimized for Mac or Windows environments.

SolidWorks

- Minimum system requirements: 64-bit Windows 10 or newer

- eDrawings for Mac: macOS Monterey (12.0)

- Recommended hardware: 64-bit; Intel or AMD processor, 16 GB RAM, certified GPU

Fusion

- Minimum systems requirements: Windows 10 or newer, MacOS Big Sur ( Until March 2024), Monterey, or Ventura

- Recommended hardware: 3.0 GHz or greater 64-bit processor with 6 or more cores, 8 GB RAM, dedicated GPU with 4 GB or more

Support

SolidWorks and Fusion are very well supported. Their developers, Dassault Systemes and Autodesk, respectively, are both huge companies with a presence in many different countries.

SolidWorks has plenty of online materials and learning resources. With a more extensive presence in the market, it’s also taught in technical university courses and third-party certification programs. Troubleshooting channels include an official forum, online support, and local resellers. Plus, because you buy it from a software license retailer you usually get (or pay a bit extra) for full tech support.

For Fusion 360, sources are considerably more accessible, with a number of free official training materials from Autodesk. Since it’s so popular within the maker community, unofficial channels on YouTube and Udemy are great platforms to learn from as well.

Final Thoughts

Although both programs are used to accomplish 3D design, they do so in different ways. If these CAD giants were to enter a competition, they’d both come out on top, but not for the same reasons.

SolidWorks offers robust simulation packages and 3D modeling tools for experienced users. It’s the go-to CAD for professionals in the industry, with a substantial learning curve that definitely pays off.

Meanwhile, Fusion offers a very intuitive assembly interface that’s versatile and friendly enough for various applications and levels of experience. And as a cloud-based platform, users can access and share their files just about anywhere. With the recent incorporation of Netfabb capabilities, additive manufacturing, and simulation tools, however, it’s luring pros looking for an easier-to-use option.

Choosing which CAD program is right for you is no simple task, but hopefully, this guide could be useful in helping with your final decision!

License: The text of "SolidWorks vs Fusion 360: The Differences" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.