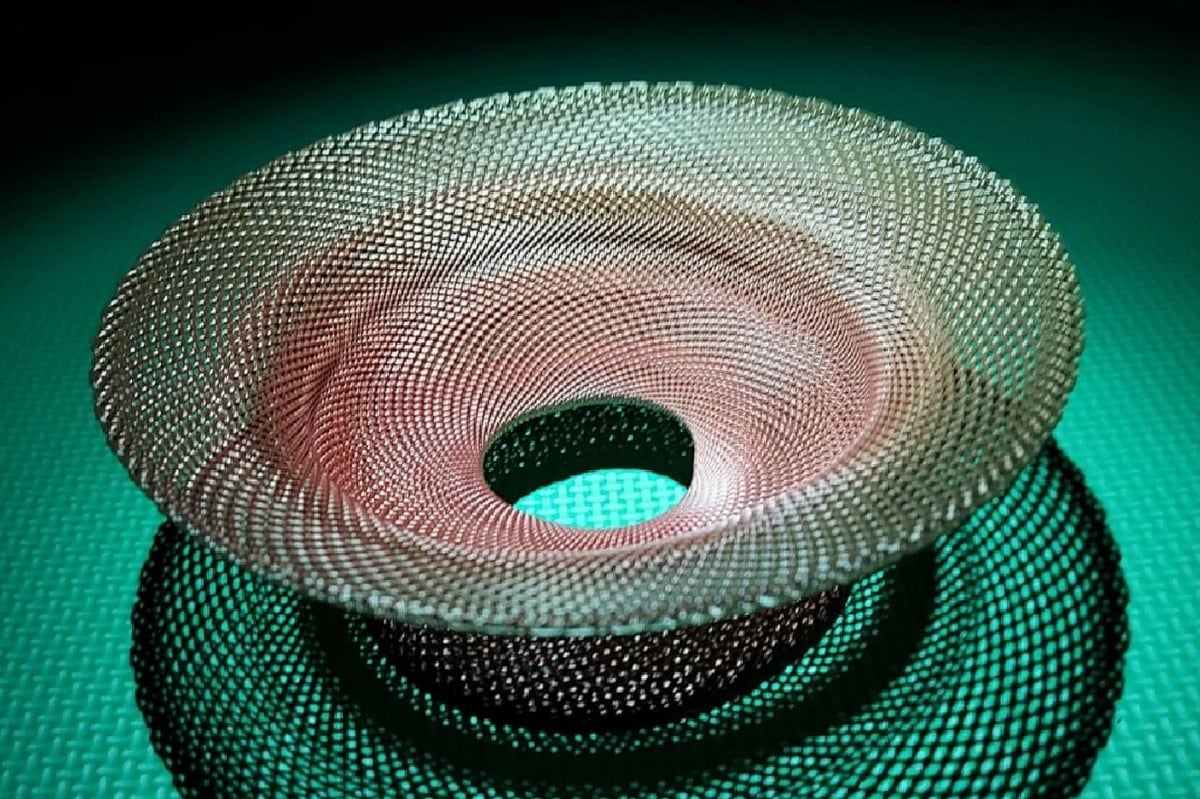

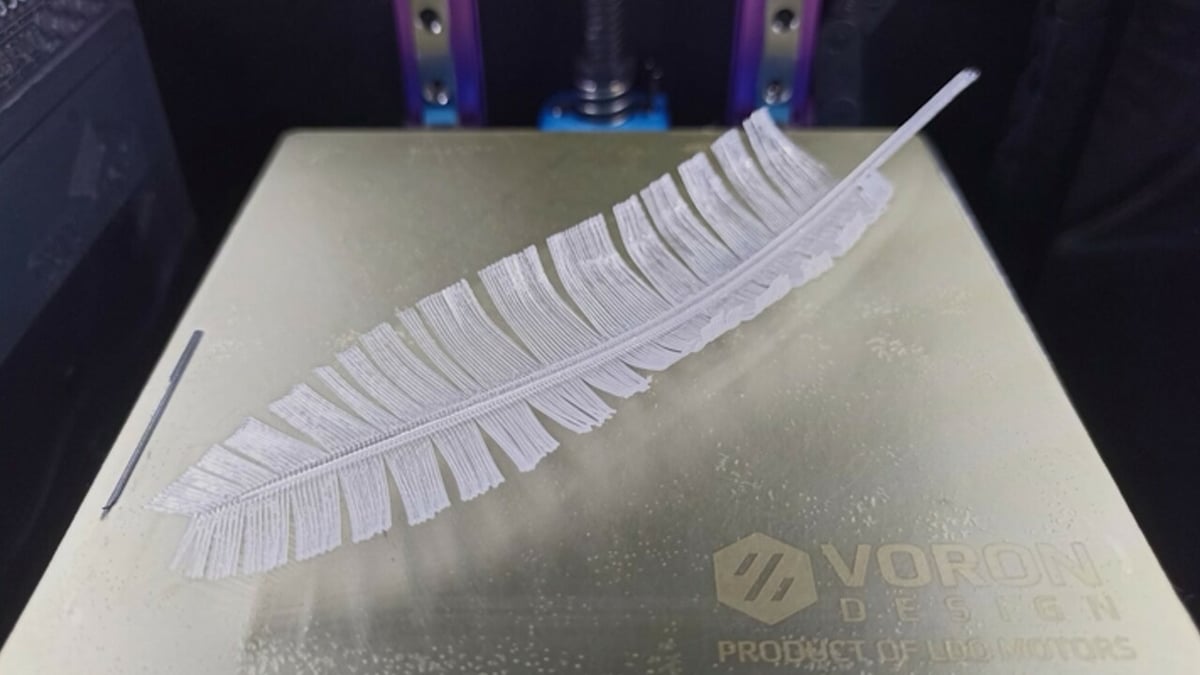

When designing parts to 3D print, it can be difficult to make large complex repetitive shapes, like those seen in the image above. This is typically where parametric design works well. However, if you were to then put your design through a slicer, it’d split it into lots of layers, potentially damaging the resolution and clarity of the shapes.

FullControl GCode Designer – a unique new software developed by Andrew Gleadall – tries to solve this problem by allowing you to easily generate parametric designs directly into G-code, which you can then print. This allows for greater control and even allows you to print vertically, something very valuable for creating more complex geometries.

In this article, we’ll dive into what FullControl GCode Designer is, how it differs from traditional CAD software, and how it works. Let’s get started!

Background

You may have heard the word “G-code” bandied about. It’s essentially at the heart of every 3D printing operation. G-code is a set of instructions that informs the printer exactly how, where, and when to move in order to fabricate the object you’ve designed.

Without G-code, your CAD design is just a theoretical model. The G-code transforms that model into a physical object layer by layer, with each command string contributing to the final product’s dimensions, shapes, and features.

Writing G-code can be very time-consuming, so the team behind FullControl GCode Designer developed this clever G-code generation software to help them create useful prints for testing. The software is a new concept for producing additive manufacturing components that are complex and strong. Instead of generating models for printing with CAD software-to-slicer workflow, users can create all kinds of shapes with parametric equations right in the software.

Parametric design is a concept often found in CAD software that’s used to create 3D models for printing. It uses mathematical equations and constraints to define the properties of the design. The exciting aspect about parametric design is its dynamic nature. Rather than being a static model, parametric designs can be easily modified by changing the underlying parameters. You can think of this like CAD with lots of rules which allow you to change the dimensions of a file with much more flexibility than traditional CAD like Fusion360.

Features

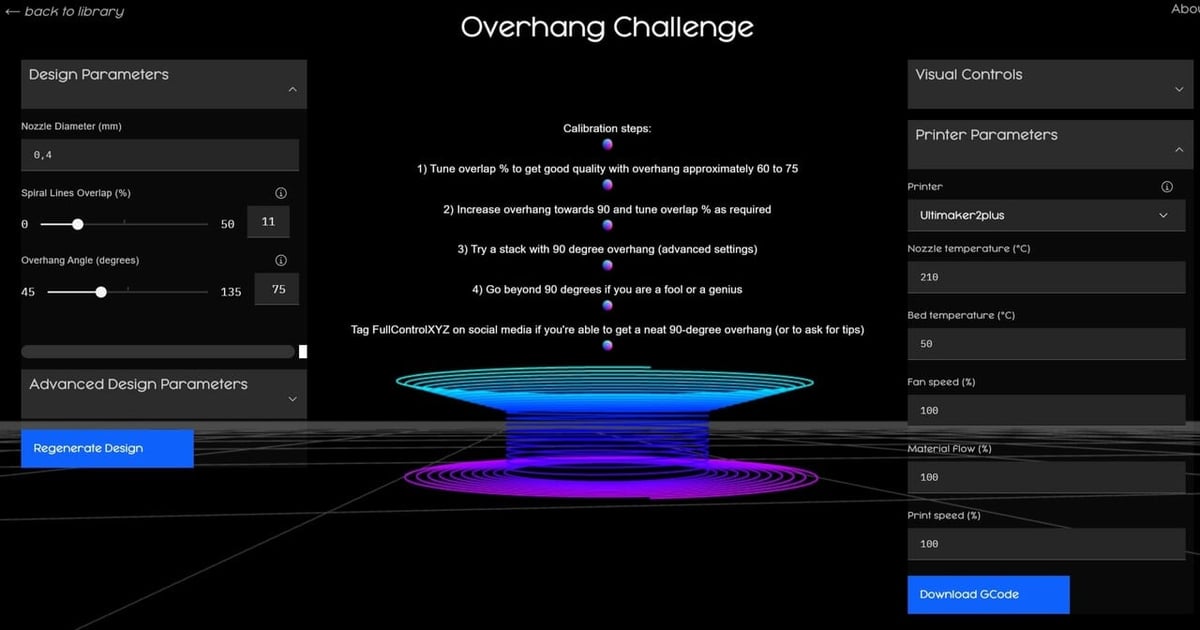

FullControl GCode Designer allows users to define the print path as well as all relevant printing parameters along it. Given the increased control over printing, users have the ability to fine-tune G-code settings, optimize print efficiency, and decrease waste. Below, we’ll discuss the software’s features in more detail.

Parametric Control

One of FullControl’s standout features is its integration of parametric control within the G-code generation process. Unlike conventional slicers that convert CAD models into G-code based on static print profiles, FullControl turns your G-code files into dynamic entities. Users can adjust print parameters within the G-code itself, eliminating the need to revisit the CAD model for changes. This not only enhances precision but also increases adaptability, offering a level of control that far surpasses conventional CAD-to-slicer setups.

Advanced G-Code Settings

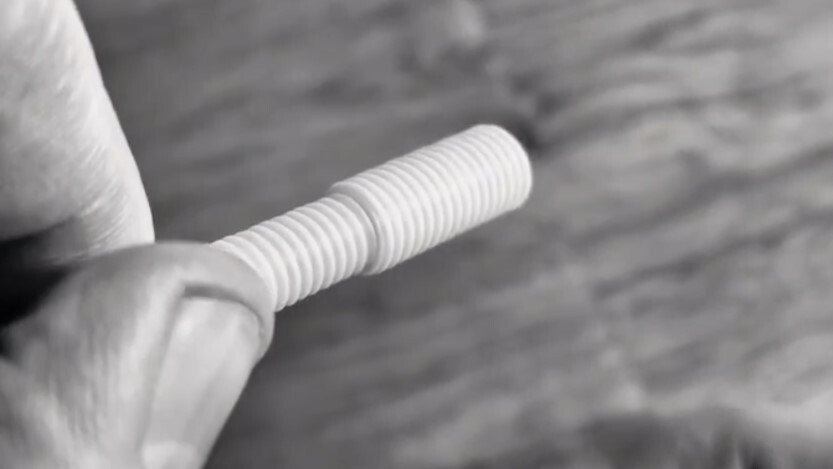

FullControl empowers users with a host of advanced G-code settings that cater to the creation of more precise shapes and structures. Users can manipulate various aspects such as layer height, print speed, and infill patterns on-the-fly by altering the vector paths for the G-code. This paves the way for intricate customization, accommodating complex structures like fully toleranced screw threads – a feature highly appreciated by its extensive Instagram community.

Parametrized Print Parameters

Through FullControl, users gain significant control over a range of print parameters, boosting print quality and efficiency. One can modulate the extrusion rate, travel speed, and layer height, among other factors. Also noteworthy is that you can plan toolpaths that allow for truly non-planar movement – even print vertically!

This granular control helps to reduce material waste and optimize the printing path, addressing both environmental and cost-efficiency concerns. With such capabilities, FullControl lies somewhere between a G-code generator, a slicer, and a parametric design software tool.

Script Enhancements

FullControl further extends its control capabilities with features to add lines, circles, rectangles, polygons, reflects, and various types of repeats directly to the script. It even offers a “Reproduce/Recalculate” function, facilitating intricate adjustments without the need to exit the program. We’ll quickly delve into what these features are below.

- Lines: Create simple straight vector paths for a specified distance

- Circles: Allows for the creation of precise circles based on equations

- Rectangles and polygons: Create more complex shapes

- Cartesian, concentric, and polar repeats: Repeat grid, circular, or self-containing patterns from pre-made shapes, allowing users to build up simple shapes and easily create a mesh matrix

- Reflects: Allows users to mirror certain components and make more advanced parts

Altogether, FullControl’s features outshine the pre-configured print profiles of traditional slicers, granting advanced users the precise control they require over their 3D prints.

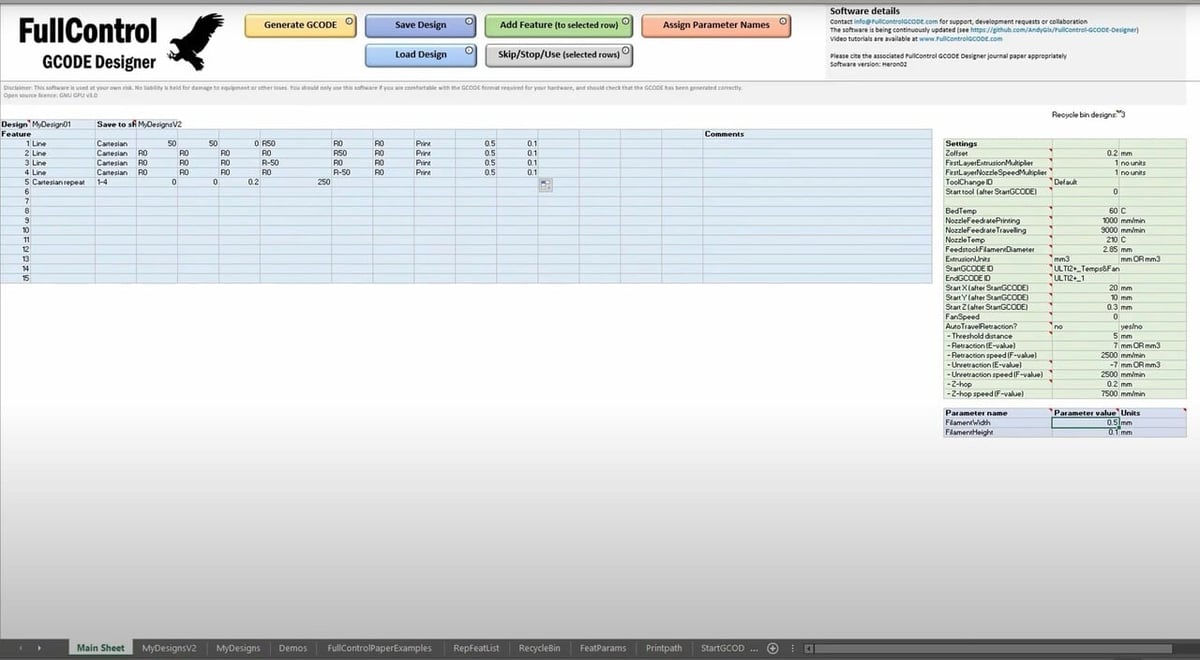

Workflow

Using FullControl GCode Designer is fairly simple. You have three options: an Excel file (Yes, this was all originally written in Visual Basic – Talk about patience!), Python Designer from GitHub, or try out their interactive models on the website. Below, we’ll discuss the workflow associated with the Excel file.

The stages are as follows:

- Create your design by defining the specific print paths in the Design section and using a G-code viewer to preview the printer’s movments.

- Add details related to your printer in the Settings section.

- Click the “Generate GCode” button, which will generate and save your printer-ready G-code to the clipboard. You can then paste it into a Notepad file and save it as .gcode.

- Load the G-code onto an SD card or upload to your OctoPrint instance.

- Set the print going and monitor it carefully, especially to make sure the first layer prints correctly.

We make it sound easy, but FullControl is definitely for advanced makers. An in-depth understanding of G-code as well as printer movements and settings is highly recommended. Fortunately, the FullControl team has posted quite a few tutorials to help makers gain facility with the software and set them on the path to achieving more design freedom.

User Experience

Now that we’ve gone through the features and the general workflow, lets delve into how FullControl GCode Designer has been received by the community.

Overall, FullControl has had a pretty warm reception, especially within academic and research environments. There’s already a growing number of students using it to create new designs that are lightweight, higher quality, and just couldn’t be otherwise done by a traditionally sliced file. This includes Reddit user FrostiFish from Eindhoven Technical University who used it to create a lightweight plastic feather.

A few users have complained about the Excel spreadsheet. Since the introduction of the new Python application, it seems to be growing in popularity. There’s, of course, still a steep learning curve, but overall, those who have spent time to get into the nitty gritty have found the rewards more than satisfying.

It’s worth noting that many in the community feel that FullControl is still in its infancy, and many are just experimenting with it. So, it’s unlikely that we’ll see it completely replace slicers anytime soon. But for the time being, this is an interesting development and opens the door to those needing to make more complex shapes with higher degrees of control.

Support

The best places to go for official support include the FullControl website and GitHub. Andrew Gleadall has also created a series of YouTube videos to showcase examples and is receptive to emails, too. There are also research papers written about FullControl floating around, including one from its developer.

Most of the community is on Reddit. Users post questions and showcase their experiments and successful prints. Besides the videos from Gleadall and an overview by Thomas Sanladerer, there’s not much on YouTube yet.

If you just want to have a play, you can check out FullControl’s design library. There are plenty of fun free models for you to experiment with, without needing to learn how to code in the software.

License: The text of "FullControl GCode Designer: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.