What Is CNC?

As the term suggests, computer numerical control (CNC) is a way to control a machine using a computer to translate numerical data. A CNC can be as simple as a household inkjet or a basic 3D printer, but it can also scale to much more advanced systems of complete manufacturing and assembly.

CNC systems have revolutionized the production of goods and made it possible to have many of today’s conveniences. Before the development of CNC, lathes, mills, wood carving, and other processes were all controlled by an operator or technician. Operators would use simple machines such as levers, hand tools, or lead-screw spindles to control the lathes or mills and modify the workpiece to a final product. Many of these early machines were specifically built to do that one task on the workpiece and required large setups and investments.

The Power of Automation

One of the key promises with computer technology is to create accuracy, reproducibility, and flexibility through software. Computers allow simple tasks to take less time and scale to broader applications.

It should come as no surprise, then, that the applicability of computer-controlled software for the use of machining components was quickly recognized. Such benefits have been taken advantage of as early as the 1940s and 1950s, before software as we know it.

What Makes a CNC System?

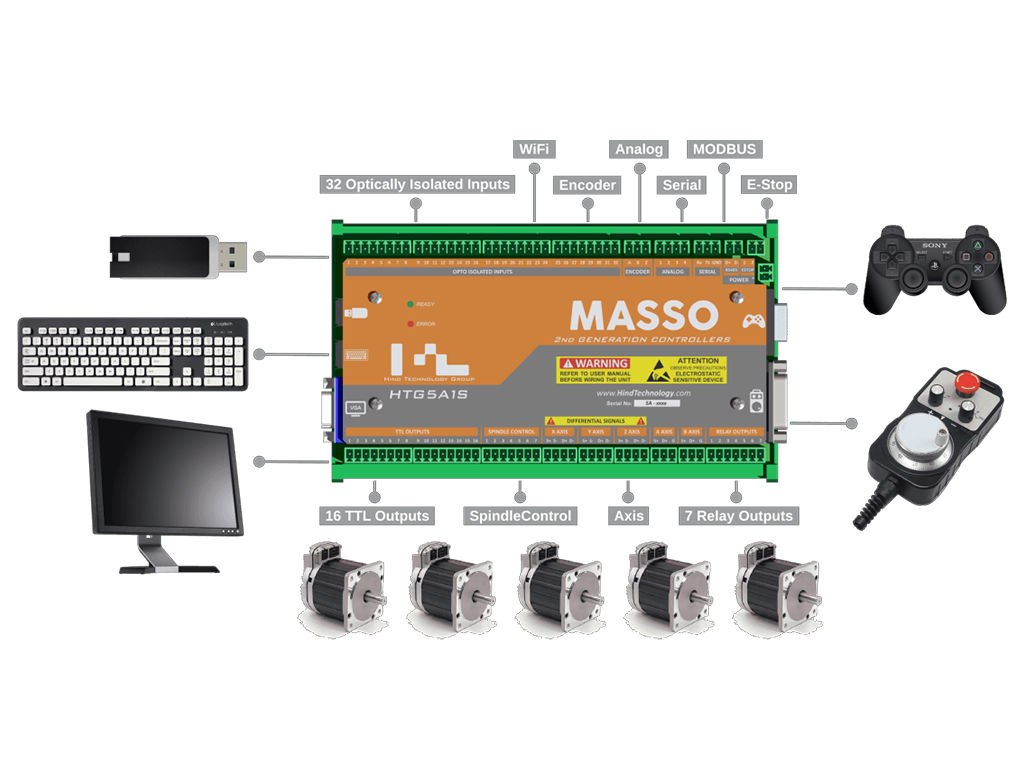

The computer component of a CNC system can be anything from a simple set of primary electronics to an advanced, full-fledged network-controlled PC. Typically, the computer has an interface that the operator or programming technician can use to tell the machine how to operate.

Most modern devices run on a standard scripting language called g-code. The primary function of the computer component is to take the user’s g-code and convert it into a sequence of specific actions for electric motors, hydraulics, pneumatics.

As an example, let’s look at a 3D printer. Such a device usually has a control board with inputs and outputs to all of the switches, each movement axis, a thermo-probe, a heater, and the extruders. Most modern 3D printer CNC boards can also interface with an SD memory card, a USB device, and some even have WiFi or Bluetooth connections.

Commanding the Machine

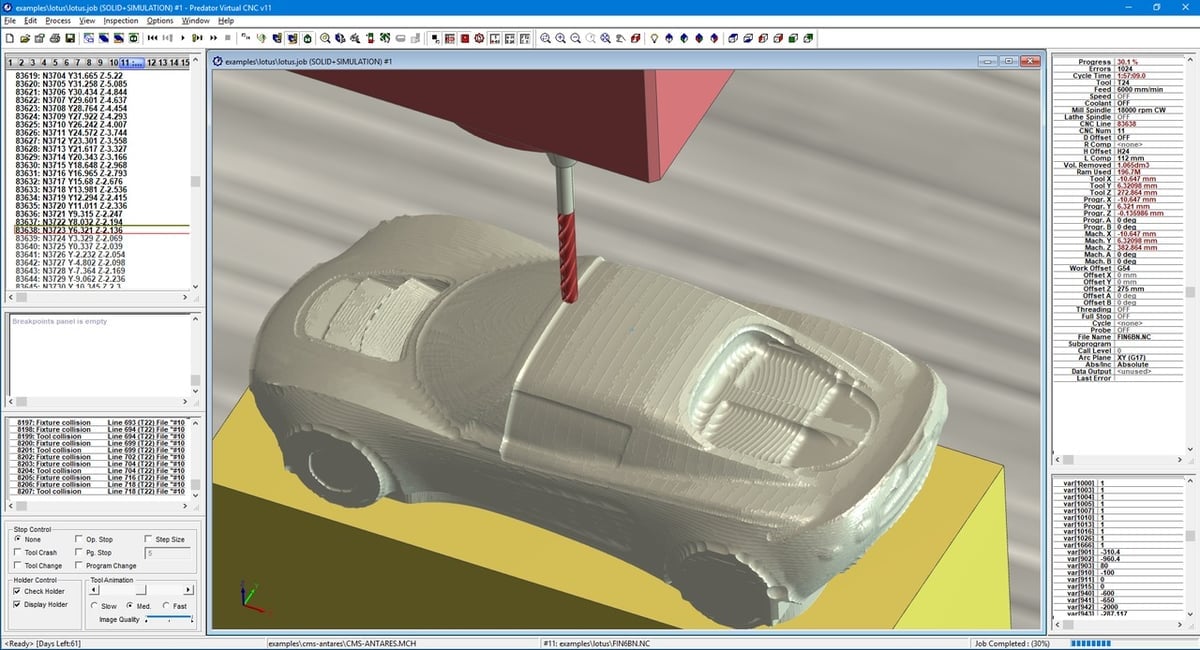

In the case of CNC mills or lathes, the CNC system reads g-code to execute a series of cuts on the workpiece, shaping it into the final product. When considering a CNC 3D printer, the g-code runs a series of movements and extrusions to create an object layer by layer.

If you’re looking for another example, consider the everyday inkjet or laser printer. These machines interpret a code sent by your computer to feed paper, move a print head, and deposit ink in exact locations. These household printers have become advanced enough to host a private print server, do paper fault detection, and even automatically order ink when low.

What Else Can CNC Do?

As you can tell, the advantages and applications of CNC are endless. Its incorporation into traditional machining methods has changed manufacturing forever. Here are a few key examples:

- Mill: Multi-axis machines to drill, face, and tap a stationary workpiece.

- Lathe: Uses machining tools and drills to make cuts to a high speed rotating workpiece.

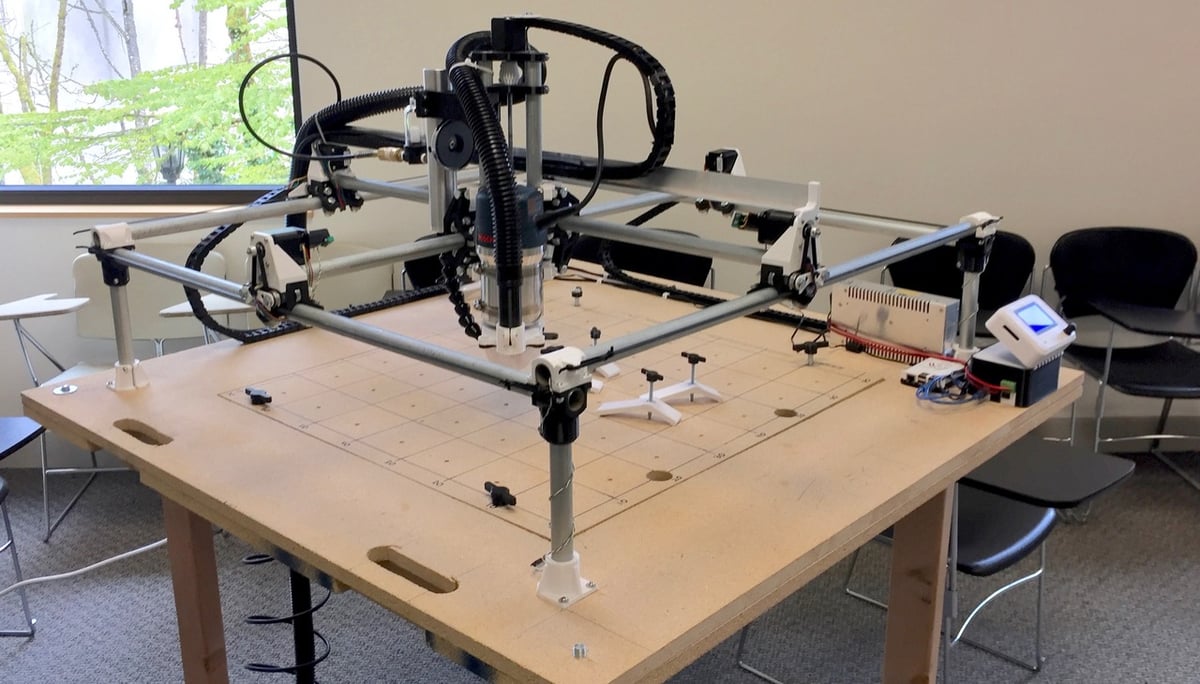

- Wood router: Uses a multi-axis spindle to carve wood similar to a mill, but specifically for wood workpieces.

- Plasma cutter: Uses an X-Y gantry and a high-temperature plasma torch to make cuts to sheet stock.

- Water jetting: Similar to a plasma cutter, but uses a high-pressure stream of water to cut material.

If automation, process, and manufacturing are something that interests you, you can find endless resources and opportunities to learn. With recent advancements in home-based CNC systems, such as desktop mills and 3D printers, learning about these technologies is more accessible than ever.

Feature image source: paragoncnc.com

License: The text of "CNC – The Meaning & Definition" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.