3D printing has evolved significantly over the years, and many new types of printers have emerged. What started as a way to create custom parts back in the 1980s has grown to become so much more.

The fused deposition modeling (FDM) printing technology alone encompasses many different styles of printers.

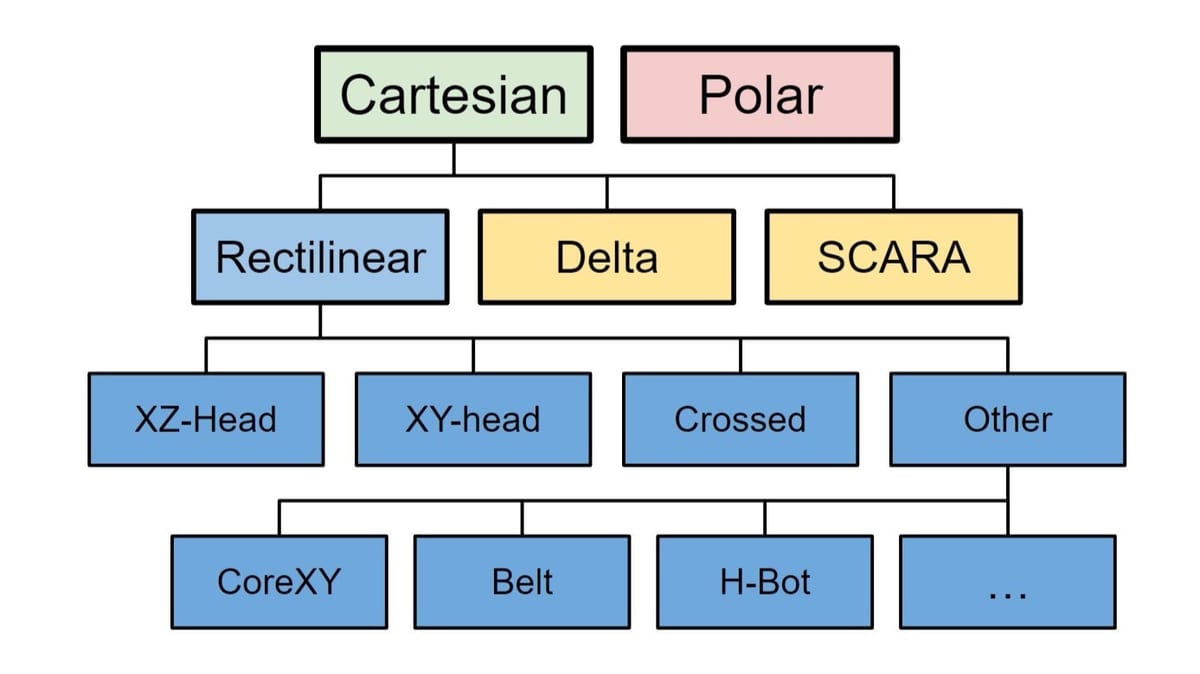

In this article, we’ll be focusing on seven popular descriptors: Cartesian, CoreXY, delta, SCARA, belt, H-bot, and polar. And although we’ll only be looking at these few, they’re not by any means the only FDM printers out there! Before we take a look at them, let’s understand why.

What Makes Printers Different?

In reality, there are many aspects that one could consider in order to differentiate FDM printers. That said, perhaps the two most important are its operational coordinate system and mechanical nature.

On the coordinate system side of things, six of our seven FDM printers – polar 3D printers being the exception – use Cartesian coordinates. This means that delta, CoreXY, H-bot, SCARA, and belt printers technically fall under the Cartesian classification. However, you’ll rarely hear them referred to as “Cartesian” because they have more popular and specific names.

Polar printers use – you guessed it, polar coordinates. Setting coordinate systems aside and focusing only on Cartesian printers, we can immediately consider delta and SCARA printers to be their own types based solely on their unique mechanical setups, the former employing three coordinating arms suspended from a frame and the latter itself being a robot arm.

The majority of other Cartesian printers (i.e. those that are perhaps most familiar to the average maker) are characterized by square or boxlike frames and linear rails. For this reason, they’re sometimes referred to as “rectilinear” printers. These include generic styles, like those with XZ-head, XY-head, and crossed gantries, as well as specific styles, like H-bot, CoreXY, and belt printers, and several other subtypes.

This classification system, which is by no means the only one, reveals why many printers without a popular or well-known designation are simply labeled “Cartesian”. Unfortunately, because the vast majority of FDM printers are Cartesian printers, it’s not a very useful label, so we’ll try to avoid it here.

Now, let’s go over each of the seven types of printers outlined above. Alongside coordinate systems and mechanical nature, we’ll discuss some history and how each works.

Miscellaneous Rectilinear ("Cartesian")

Let’s start by understanding more about rectilinear printers, especially those falling under “Other” in the image above. These are the ones most often referred to as “Cartesian” printers, which again, isn’t a very descriptive term.

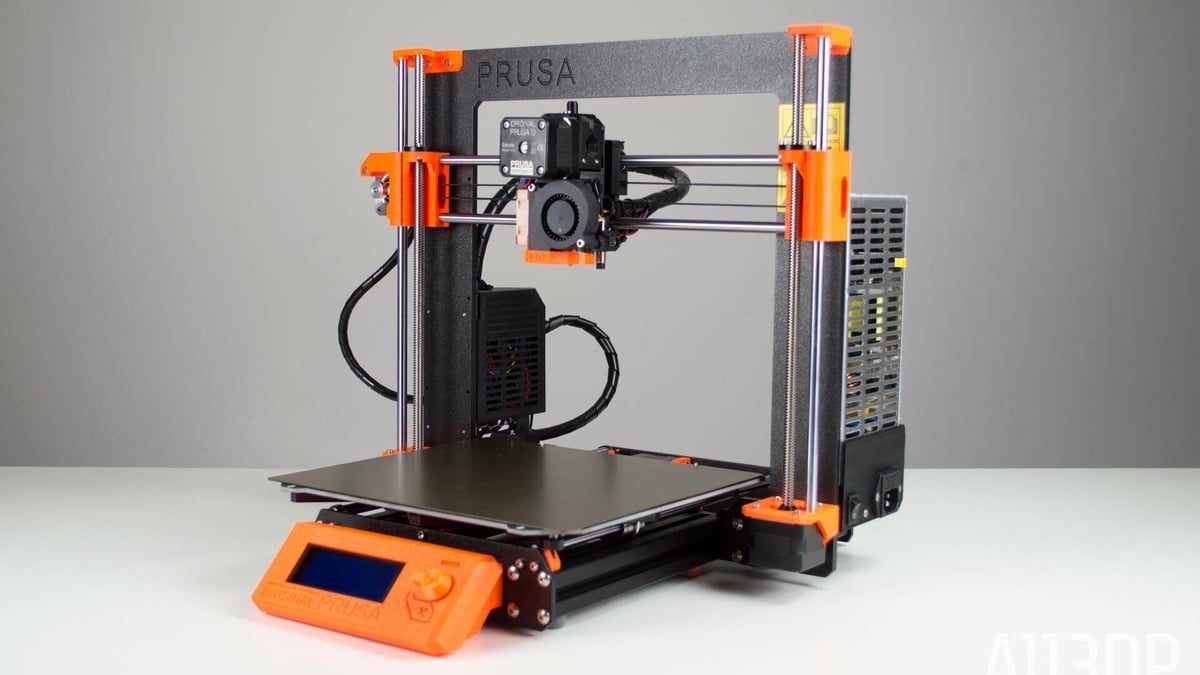

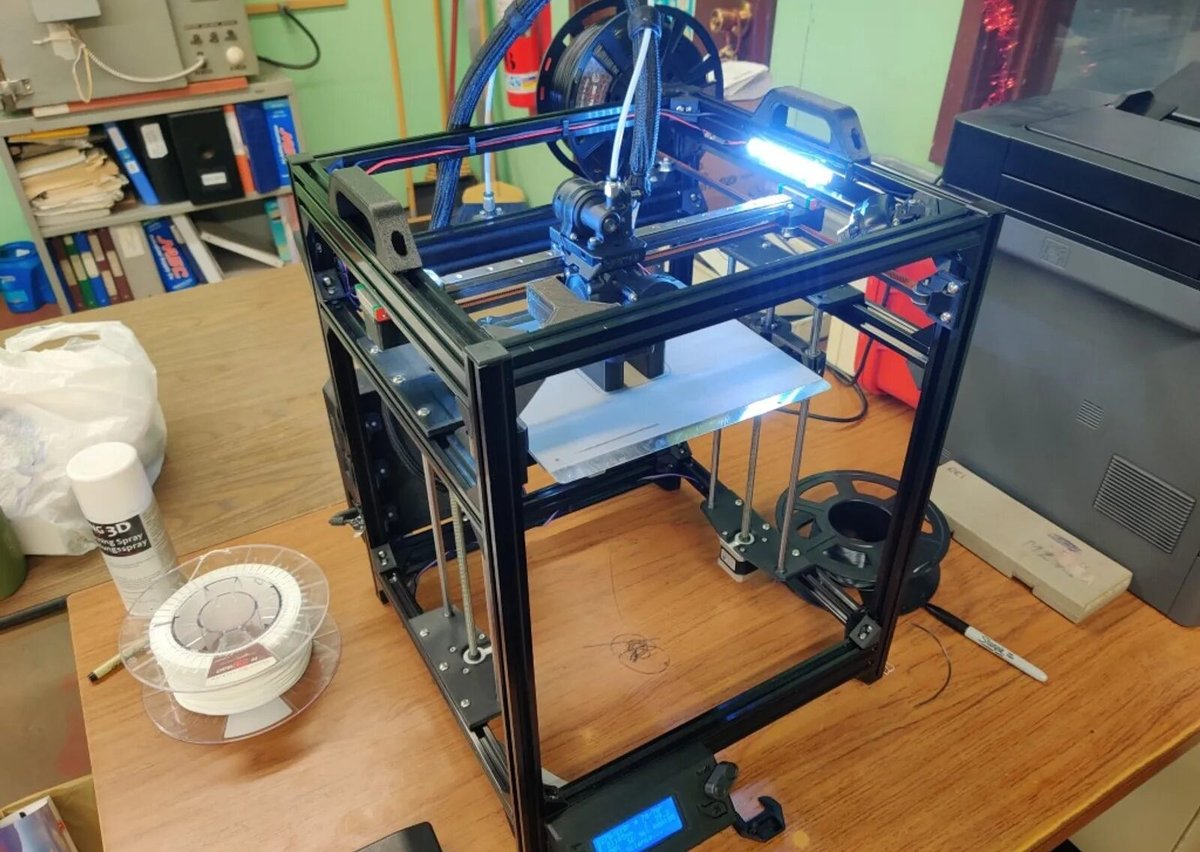

As mentioned above, rectilinear printers are the most commonly used setup among consumer 3D printers. They are the “stereotypical” 3D printer, with right-angled frames and linear axes. Subtypes include the Cartesian-XZ-head and the UltiMaker-style crossed printers. Cantilever-type printers could also be considered a subtype, often found in compact printers like the Prusa Mini and Mini+.

If you have an Ender 3 or Prusa i3 MK3S+, then you may already have an idea about how these types of printers operate. If not, don’t worry because we’ve got you covered.

How Do They Work?

Rectilinear printers move components linearly along the X-, Y-, and Z-axes to position the printhead and print within three-dimensional space. The printhead generally moves along an X or Y gantry, which in turn moves along the Z-axis, though other motion variations are also possible, depending on the printer.

What Makes Them Different?

As Cartesian devices, rectilinear printers are distinct from polar printers in that they position their nozzles using X, Y, and Z coordinates.

Otherwise, rectilinear printers differentiate themselves from non-rectilinear printers in that they employ simple linear motions to position the nozzle relative to the print bed. In most cases, motion along one axis is completely independent of motion in the other axes (i.e. a single motor is responsible for each of the three axes). For this reason, rectilinear printers appear square or boxy.

Pros

- Relatively cheap

- Simple to understand and implement

- Comparatively easy to upgrade and fix

- Lots of community support

Cons

- Large and heavy frame

- Relatively slow

- Limited print height

CoreXY

CoreXY printers are a relatively new type of FDM 3D printer, first made in 2013 by an MIT engineer. CoreXY printers are classified as Cartesian with regards to the printer’s operational coordinate system but use a clever motion system.

Creality is one of the leaders in this type of printer mechanics, which you can see in the Ender 6, 7, and the K1 Max. However, the Voron 2.4 R2 and the Bambu Lab P1P are impressive alternatives with lots to offer when it comes to speedy printing.

How Do They Work?

Motion on CoreXY printers incorporates a system of belts and pulleys to move the printhead on the XY-plane. In particular, CoreXY printers use two stepper motors that move one belt each to position the printhead. The end result is sort of like a complex but coordinated tug of war.

Meanwhile, the print bed is mounted on a Z-axis motion system, such as threaded rods. This system moves the print bed up and down so that the printhead can print layers for the desired part. CoreXY printers are usually cube-shaped to maximize stability.

What Makes Them Different?

CoreXY printers are often mixed up with their H-bot cousins. Though the two are very similar, the belt system in a CoreXY is different, allowing for less torque and even fewer vibrations. Indeed, if you’re looking to purchase this type of printer, be cautious of H-bot printers mislabeled (or falsely advertised) as CoreXY printers.

Regardless of their differences, both machines differ from other rectilinear printers because they use belts and pulleys to move the printhead on two axes at once.

Pros

- Large print area

- Relatively stable

- Lightweight parts

- Few vibrations (even compared to an H-bot)

- Relatively high accuracy

Cons

- Relatively expensive

- Requires a powerful controller board

- Energy inefficient

- Higher risk of print failures

Delta

Delta 3D printers are a type of FDM printer that also uses Cartesian coordinates. Yet, they’re mechanically unique from rectilinear printers in a few different ways.

While this type of printer is not as common as those we’ve already covered, there are nevertheless a few great examples out there. FLSun has produced several consumer delta printers, such as the V400 and SR. A slightly older but reliable delta printer comes from Monoprice called the Delta Pro. There’s even a smaller version, the MP Mini Delta, if a small form factor is important to you.

How Do They Work?

Delta 3D printers work with three (or sometimes even more) arms attached to vertical rails. The printhead is connected to the end of each arm with hinges, and the arms work together to adjust the printhead’s position. The coordinated movement of a delta printer’s arms controls the printhead’s height (Z-axis) and location (X- and Y-axes) relative to the print bed.

What Makes Them Different?

Delta 3D printers are mechanically distinct from all other FDM printers due to the movement of the printhead being controlled by arms rather than fixed axes. However, the operational coordinate system is the same as other Cartesian printers.

Typically, delta printers are also unique in that their frames (usually) consist of three vertical elements rather than four, two, or one. As such, they resemble upright triangular prisms.

Pros

- Relatively fast

- High print quality

- Generally capable of tall prints

Cons

- Difficult to fix and upgrade

- Less compatible with direct extruder setups

- Relatively small build area

SCARA

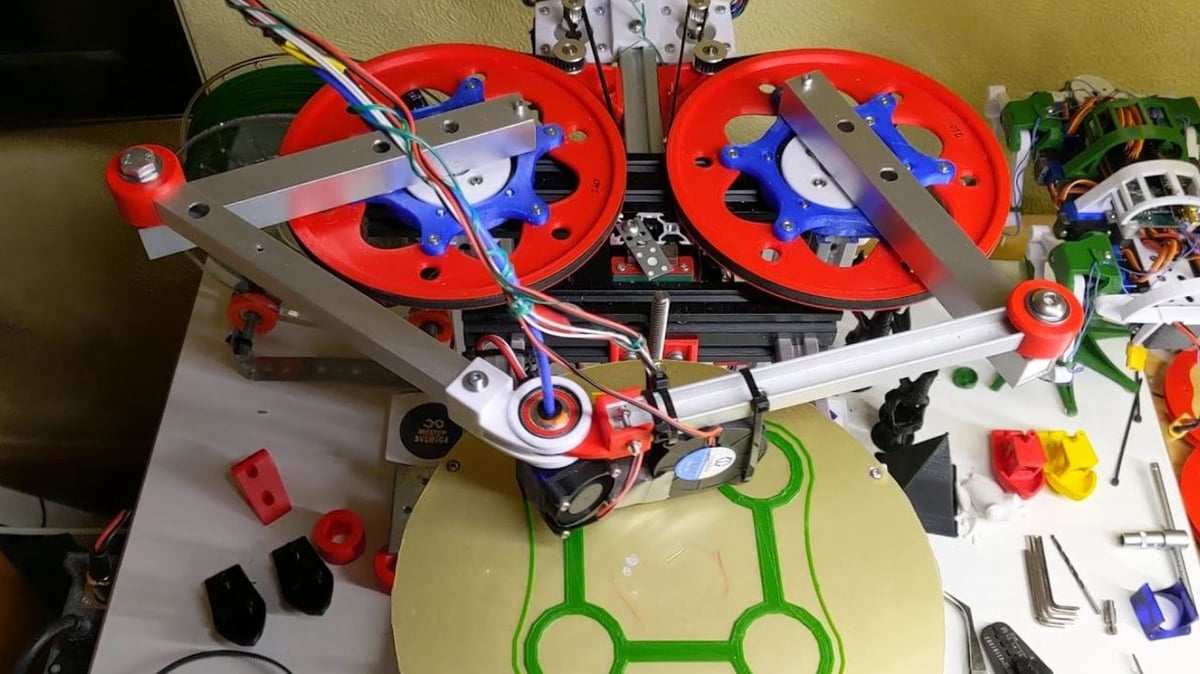

SCARA 3D printers are a more complicated type of FDM printer, using Selective Compliance Assembly Robot Arm (SCARA) technology to function. The technology was developed in the early 1980s and later came onto the scene in 2013 with the RepRap Morgan.

The open-source maker community primarily fuels these printers. Aside from the RepRap Morgan project, the RepRap Helios is another popular project used to bring these mechanics to life.

How Do They Work?

Like the previous types of printers, SCARA printers also use a Cartesian coordinate system, but they belong in their own subcategory due to their unique mechanical setup.

SCARA printers feature a printhead attached to a robotic arm powered by two motors. The motors are both connected to linkages that move the printhead around the XY-plane, while another motor controls motion along the Z-axis. Usually, this motor elevates the whole linkage-motor system along with the printhead in order to print each subsequent layer.

Other styles of these printers exist, too, such as this open-connection arm SCARA printer, which doesn’t use connected linkages.

What Makes Them Different?

SCARA printers are different from other types of FDM printers due to the unique system used to control the printhead’s motion on the XY-plane; most FDM printers use more standard mechanical features, such as fixed axes.

Additionally, SCARA printers don’t usually have an attached build plate, and the frame for this type of printer is typically significantly smaller than that of other printers.

Pros

- Good for industrial printing

- Relatively fast

Cons

- Relatively imprecise

- Relatively obscure

- Limited community support

Belt

Belt 3D printers are slightly different from the other Cartesian styles because, mechanically speaking, they use a large movable belt for the print bed.

Creality once again jumped on the chance to produce its own consumer-grade version of this type of printer – the CR-30, also known as the 3DPrintMill. Although user feedback was mixed, it’s one of the few purchasable options out there other than larger, manufacturing-focused printers like the Blackbelt. If you are considering purchasing one of these printers for yourself, the iFactory One is worth checking out given iFactory’s focus on continuous printing solutions that has led to an arguably more well-rounded printer.

How Do They Work?

Concerning the printhead’s motion system, most belt printers are essentially Cartesian-XY-head printers or CoreXY printers with the frame (but not the bed) tilted at a 45-degree angle. Then, the print surface is replaced by a sort of conveyor belt, which moves one way or the other in the combined Z- and Y-axes. This belt can print a single infinitely long piece or it can continuously print many small parts.

The coordinate system of belt printers is considered to tilt along with the frame. Thus, the belt provides movement along the Y- and Z-axes.

Belt 3D printers can also have a partially heated bed; however, the build surface can’t reach very high temperatures since the belt is always moving.

What Makes Them Different?

Belt 3D printers are different from other FDM printers because they use a unique type of print bed that serves many purposes. This type of printer commonly has a tilted Z-axis, too, which no other types of printers use. Lastly, belt 3D printers have speed limitations and can’t work with filaments that require a high-temperature heated bed.

Pros

- Continuous printing

- Effortless print removal

Cons

- Relatively slow

- Limited community support

- Requires additional support to print long parts

H-Bot

H-bot 3D printers represent a different approach to box-like printer design. Like all the previous printers, they belong in the Cartesian category because they operationally use a Cartesian coordinate system.

This type of printer you’ll often see for self-made printer builds, such as the Double H-Bot and Tribotron.

How Do They Work?

An H-bot printer uses a single belt to move the printhead within the XY-plane. Typically, the printhead runs across an X-axis gantry, which in turn moves along the Y-axis. To move along the Z-axis, the build plate starts at the top, close to the nozzle, and moves downward.

Using the previous description of a CoreXY printer’s motion system, that of an H-bot printer is like a slightly less complex, but also less coordinated, tug of war.

What Makes Them Different?

Again, H-bot printers are often confused with CoreXY printers. Though they look similar, H-bot printers make use of an alternative, single-belt system. In most cases, they can easily be distinguished by the shape of their belts when looked at from above. An H-bot’s belt will form, well, an H, while a CoreXY’s belts form more of a boxy A.

Together, H-bot and CoreXY printers differ from other printers because their print beds move up and down.

Pros

- Large print area

- Relatively stable

- Lightweight parts

- Few vibrations

Cons

- Relatively expensive

- Large machine size

- Limited community support

Polar

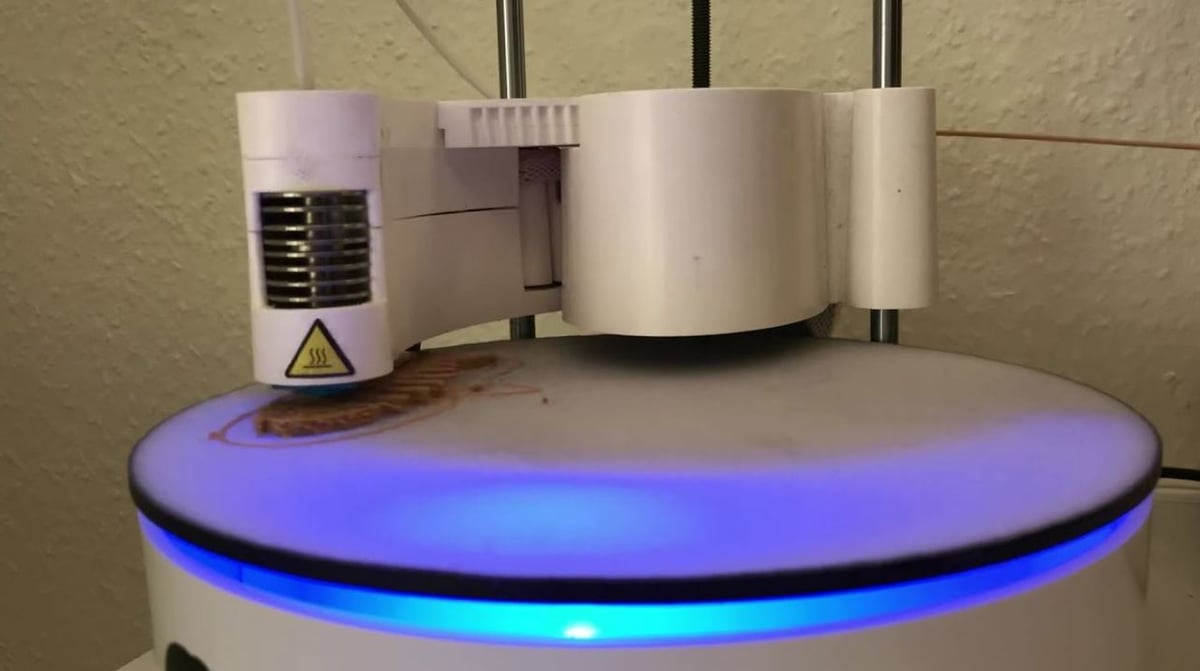

And now for something completely different. Polar 3D printers were first made in 2015 and gained more popularity with the production of the Sculpto polar 3D printer. Unlike the rest of the printers on this list, polar 3D printers use a different operational coordinate system.

Unfortunately, this approach to 3D printing seems to be fading into obsolescence, at least in the consumer space. 3D Systems has described its DP Polar printing system for production settings with continuous operation, but you’d be hard-pressed to set it up in your home garage. The Sculpto PRO2 used to be available as an entry-level desktop printer, but it has since gone out of production.

How Do They Work?

As opposed to Cartesian, this kind of printer uses a polar coordinate system, meaning it plots points on a circular grid rather than a rectangular one: in two dimensions, polar printers use angle and distance rather than X and Y distances to locate points relative to the origin. This type of printer extrudes filament like other FDM printers, but the printhead usually connects to a curved arm that can swing outward.

Polar printers use a spinning circular build plate. With this motion, the machine prints the desired object layer-by-layer as the mounted printhead arm moves up along the Z-axis.

What Makes Them Different?

Polar 3D printers are unlike the other FDM printers because they use the polar coordinate system. They also differ from other classes because the printhead is connected to a single arm. Lastly, they use a spinning bed, which no other type of printer uses.

Pros

- Relatively inexpensive

- Fewer motors and less noise

Cons

- Low print quality

- Relatively slow

- Relatively obscure

- Limited community support

License: The text of "The Types of FDM 3D Printers: Cartesian, CoreXY & More" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.