From Rocks to Robotics: The Evolution of Home Construction

House building, generally speaking, has changed little since humans began stacking rocks to make shelters. Most homes still require teams of workers to stack layers of bricks or cinder blocks manually, hammer nails into wooden frames, and attach the siding. This method heavily relies on individual skills and manual labor. It produces large amounts of waste and noise, takes time, and is inefficient when you compare it to how we build other things today, like cars or computers. In other words, it’s ripe for disruption.

The 3D printing construction approach promises to build houses faster, cheaper, and more accurately with fewer people. 3D construction companies also say their materials will last longer and are more robust than most traditional building materials. With benefits like these, it’s no wonder that 3D printing construction is gaining momentum worldwide. In fact, the global construction robot market (something that didn’t exist not long ago) is projected to grow nearly 20% in the next five years.

The 3D printed pilot projects and display homes stage is coming to an end as more developers break ground on plans to 3D print entire communities. Likewise, cites across the globe are looking to 3D printed houses as the the answer to affordability and sustainability. In fact, in March 2024, Canada’s Prime Minister Justin Trudeau pledged $36.8 million to “support the scale-up, commercialization and adoption of innovative housing technologies and materials,” including “modular housing, mass timber construction, robotics, 3D printing, and automation.”

With the growth in 3D printed buildings, you may wonder, who is building these structures and who’s buying them? Let’s take a look.

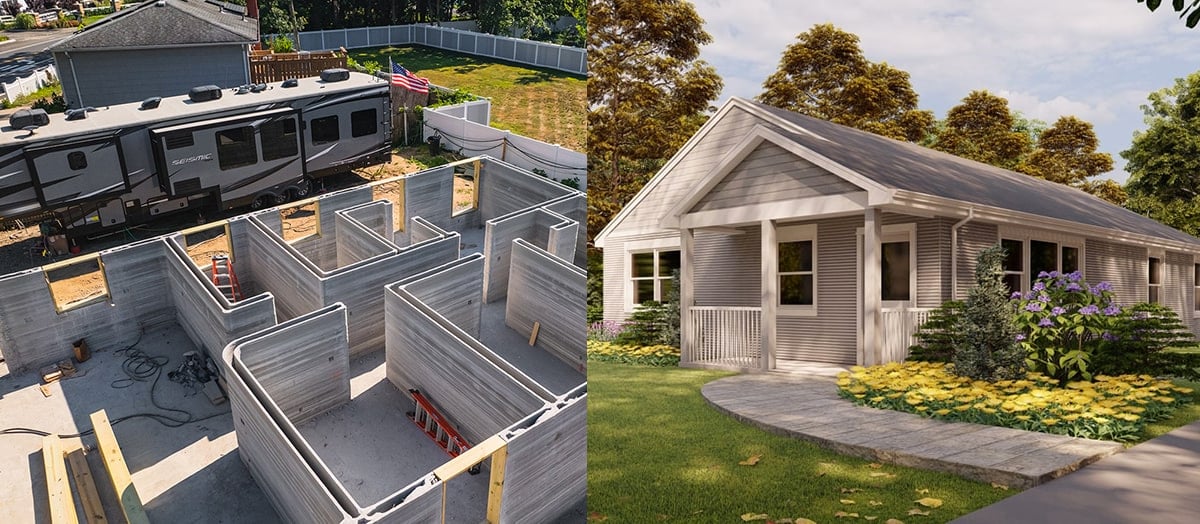

The Most Recent 3D Printed House Projects

2024 has gotten off to a promising start in the 3D printed home construction market with notable progress on existing projects and the unveiling of new construction printers, materials, and builds.

The most buss in 3D printed housing is surrounding the latest announcements from market leader Icon, which debuted a new multi-story 3D printer in March along with plans to produce some of the home designs that won its recent 3D printed home design competition called Initiative99.

“When we launched the company and the first permitted 3D-printed house in 2018 […], we set out to both decrease the cost and increase the quality of building instead of choosing one or the other,” says Icon CEO Jason Ballard. “We didn’t want to just be the best at 3D printing, we wanted to be the best at building, period.”

Construction on on of the “world’s tallest 3D printed structure” got underway earlier this year. The Tor Alva, or the White Tower, is designed by architects Michael Hansmeyer and Benjamin Dillenburger and printed with concrete by the technology University ETH in Zurich, Switzerland. Nestled in the village of Mulegns in the Swiss Alps, the White Tower is designed as a venue for music and theater events. Standing at 30 meters, the design features 32 distinct Y-shaped columns, each boasting a pattern of textured details.

In Canada, local construction company Nidus3D has completed what it says is North America’s first three-story 3D printed house. Construction of the 420-sqare-meter building near Toronto involved the use of a 3D printer from Cobod International using local materials. The basement of the building was also printed in concrete, with the 3D printer placed directly within the excavation for the home’s foundation, rather than pouring concrete. The building, which will house four apartments, doesn’t look 3D printed because it has been faced in traditional brick and has a steel-framed roof.

Projects recently announced include Portugal’s first 3D printed house from Lisbon start-up Litehaus. The company says it wants to 3D print 100 modular houses a year in the country.

Looking back to the second half of 2023, we saw New Zealand 3D concrete printing company, QOROX, complete the Southern Hemisphere’s largest 3D printed building; the planned 3D concrete housing project for the Siksika Nation in Canada plans to be a big step towards sustainable, affordable, and innovative housing solutions for Native Americans; US-based construction 3D printing start-up AC3D launched operations in the UAE focusing on low-rise housing, commercial real estate and infrastructure; and Hive 3D in partnership with Utah-based Eco Material Technologies are building what they call the world’s first near-zero-carbon, 3D-printed homes.

3D Construction Standards & Permits

3D printing construction companies today are in the spotlight as engineers, project developers, and clients try to wrap their heads around this new phenomenon. After all, it’s still a relatively new technology.

So far, there are no universal standards around the methods and materials used as innovations surface from a wide range of global players. Many local building codes have no provision for 3D printed homes, but that’s also quickly changing. Yet, standards for concrete stress and pressure can be applied to 3D printed materials.

In 2018, building company Icon was the first in America to secure a building permit for and build a 3D printed home in Austin, Texas. Other cities have followed suit. In places where building codes are broader or non-existent, 3D printing construction companies are helping alleviate housing shortages and build much-needed structures, such as school buildings and housing developments in Africa, low-income housing in Mexico, and homes for people experiencing homelessness in Texas.

Icon’s printed walls recently passed two standards, ASTM E1886 and E1996, related to resistance to sustained and fluctuating wind pressures experienced in hurricanes. These standard tests, along with other key details like impact resistant windows and doors, can help homes meet the stringent requirements of the Insurance Institute for Business and Home Safety’s (IBHS) Fortified Gold rating. Icon’s printed load bearing 2-bead wall has achieved a 2-hour fire rating and development is underway to surpass a 3-hour rated wall.

Cement company Progreso recently completed Guatemala’s first 3D-printed building as a prototype dwelling designed to withstand local seismic activity.

Top Companies Building 3D Printed Houses

Icon

- Headquarters: Texas (US)

- Type of structures: Low-rise buildings

- Region of operation: Global

- Printer: Vulcan (11.5 feet tall, 33 feet wide), Phoenix (robotic arm)

- Projects: Project Olympus, Genesis Collection, East 17th Street Residences, Community First! Village, New Story + ECHALE, US National Guard Barracks at Camp Swift, House Zero

Icon is a Texas-based developer of advanced construction technologies, including robotics, software, and building materials. Starting with smaller charity-backed projects to build homes in impoverished areas, the company has since gained hundreds of millions of dollars in investment financing to expand its technology. Currently, Icon is working with NASA on possible construction methods for habitats on the moon while at the same time expanding its house-building pursuits here on Earth to more extensive, mainstream American homes.

The company says that its Vulcan II construction 3D printer is specifically designed to produce stronger, more affordable buildings with increased design freedom, expanding printing capacity to approximately 600 square meters.

The Vulcan can create an entire home in about 24 hours using Icon’s proprietary Lavacrete material. The first Icon home was permitted and built in Austin, Texas, in 2018. Since then, the company, in cooperation with local nonprofit Mobil Loaves & Fishes, has built a community for people without homes in the Austin area. Known as Community First! Village, it features a cluster of 400-square-foot, one-bedroom dwellings.

Reservations for Icon’s Genesis Collection project, one of the largest 3D printed housing developments to date, co-led by Lennar and Big-Bjarke Ingels Group, have opened this year. Prices for one of the 100 three- and four-bedroom homes located at Wolf Ranch in Georgetown, Texas, are said to start at around $450,000.

In 2024, Icon launched its newest printer the Phoenix. Looking a bit like a giant drafting lamp, the company’s new robotic-arm 3D printer enables multistory construction because of its huge reach. Technically, it’s an articulated arm on a rotating base. The major innovation, and key to its speed and accuracy, Icon says, is its stabilizing tool head that keeps the extruder nozzle exactly where it should be, compensating for wind, vibrations, and other forces.

Projects using Phoenix will be priced per square foot starting at $25/square foot for wall systems or $80/square foot including foundation and roof. This cost to build is lower than the most recent publicly available data for conventional construction of wall systems, according to Icon. The Phoenix prints with a new material called CarbonX.

Peri 3D Construction

- Headquarters: Weißenhorn, Germany, with offices in Houston, Texas

- Type of structures: Low-rise buildings, multi-story buildings

- Region of operation: Global

- Printer: COBOD

- Projects: Beckum Germany home, Arizona Habitat for Humanity home, apartment Building in Germany, office building in Austria, data center in Germany

Germany-based Peri is no newbie in the construction industry. It’s one of the world’s leading manufacturers and suppliers of formwork and scaffold systems. More recently, though, the family-owned company has seen the writing on the wall and launched several 3D printing projects with Danish technology partner Cobod, which makes concrete 3D printers. Peri acquired a stake in Cobod back in 2018. Today, it has more than a dozen 3D printed project under its belt including a lot of Europe’s firsts.

Most notably, Peri completed Germany’s largest 3D printed building in 2024. It cut the ribbon on Germany’s first printed house in 2021. Printing started on Sept. 17, 2020, and the Peri 3D Construction Printing Team used a Cobod Bod2 concrete printer and, as printing material, the printing mortar “i.tech 3D” from Heidelberg Materials.

Another testament to the company’s lighthouse status stands in the Bavarian city of Wallenhausen. Together with Rupp Gebäudedruck, Peri built Europe’s largest apartment building, standing at 380 square meters and offering living space for five families on three floors. Interested customers could visit one of the apartment units for a while, but today the building is wholly rented out.

CyBe Construction

- Headquarters: Netherlands

- Type of structures: Low- and high-rise buildings

- Region of operation: Global

- Printer: CyBe G, CyBe RC, CyBe RT, CyBe R

- Projects: Robust Villa, G+7 apartment complex, R&Drone Laboratory, 3D Studio 2030, affordable housing

CyBe Construction is a Dutch company with an office in Florida. With the in-house development of software, hardware, and materials, CyBe Construction calls itself the technology company for the construction industry.

It was selected to 3D print houses in the UAE and Canada and have plans to introduce 3D printed homes to the Caribbean with a new project on the island of Curacao. It also has a new project set to be Europe’s largest 3D printed residential development.

The company is makes, sells, and uses four printers – the CyBe R, CyBe RC, CyBe RT, and CyBe G, their latest gantry-based addition– as well as their in-house mortar material. With up to 500-mm/s printing speed, the printers can print large structures in only 20 minutes but require two hands-on operators.

The RC is a mobile printer with rubber tracks that allow it to roam freely around a construction site. According to CyBe, this printer has various other applications, such as abutments, floors, walls, formwork, and sewer pits.

Before the UAE project, CyBe completed another development in Dubai, where it was tasked with 3D printing a 168-square-meter drone R&D lab. The laboratory was printed onsite in three weeks using the mobile 3D printing machine.

Mighty Buildings

- Headquarters: California (US)

- Type of structures: Low-rise modular buildings

- Region of operation: Global

- Printer: Custom

- Projects: Desert Hot Springs, Calif.

Mighty Buildings is a construction technology company based in Oakland, Calif., that recently shifted from creating 3D printed modular, pre-fab “accessory dwelling units” to planning full communities of 3D homes using proprietary 3D printing robots, automation, and partially recycled materials.

The company’s 3D printing technology produces building components faster than traditional construction, it says. Recently, the company opened a new factory in Monterrey, Mexico to serve the growing US market with their prefabricated housing solutions.

Its 3D printers use a thermoset composite material called Light Stone Material (LSM) that hardens when exposed to UV light, making it an efficient building material. All construction takes place in the Mighty Building factory. Then pieces are transported to the building site, currently limited to California.

In September of last year, the company finished its first Quatro unit in Desert Hot Springs, claiming it’s the only 3D printed net-zero home, producing as much energy as it consumes.

Recently, Mighty Buildings announced a partnership with Palari Group, a sustainable real estate development company, to build a community of 3D printed zero net energy homes in the upscale city of Rancho Mirage in California’s Coachella Valley. The plan reportedly received over $70 million in capital infusions from investors.

SQ4D

- Headquarters: New York, US

- Type of structures: Homes, Offices

- Region of operation: New York

- Printer: ARCS

- Projects: Islandia, N.Y.; Riverhead, N.Y.; Calverton, N.Y.

SQ4D is a New York-based construction start-up that has built its own concrete 3D printer series. It has three residential builds under its belt.

The company says it is introducing a better way to build. “With SQ4D’s ARCS line of construction 3D printers, the world now has a safe, affordable, and sustainable successor to outdated building methods.”

Its latest project, completed in Aug. 2022, is a four-bedroom, two-bath, 2,000-sq-ft home in Islandia, N.Y. Aside from its size, another factor that makes this home unique is the percentage of it that was 3D printed. Unlike many other 3D-printed homes, the foundation of this house was built using our ARCS printer, including the slab, footings, foundation walls, interior walls, and exterior walls. The construction took 15 days. SQ4D says it’s building full-scale homes in hours, not days or months.

Regarding sustainability, SQ4D says its printer uses the same amount of power as a standard hairdryer, building materials are locally sourced, and it’s also experimenting with recycled materials.

Printed Farms

- Headquarters: Florida (US)

- Type of structures: Low-rise modular buildings

- Region of operation: Florida, US

- Printer: Cobod Bod2

- Projects: Luxury Horse Barn, Fla.

This Florida-based start-up has used its Cobod Bod2 construction 3D printer on several projects, including what it says is Florida’s first 3D printed home near Tallahassee and the massive multi-million dollar in equestrian facility project they have underway now.

Because Printed Farms printer can lay up to two feet of wall a day, the thought is that it could be a valuable asset in quickly building homes after a hurricane. The 3D printed homes will be flood- and hurricane-resistant, the company says. Currently, the company is staying true to its name and building a $3,000,000 farmhouse, including a 3D printed horse stable. To achieve this massive feat, the company uses a combination of on-site manufacturing and prefabricated connection pieces made with their Cobod printer. The printer must be repositioned five times to complete the entire structure.

Nidus3D

- Headquarters: Canada

- Type of structures: Low- and high-rise buildings

- Region of operation: Canada

- Printer: COBOD BOD 2

- Projects: Multi-unit Housing, Bostock Studio, Multi-story residential

Nidus3D is a Canadian start-up offering on-site 3D construction printing to build sustainable, resilient homes. The company has completed two impressive projects so far.

Nidus3D was founded in 2021 with the conviction that technology and innovation can address the challenges in the building sector. In partnership with COBOD International, Nidus3D brought 3D construction printing to Canada.

WASP

- Headquarters: Italy

- Type of structures: Low-rise buildings

- Region of operation: Mainly Italy

- Printer: Big Delta, Crane Wasp

- Projects: Dior concept store, TECLA habitat

World Advanced Saving Project, or WASP, makes large construction 3D printers and partners with companies interested in eco-sustainable 3D printed habitats and buildings with local materials.

WASP offers a 3d printer named Big Delta, 12 meters in height and 7 meters wide, with adjustable arms extending up to 6 meters. WASP aims to use the Big Delta to extrude straw and earth to produce “zero-mile” homes built using naturally-sourced materials.

A significant milestone for WASP was the Gaia project. Apart from the local soil used to produce the main structure, the 30-square meter house used natural waste materials from rice production, as was presented in the “A Call to Save the World” conference.

Gaia is an eco-sustainable house designed and built using the Crane WASP, a modular 3D printer that can create homes in various formats and sizes. The house was printed on-site in Massa Lombardo, Italy, and is the result of seven years of architectural and 3D printing research. Its purpose is to demonstrate the potential of 3D printing in architecture.

Recently, WASP built a pop-up store for Dior in Dubai out of natural materials, combining clay, sand, and raw fibers.

Alquist 3D

- Headquarters: Iowa (US)

- Type of structures: Low-rise buildings

- Region of operation: US

- Printer: Cobod, Black Buffalo

- Projects: Habitat for Humanity Williamsburg, Va.

This Iowa-based construction company aims to revolutionize affordable housing with 3D printing. With four completed homes under its belt, it had planned to take on a 200-home goal in Virginia, starting with two homes in the town of Pulaski, but pulled out of the project earlier this year due to funding constraints.

Alquist partners with construction 3D printer maker Black Buffalo to manufacture its homes but also uses the Cobod gantry 3D printer in its projects. Recently, Iowan community development Project Better Together has announced a housing development project in conjunction with Alquist 3D to construct six two-bedroom townhouses in Iowa City. The units will be sold to members in the Johnson County community making between 60 and 80% of the area’s median income.

In November 2023, the city of Muscatine in Iowa, which had planned to finish nine 3D printed affordable houses by the end of this year, tore down the first house because the concrete strength did not meet the project’s requirements. According to local reporting by ABC news channel 8, the concrete failed to meet the county’s PSI (pounds per square inch) strength standard for construction, which was 5,000 PSI. Alquist told Channel 8 that the material met standards in the lab, but a new concrete formulation will be used on the project when it resumes.

Alquist’s 1,200-square-foot Virginia home for Habitat for Humanity was completed in December 2022 and 3D printed in about 28 hours, four weeks faster than the standard construction schedule. Habitat says using concrete for the walls saved an estimated 15% per square foot in building costs.

Xtreee

- Headquarters: Rungis, France

- Type of structures: Low-rise buildings, architectural features

- Region of operation: France

- Printer: Cobod Bod2

- Projects: Reims Viliaprint

In June of last year, French large-scale additive construction printer manufacturer Xtreee inaugurated not one but five homes in the city of Reims. Dubbed the Viliaprint project, the social housing project initiated by Plurial Novilla was completed in 12 months instead of the projected 16 it would have taken via conventional construction methods. The builder also says 3D printing enables these homes for low-income residents to have “high-level architecture” not typical with government housing.

Spurred on by the project’s success, the social housing innovator has now launched ViliaSprint2, a collective housing program with the goal of building a three-story apartment building from concrete using Peri’s Cobod Bod2 gantry printer. The project also plans for a second building to be “traditionally” constructed on the same premise to compare the benefits of the two construction methods in situ.

Their next big project focuses on constructing a 40-meter pedestrian footbridge in Aubervilliers for the 2024 Olympic Games.

Start-Up 3D Printing Construction Companies To Watch

Evocons: Evolution Construction System S.L. is a Spanish start-up developing its own gantry printer, the Evoconstructor, since 2018. This year, the company presented a prototype in its headquarters on Gran Canaria, claiming that it managed to automate 60% of the construction process.

Twente Additive Manufacturing: This Dutch company aims to build homes using 3D printing technology that emphasizes the objective that a home and the humans that inhabit it are joining the environment, not controlling it. Helping to reduce unnecessary material consumption and increase connectivity to the natural world is at the core of its mission statement. Twente Additive Manufacturing also holds the record for the largest concrete 3D printed arch built entirely without overhangs. This is possible because of a unique concrete mixture that seemingly cures the concrete as it’s printed.

Tvasta Manufacturing Solutions: This India-based start-up was founded by three alumni of IIT Madras. Their concrete 3D printing technology was developed in collaboration with Habitat for Humanity’s Terwilliger Center for Innovation in Shelter. The lay claim to the first 3D printed house in India, which was completed in 2020.

Emergent 3D: This US-based start-up finished its first home in California in late 2022. The 1,200-square-foot house was 3D printed in Redding, an area frequently experiencing wildfires. The 3D printed house is made using real concrete, far more resilient to wildfires than conventional stick-built homes. The one-story house is 8 feet tall, with cavity concrete walls of 50 mm, and was permitted according to the strict California Building Code. The cost of the concrete for the walls was less than $5,000, and it took 30 hours to print.

Saint Gobain Weber: This construction offshoot of its French parent company Saint-Gobain has one occupied 3D printed home under its belt in a partnership with Eindhoven University of Technology.

HTL.tech: Harcourt Technologies Limited is the sole distributor of Cobod 3D construction printers in the North of the UK, Northern Ireland, and the Republic of Ireland. Together with Building for Humanity, the company will construct 46 eco-friendly social housing units in Accrington, Lancashire, UK. The project, which claims to be the United Kingdom’s first 3D printed housing development project, is set to start this year and provide affordable living space for homeless veterans and low-income families.

14Trees: Hell-bent on bringing 3D construction innovation out of the lab and into the field, 14Trees operates on the African continent and has built the first 3D printed school in the world. Spurred on by this success, their ambitious follow-up project, Mvule Gardens, aims to create a 52-house community in Kilifi, Kenya, consisting of two- and three-bedroom 3D printed bungalows.

Domex 3D in an enigmatic German start-up with a foundation in animation, computer graphics and, architectural and interior visualization that says, in its media material, that it is partnering with another start-up in Delaware, AC3D, and others to “take a holistic view of optimizing the construction process.” It plans to offers a turnkey additive construction system, “equipped with everything the end user needs” to make building greener, cheaper, and faster. We’ll be keeping an eye out for its first project.

3DConcrete is the first company to introduce 3D concrete printing in the Caribbean. Located on the island of Curaçao, its mission is to bring innovative solutions and affordable housing to the market.

Qorox: This New Zealand start-up started small with 3D printed concrete structures, such as landscaping walls and public seating, but aims higher. The company says it works closely with CyBe Construction, which indicates they use one of the CyBe 3D printers.

Vertico 3D: This Dutch start-up specializes in large-scale concrete printing for architectural features and bridges but has yet to graduate to buildings.

Azure Printed Homes is a Culver City, Calif., start-up that’s 3D printing prefab homes to tackle the affordability crisis, it says. Their homes are meant to serve as second or third units on residential properties with an existing home, offering affordable housing to renters and giving homeowners a new revenue stream in place of a backyard or driveway.

Hive 3D is about to complete The Casitas at The Halles, which is a collection of five 3D printed studios, single-bedroom and two-bedroom affordable housing units in Texas using a low-carbon cement from Eco Material Technologies.

Lead image source: 3D printed home by Icon

License: The text of "Top Companies Building 3D Printed Houses" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.