For 3D printing, it’s essential to make sure your bed is level before starting any print. An unlevel bed often results in print quality issues, like warping or completely ruined prints, which means wasted material and time.

On most consumer-grade 3D printers, leveling your print bed involves rotating a few (usually four, one for each corner) screw knobs to raise or lower the bed incrementally at different points. This process can be tedious and inexact, but there’s an automatic answer! Auto-bed leveling (ABL) is an excellent feature for 3D printers that can very accurately level your bed with almost no manual effort.

Auto-bed leveling uses a sensor, usually attached to the printhead, to measure the height of your build plate at different points. These measurements are then used to create a leveling mesh to ensure that the nozzle maintains the same distance from the bed at all points during printing.

There are many sensor probes out there, but they aren’t all the same. Different ABL sensors use various technologies to function and provide different accuracies. In this article, we’ll go over some of the best ABL sensors and their main characteristics, like price and compatible surfaces.

Types of Leveling Sensors

Before we dive into the list of the best ABL sensors, it’s important to note that there are a few different types. In this section, we’ll briefly go over the main leveling technologies.

Hall-Effect

Hall effect sensors determine an object’s proximity by detecting the strength of static magnetic fields. Some auto-bed leveling sensors use Hall effect sensors in a mechanical way: A pin is extended and retracted using magnets. This configuration allows ABL Hall effect sensors to work on build plates of any material, not just metal plates.

Inductive

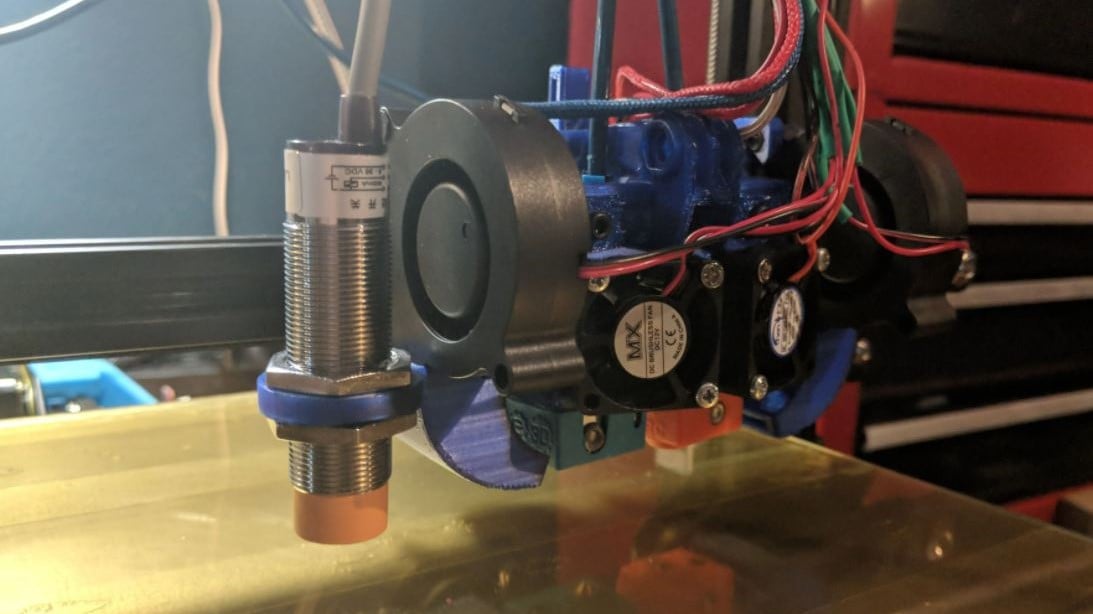

Similar to Hall effect sensors, inductive sensors also use magnetic fields to determine an object’s proximity. However, they measure the change in a magnetic field due to, for example, movement. This is done by charging a coil of wire and measuring its current.

Inductive ABL sensors are non-contact devices that usually come in the form of a small metal cylinder with a rubber tip. Unfortunately, they can only detect metal surfaces, which excludes plastic or other non-metal build plates.

Capacitive

Capacitive sensors look a lot like inductive sensors, but the key difference is that they can detect both metal and non-metal surfaces. Capacitive ABL sensors, like inductive options, are non-contact, but they detect electrostatic fields rather than magnetic fields. Although they work with any surface, tests have shown that this type of sensor is less precise than other technologies.

Smart Effector

Smart effectors are a special type of proximity sensor meant for 3D printing. While most ABL sensors attach to a machine’s printhead, a smart effector is an all-in-one option that integrates the ABL sensor into the hot end. These sensors work by measuring the change in a nozzle’s electrical resistance when it gets close to a surface (i.e. the build plate).

As you might expect, there are a limited number of options for smart effectors. It may be more challenging to find one that’s compatible with your printer. Luckily, though, wiring a smart effector hot end should be easier than wiring a hot end and an ABL sensor separately.

Infrared

Infrared (IR) sensors, as indicated by their name, are devices that use infrared light to detect an object’s proximity. IR leveling sensors usually have an LED, and the light reflected off of nearby surfaces is measured to tell when the sensor is close to the bed. This sensor may be more difficult to configure but won’t take up much space.

Piezo

Piezo sensors, while not very popular for auto-bed leveling, can also be used for leveling the print bed. These devices are similar in functionality to a smart effector, using the nozzle to detect when a surface is close. However, Piezo sensors differ in that they rely on measuring a property known as piezoelectricity.

As there aren’t many popular options meant for 3D printing, finding a compatible Piezo sensor may be slightly difficult. Nonetheless, Piezo sensors should work on most build plate materials and are considered pretty accurate.

Microswitch

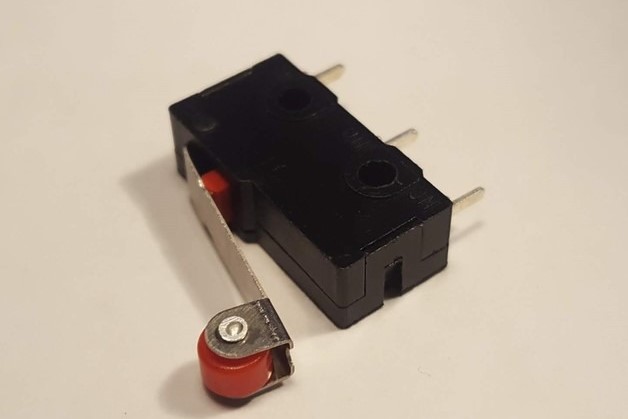

Microswitches are the same devices that most 3D printers use to home the axes. They can be found on many other everyday devices that may require a button press, including washing machines, refrigerators, home security, and even elevator buttons.

Microswitches are not used often in ABL because they need to be stowed away manually, but they are very useful for homing axes when they aren’t mounted to the printhead. Many microswitch users will use a G-code command to quickly stow the sensor away in a caddy after leveling the print bed.

Despite its drawbacks, this is one of the most accurate and precise sensor types of the bunch. This is due to the simplicity of the device and the tight manufacturing tolerances of the inner components. It’s compatible with all types of build surfaces, as it makes mechanical contact with them.

Optical

Optical sensors are the newest type of sensor on this list, and they aim to improve the design of the Hall effect sensor. They may look and function exactly the same as a Hall effect sensor but are generally more accurate.

This accuracy bump is due to the inherently digital nature of the sensor. An optical sensor gauges when the probe contacts the bed by breaking a beam of light, providing a digital output. Hall effect technology must be converted from analog to a digital string before the printer can use the data, adding another layer of potential rounding errors. This sensor is compatible with all types of build surfaces since it makes mechanical contact with the build plate.

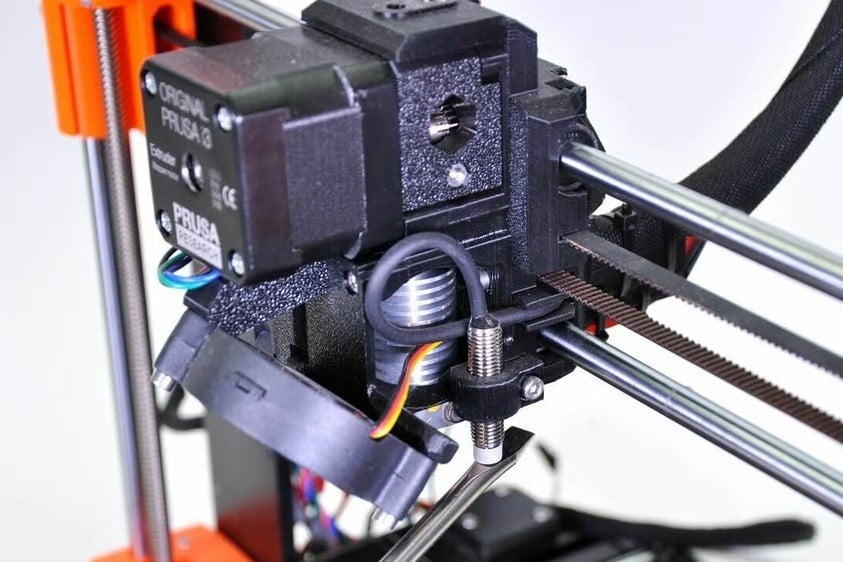

BLTouch

The Antclabs BLTouch device is perhaps the most popular auto-bed leveling sensor out there, commonly used on budget printers like the Ender 3 V2. The BLTouch V3.1 is a direct contact sensor that extends a peg that activates a sensor in the device once pushed far enough. The sensor operates via the Hall effect. When the peg moves up, it changes an electric field in the device, and this change is detected by the sensor with an accuracy of about 0.01 mm. As a physical sensor, the BLTouch device doesn’t have any restrictions for compatible build plate materials.

The BLTouch is also compatible with certain firmware. For example, Marlin‘s public configuration files contain ready-to-work code for the device. The BLTouch V3.1 also has two mounting holes that make attaching the device to the printhead a breeze, especially with the hundreds of available 3D printable and purchasable mounts.

As you might expect, installing the BLTouch V3.1 should be pretty easy. However, according to reviews, some users have experienced issues getting the device to work with their printer’s mainboard. For this reason, we suggest checking the compatibility between your printer and the BLTouch before buying.

- Price: ~$35-40

- Technology: Physical (Hall effect)

- Compatible surface materials: Any (e.g. metal, glass, plastic)

CR Touch

The CR Touch is a direct competitor to the BLTouch. This sensor uses optical technology, as opposed to the BLTouch, which uses Hall effect technology. This makes the CR Touch ever so slightly more accurate. It’s a drop-in replacement for the BLTouch, only requiring the user to change the included mounting bracket and adjust the Z offset on the printer’s interface.

One of the drawbacks of using an optical sensor is that it may not function correctly near a bright light source due to interference. If a bright light is near the sensor, it could error out before starting the leveling procedure. Another problem with the device is the rattling of the probe during printing. This issue is well documented, and there are several ways users have experimented to fix the problem. Neither of these problems is present on the BLTouch, which uses Hall effect technology and a plastic probe instead of a metal one.

- Price: $40-50

- Technology: Optical

- Compatible surface materials: Any (e.g. metal, glass, plastic)

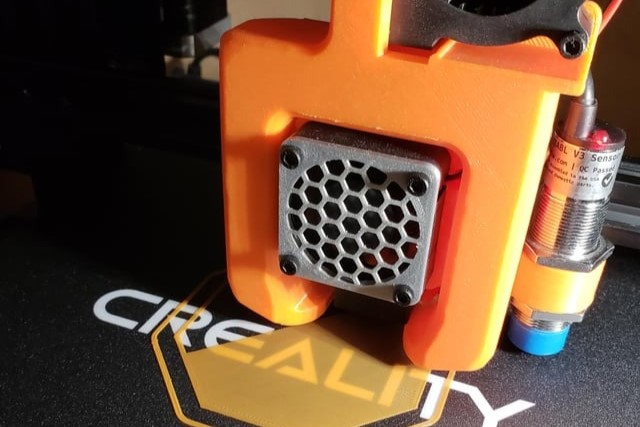

SuperPINDA

The SuperPINDA (Prusa Induction Auto Leveling Sensor) is an inductive leveling probe developed by Prusa Research, a high-quality and open-source 3D printer manufacturer. The SuperPINDA was Prusa’s replacement for the previous PINDA V2 sensor.

As an inductive leveling probe, the SuperPINDA uses electrical induction to sense the magnetic fields of surfaces. This means you are only supposed to use a metal build plate (e.g. spring steel PEI sheet) with the SuperPINDA. However, some users have found that with the right Z offset and a thin enough build plate, you can use bed surfaces of other materials (e.g. polypropylene) because the sensor can detect the printer’s metal bed underframe.

Previous PINDA sensors used an integrated temperature sensor to detect the build plate’s temperature to attempt to compensate for measurement differences. The SuperPINDA improves on this by replacing the temperature sensor with components that take more consistent measurements, regardless of temperature.

Besides being inexpensive when compared to other ABL options, the SuperPINDA can be easily attached to a printhead, as the sensor’s frame has screw threads on it and a mounting nut.

- Price: ~$26

- Technology: Inductive

- Compatible surface materials: Metals (non-metals work if thin enough)

BD Sensor

How about being able to level your 3D printer bed in 15 seconds, without physical contact from the probe, with an accuracy of 0.01 mm? That’s what you get with the BD sensor, which first appeared on Hackaday in 2022. You can also adjust the nozzle in real time, even at temperatures of up to 120 ºC, for a flawless first layer. The BD sensor has a few other tricks up its sleeves, such as a compatible BLTouch interface for easier installation and compatibility.

This inductive sensor works by measuring the variation in electrical current in the coil at the tip of the probe, with a response time of less than 4 m/s. The probe is kept away from the main electronic components, and it’s capable of withstanding temperatures up to 85 ºC. The height can be adjusted in real time without the need for Z-axis movement for measurements. Of course, like any inductive sensor, it has its limitations. For example, it requires a metal surface and is affected by variations in temperature.

Variations of 0.06 mm can be observed in tests where the bed temperature exceeds 100 ºC, as shown in a video from Mark Yu on YouTube. In another video, he demonstrates that the probe is not affected by the magnetic base. The sensor is also compatible with both Marlin and Klipper. Some comments from the Klipper community on Reddit emphasize the limitations of an inductive sensor compared to a lidar-type sensor. For more details, check the GitHub repository, and there’s also installation information available with technical details and recommendations.

- Price: ~$30

- Technology: Inductive

- Compatible surface materials: Metal

Taiss Capacitance Proximity Sensor

The Taiss Capacitive Sensor (model LJC18A3-H-Z), as the name suggests, is a capacitive leveling sensor. This means it functions by measuring the energy capacitance it can hold, which changes when objects are in front of the sensor with an accuracy of 0.001-0.01 mm. The device has a detection distance of 1-10 mm and an operating temperature of up to 65 °C, so it should work on a 3D printer as long as you’re not printing high-bed-temperature materials (e.g. ABS).

According to customer reviews, the Taiss sensor is very accurate and works on all bed materials, as expected from a capacitive sensor. Other users have also stated that the sensor performs very well, but only after calibrating the device’s sensitivity.

- Price: $10-15

- Technology: Capacitive

- Compatible surface materials: Any (e.g. metal, glass, plastic)

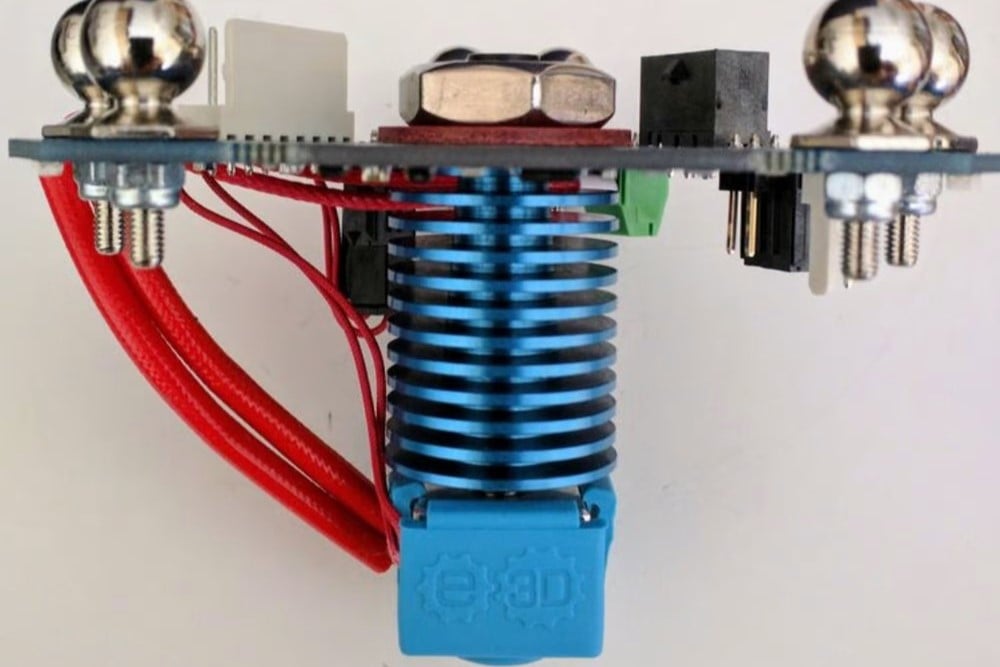

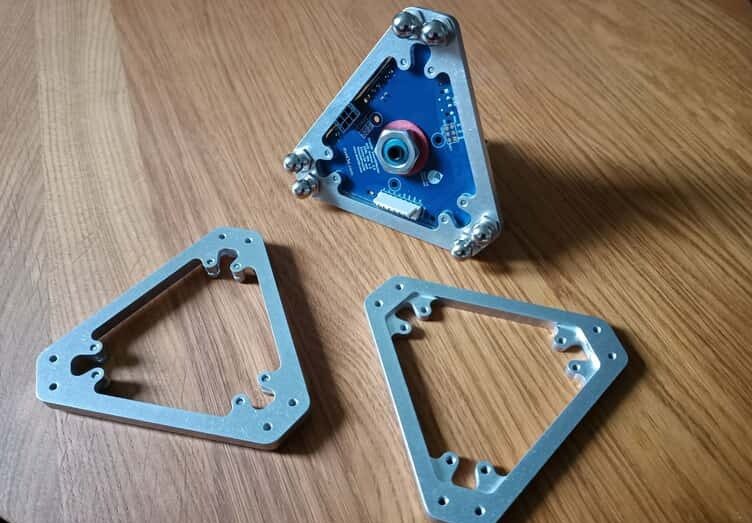

Duet3D Smart Effector

While it only works for delta FDM 3D printers, the Duet3D Smart Effector is a hot end that also serves as an ABL sensor. Created by Duet3D, a manufacturer of 3D printer mainboards, the Smart Effector uses a modified version of the E3D V6 hot end with a special PCB that enables the nozzle to take leveling measurements.

Duet3D notes that the Smart Effector simplifies the wiring process as the hot end and ABL wires are all together. While this is true, given the complexity and lack of popularity around the device, the overall installation (firmware and hardware) for the sensor may be somewhat tricky.

- Price: $60-$80

- Technology: Smart effector

- Compatible surface materials: Any (e.g. metal, glass, plastic)

Duet3D IR Probe

The Duet3D IR Probe is another ABL device offered by Duet3D, and it relies on infrared technology to function. The device measures distance by projecting light from two specially-placed LEDs and measuring the distance between the two beam’s reflections.

As light is involved in the Duet3D IR Probe’s leveling process, the device works on transparent surfaces like glass if it’s placed directly on a PCB bed heater or surface that doesn’t reflect strongly. Moreover, it’s recommended to cover these surfaces with an opaque surface, with or without an adhesive (it can affect trigger sensitivity). Nonetheless, the sensor is somewhat inexpensive and takes up a small footprint. There are also a few installation guides for the sensor.

- Price: ~$35

- Technology: Infrared

- Compatible surface materials: Glass, PEI, BuildTak, PrintBite, metal (all with opaque covers)

EZABL Pro

The EZABL Pro is a capacitive leveling sensor created by TH3D, a developer of 3D printer accessories and custom firmware. As a capacitive sensor, the EZABL Pro doesn’t rely on magnetic fields to detect objects, meaning it can detect bed surfaces of all materials (unlike inductive sensors, which can only detect metals).

The EZABL is undoubtedly at the higher end of the price spectrum for ABL sensors, but it comes with its own power supply that allows you to install the sensor without any soldering. It’s recommended to flash TH3D’s Marlin-based firmware to your printer’s mainboard, but TH3D also states that it works with other firmware programs, like Klipper and RepRap. As for the hardware, you can attach the EZABL Pro to your printhead using a 3D printable mount.

- Price: ~$37

- Technology: Capacitive

- Compatible surface materials: Any (e.g. metal, glass, plastic)

Euclid Probe

The Euclid Probe is a semi-DIY kit sold to users who may want a new project to work on or need an accurate microswitch probe with no moving parts. There are two parts to this sensor: the microswitch and the connector. These two parts are magnetically connected to probe the print bed and are separated to print. The two sections must be disconnected from each other to leave enough room for the nozzle to make contact with the bed.

The instructions for putting this kit are thorough and straightforward, even including files for 3D printing mounting solutions for different printers. Even though this probe is sold as a kit, it still requires soldering a few pins, which may be a turnoff for some people. If soldering is not your thing, one of the preassembled probes may be a better fit for you.

- Price: ~$25

- Technology: Microswitch

- Compatible surface materials: Any (e.g. metal, glass, plastic)

Precision Piezo Orion

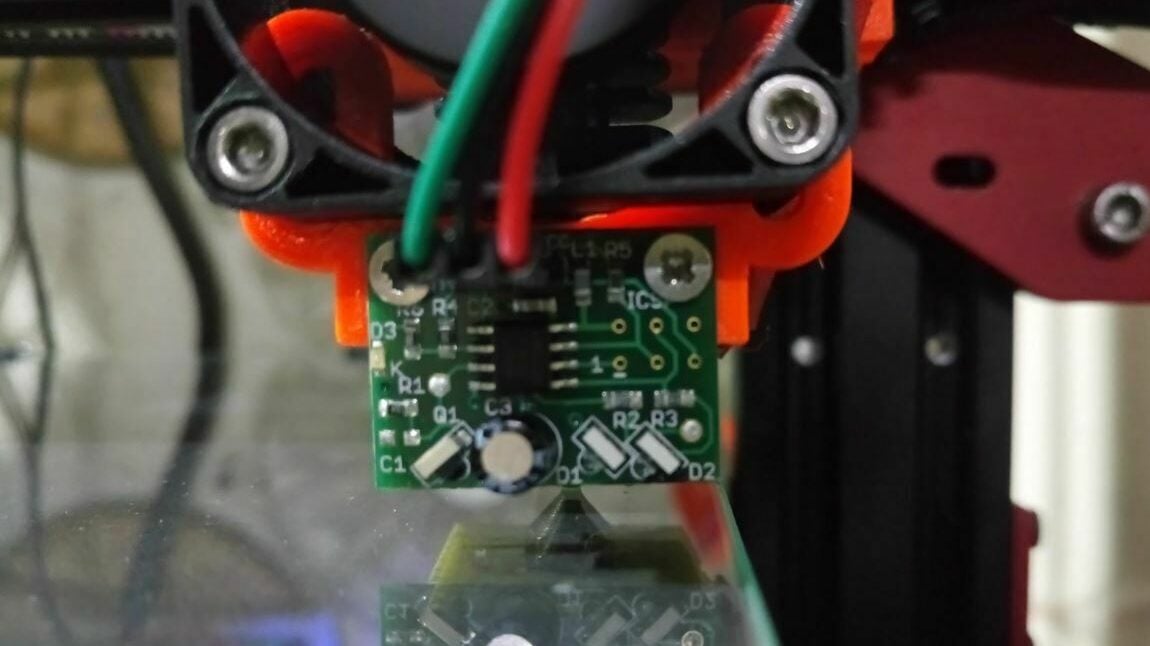

Precision Piezo is a company that specializes in auto-bed leveling solutions with Piezo sensors. The Precision Piezo Orion is a DIY auto-bed leveling kit similar to the Duet3D Smart Effector, as it allows you to add ABL functionality to your hot end.

The Orion uses a Piezo sensor that detects and measures electrical charges produced by objects with an accuracy of 0.005 mm. The Orion is meant to be attached to your hot end, specifically the area near the heat break, to detect the build plate when the nozzle touches it.

Precision Piezo states that the Orion can work with any material build plate, including glass, polypropylene, and metal. Installing the Orion may be more complicated than more popular sensors (e.g. BLTouch), but it’s proven to work with the E3D V6 hot end and Precision Piezo’s official 3D printable mount.

- Price: ~$50

- Technology: Piezo

- Compatible surface materials: Any (e.g. metal, glass, plastic)

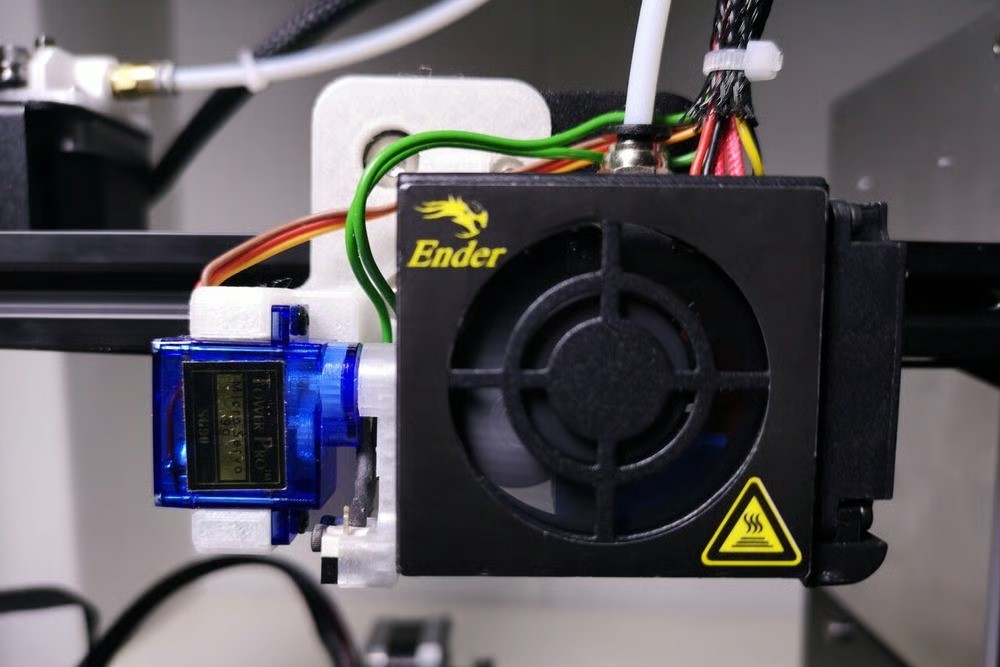

DIY Microswitch

If you’re willing to take a few more steps with a DIY probe to save a buck or are just looking for a new project, this may be a great idea! This DIY microswitch probe aims to transform your Z endstop microswitch into a fully functional auto-bed leveling sensor. This guide is created specifically for the Creality Ender 3 with detailed instructions on assembling the printed parts and modifying the firmware.

Although the mounting bracket files in this guide are only compatible with the Ender 3, it works with the Ender 3 Pro and Ender 3 V2 with no modifications. This project should be compatible with any printer large enough to support an auto bed leveling sensor with some modifications to the mounting brackets, which can be done in a 3D modeling program such as Tinkercad.

Clever firmware tweaks and 3D printed parts will make this sensor perform nearly as well as the best commercial auto bed leveling sensors, mostly because it uses accurate microswitch technology. While this project requires soldering experience and some know-how in editing Marlin firmware, it can be great for anyone looking to learn some fairly basic 3D printer modding techniques and improve their skills.

- Price: <$10

- Technology: Microswitch

- Compatible surface materials: Any (e.g. metal, glass, plastic)

License: The text of "The Best 3D Printer Auto-Bed Leveling Sensors in 2024" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.