In an interesting head-to-head comparison, we have two siblings from the same product line that are very different 3D printers. Anycubic introduced the Kobra series in 2022, and both the Kobra and Kobra Max have since gotten a lot of traction in the community given the features they each bring to the table.

While the Kobra has a smaller build size, it’s not going to sit on the sidelines. It’ll give you things to look forward to, like its pretty great auto-bed leveling (ABL) mesh mapping system, a direct extrusion setup, and a stock removable PEI-coated spring-steel plate, just to name a few.

The bigger sibling has also been leaving big footprints (or snake tracks, ba dum tss). The Kobra Max carries over some parts that may feel familiar to dedicated Anycubic fans, as it uses the same Volcano-style Bowden setup as the Vyper. However the Vyper doesn’t come close to the 400 x 400 x 450-mm build volume that the Kobra Max holds.

But back to more differences between the two Kobras. The print bed, ABL system, and price are some major points to compare. While the Kobra Max dominates over the Kobra with almost double the printable area, nowadays there are so many ways to split STL files and assemble the parts that you may wonder how much benefit there really is to having a bigger build volume.

Let’s talk about all of these things and more so you can figure out which of these may slither into your workspace.

Sit back and grab the popcorn because here we go.

At A Glance

Features

With these printers coming out in 2022, we can expect certain features from each given their price points, but both bring a little something extra to the table.

They share a name and a few other features, but one is significantly bigger. That’s not where the differences end, though.

Design

The Kobra and Kobra Max are often considered predecessors to the Anycubic Vyper. While there are subtle improvements, that doesn’t mean that they’re without fault.

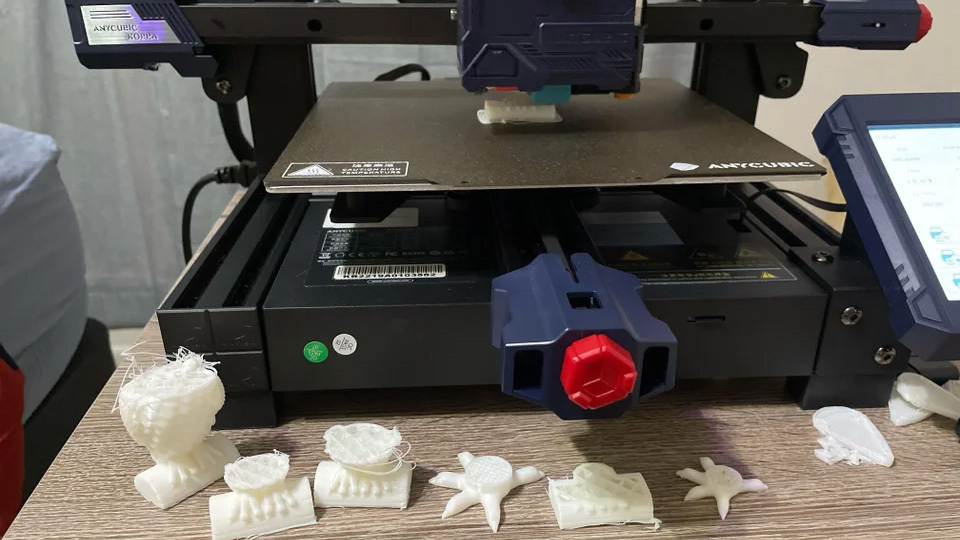

The Kobra goes for an industrial style choice that’s pleasant and doesn’t stand out if it’s sitting in your house. Anycubic seemingly enjoys this look and has kept it for the Kobra Max as well. The red tension screws add a pop of color without being over the top. Despite the nice color palette, it’s impossible not to notice how plasticky the Kobra looks. This isn’t to say it looks bad, but it is something you might pick up on when you see the printer in person.

Something to mention about the Kobra is the lack of dual Z-axis rods and motor, which would put this machine in a league of its own. You can try to work around this by tuning everything correctly on the X-axis gantry (without over-tightening) to ensure that there’s no imbalance of the X-axis beam while it travels up or down the Z rod. The reason for the lack of dual Z rods and so much plastic on the Kobra might become clearer further along.

The Kobra Max has a look that gets noticed. That mostly comes from the fact that it doesn’t take much of a table for the top the printer to sit at eye level with you. You don’t get as many little frills and small design elements as there are on the Kobra, yet its bare-bones structure might be a blessing when you need to move it.

A possible downside to this is not having the extra support at the base to help the frame’s alignment, although the braces should help avoid any issues with vibrations. When you’re looking for a place to home this big 3D printer, pay close attention to how far back and forward the build plate goes – its reach may surprise you.

This leads us to the next topic in this comparison.

Build Volume

Okay, so here’s the thing: Comparing such different build volumes can either be considered very easy or just odd. The main takeaway is that these printers have a lot in common – their size is not one of them.

Measuring in around 222 x 222 x 252 mm, the Kobra sports a slightly different build volume compared to other popular 3D printers out there, including the Ender 3 series. This gives a nice starting point if you’re beginning your journey into the world of 3D printing. If you’re worried about not being able to 3D print big things, you can always take You-Know-Who’s approach and split the models (no need to worry about your soul, though).

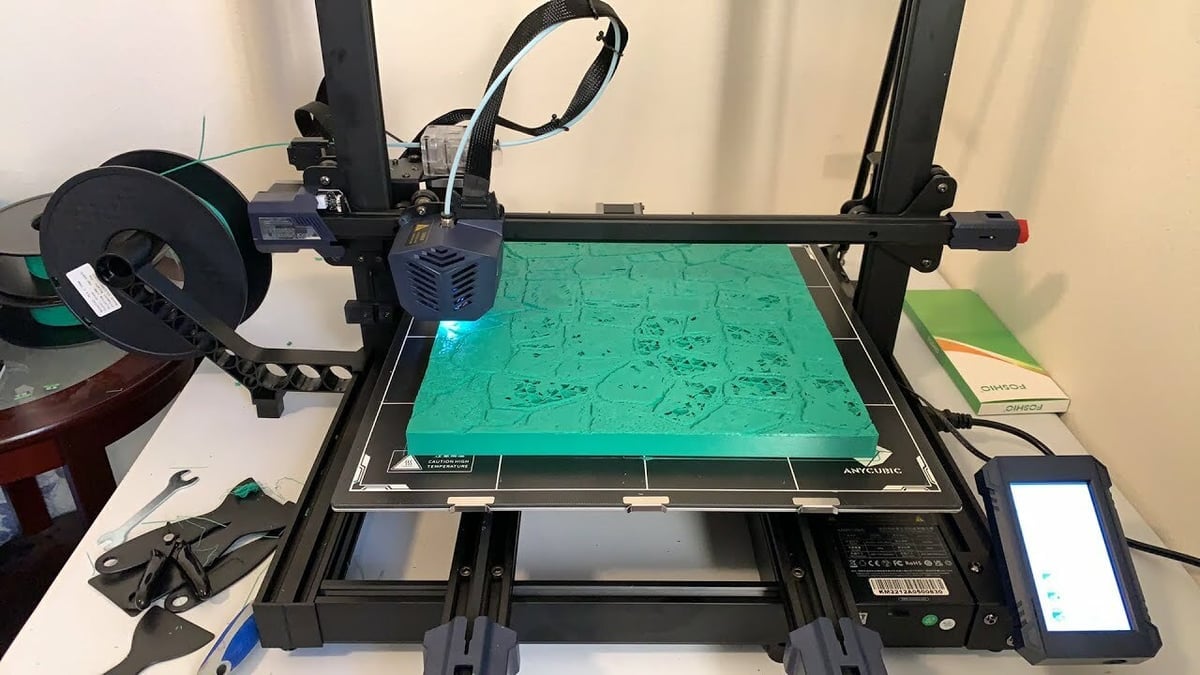

The Kobra Max’s behemoth of a build volume stacks up at 400 x 400 x 450 mm. That is an impressive difference, as it almost doubles the more typical build volume. This opens up a lot of different options that you can take advantage of, like being able to print a full helmet that’s too large for the normal Kobra. Post-processing will decrease if there’s less gluing and assembling to be done, and you can print a larger number of parts in fewer batches with the right configuration on the build plate.

Build Plate

Build plates play a big role in how you may feel about a certain printer. You may feel the urge to put a PEI-coated spring-steel plate onto every machine you come in contact with, or you might live by the rules of the old and trustworthy where glass is still king. Depending on the 3D printer, choosing the right or wrong material could have a huge impact on the adhesion of your 3D prints.

The Kobra starts things off with a PEI spring-steel plate and there are almost only good things to say about it. The adhesion to the bed is great. There are some people who disagree, but there’s usually a reason for it failing. The surface needs to be clean and dry; this may be the only maintenance necessary to improve adhesion.

The Kobra Max goes in a completely different direction with a massive slab of glass, although they didn’t stop there. They gave us carborundum glass, which is best identified by the perforated black layer over the glass bed. This helps separate the prints from the plate. If you plan to primarily work with PLA then you’re in good hands. Every once in a while you may hear horror stories about PETG and even PLA on a glass build plate, but this is more of an exception than a rule, and care is always warranted no matter what build plate material and no matter what filament.

UI

Finally, something that marks these two 3D printers as being in the same family beside their name. The UI between these two machines is nearly identical. The only difference is that the Kobra immediately sets up the nozzle to measure your Z offset after the ABL (auto-bed leveling) is finished, whereas the Kobra Max assumes you’re good to go.

There isn’t anything else to compare these two UIs because they’re identical in every way, including the firmware they use. While are several things to mention about the UI, it will go for both the Kobra and Kobra Max. The lack of options in the menu is lackluster, yet there’s enough to get the job done and leave the rest to the slicer you’re using.

The screen’s touch sensitivity is very responsive, which is nice. It doesn’t use pressure but rather something similar to a smartphone screen’s touch capabilities. The screen is large enough, even as some of the latest 3D printers are opting for larger ones – this one’s perfectly acceptable.

The main issue isn’t even about the UI itself, which leads us to the software.

Software

Here’s another aspect that’s not different – the two 3D printers’ software is the same. They use Marlin 2.0 although Anycubic’s dev-team had to block linear advance from being enabled in both because it causes a crash when activated.

If this is especially important to you, you may be sad but you’re not defeated! Anycubic recently released their firmware source code and the community has shared custom Zombie firmware with activated linear advance. The only thing that’s being sacrificed is how quiet the X-axis will be. Now, this requires putting some internet stranger’s custom firmware on your machine hoping that they know what they’re doing. While we can’t vouch for any specific user, if your curiosity can’t be quenched, then we’ll leave such a decision up to you.

Whatever you decide, always make sure to do enough research so you feel safe with any choice you will be making when it comes to firmware. That said, another benefit of taking this risk is the possibility of going from the Kobra’s stock 0.05-mm Z offset to a much more appreciated 0.01-mm Z offset during prints.

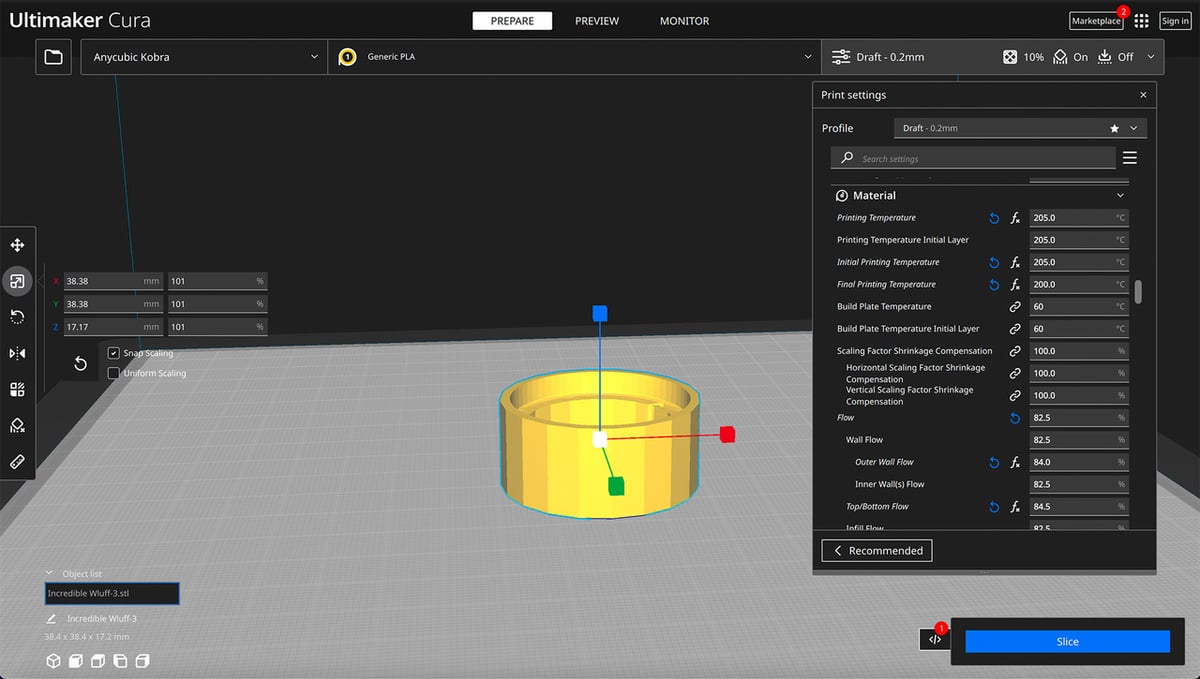

And when it comes to the slicer, apparently only Cura has added the Kobra and Kobra Max as default printers – yet you’ve got to update to at least the 5.1 version. Older versions (4.2) might work, but not all of them have the default printing profile ready to go.

Extrusion

Here’s where we see a noticeable difference (besides the build plate). When it comes to these two 3D printers you’ll find that one has a direct extruder, while the other includes the same Volcano-style hot end that was used by its predecessors.

The Kobra has a direct extruder setup with a double-gear system that can be problematic over time, but we have to give credit where credit’s due. When you pull up the test file and print it without changing anything else, you’ll be pleased to already be seeing some pretty great results. This nozzle is a dream for beginners because of how much play is allowed while still getting good prints. Possibly noteworthy are the overhangs, which proved better than expected when we tried them out. That is until we ran into a clogged extruder. Sadly, Anycubic’s choice to use a piece of Bowden tube at the heat break doesn’t seem to help any clogging issues you might run into.

On the other hand, we have the Kobra Max whose extruder did come as a little bit of a letdown to some when they noticed that it was rocking the same one as the Vyper and Chiron models instead of a direct setup. The main reason we don’t mind this ourselves is because of a little saying that you may have heard: “If it ain’t broke, don’t fix it.”

This Volcano style is perfect for larger printing areas because the nozzle gives the filament enough time to melt before it’s called to duty, which is something that the Kobra Max definitely needs, given its massive build plate.

While changing the Kobra Max’s setup to a direct extrusion one is doable, comments online have referred to how taxing it can be. So if it’s not something you’re ready to invest time into, be sure to consider each of the setups before making your purchase.

Bed Leveling

The bed leveling for these two printers is yet another significantly differing point, but there seems to be no general consensus on which is preferred. For the most part, the Kobra is going to sound really nice and advanced compared to its bigger sibling because its bed leveling strategy is uncommon within the price range.

While they’ve both got an auto-bed leveling system that Anycubic refers to as “LeviQ”, the approach is different on each machine.

The Kobra’s process avoids touching the bed, instead using an inductive probe to sense whether there are any obstacles or uneven parts on the bed.

The Kobra Max opts for a more traditional strain gauge-based system. This allows you to use the nozzle itself to detect when it meets the bed, then it makes the calculations to accurately give you a close-to-perfect Z offset. This is the same system that can be found on Vyper.

As a side note, with custom firmware, you’re able to add extra points to the bed leveling for a more accurate reading that improves the first print layers right away.

Mainboard

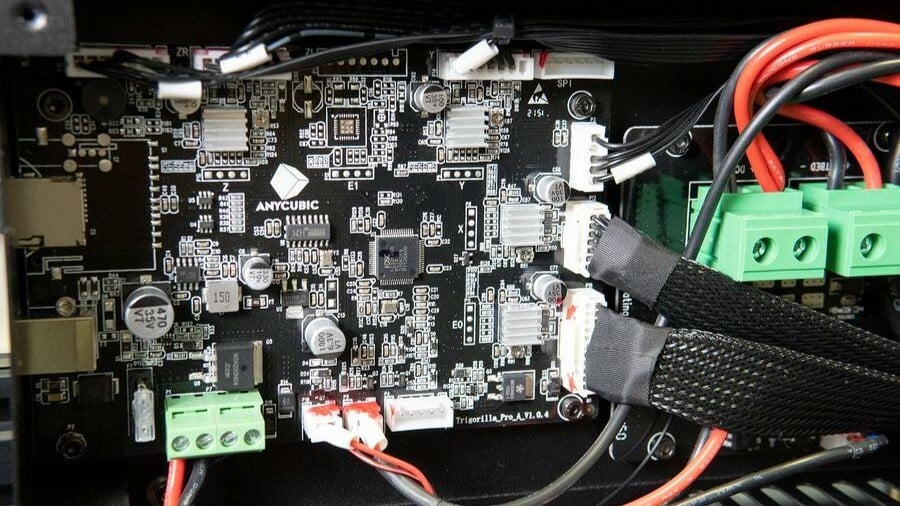

When it comes down to it, these two models may look quite different on the outside, yet they have the same brain.

Both run on a Trigorilla Pro A (V1.0.4) mainboard and, given both the printers’ designs, it’s fairly easy to access it should you need or want to tweak anything.

The nice part about this mainboard is that the stepper drivers are the TMC2209 (at least in the Max), which are compatible with linear advance, as we mentioned prior.

There are slight differences in the bodies of the mainboards, yet most of the components are the same. It seems to be a solid mainboard on both of these machines, with some differences given the scope of each printer, and they don’t leave much room for complaining.

Price

Remember how we mentioned that there might be an explanation as to why there were so many plastic parts on the Kobra? Well, when you get a very nice sensorless leveling system, a great mainboard with a reliable power supply, a direct extruder, plus a few more bits, and that’s all under the price of $300, it’s quite a nice trade-off if you ask us.

The Kobra Max is almost double the discounted price of the normal Kobra at around $570. With that large of a build plate and mechanism, we’re not taken aback by this price tag. And when you compare the build size to other printers sporting the same gear, you’ll see that the Kobra Max is a bit cheaper than the other options out there.

Verdict

We’ve gone over the good, the bad, and the ugly. What we conclude isn’t surprising – these are two very different printers. This does make it harder to choose a winner. If you’ve been around the block, you may agree that there’s never a “one printer to rule them all”.

The Kobra is perfect for those who want to set it up and let it go, with its great build plate and portability as well as its amazing direct extruder. While this might be the option for someone who wants an easy yet smaller print, the main downside is the lack of an additional Z rod. Even without the extra Z-axis rod, we can say that the only reason you would pick the Kobra Max over this Kobra would be because you want to print bigger.

The Kobra Max will definitely need some tuning before it’s worth bragging about. But, once it’s dialed in, you can see that the extruder doesn’t mess around. It’s no direct setup, but if printing large parts is your goal and you want to avoid splitting prints into so many pieces, then this is the clear winner for you.

License: The text of "Anycubic Kobra vs Kobra Max: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.