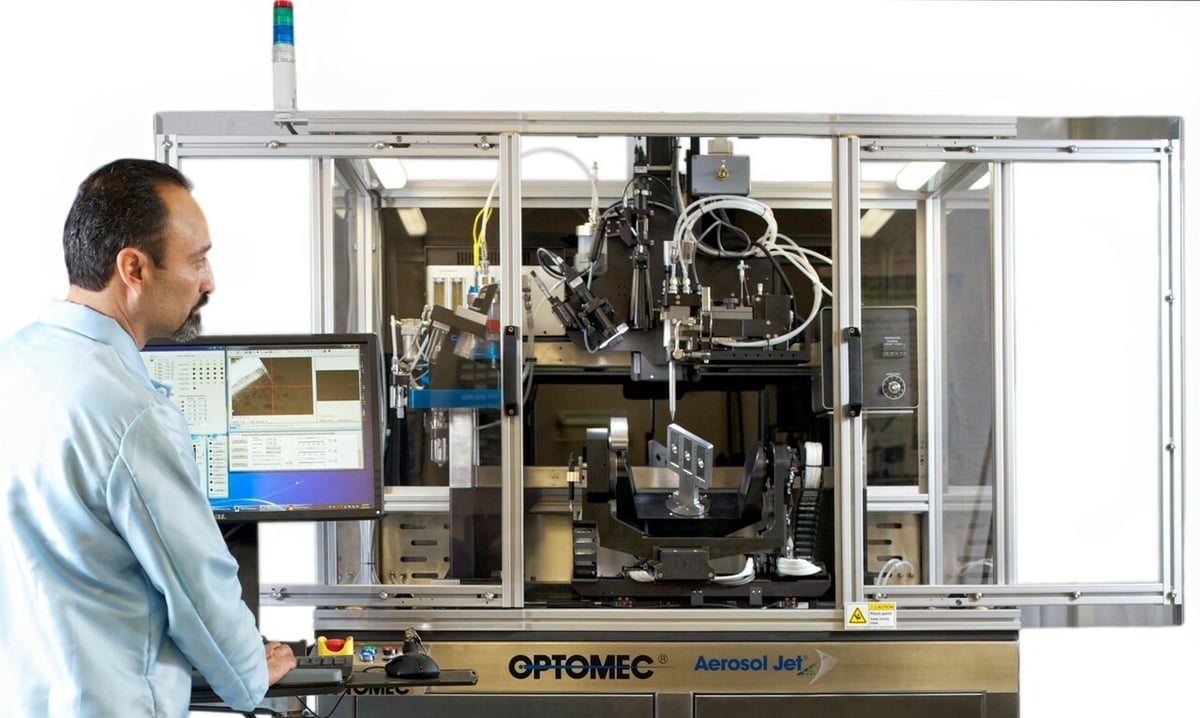

An impressively versatile technology, aerosol jet (AJ) printing enables high-speed printing in a uniquely wide range of materials, ranging from platinum to proteins. Also called maskless mesoscale materials deposition, the technology was first patented and commercialized by Optomec Inc. in 2004.

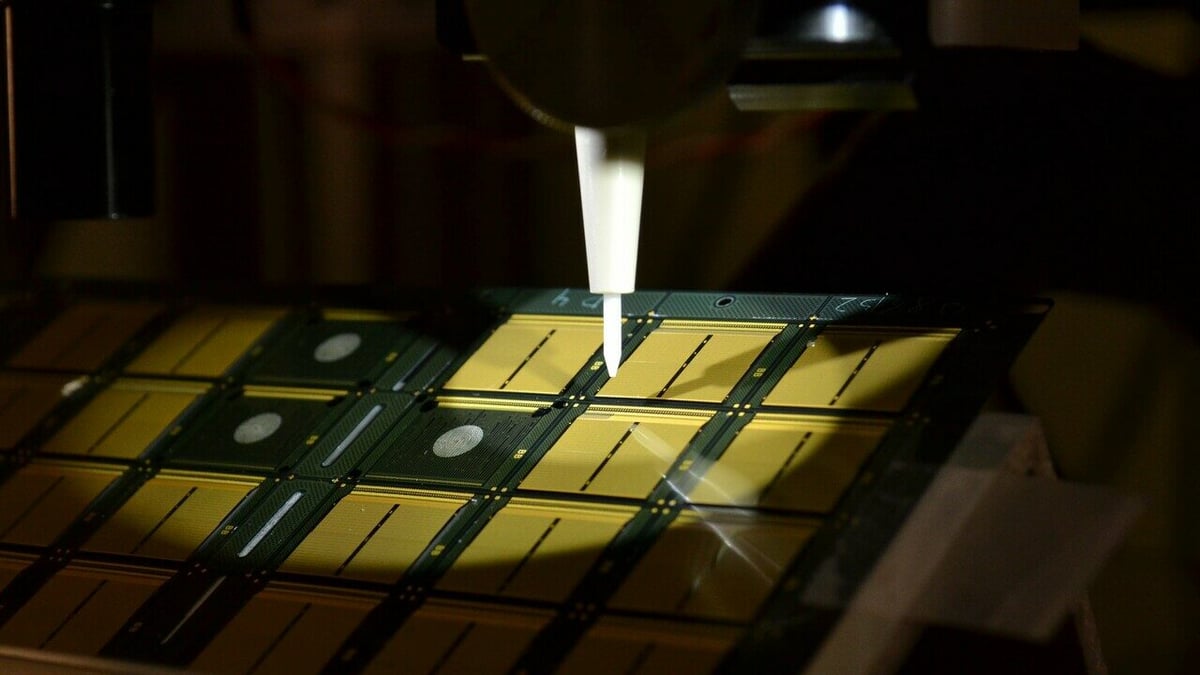

AJ printing relies on aerosolizing inks and depositing them along precise paths. This has made the technology popular in printed electronics, especially cell phone antennas. Other use cases include the semiconductor, energy, aerospace, and automotive industries, alongside various other areas of research.

In this article, we’ll explore how AJ printing works, its main advantages, and some helpful specifications for the technology. Towards the end, we’ll also provide additional resources for further reading.

Let’s get started!

How It Works

In principle, AJ printing works by spraying out an aerosol – a suspension of small liquid droplets in air – in a process that parallels spray painting. Unlike spray paint, however, this aerosol is very precisely deposited, supported by a series of steps that ensure a small, focused beam of material.

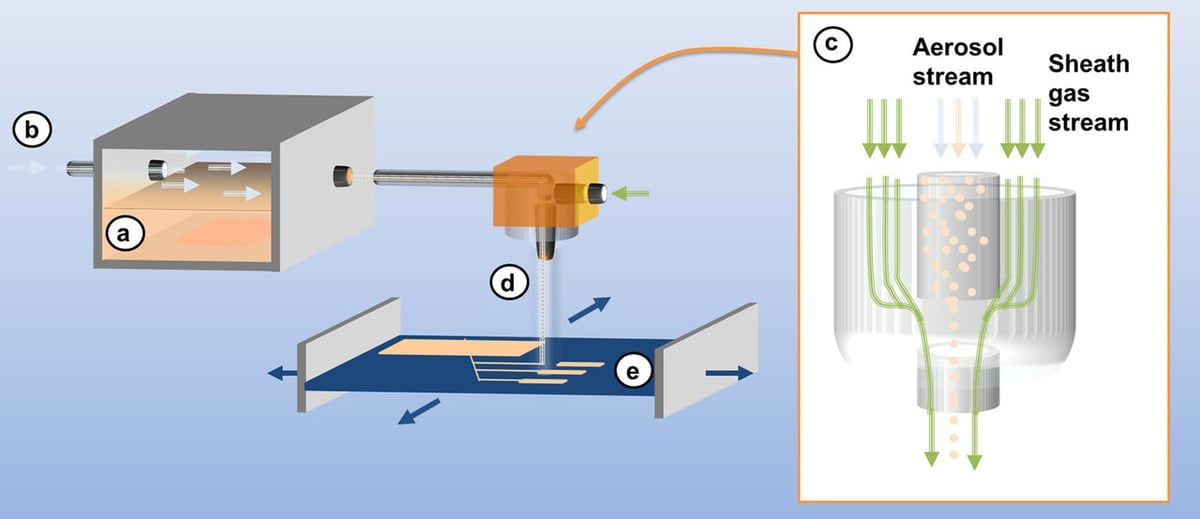

The process begins in the aerosol chamber (a), which stores the printing ink. This ink contains particles of your desired printing material in an appropriate liquid solvent. Within this aerosol chamber, you’ll also find the atomizer, which aerosolizes the ink into small, airborne droplets.

From there, an inert gas (b) is pumped in, carrying the aerosol with it. Once the stream is out of the chamber, a virtual impactor (not depicted) removes excess gas to create a denser aerosol mist.

Finally, a sheath gas stream (c) is introduced, surrounding the aerosol to help it focus and prevent clogging. This aerosol stream exits the nozzle (d) with a variable diameter and is deposited onto your desired substrate (e.g. a smartphone casing). This substrate is held on a moving build platform (e), with the aerosol’s long focal distance helping it better accommodate 2D and 3D substrates alike. To target deposition, a controllable shutter precisely blocks and releases the stream based on inputted CAD data.

After printing, thermal and photochemical processing (e.g. sintering and UV curing) can be used to achieve the final material properties and enhanced substrate adhesion. For reference, Optomec has cited improvements in silver nanoparticle substrate adhesion when heated to 120 °C for an hour.

Depending on the specific printer system, various additional configurations are also supported. These include multiple print modules, IR lasers, UV curing modules, and wide-feature print heads. The build platform is also available beyond the conventional 3 axes to include 5- and 6-axis variants.

This setup allows for the precise deposition of a wide range of materials, printed onto various 2D and 3D substrates (e.g. the dome pictured above). While this is mainly for printing conformal lines, not complex 3D structures, researchers have successfully printed AJ microstructures with UV inks. This is thanks to the technology’s ease of configuration, where its core printing process can be tailored to specific applications.

Next, let’s explore some key advantages and specifications of the technology.

Advantages

AJ printing stands out for three main qualities: precision, print speed, and material selection. This has earned the technology several applications in manufacturing and research alike, from aerospace to solar cell development.

From a precision standpoint, the sub-10-μm feature sizes achieved by AJ printing exist in a different class compared to other printing technologies. For reference, the lasers used in SLA printers range from 50 to 80 μm in diameter, and this is already considered excellent for 3D printing. AJ printing’s high precision opens up worlds of possibility, especially with the fine features demanded by modern electronics.

Speed is also an advantage of AJ printing. While 80 mm/s is already considered quick for FDM, AJ printing can comfortably reach up to 200 mm/s. This high speed, coupled with support for multiple print modules, makes the technology a viable candidate for manufacturing applications. Indeed, the technology is currently used to print antennas in cell phones.

Finally, AJ printing works with a uniquely diverse range of materials that aren’t found with other printing technologies. While most 3D printers specialize specifically in thermoplastics, photopolymers, ceramics, metals, and so on, AJ printing does it all. This is thanks to the aerosol-based system, which only has the ink requirements detailed below; anything meeting these specifications, be it DNA or carbon nanotubes, has the potential to be printed (given an appropriate liquid solvent). Below, you’ll find Optomec’s official list of supported materials, alongside a compilation of different materials tested by researchers.

Specifications

According to Optomec, these are the main capabilities and limitations of AJ printing:

- Droplet size: 2-5 μm

- Ink viscosity: 1.0-1,000 cP (range varies by printer)

- Ink particle size: <200 nm preferred (300-500 nm max)

- Ink particle content: 5-70 wt%

- Aerosol line width: <10-2500 μm

- Aerosol jet speed: 10-100 m/s

- Layer thickness: 0.1-100 μm

- Maximum print speed: 200 mm/s

- Ink materials: Gold, platinum, silver, ruthenate, multiwall carbon nanotubes, polyimide, SU-8, UV acrylics, organic semiconductors, DNA, proteins, enzymes, and more (full supported list, materials tested by researchers)

- Substrate materials: Polyester, polyimide, glass, C-Si, ceramic, FR4, metals, and more

Where It's Used

AJ printing is less commonly discussed in consumer 3D printing, as it’s more typically found in industry and research. Within these spheres, however, the technology has certainly earned its place.

Currently, AJ printing is being used in the mass production of consumer electronics, especially with printed sensors and antennas. It also has ties to several big-name partners, including Lockheed Martin and GE. In academia, it’s found across many universities, through projects ranging from machine-brain interfaces to Covid-19 antibody testing. Though many of Optomec’s partners are not explicitly named, it’s clear that the technology has deep, far-reaching roots.

As of writing, Optomec has four main offerings for AJ printer systems. These are:

- Aerosol Jet Flex is a simple, scalable platform, designed to address a wide range of applications. Beginning as 3-axis machines, it features expandability up to 5 axes, among other optional add-ons.

- Aerosol Jet 5X is a fully-featured 5-axis printing setup with “advanced vision and process controls” that’s targeted at 3D printed electronics.

- Aerosol Jet HD & HD2 are machines designed for inline production, offering a drop-in IC packaging solution for mobile and wearable devices. These can be configured with conveyor stations and in-situ laser and UV curing.

- Aerosol Jet Print Engine is Optomec’s “most scalable and versatile” system, featuring quick-release ink cassettes and multi-print-head functionality. Two simultaneously operating print modules can be run from a single controller, which can be linked up to other controllers to enable high production volumes.

Further Reading

There you have it – the basics of AJ printing, how it works, and what sets it apart from other 3D printing technologies.

If you’re interested in exploring further, Optomec has more detailed explanations of AJ printing’s core and emerging applications. Their website also has handy information on the most up-to-date system configurations that are available.

To explore AJ-based research, the previously-linked Chemical Reviews paper by Ligon et al. is an excellent resource. In it, you’ll find general information on AJ printing, as well as an overview of specific research that has been conducted with the technology.

Finally, for more on 3D printing electronics, check out our roundup of the main players, as well as our breakdown of the key 3D printing technologies out there.

Lead image source: Semitronics

License: The text of "Aerosol Jet Printing – Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.