There’s been news about 3D printed houses and construction almost daily for the past few years, but what are these houses actually built out of?

Even though the specific combinations or quantities may not be public knowledge, a general list of materials that have been successfully used in projects like WASP’s Gaia, the Fibonacci House, the Canal House in Amsterdam, and other 3D printed housing projects, is accessible. This not only gives a view of how traditional and developing technologies merge, but also offers a glimpse into what will be possible in the future.

In this article, we’ll take a look at the materials we’re seeing used in 3D printing construction, whether for prototypes, for projects that are in development, or for structures that are already in use.

Concrete

Confusion may arise when thinking about concrete, as the term is sometimes used interchangeably with cement. Cement is actually one of the ingredients of concrete, along with water and sand, gravel, or crushed stone.

The majority of 3D printed housing projects you’ve heard of used concrete-like materials, but not necessarily concrete. As mentioned, that means they’re using a mixture of cement, sand (or crushed stone or gravel), fibers, and occasionally other materials.

The most common concrete mixtures use Portland cement (not a brand name, but rather a generic type of cement that’s most commonly used) as the key ingredient, and projects such as the first 3D printed house in India from Tvasta based their concrete mix on it, as reported in IIT Tech Ambit in 2021.

Due to the challenges that concrete (or a more traditional concrete-based mix) represents, other companies have opted to develop and use their own proprietary concrete materials.

Proprietary Concrete

As explained, concrete is a mixture of cement (often Portland cement), sand, and other materials. But what’s proprietary concrete? It’s an important distinction to understand, because many of the companies that are 3D printing homes (or developing the technology) have come up with their own proprietary concrete mixes and are introducing them with closed-use compatibility to their machines.

Because traditional concrete isn’t suitable for 3D printing, as it would clog the printer nozzle and not adhere properly to the previous layers, proprietary concretes are created to avoid these issues.

Instead of Portland cement, these companies have one or more special additives that aren’t necessarily specified, but that make the mixes functional. While the benefits of these proprietary concretes have yet to be proved over the long term in the houses’ durability, they make the concrete much easier to 3D print with the standard extruder model, whether using a gantry or stand-alone machine.

A Few Examples

Apis Cor was able to 3D print the first two-story project in Dubai (the world’s largest at the time of completion) reportedly using “concrete, gypsum, and proprietary materials developed by the company.” They don’t offer any of the materials for sale for use outside of their own printer or get more specific on what the ingredients are.

Icon’s House Zero project in Austin, which drew much media attention during South by Southwest (SXSW), was printed using a “proprietary cementitious-based material, ‘Lavacrete’, insulation, and steel for reinforcing” according to the company. This proprietary material will serve as the basis for the rest of their ambitious projects in Texas.

Winsun was one of the first companies to successfully 3D print buildings in its Chinese factory before shipping them abroad to locations like Dubai. These buildings were all constructed using their proprietary Special Reinforced Concrete, which they continue to use on upcoming projects.

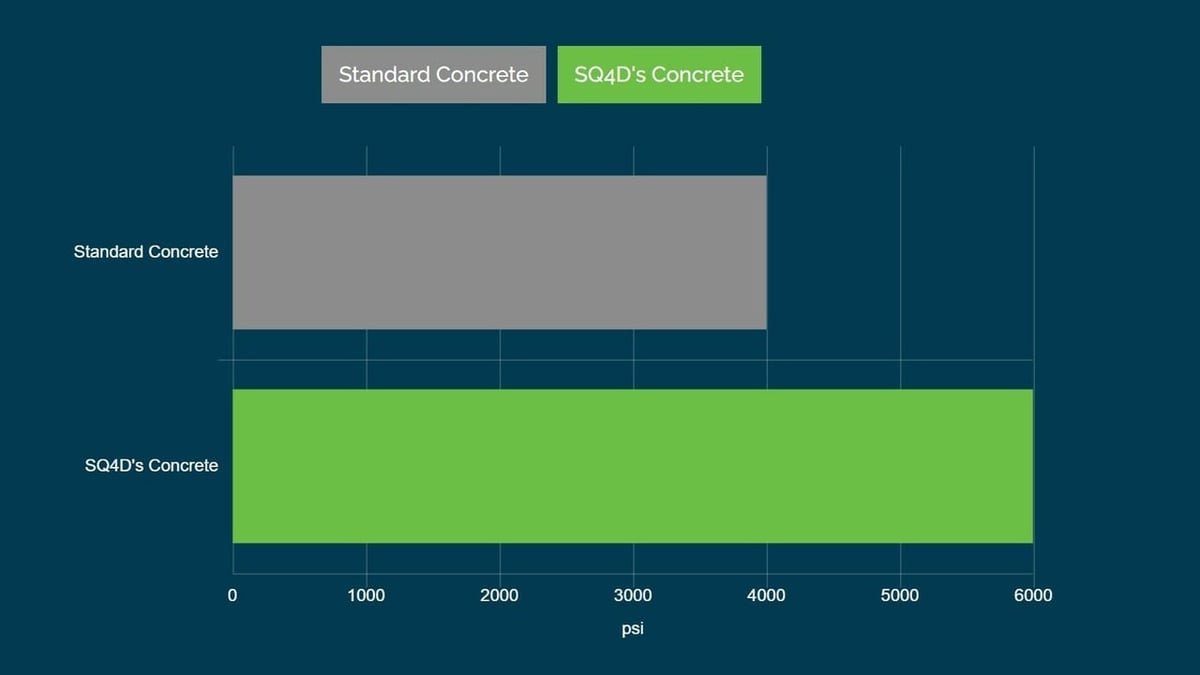

When SQ4D unveiled the first commercially listed 3D printed home for sale, they directly compared “SQ4D concrete” against “standard concrete” to show the difference in benefits, without revealing what makes their concrete different or the ingredients in the mixture.

DFab

Another proprietary concrete blend, DFab deserves separate recognition. Unlike the closed-use concrete above, COBOD and Cemex partnered to create this as a widely compatible concrete mix specifically formulated for 3D printing construction. It works with COBOD’s own BOD2 printer and is currently being used by them to print homes in Oman, but they’re aiming for universal compatibility across brands of cement printers.

99% of the ingredients in this special mix can be sourced locally by builders, but COBOD’s Magic Mix is needed as the final additive ingredient to make the DFab mix work properly.

Mortar

Mortar is best known as the material between layers of bricks, but with bricks (and the highly trained tradespeople who apply them) not finding a place in 3D printed construction, mortar is getting its chance in the home building spotlight.

Mortar is traditionally made from a similar mix to concrete but adding lime as a key ingredient, and it isn’t as durable as concrete, which is why it’s used instead as a binding agent between layers. However, with 3D printers, proprietary mortars are more malleable than traditional concrete, which is an advantage for the extrusion process that leads to fewer nozzle clogs or errors between layers.

One of the most publicized 3D printed houses, the Fibonacci House, used mortar to construct its walls, and they aren’t alone. Other projects from Peri and 3D Printed Farms primarily using mortar in recently completed housing projects. For the most part, the mortar is coming from companies like Laticrete that manufacture it specially formulated for 3D printers and their extruders.

Plastic

Could we have a list of 3D printing materials without mentioning plastic? The makers taking up the housing challenge don’t think so, since one of the very first houses ever 3D printed was made out of plastic. We’re referring to the 3D Printed Urban Cabin in Amsterdam, printed all the way back in 2015.

While some may hesitate at the use of plastic compared to other sturdier or more sustainable materials, this project was proud to use bioplastics and recycled shredded water bottles to be environmentally friendly. They also announced that the entire home will be recycled when it’s no longer in use. We can’t remember the last time we heard the builder of a traditional home brag about 100% of it being recyclable.

Local Natural Material

There are a few materials that can represent an environmentally friendly alternative, not just in how they’re sourced, but also in terms of transportation.

Mud

Sometimes, new technologies need to find their inspiration in the distant past to find success. Humans have been using mud and other natural earth materials to build their dwellings for thousands of years. When it comes to sustainable construction, building mud houses is among the most environmentally friendly concepts, since mud doesn’t require transportation to the construction site.

Italian 3D printing company WASP was able to successfully manufacture homes using only mud in northern Italy in 2020. The project partnered with Italian architect Mario Cucinella. and naturally, it generated quite a bit of buzz. While WASP’s printer may be high-tech, it can be transported anywhere in the world and work successfully, using the local ground as its printing materials.

We might not see these houses in Manhattan or London, but WASP’s goal of attacking climate change and reducing emissions will have plenty of opportunities in rural and developing communities.

Rice Waste

Another material deemed a success thanks to the work of Italian 3D printing company WASP, rice waste made up 65% of the materials used to print the Gaia house. Another 25% was made up of local soil (like the mud mentioned above) and then the rice waste was composed of the straw chopped from rice and rice husks that would have otherwise been disposed of.

They duplicated this process more recently for a partnership with Dior to print two pop-up stores in Dubai, using a similar mixture of raw fibers (rice waste), clay, soil, and sand.

WASP was able to turn waste into a livable building and in the process create a home with no environmental impact. Many 3D printing companies preach sustainability and the benefits of the technology, but WASP is among those leading the charge with actual results.

Sand

Cement is a popular construction material, but some of its ingredients are gaining more popularity. The first such material is sand.

D-Shape was one of the first prominent examples to use sand in construction for a house in 2010, and did so by extruding a layer of sand at high temperatures and speeds, then spraying it with a material that hardened and solidified the sand before the next layer was put down.

Because the 3D printing process is similar to that which takes place with a hobbyist machine at home, but with an extra step to bind the sand, there’s no fear about the construction being blown or washed away.

While there’s still a way to go until construction printers are equipped to handle sand, the material is already used for 3D printing industrial molds, and it’s likely that it will have a wider reach in the future.

Metal

Although there isn’t a completed residential project using metal, it’s a matter of when not if. Metal 3D printing has come an unbelievably far way in the past few years and companies like MX3D want to bring the technology to construction and architecture. They’re already successful in producing metal bridges and key components of commercial buildings with 3D printed metal.

Steel appears to be their metal of choice, but 3D printing now offers a massive variety of metals and they’re willing to experiment with any that could get the job done. There’s little reason to doubt this will soon be a reality.

Other Materials

We’ve covered a variety of materials on this list, but it’s only the beginning of what the future has in store for construction.

Black Buffalo has already unveiled a line of experimental dry mixes that can be used to print a variety of new materials with the goal of them being sturdy and reliable enough for home construction. We’re yet to see their pros and cons when put to use, but Black Buffalo claims they have “undergone extensive in-house, partner level, and external testing to exceed traditional requirements for building.”

These materials include clay, wood, hemp, oyster shells (which are already a common construction material as the key ingredient to tabby concrete), and colored clays. We may be on the verge of a revolution in construction, with the materials listed in the article being only the beginning.

Stone

While crushed stone can be an ingredient in some of the concretes listed above, on its own it’s a far more expensive and durable material that’s known for its smooth surface. Stone or stone-like substances have been used in some ambitious housing projects from companies like Mighty Buildings and Concr3de.

It’s worth mentioning that like concrete, stone is seeing different proprietary versions developed to make 3D printing with it much easier. Two examples are Winsun’s “Crazy Magic Stone” (which they describe as “an artificial stone“) and the material Mighty Buildings uses for its pre-constructed walls, “Light Stone” (which “cures into a stone-like composite“).

With developing technologies and the need to create more sustainable and accessible housing, it’s important to stay informed about what companies are working on and to imagine what the future has in store.

Lunar Soil

The recent advances in space exploration has led to several companies experimenting with and testing how to make habitats on the Moon and potentially other planets using local soil.

With the aim to expand construction capabilities in different planets, a forthcoming project has been granted to Icon. A semblance of lunar soil will be tested with different technologies with the objective of developing “prototype elements for a full-scale additive construction system.” Should the project be successful, Icon could be awarded the possibility of testing on the lunar surface – increasing even more the development of 3D printing and construction technologies.

In the same area there’s also LINA, a 3D printed structure revealed by AI SpaceFactory and the NASA Kennedy Space Center. Planned as a lunar outpost to support astronauts, the idea is for it to be 3D printed with both an Earth-sourced polymer and lunar regolith, which would protect the construction from lunar-specific issues like radiation, thermal oscillations, and seismic activity. However, unlike traditional 3D printing, due to the design’s vaulted roof, LINA will be 3D printed at a 60° angle as opposed to parallel to the ground (or the build plate).

While technologies keep adapting to encourage the use of a variety of materials on Earth (and beyond), it’s clear that boundaries are decreasing to allow for more options.

License: The text of "3D Printed House Materials: What Are They Made of?" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.