This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Inspecting the Path

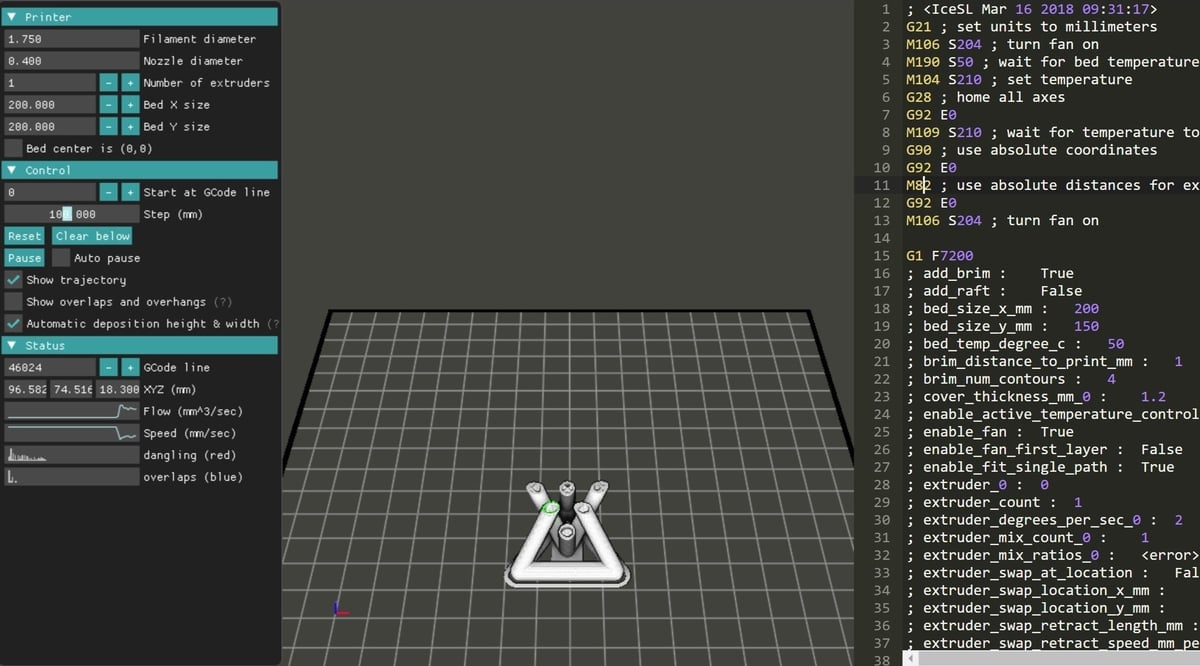

The Best G-code Viewers & Simulators of 2023

A G-code viewer allows you to simulate your 3D prints before starting them. Read on to learn about the best G-code simulators!

Advertisement

Advertisement