When it comes to 3D printing safety, most people think about printers catching on fire. However, 3D printers generate ultrafine particles and volatile organic compounds (VOCs) as well. So what’s the big deal with 3D printing and particulates or VOCs anyway?

In this article, we’ll go through the main issues with 3D printing emissions from a safety standpoint and, more importantly, the misconceptions. Finally, we’ll give you some solutions so you can ensure that you and whoever is near your 3D printer are safe when printing.

Fact vs. Fiction

When it comes to 3D printing safety, there are several misconceptions that arise with regard to emissions. These misconceptions can be broken down into four general claims.

Fiction: Printing with PLA is completely safe without a ventilation system.

PLA is not an innocent bystander here. Studies have also shown PLA to be an emitter of particulates and VOCs.

Although, one meta-analysis of 3D printing emission studies found that PLA emits significantly less compared to ABS, potentially due to its lower printing temperature.

However, due to the lack of standardized testing of emissions in the context of 3D printing, it’s difficult to make concrete conclusions. Large variations in emission have also been observed across different filament manufacturers of the same material.

Fiction: If it doesn’t smell bad, it isn’t harmful.

This simply isn’t true. This is because many of the trace VOCs and ultrafine particles that come from 3D printing do not have a strong smell. That being said, if you can smell fumes from your 3D printer, you are likely breathing in VOCs and ultrafine particulates that may cause health problems later on.

Fiction: The printer has to be ventilated outdoors, otherwise it cannot be filtered.

In fact, most 3D printers are not ventilated to the outside due to the fact that chamber heat will be lost, increasing the chances of warpage and other undesirable effects. But there are alternatives, as we’ll go over below.

Fiction: HEPA filters will not filter out nanoparticles generated by 3D printers.

This is complicated. HEPA filters can filter out particles generated by 3D printers, including some ultra-fine particles (less than 100 nm in diameter). However, consumer air filters (activated carbon) struggle much more with effectively filtering out VOCs associated with 3D printing.

Emissions

3D printing emissions generally fall into two main categories: particulate emissions and VOC emissions. We’ll discuss each one in detail below, then explore how hazardous they are.

Particulate

First of all, let’s define particulate. Due to the way that FDM and resin 3D printers manipulate plastics, there will always be ultrafine particles released into the air that could be inhaled during the printing process. However, due to their size, it’s impossible to see these “ultrafine particles” because they are 100 nanometers or less in size. (For comparison, a strand of hair is around 50,000 nanometers thick.)

Therefore, it’s the size of these particles that make them dangerous. Since they can be easily inhaled, exposure over time can cause damage to the lungs or other tissues.

VOCs

In contrast to particulate, VOCs are the gases that you may be able to smell when a 3D printer is printing with certain filaments such as ABS.

If you’ve ever smelled burning plastic, drying paint, or even smoke from a campfire, you’ve likely inhaled VOCs of some sort. We aren’t suggesting that campfire smoke is extremely dangerous, however, inhaling fumes day after day can cause a variety of illnesses depending on the chemicals inhaled.

Does the Type of 3D Printer Matter?

Unfortunately, the two most common types of 3D printers, FDM and resin, can generate particulates and VOCs under normal printing conditions.

There are not nearly as many studies on emissions from desktop resin printing as there are for FDM, but what we do know suggests there are a few extra things to be wary of. Uncured resin not only contains small monomers that can volatilize but also other additives like photo-initiators and stabilizers. Such chemistries are particularly hazardous to health and have been found in particulate emissions from resin printers.

This means that if you have a resin printer at home, it’s especially important for you to implement ventilation strategies to limit your exposure.

Hazardous Effects

The big question is, why is inhaling VOCs and particulates potentially hazardous? Well, when it comes to VOCs, the answer is pretty straightforward. If you’ve ever looked at the side of an aerosol can where it says “Do not inhale”, you’ve probably seen numerous warnings about health hazards related to inhalation; these are the same kinds of compounds produced by 3D printing.

Specifically, inhaling certain VOCs can cause a variety of short-term health issues, such as “eye, nose and throat irritation, shortness of breath, headaches, fatigue, nausea, dizziness, and skin problems”, according to HealthLinkBC. Longer-term health problems can include permanent organ damage or even cancer for some VOCs.

In contrast, ultrafine particles may not be toxic like VOCs, i.e. the particles themselves don’t necessarily have to be harmful chemicals. The harm from ultrafine particles comes more from their small size and their ability to lodge themselves deep in your lungs and other similar issues. Additionally, they have the ability to carry along hazardous materials with them as they travel. There’s also evidence to suggest that ultrafine particles (from traffic pollution) can even have long-term cardiovascular effects, as well as a variety of health risks.

What’s the Relative Risk?

It should be noted that many processes in daily life generate ultrafine particles and VOCs. Activities such as cooking on a gas stove can generate similar amounts of ultrafine particles to 3D printing, indicating that while the risk is there, it isn’t orders of magnitude worse than what you’re already exposed to. However, extra care should be taken since 3D printers often run much longer than a traditional gas stove and therefore can generate more particulates and VOCs overall.

Solutions

Hopefully, we haven’t scared you too much. And, not to fear, you can certainly do something about it! There are three primary methods for reducing VOCs and particulate emissions during 3D printing.

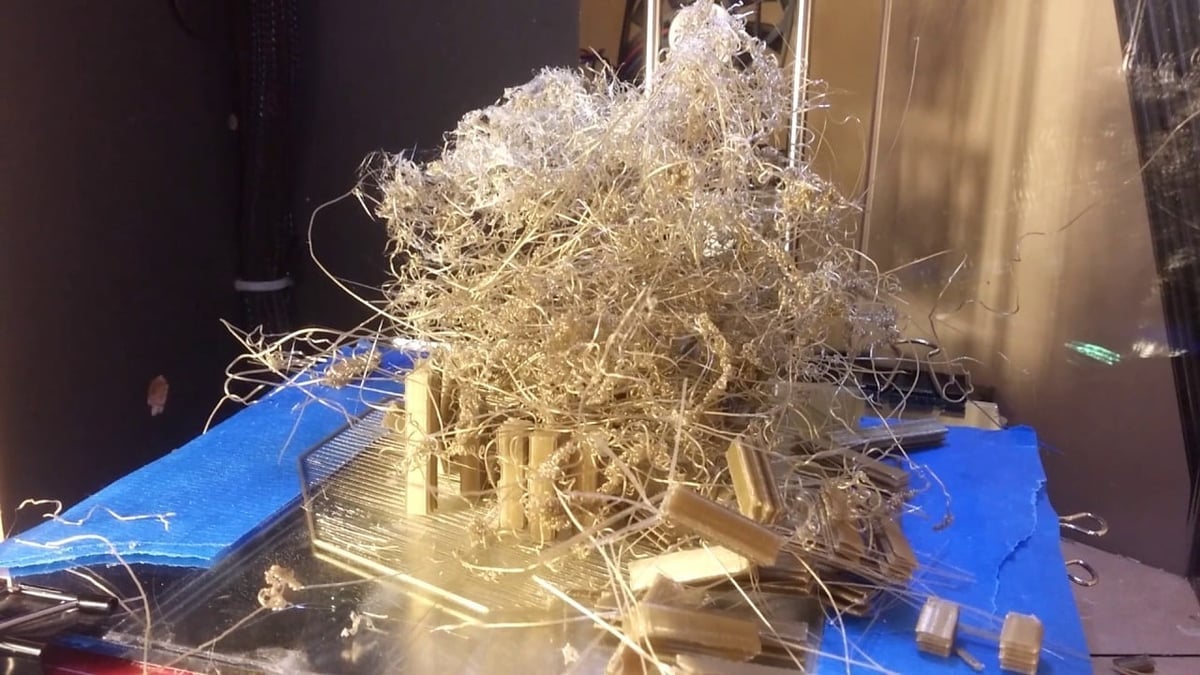

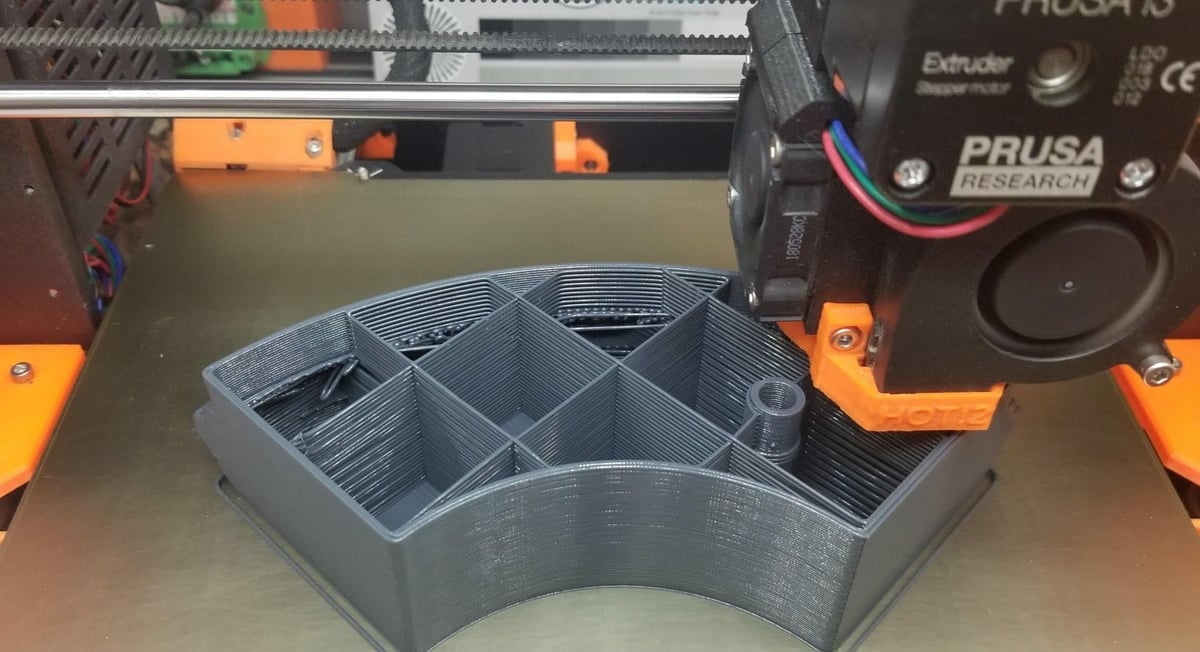

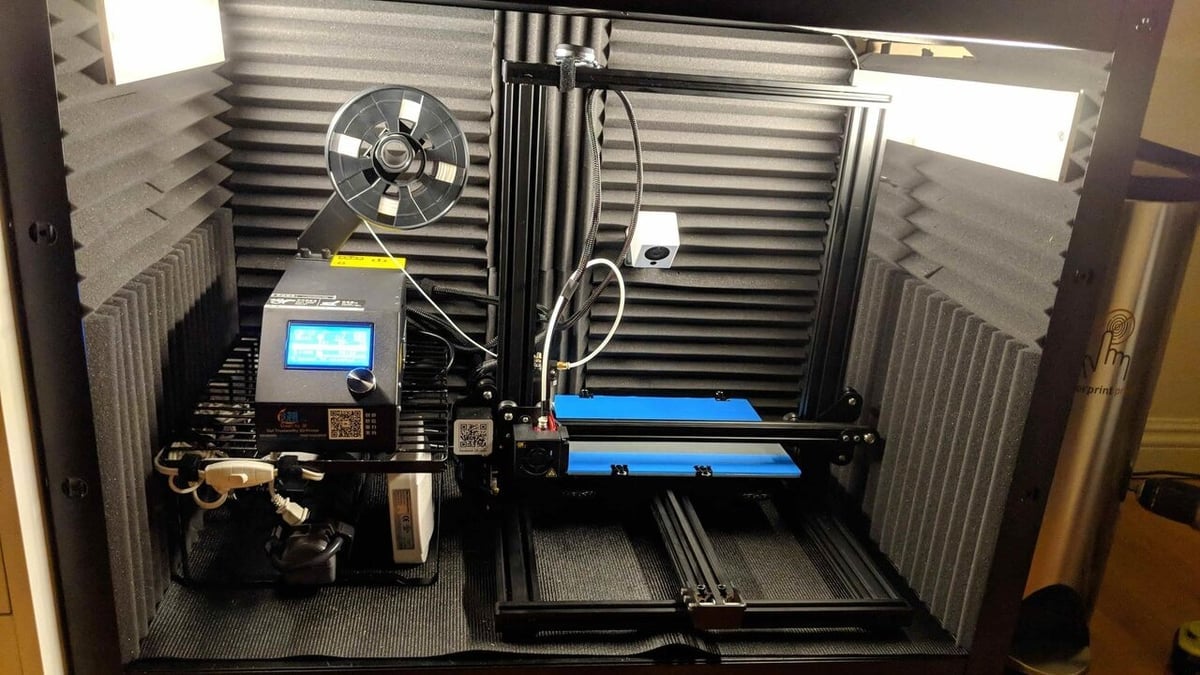

Use an Enclosure

The most significant action you can take to reduce particulates and VOCs is to prevent them from leaving the work area around the printer in the first place. Many people do this by building 3D printing enclosures in order to slow down the spread of toxins, essentially trapping them within the printing area.

Of course, due to the size of particulates and the nature of the VOCs, unless your enclosure is perfectly sealed, this won’t keep you safe entirely because VOCs and particulates leak out over time. However, in many cases, enclosures will keep levels fairly low outside of the enclosure.

Use a Filter for Particulates & VOCs

The second option is to use an air filter with an enclosure so the particulates and VOCs are absorbed by the filter. There are a variety of options at your disposal, from relatively DIY to expensive.

Note that this applies to both FDM and resin printers, despite the relative differences between the two methods: resin tends to produce more VOCs, whereas FDM printers tend to produce more ultrafine particles.

To filter out both VOCs and particulates, you’ll need two types of filters.

- HEPA filter or high-rated MERV filter (MERV 17 or higher): These types of filters work to remove ultrafine particles.

- Activated carbon filter: This type of filter works to remove VOCs.

Of course, activated carbon and HEPA (or high MERV) filters come in many shapes and sizes. Despite that, they are a relatively simple solution for removing particulates from the air. HEPA air purifiers will even remove ultrafine particles from the air.

Interestingly enough, despite there being a misconception that these filters only work down to a particle size of 0.3 µm, smaller particles can be caught by the filter in significant amounts.

So, if you want to keep the heat in your 3D printing enclosure but still be safe and remove particles and VOCs, you can simply put an air purifier in your enclosure. The air purifier should use filters that are both HEPA and activated carbon in order to ensure that both types of emissions are significantly reduced.

Which Filter to Buy?

Here are a few options that would work for filtering out these emissions.

- Wall-mountable unit: Alveo3D makes a 3D printing filtration unit that will filter out both VOCs and ultrafine particles. Each filter is made of HEPA H13 and activated carbon and includes a high-pressure 120-mm fan to move air through the filter.

- Air purifier: Another option is to purchase an air purifier (or similar) and use it inside your 3D printing enclosure to filter out the VOCs and particulates.

- 3D printed purifier: Our final option looks rather silly, but you can make it with a disposable P100 filter and some 3D printed parts, though you may need an additional fan to make it work. Since these are small filters, they can’t be used for large spaces.

It should be noted that where you place the filter can affect its efficacy. If you have a compact filter, placing it inside a printer enclosure or as close as you can to the printer will be most efficient.

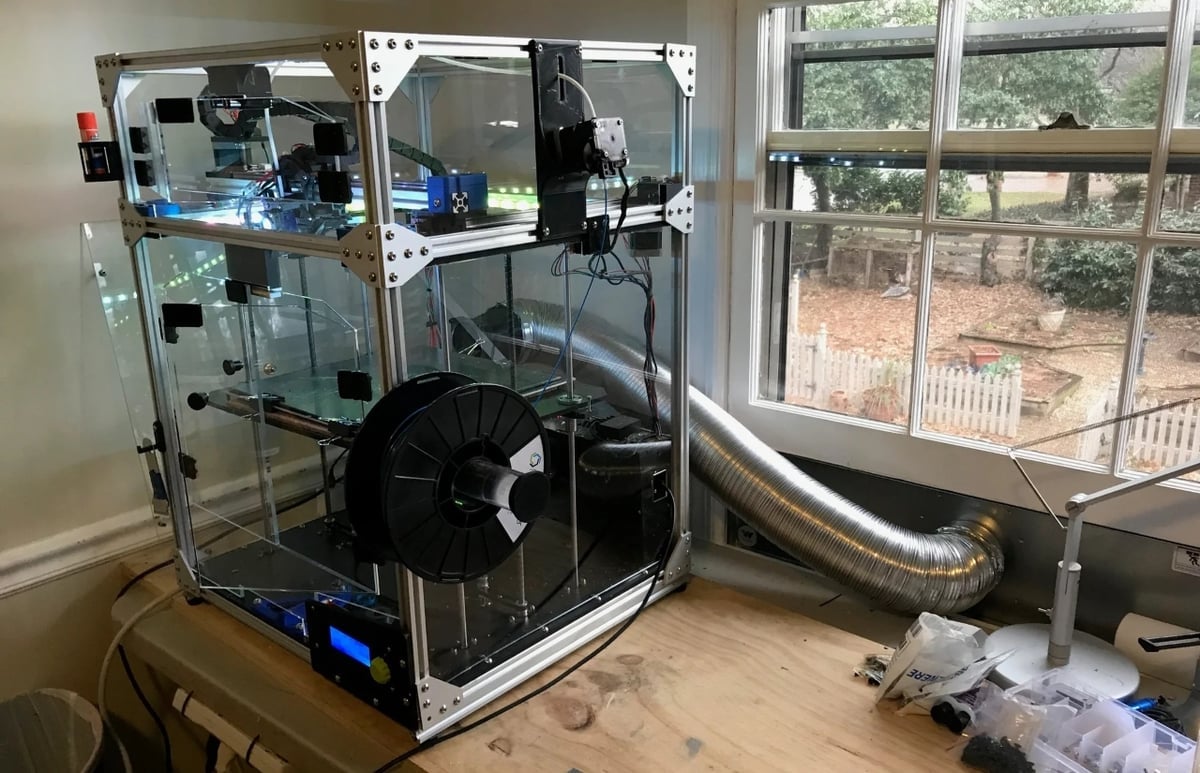

Vent the Fumes to the Outdoors

The third way to reduce particulates and VOCs is to simply vent your print area to the outdoors.

The reason this option is listed last is that it has a significant drawback: By venting the printing area to the outdoors, you’re likely to be cooling off the print area. This will make printing difficult for filaments like ABS, which tend to warp without a heated build plate and chamber.

What Can I Do in the Meantime?

If you’re looking for a quick fix and haven’t decided what type of filtration system to use, you can minimize the impact of emissions with a couple of easy changes.

First off, if your house normally filters particulates using a furnace filter, temporarily upgrading the MERV rating of this filter (to as high as your furnace can handle) will lower particulate in the air while you wait on your permanent fix.

Alternatively, you can print near an open window if the outside temperature isn’t too hot or cold, lowering the total particulates and VOCs you’re exposed to. Ideally, this should be done with a fan near the printer to blow the particulates and VOCs outside and minimize the circulation in the house.

Now that we’ve cleared the air around 3D printing, you can get back to printing that baby Yoda you always wanted.

License: The text of "3D Printer Enclosure Ventilation with Air Filter: The Basics" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.