Walking the aisles of Formnext, the world’s largest expo for 3D printers, it was clear that printer makers all got the same memo: Display impressive parts your printer can make, keep the printers in the back of the booth.

From massive copper rocket engines to colorful polymer-printed ice cream cones, an entire EV concept car, and countless medical models, jigs, tools, and molds. The product, not the process, was the star of this year’s Formnext.

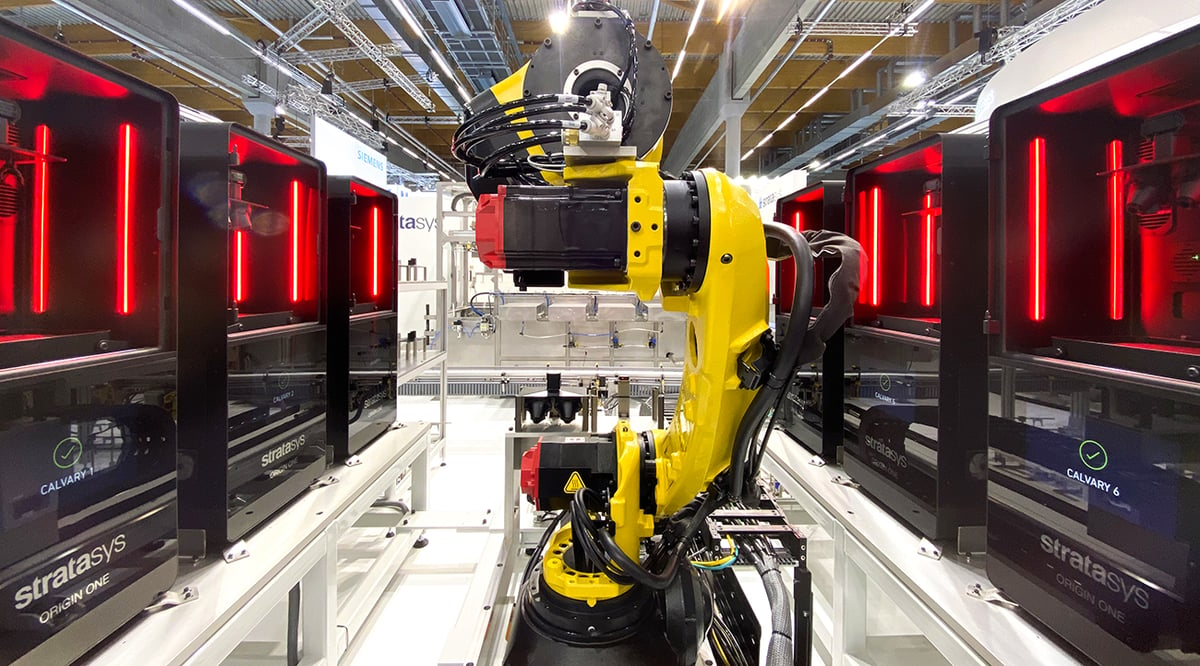

Stratasys, the giant 3D printer and material maker, for example, displayed its future vision of automated additive manufacturing with a production cell prototype, complete with robotic arms to move printed parts from one stage to the next.

Italian 3D printer maker WASP featured a production automation solution it developed for a customer who wanted thousands of clay vases 3D printed. The conveyor system moves one finished print down the belt, lays down a new build plate, and the next print begins. Another printer maker Traditive was on hand to show off its Amcell 8300 that prints parts, ejects them to a storage module, and loads a platform unattended for continuous production. Lastly, 3D printer manufacturer 3DCeram featured its Smart Ceramic Factory for printing ceramic parts in a semi-automated line.

From automation to acquisitions, materials to software, and especially upgraded printers, the list of those who didn’t have news at Formnext might be shorter. Below is a look at some of the most promising printer debuts, but keep in mind that very few of these are currently available. They’ll be rolled out with more detail in 2023, and we’ll add them to our new printer guide here:

New FDM 3D Printers Coming Soon

FDM Segment is Getting Hot!

All of the new FDMs at Formnext were high-temperate machines. We’re talking heated beds, headed chambers, and superhot nozzles for materials, such as PEEK and PC. Are industrial FDM makers completely ceding the PLA territory to non-industrial giants like Ultimaker and Raise3D, or are we seeing companies filling the demand for end-use parts in high-performance materials?

Regardless of the answer, engineers looking to 3D print with technical polymers to replace metal in demanding environments now have more printers to choose from.

miniFactory Ultra 2

miniFactory unveiled the latest edition of its high-temperature FDM, the Ultra 2, which replaces the previous Ultra. The new version has some impressive performance enhancements engineers will appreciate, including being twice as fast (120 mm/s print speed) and it has a new “smart” heated chamber that can be heated up to 250 ºC.

The more interesting upgrade, however, is the software. Called Aarni, this software is intended to give users a sense that the 3D printing processes going on in the build chamber are being monitored and recorded so that errors can be detected on the spot and successful prints are repeatable. Aarni records the material history of the part and any operator information, plus statistical data for each layer printed. It’s all detailed in a “manufacturing report” and a virtual part for inspection. Engineers can now see the statistics from the actual print job, layer by layer, and any deviations from the plan, especially any internal anomalies not visible from the outside that could affect part performance.

Intamsys Fumnat Pro 310

The fourth and newest FDM from Intamsys, the Funmat Pro 310, is a high-temperature FDM desktop machine. With a build volume of 305 x 260 x 260 mm, it’s slightly smaller than the company’s Funmat Pro 410 and doesn’t get quite as hot, but for engineers looking for a desktop printer for materials like carbon-fiber-filled Nylon, it hits the spot. Plus, it’s the company’s first independent dual extruder (IDEX) machine featuring modular, quick-change printheads.

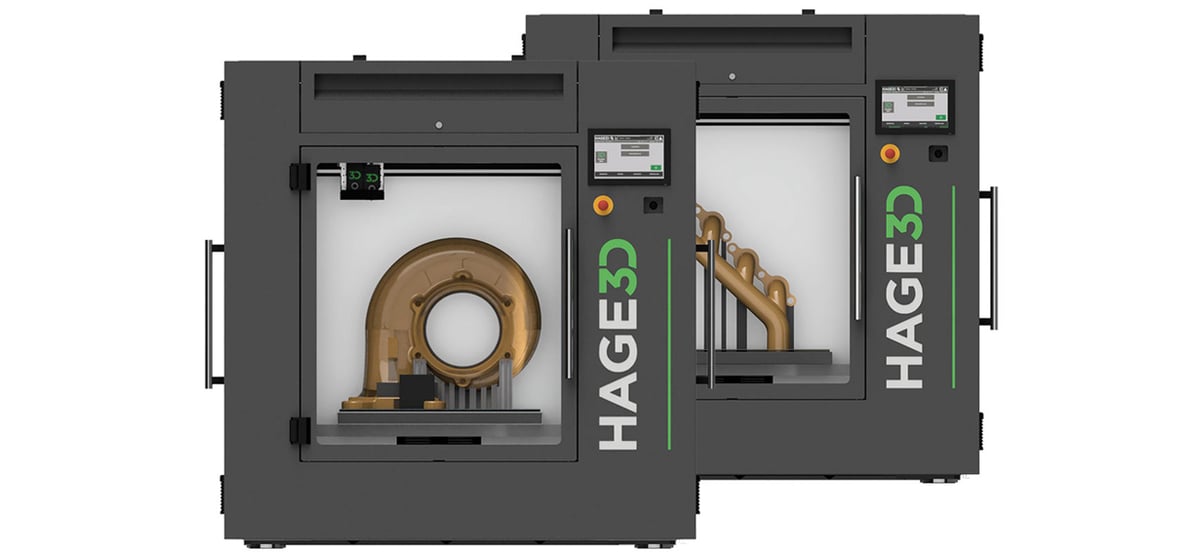

Hage3D Mex & Precise Line

Not necessarily new, but new at Formnext was the Austrian 3D printer maker Hage3D with an impressive debut. They’ve actually been making printers since 2014, mostly for the EU and Asian market. In addition to having all the usual features of high-temperature industrial FDMs — 450 ºC nozzle, heated chamber, open materials, onboard camera, HEPA filter, fast (up to 350 mm/s), and detailed (0.05 mm layer thickness) — the Hage3D offers up to four extruders on one machine to print four materials at once and a pellet material extruder. Available now.

NematX Nex 01

Swiss Start-up NematX introduced its material extrusion platform Nex 01. It looks like an FDM, but it doesn’t print with the thermoplastics you may be familiar with. Instead, it prints with liquid crystalline polymers, which are a special type of thermoplastic, NematX says produces parts with mechanical and thermal properties better than PEEK. The company has its eye on appealing to industries that need exceptionally durable parts for harsh environments. Price: $150,000 – $180,000.

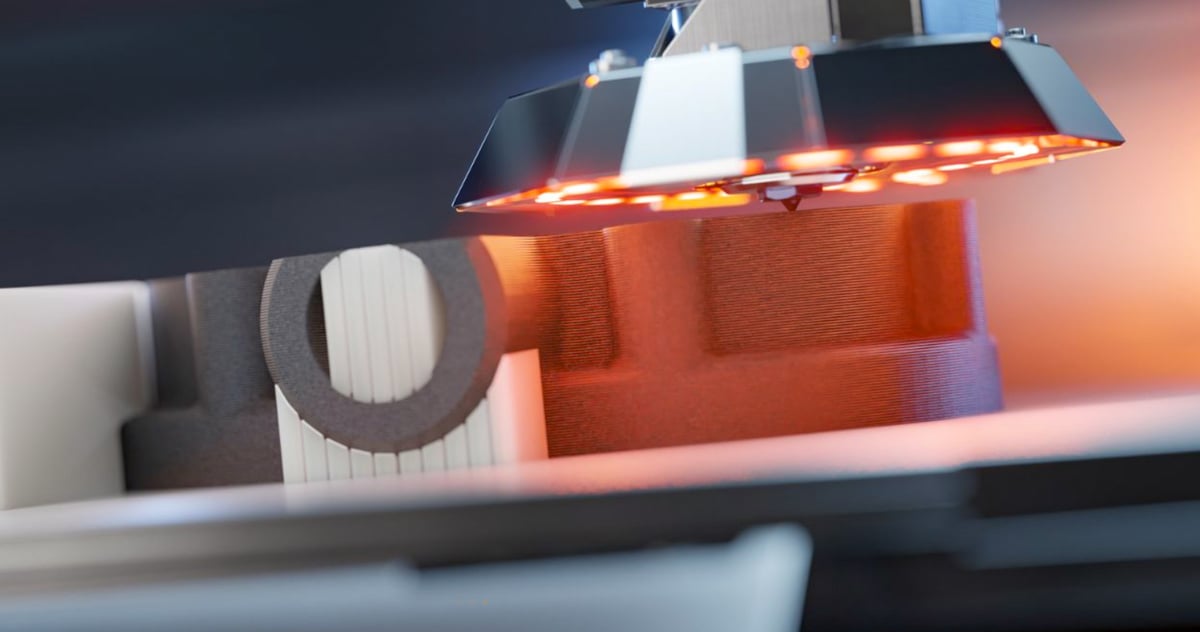

Apium P400

German start-up Apium has offered high-temperature FDMs for several years now and its latest, the P400, is its largest at a build volume of 400 x 300 x 300 mm. The P400 is a larger version of the company’s P220 and includes an integrated filament drying unit. Apium’s most novel feature is how it heats parts during the build process. Instead of heating the entire chamber, which the company says is unpredictable, plus take time to heat up and cool down, the heaters are directly on the extruding head, offering zone heating. This comes in handy considering that the P400 is a dual extruder and therefore you can print two parts with two different materials that each require a different temperature. Not sure how often this feature would come in handy, but it could be ideal for some. The P400 is also an open material platform and you can use your favorite slicing software.

Modix Generation 4

It’s the same Modix, only better! In a sweeping product-line upgrade, Modix, the maker of extremely large FDM 3D printers, has improved all five of its machines at once. The Modix line (Big-60, Big-120X, Big-120Z, Big-Meter, and Big-180X) will all have “Generation 4” in front of the product name to reflect the changes. The most significant of which is a move from dual extruders to independent dual extruders (IDEX). The machine lines now boast a high-quality print speed of 100 mm/s and higher speeds in draft printing mode. The new speeds are attributable to a more powerful motor (a Nema-23 vs. the previous Nema-17).

Liqtra FX-7 Pro

German start-up Liqtra has a narrow focus on the productivity of the FDM printing process without increasing speeds or nozzle diameters. The Liqtra FX-7 Pro’s multi-nozzle technology uses up to seven nozzles in a print head simultaneously, each of which can be individually controlled during the printing process. The process can be used for part production with Liqtra planning software, a slicer specially developed for multi-nozzle applications. Liqtra multi-nozzle technology uses parallel extrusion from multiple nozzles throughout the entire printing process. Liqtra says its multi-nozzle technology is particularly suitable when medium to large components need to be produced quickly. Available: 2023

Raise3D Hyper FFF

Not a new printer from Raise3D, but a new upgrade to the Pro3 that makes it much faster. The upgrade kit, called Hyper FFF, includes some new hardware, new software, and new filament. Raise3D says professional FDMs average 50 to 80 mm per second print speed, while the new Hyper FFF can push the print speed on the Pro3 Series to 350 mm/s. The new speed is attributable to new dual extruders with vibration cancellation technology along with special high-speed filaments. The company promises that speed does not come at the cost of quality and says the Pro3 keeps the same quality of layer adhesion and surface finish as before.

New Resin 3D Printers Coming Soon

Resin Branches Out in Tech & Materials

Although it was great to see the latest resin printers from 3D Systems, Carbon, Formlabs, Zortrax, and Nexa3D, which all introduced new machines in 2022, there were relatively few resin debuts at Formnext this year. The ones we found, however, were not your father’s resin 3D printer. Innovations in technology and advancements in size and speed show there’s so much more to achieve in resin.

However, most of the resin buzz was about materials. New resins launched from Evonik, Carbon, Inkbit, Nexa3D, and Arkema target industrial and medical applications.

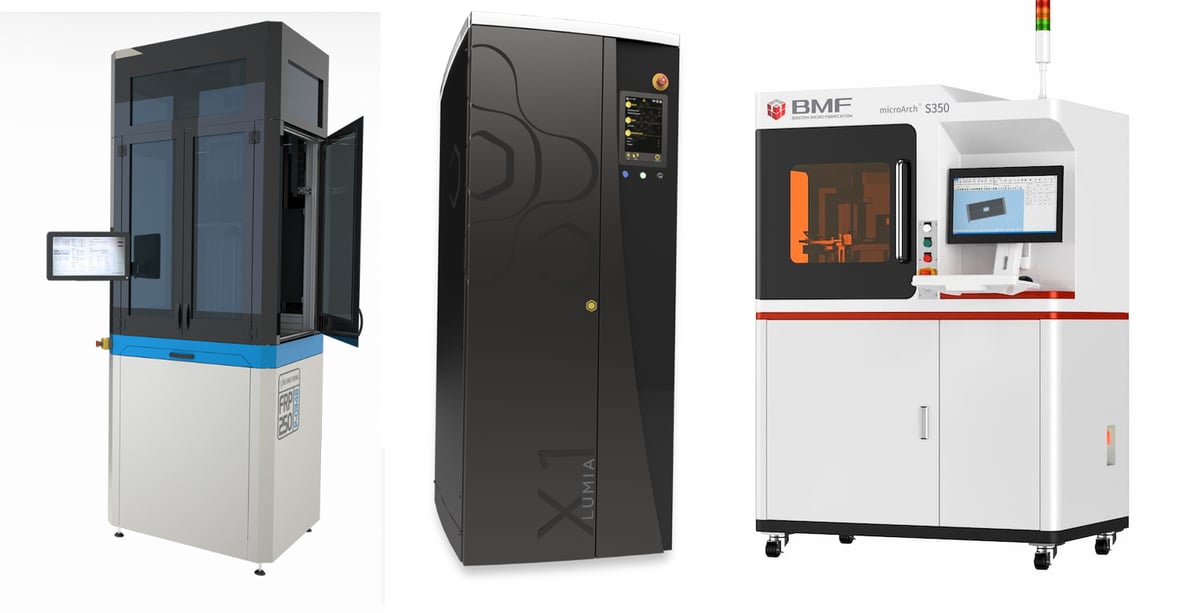

BMF microArch S350

Boston Micro Fabrication (BMF) released its latest resin micro 3D printing machine, the microArch S350, the week before Formnext. The microArch S350 is BMF’s highest throughput printer designed for end-part production, the company says, because it can not only print microscale parts with high-resolution (down to 10 μm) features, but also an array of small parts requiring high accuracy or precision in volume. The machine is aimed at researchers and manufacturers for prototyping and production in the 1,000-30,000 part volume range.

The microArch S350 is based on BMF’s projection micro stereolithography (PµSL) technology, which is a type of masked stereolithography (MSLA) on the micro-scale using a flash of UV light.

Photocentric LC Titan

The resin LCD 3D printer Liquid Crystal Titan by resin 3D printer maker Photocentric was a “soft launch” at the Formnext expo. Even though the company is still calling it a “prototype” and its 2023 launch is uncertain, people are excited partly because Photocentric invented LCD 3D printing, which is today the backbone technology for dozens of printer brands. The Titan doesn’t promise any groundbreaking technology advancements, but rather its large size is what’s interesting (700 x 395 x 1,200 mm) and its 8K 32-inch LCD screen. Available 2023.

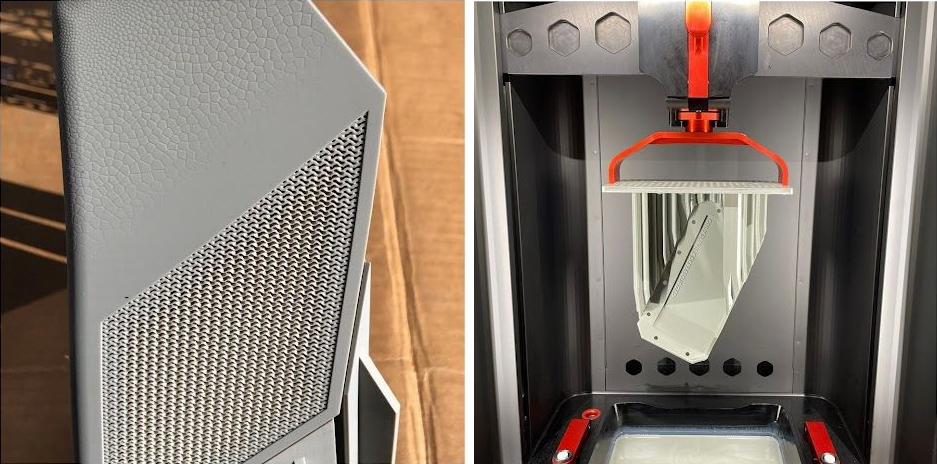

Axtra3D Lumia

The Lumia was actually the buzz at Formnext 2021 for its new technology that combines resin methods so the core of a part is printed quickly with DLP while the outer shell is printed with finer detail using SLA. The company calls it Hybrid PhotoSynthesis technology (HPS). Founded by Gianni Zitelli, who was a co-founder of Nexa3D, the company seems to have quickly brought its machine from mere beta testing last year to an actual offering in 2022. The Lumia X1 features HPS technology, and the also new Revox X1 features just DLP.

Fiberneering XD8

This young Dutch start-up says its materials and machines are just about ready to show off, but you can’t buy one. Instead, the company is offering its technology only as a service for now. Fiberneering says it began work on its large-format resin DPP 3D printer because there wasn’t another on the market at 1,000 x 1,000 x 800 mm. As a service, the company plans to focus on large resin parts, such as molds, mannequins, signage, and art pieces. According to Fiberneering, the build volume of the XD2 machine is more than 3 times larger than the largest currently commercially available DLP machine. In combination with the proprietary resin systems offered by Fiberneering, it is possible to complete a full meter-long print in 24 hours, the company says.

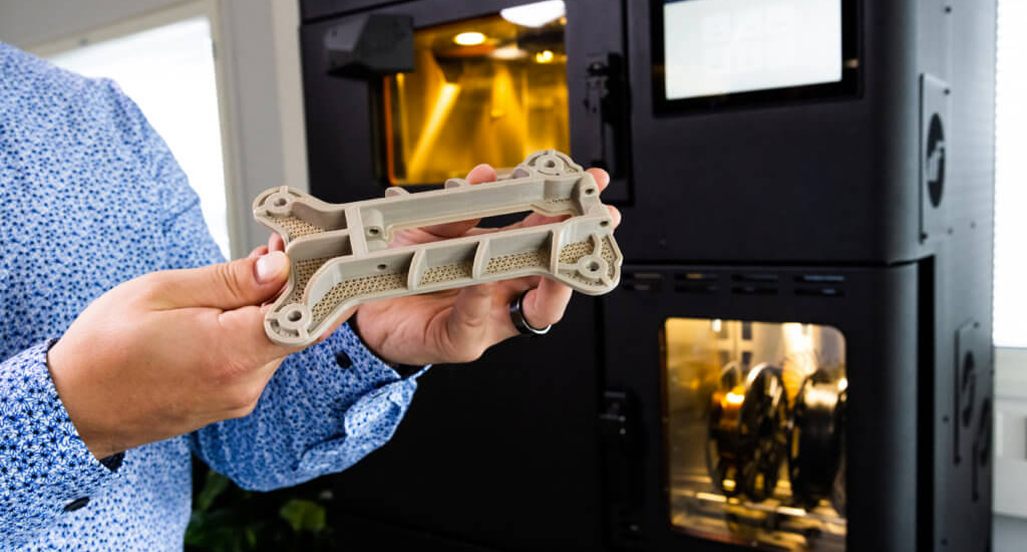

Arburg Freeformer 750-3X

Arburg’s new Freeformer 750-3X, which debuted at the expo, looks the same as its older 300-3X on the outside. Inside, its print volume is 2.5 times larger at 330 x 230 x 230 mm. Other platform upgrades include “technical innovations” that increase the print speed considerably, the company says. The larger build chamber targets manufacturers interested in series production of large components or several articles per build job. Arburg’s method melts granulate thermoplastics through a heated reciprocating screw and deposits droplets layer-by-layer to build three-dimensional objects.

New Metal Printers Coming Soon

Massive metal 3D printing systems are the giants of the show every year and attendees marvel at the 3D printed heat exchangers, manifolds, rocket thrusters, and other tools and spare parts on display. In addition to promising new metal machine technologies, there were a flock of upgrades to already popular models:

- Trumpf’s TruPrint 1000 became TruPrint 1000 Next Gen

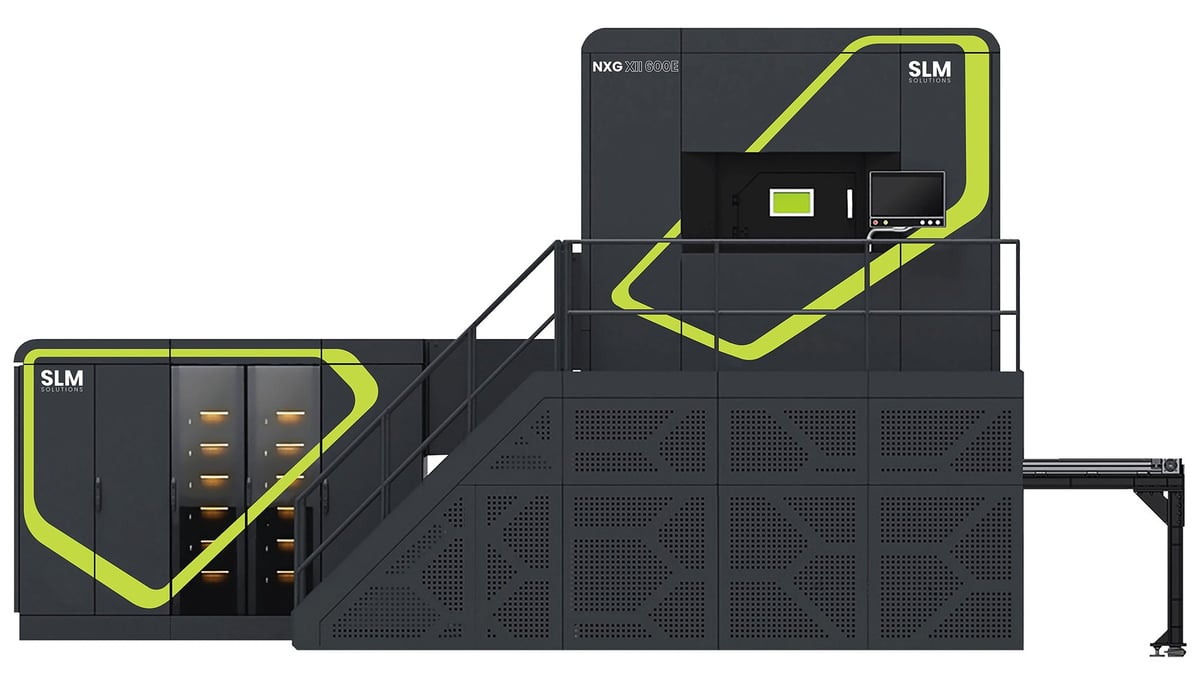

- SLM Solutions NXG XII 600 became NXG XII 600E for “extended”

- AddUp’s FormUp 350 became the FormUp 350 Evolution

Trumpf TruPrint 1000 Next Gen

No, the TruPrint 1000 metal laser powder bed fusion machine from Trumpf isn’t completely new, but it’s been upgraded and downsized. With the new design, the TruPrint 1000 Next Gen can fit through a standard door, which was apparently enough of a problem to warrant a fix. More important, though, is the speed. The new system is twice as fast as the previous version and is aimed at series production. In related Trumpf news, the large TruPrint 5000 is now equipped with a green laser enabling larger parts in copper.

SLM Solutions NXG XII 600E

SLM Solutions debuted its new NXG XII 600E metal laser powder bed fusion machine the week before Formnext. It’s based on the company’s popular NXG XII 600 with an E for “extended” 1,500 mm build envelope in the Z-axis. Driving the development of this model was customers’ need to produce larger components, the company said. Available in 2023.

AddUp FormUp 350 Evolution

Like SLM Solution, AddUp heard consumer demand for a larger build volume. The newest edition of the FormUp 350 Evolution features an extended Z height (now 1,000 mm) for larger build capacities. Available in 2023.

Freemelt eMelt

Freemelt unveiled its new industrial electron beam powder bed fusion machine eMelt at Formnext that, it says, has higher beam power compared to other systems on the market, although there are no solid details released yet. Developed for large-scale additive manufacturing of parts, such as titanium implants for hip and knee surgeries. In addition to manufacturing implants, eMELT can also be used to manufacture components in tungsten and copper. Available Q4 2023.

Sinterjet M60

Desktop metal binder jetting for under $66,000? The excitement was palpable for every Formnext attendee who happened to stumble upon the Sinterjet M60 booth, tucked away in one of the last aisles by the outer wall. Boasting print speeds up to 50cc/h paired with a fast sintering furnace, the company says the M60 can deliver parts in hours, not days. No release date has been announced.

Grob GMP300

Not a start-up, but making its additive manufacturing technology debut at Formnext is German multi-axis machining company Grob offering a new powder-free, liquid metal manufacturing process. The company’s machine GMP300 safe, fast production of near-net-shape components ready to machining on your plant’s existing equipment. The feed material is aluminum alloys in wire form.

Ponticon pE3D

The new pE3D metal directed energy deposition (DED) machine from German start-up Ponticon is representative of the growing interest in 3D printing for near-net shapes and metal part repair. The pE3D‘s 5-axis build plate and 700 x 700 x 800 mm build volume can accommodate medium-size parts for additive manufacturing, coating, and repair. Ponticon says the pE3D can deposit alloys of almost any composition on metallic and ceramic components.

Look for more new printer details as they become commercially available. If you missed some of the other great machines introduced this year, check out our coverage of everything launched in 2022 here:

Lead image source: Photo of the HP booth at Formnext 2022 by Stefan Filff.

License: The text of "Top 3D Printers Launched at Formnext 2022" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.