Professional-level resin 3D printing is used for everything from tools, molds, and prototypes to end-use sports equipment and dentures. These machines typically feature larger build volumes than their consumer-level cousins, more advanced and durable material options, and the ability to finely tune the part quality and achieve consistency over larger volumes.

Resin printing is prized by companies in virtually every industry that needs:

- parts comparable to injection molding

- parts with intricate details, complex geometries, and fine features

- parts with very smooth surfaces or soft textures

- parts in various materials (flexible prints one day, sturdy prints the next, etc.)

- parts in biocompatible plastics

- transparent parts

In this guide, we walk you through the essentials of resin printing technology, what to look for in a professional resin printer, how to buy a resin printer, and what you need to know about advanced resin materials.

Here, we focus on professional or industrial resin printers – the machines averaging about $10,000 and up to $450,000. If your budget is smaller ($200 – $1,000) or you’re new to the technology, you could find a printer to fit your needs in our other All3DP guide linked below:

Resin State of the Art

In recent years, the growing resin printer market has been branching out into more specialized areas. Some companies that make high-precession resin 3D printers have shifted focus to concentrate on the billion-dollar dental 3D printing market, which is the largest segment of the resin 3D printing industry.

Therefore, in this guide, dental-specific resin 3D printers are not represented but instead have earned their own guide linked below:

Resin and wax 3D printing for the jewelry industry is also a rapidly growing market with some specialized printers. We take a closer look at 3D printers for jewelry molds in this guide linked below:

Remove dental and jewelry resin 3D printers and you’re left with those that focus on manufacturing in highly durable and flexible materials. Not that some of these can’t be used for dental and jewelry, but the main goal to deliver ruggid and extremely accurate parts.

All resin printers do not use the same technology so if you don’t know a DLP from an SLA from an LMM, skip to the technology section first.

| company | Price | Tech / Min. Resolution | Materials | Build Volume |

|---|---|---|---|---|

| Formlabs Form 3+ | $3,000 | SLA / XY: 25 μm, Z: 25-300 μm | Open | 145 × 145 × 185 mm |

| Zortrax Inkspire 2 | $4,500 | LCD / XY: 50 μm, Z: 25 μm | Open | 192 x 120 x 280 mm |

| Photocentric Magna v.2 | $24,000 | LCD / XY: 81 µm, Z: 25 - 100 µm | Open | 510 x 280 x 350 mm |

| B9Creations Core 5 Ascent | $26,000 | DLP / XY: 25 µm, Z: 10 µm | Open | 124.8 x 70.2 x 320 mm |

| Asiga Pro 4K | $26,000 | DLP / XY: 65 - 80 μm, Z: 56 μm | Open | 217 × 122 × 200 mm |

| Nexa3D NXE 400Pro | $42,000 | LCD / XY: 76.5 μm, Z: 50 - 200 μm | Open | 275 x 155 x 400 mm |

| Stratasys Origin One | $50,000 | DLP / XY: 50 μm, Z: 25 - 200 μm | Proprietary | 192 x 108 x 370 mm |

| Carbon M3 Max | $50,000 - $150,000 | DLP / XY: 75 µm, Z: 25 - 100 µm | Proprietary | 189 x 118 x 326 mm |

| LuxCreo Lux 3Li+ | $56,000 | DLP / XY: 162 μm, Z: 20 - 200 μm | Proprietary | 400 x 259 x 380 mm |

| Nexa3D XiP Pro | $60,000 | LCD / XY: 46 μm, Z: 25 - 200 μm | Open | 292 x 163 x 410 mm |

| Rapid Shape I100+ | $120,000 | DLP / XY: 44 μm, Z: 35 μm | Open | 400 x 335 x 190 mm |

| ETEC Xtreme 8K | $175,000 - $225,000 | DLP / XY: 100µm, Z: 100 - 175µm | Open | 450 x 371 x 399 mm |

| Fortify Flux 3D | $185,000 | DLP / XY: 75 μm, Z: 25 - 150 μm | Proprietary | 204 x 115 x 330 mm |

| 3D Systems SLA 750 | $400,000 - $420,000 | SLA / Z: 50- 200 μm | Proprietary | 750 x 750 x 550 mm |

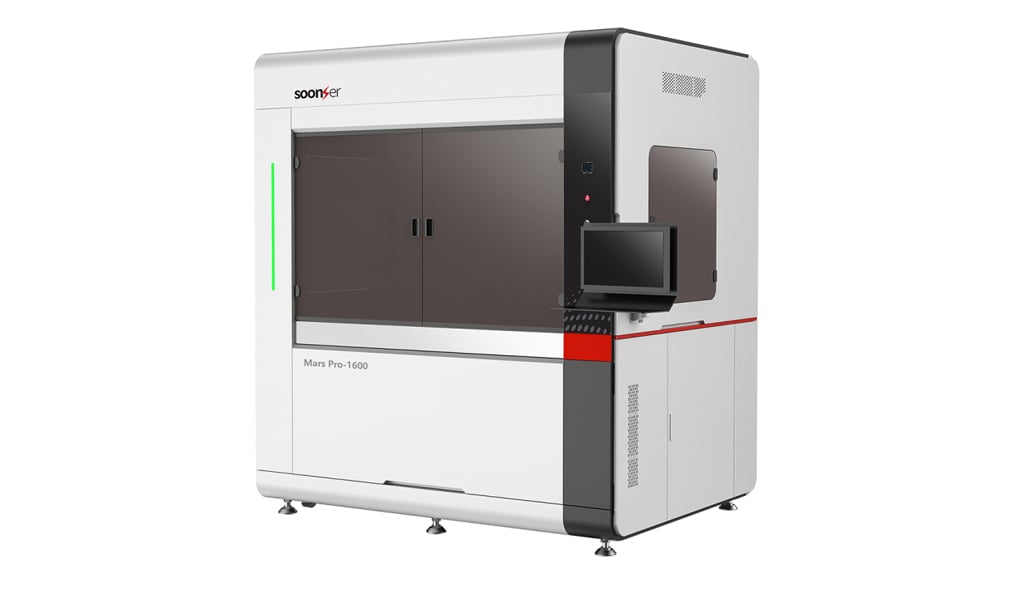

| SoonSer Mars Pro 1600 | - | SLA / XY: 75 μm, Z: 50 - 250 μm | Open | 1,600 × 800 × 600 mm |

Different Technologies Behind Resin Printers

You’ve concluded that resin is right for you, now what? Let’s assume you’re familiar with the basics of resin printing – using a vat of liquid photosensitive plastic exposed to UV light to build an object layer by layer. All resin-based 3D printing, in which a liquid photopolymer resin is stored in a vat (as opposed to being ink-jetted through a nozzle), is collectively known as vat polymerization. All other names are subcategories of this technology.

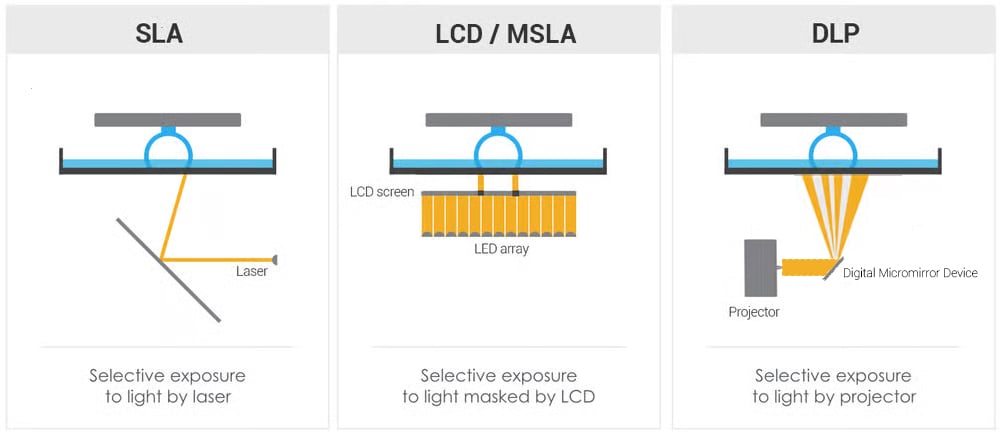

Within the vat polymerization 3D printing category, you’ll find slightly different printer technologies – stereolithography (SLA), liquid crystal display (LCD), digital light processing (DLP), and others – to create somewhat different results making trade-offs between speed and fine detail, and distinguishing some unique printers from the pack. All of these technologies cure resin using UV light, but how the resin polymer is cured is slightly different.

The 3 Major Resin Types in Brief

Stereolithography (SLA) today generally always refers to laser stereolithography, although you might still hear it used as a catch-all term for all types of resin 3D printing. Chuck Hall, who invented the process and coined the term stereolithography, describes it in his 1986 patent as a concentrated “beam” of ultraviolet light focused onto the surface of a vat filled with liquid photopolymer. Today, SLA refers to a machine that uses one or more lasers as the light source.

Digital light processing (DLP) uses a digital light projector as its light “engine”. It flashes light onto a digital micromirror device (DMD) consisting of hundreds of thousands of tiny mirrors. Some mirrors direct the light to the resin in the pattern of a cross-section of the part to be printed while other mirrors deflect the light off to the side. Layers generated using DLP printers consist of so-called voxels, the 3D equivalent of pixels. That’s because the projector screen itself consists of pixels. Flashing an entire layer at a time, as you can guess, is faster than tracing the layer with a laser.

Liquid crystal display (LCD) is the third type of vat polymerization also known as masked stereolithography (MSLA). 3D printer manufacturers use these terms interchangeably. This 3D printing technology is nearly the same as DLP in that it flashes a complete layer at the resin tank, but the source of the light is different. Instead of a projector shining on a digital micromirror, the UV light comes from an LED array shining through an LCD screen. The screen acts as a mask, revealing only the pixels necessary for the current layer. Due to the low cost of LCD units compared to projectors and micromirrors, LCD has become a common technology for the budget desktop resin printer segment, but don’t be put off; some printer makers are taking the technology to the next level for professionals.

We’ve already established that DLP and LCD are generally faster than SLA, but which one yields more finely detailed prints? The fact is that all technologies can produce super-fine details, and you may be surprised by the resolution you can get from very affordable machines.

If you want a deep dive into the specifics of resin technology resolution, check out our guide, High-Resolution 3D Printers – The Ultimate Guide.

Patented Resin Technologies

Although some patented resin 3D printing technologies are more marketing than science, some manufacturers have variations on the common technologies (SLA, LCD, and DLP) that actually represent significant advances and set their machines apart from the rest.

3D printer manufacturer Carbon, for example, calls its resin printing technology Digital Light Synthesis (DLS), which is a take on DLP. In DLS, the resin pool is exposed to both UV light and oxygen. Unlike traditional layer-by-layer approaches, DLS uses a continuous process where the object is pulled from the resin bath. The bottom of the resin pool has an oxygen-permeable window. Oxygen inhibits the curing process, and by controlling the oxygen levels through the window, the printer can precisely control the solidification of the resin. DLS requires special resins and the entire process is extremely fast.

Printer maker Stratasys offers another take on DLP in its Origin printer called Programmable Photopolymerization (P³). The outstanding feature of P³ is its ability to dynamically adjust the light patterns during the exposure process to create more sophisticated curing profiles, leading to, the company says, improved accuracy and the ability to optimize material properties.

Formlabs offers what it called Low Force Stereolithography (LFS), while Nexa3D has a type of SLA called Lubricant Sublayer Photo-curing (LSPc).

One new technology from start-up Axtra3D combines resin methods, so the core of a part is printed quickly with DLP while the outer shell is printed with finer detail using SLA. The company calls it Hybrid PhotoSynthesis (HPS) technology.

Know Your Needs

To uncover which machine will best meet your needs and budget, first ask yourself:

- What are the qualities of the parts I need to print (flexible, sturdy, clear, etc.) and will I want to print different parts with different qualities?

- How exact are my detail requirements? For example, dental applications typically require print detail within 50 microns, while product prototypes may require far less detail.

- How big are the prints I need to make? Note that a large build volume can create one large item, such as a helmet, or many small items, such as 60 individual parts.

- How much do I plan to print, and how quickly do I need them printed?

- Will I need to use biocompatible materials?

- Are there printers specific to my market, such as dental and jewelry?

- Do I have space and labor available for post-processing and the associated machines?

Although we give price ranges for the printers in our list, don’t let that be your only guide. As with any major equipment purchase for your business, carefully evaluate durability and ease of maintenance, warranties and support, plus the maturity of the technology and the level of industry adoption.

Resin printer manufacturers tout the uniformity and life span of their light sources, the ease of calibrating their build plate, the intuitiveness of their user interface, and special features, such as real-time image monitoring, software-driven control over conditions inside the vat, and a robust menu of compatible materials. Other bells and whistles of resin printers include mess-free resin cartridges, integrated automatic print-wash-cure handling, and variable temperature printing.

These features, and many more, will make – depending on your use case – subtle or significant differences in your workflow, efficiency, and end result.

The Details Behind Fine-Detail

If looking at a printer’s technical specification sheet makes your head spin, know that you won’t find huge differences within comparable price ranges using the same technology. For example, the finest XY resolution for resin printers (apart from the industrial micro 3D printers) is generally around 25 – 50 microns (μm). (For reference, 50 μm is the width of a human hair.)

Some manufacturers only talk about resolution, while others mention resolution and accuracy. Resolution refers to the possible layer thickness, for example, 50 μm or 100 μm. The accuracy refers to the window of error for consistency print after print. For example, an accuracy of +/- 20 μm means your print resolution could be 20 μm over or under what you programmed.

In many industries, accuracy is critical. For most dental applications, professionals typically look for an accuracy of within 50 μm. For fine jewelry, some professionals require an accuracy of 25 μm, and for some medical applications and electronics, companies require an XY printing resolution of 5 μm with an even smaller accuracy, which you can find in a handful of ultra-high micro-precision printers.

The general rule is that the higher the resolution, the longer your parts will take to print. But this is where professionals and industrial machines differ from consumer resin printers, printing high-resolution parts quickly.

For a deep dive into resin printer resolution, such as what 4K and 8K resolution refers to and terms like pixel-shift really mean, check out our guide to resolution linked below.

The Fastest Resin Printer

There’s a long list of resin 3D printer makers that claim to have the fastest machine, but the comparisons are often apples to oranges considering all of the variables and technologies involved.

Speed in resin printers depends on the selected print resolution, materials, and volume, plus the type and quality of the light source. This is why there are $2k resin printers, and then there are $100k resin printers. That being said, there are some technologies that are faster than others.

For example, single-laser SLA is slower than DLP and LCD. The lasers used in SLA have to trace out each layer. However, projector and LCD light source-based printing methods tend to be faster because they don’t trace out each layer being printed point by point; they cure entire layers in one flash. The quality and intensity of the light source may cure the resin even faster.

When you’re shopping for a resin printer, many manufacturers will give you an example speed. For example, sportswear giant Adidas says it can produce a shoe midsole in 20 minutes on Carbon printers. Formlabs gets specific with its claim to print a single retainer in its Dental LT Clear resin in 50 minutes, while Photocentric says its LC Magna printer can churn out 48 dental models horizontally on a build platform in 80 minutes.

If you have a particular product or type of part in mind to print, you can send the manufacturer the file and it can tell you about how long your parts will take on its machine.

Once you’ve narrowed down three to five printers that meet your needs, take them for a test drive if possible, but, at the very least, request free sample prints with specs on how long the print took to complete.

Accessories You'll Need: Print, Wash, Cure

Parts don’t emerge from resin 3D printers ready to use, in fact they’re completely useless. Parts may be only partially polymerized (not fully cured) when they leave the printer, creating opportunities for warping in the cleaning and curing steps. This is one of the drawbacks to resin printing; the often-messy and somewhat labor-intensive post-processing.

Although industrial printers and many professional ones have a fully automated print-wash-cure process, others require more equipment, namely a washing unit and a curing unit.

Indeed, the sophistication of your printer and the quality of your resins are proportional to the amount of post-processing labor involved. So if you’re spending too much time and effort post-processing to get the desired quality, consider upgrading your resin, your printer, or both.

Most resin parts need support structures during printing that require removal after printing. Removing supports and the marks they leave on the surface may involve sanding or polishing.

Most resin printer manufacturers make their own accessory machines (if they are not fully incorporated into one unit) and many produce their own post-processing chemicals, but you’re not limited to selecting only from your printer manufacturer’s offerings. Shop around for the accessories that best fit your needs and budget.

Materials: Understand Your Options

Resin manufacturers will argue that it’s the materials that make the print, and that may often be true. There are thousands of materials available for resin printing from a wide range of manufacturers and at prices ranging from $15 a liter to more than $300. In fact, you can resin-print in everything from a highly flexible silicone-like material to a metal-infused polymer.

Your resin 3D printer, however, is either restricted to proprietary resins or it’s an “open material” machine, meaning it can print with a wide range of third-party materials offering great flexibility but also a bit of trial and error to dial in the print settings just right. To cut down on the tinkering, printer makers often work directly with the resin material developers to establish optimal setting. You may hear of certain materials being “certified” for certain printers. This is something to look for, since it’s designed to save you time and money.

Resin Variety

Resins come in a full rainbow of colors, transparencies, properties, and textures. At the dawn of resin 3D printing, most printed parts were stiff and brittle. Those days are long gone. There are flexible resins, durable resins, filled-resins, hybrid resins, exotic resins, biocompatible resins, and degradable plant-based resins among many more categories. Yet, because most professional resins are trademarked, proprietary formulas, it can be difficult to understand the differences. For example, most resin makers offer a “tough” resin, but how one tough resin compares to another is often difficult to track down.

Note that resins are typically formulated to be responsive to specific wavelengths of UV light, such as 355 nm, 385 nm, or 405 nm. If you’re 3D printer emits 355 nm light, don’t use a 405 nm resin. Fortunately, most resins today will cure in all three wavelengths, but always follow the manufacturer’s recommendations for resin compatibility and curing conditions to achieve the best results in 3D printing.

Likewise, a resin formulated for a DLP 3D printer may not work in an SLA printer, so read labels carefully.

Manufacturer vs. Third-Party Materials

A resin printer’s claims of accuracy, speed, and quality are based on using specific resins. Although you can use third-party resins in many resin printers, your results may not match what the manufacturer claims its printer can produce. For example, the resin part may not fully cure or may not print as fast with a third-party material.

Despite the risks of uncertified third-party materials, a resin printer with an open-mode or experimental mode for materials is an important feature. Material manufacturers are introducing new resins so quickly that it’s often not possible for printer manufacturers to keep up on certifying or adapting innovative materials for use in their machines. Open-mode enables you to take advantage of the latest developments in materials.

Several printer manufacturers have alliances with major chemical companies to research and develop proprietary materials. For example, Nexa3D and global chemical company Henkel have launched a resin called xMED412, which is a high-impact, durable plastic that has also been tested and cleared by the U.S. Food and Drug Administration (FDA) for use within clinical environments.

Of course, there are plenty of high-quality resins by third-party manufacturers that will work as good or even better in whichever machine you choose. The only drawback, as we mentioned above, is taking the extra time to experiment and fine-tune your print settings and post-processing to get the print you require.

Many resin manufacturers, including Liqcreate, offer custom material development to fit your company’s specific needs for colors, properties, and the specific printer you’re using. In fact the company has produced nearly two dozen custom resins in the past few years.

By working with engineers at consumer product companies, such as Adidas, Invisalign, and Riddell, resin manufacturers have researched and created application-specific resins and helped 3D printing to rival injection molding and further the mass production of end-use products.

If you have specific requirements for your final part’s stiffness, strength, stretch, durability, heat resistance, or other attributes, check out the materials’ technical data sheet, which should provide details including tensile strength, percent of elongation at break, and water absorption.

Ultimately, where you buy your resins may be tied to your location. Although companies in Europe and the North America may have the widest selection of vendors to choose from, companies elsewhere may want to first try sourcing resins locally before paying shipping and import duties for the printer manufacturer brands.

Where to Buy Resins for 3D Printing

Your printer manufacturer or reseller is the first place to turn for resin materials, but there are a host of third-party resellers for printer-branded resins plus alternative resins that also may work well in your resin printer. Third-party resins will either list the compatible printer or give a general statement, such as “this resin is designed for printing on DLP/LCD 3D printers.” These third-party resins may be a risk and take some experimenting, but can often be up to half the cost of the manufacturer resins.

Top Resin 3D Printers

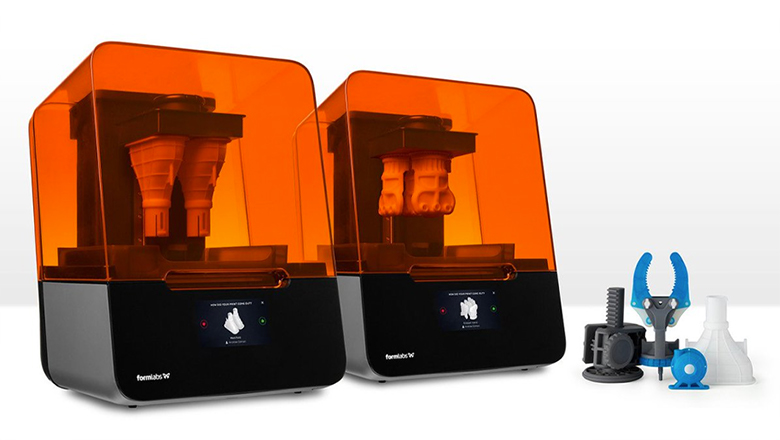

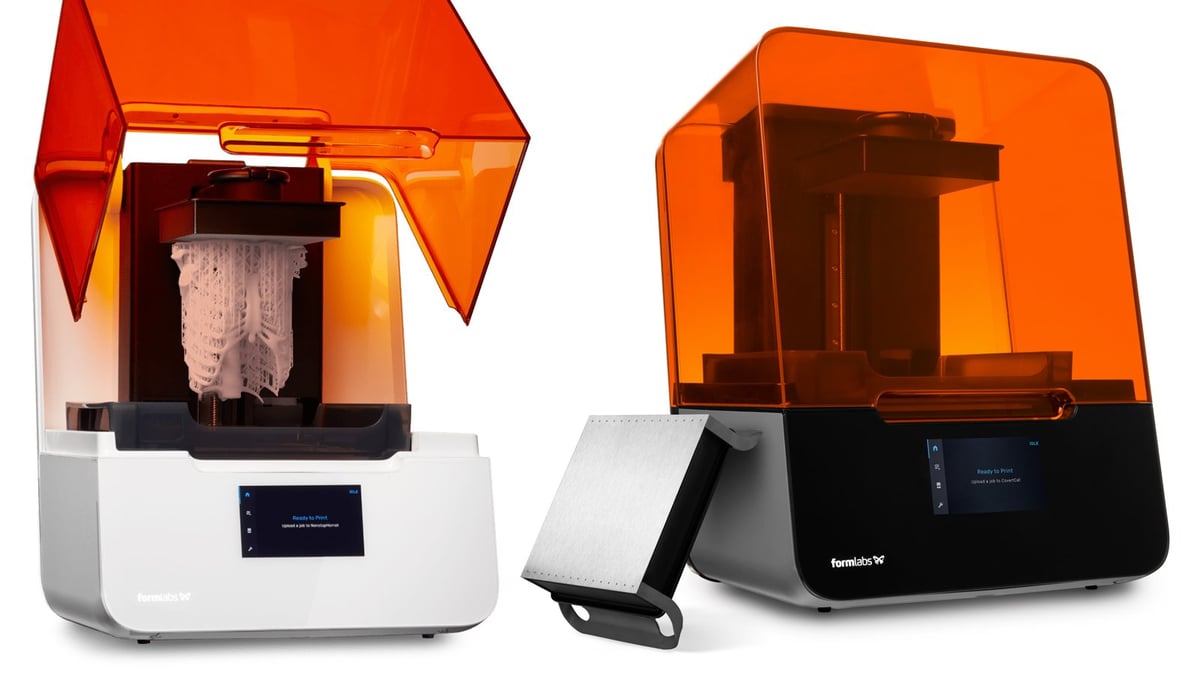

Formlabs Form 3+

Formlabs launched its newest SLA printer, the Form 3+ and the Form 3B+ in 2022, which are 40% faster than its older versions. The changes that enable faster printing include new software and the company’s “expansion” of a feature called Adaptive Layer Thickness that analyzes the geometry of parts and assigns layer heights throughout the sliced model, using thicker layers to maximize print speeds in some areas of the print while using smaller layers to preserve fine details in other areas.

The second speed-enhancing upgrade is a hardware and manufacturing process that enables tighter alignment between the light processing unit (LPU) and the build platform, the company says. This enables the printer to deliver less laser exposure to early layers, reducing print times by five to 15 minutes in the first few layers of the print.

The new preheat feature speeds up the overall time it takes to produce parts. Previously, preheating the build chamber would only begin once a user confirmed a print on the touchscreen. But now, preheating will begin once the printer receives a job.

Formlabs boasts one of the largest libraries of proprietary resins (more than 45), including two new high-performance polyurethanes ideal for producing rigid and durable parts, a new silicone and more biocompatible materials. Despite the wealth of material options, Formlabs decided to offer a new “Open Platform” paid-option to enable advanced users to print with any 405 nm photopolymer resin and edit print setting accordingly.

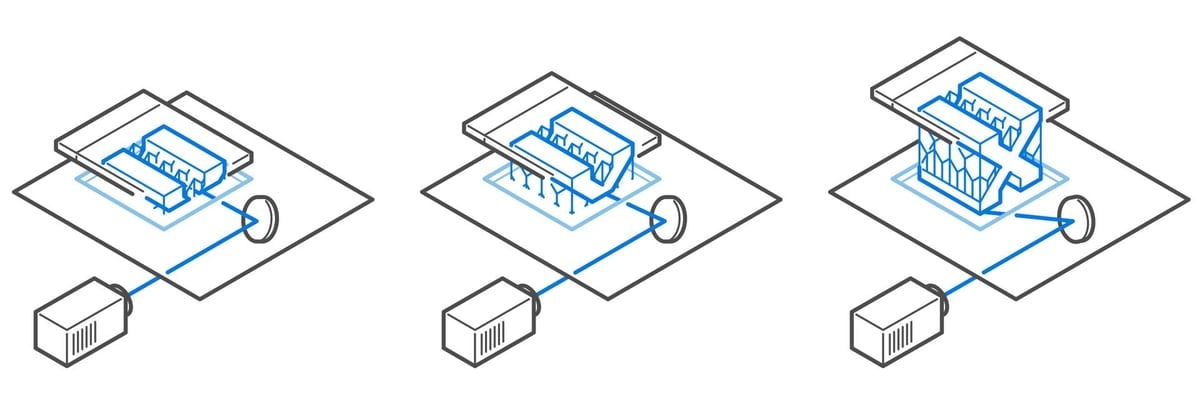

In 2023, Formlabs launched its Automation Ecosystem, which is a hardware and software solution that enables your printers to print parts around the clock without your help. The aim is to enable large-batch 3D printing to reduce cost per part and manual labor.

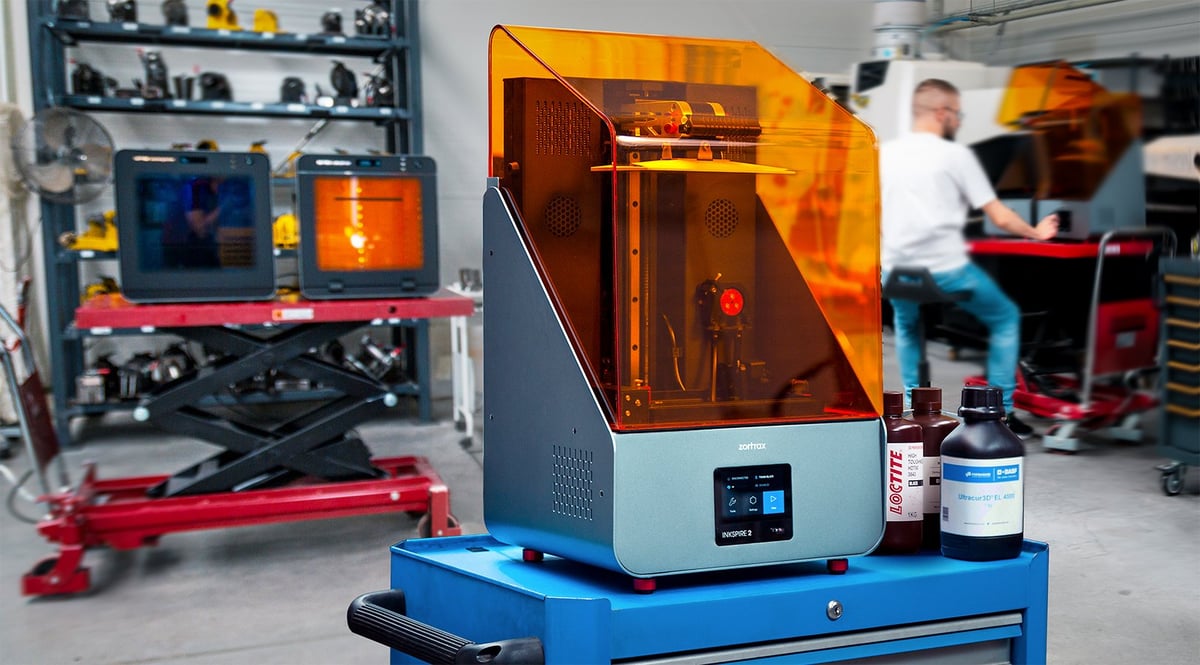

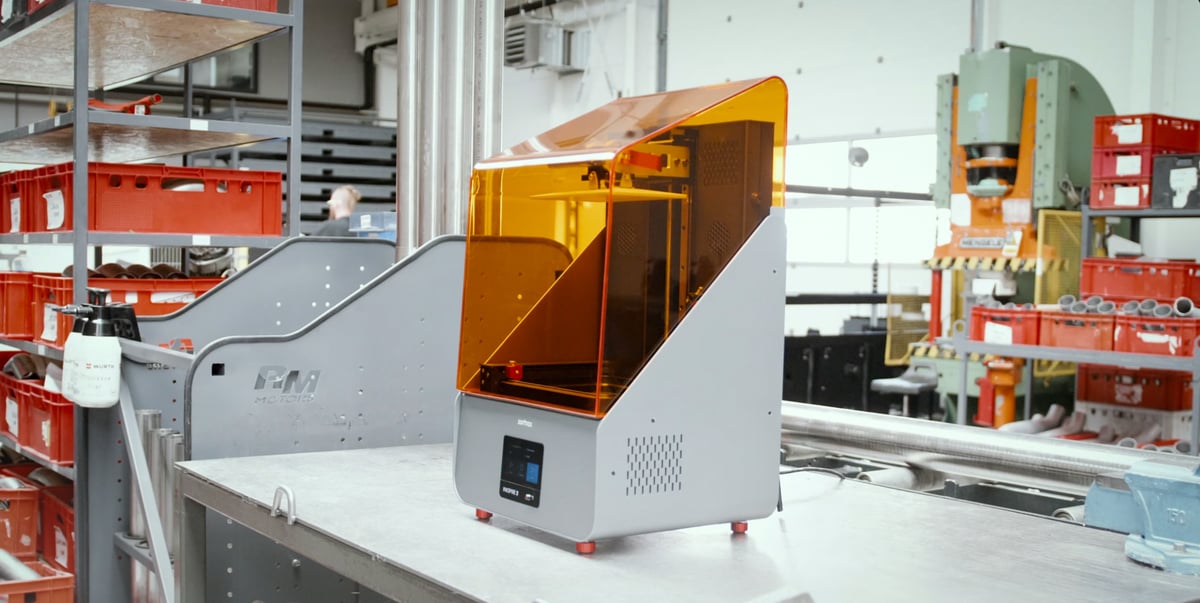

Zortrax Inkspire 2

The Zortrax Inkspire 2 launched in 2022 and is based on the company’s popular Inkspire LCD technology introduced in 2018. The newest version is aimed at small manufacturers looking for an affordable resin option for functional end-use parts. The Inkspire 2 is larger and more powerful than the original.

Zortrax says its durable engineering resins from BASF Forward AM and Henkel/Loctite are functional equivalents of high-performance filaments. The printer’s light engine is powerful enough to work with high-grade engineering resins (those cured by light with 405 nm wavelength) that used to be supported only on industrial digital light processing machines.

The Inkspire 2 features liquid-crystal display (LCD) technology that flashes complete layers of the part at the resin tank with UV light from an array of LEDs shining through the LCD screen.

Zortrax offers the 3D printer along with a full ecosystem of software and accessories including the Zortrax post-processed cleaning station and curing station. The Zortrax inCloud connectivity enables real-time, remote management capability over all available Zortrax 3D printers so you can upload, start, and pause prints on each machine connected to the inCloud account.

Photocentric Magna v.2

UK-based resin 3D printer maker Photocentric’s re-engineered its Magna v.2 desktop resin printer in 2022. It prints at 16 mm per hour depending on the resolution, which is like 36 custom dental trays (80-mm Z height) at 250-micron layers in 1 hour 13 minutes, compared with 2 hours 22 minutes on the previous version of the LC Magna. So, twice as fast as the previous version of the Magna, the company says.

Another feature is the quiet, 6-fan cooling system, which the company says enables faster production time, particularly for small models. A new software integration ability enables communication with MES systems, such as 3YourMind. There’s also a new quad-core processor with a 7-inch touchscreen. The v.2 has a 4K screen (3840 x 2160 pixels). The idea behind the updates is to position the Magna v.2 as a production resin printer for batch volumes.

B9Creations Core 5 Ascent

B9 Core 5 Ascent is B9Creations largest resin 3D printer built on its existing technology found in its four other machines. It boasts a 317.5 Z-height, a print speed between 15-85 mm/hr depending on material, and an effective resolution between 25 and 50 microns.

The Ascent is tuned to 385 nm resin, but three of the company’s other Core series printers are tuned to 405 nm resin with a 405 nm light engine. The B9 Core 530 boasts a print speed of up to 120 mm/h.

US-based B9Creations started producing 3D printers 2011. The company offers a full solution to resin 3D printing including materials, software, the B9Clean washer that lets you insert the whole build platform or loose models, two sizes of curing stations, and a 3D scanner.

Asiga Pro 4K

The Pro 4K from Australia-based Asiga, combines 4K imaging technology with an open material system boasting hundreds of compatible materials.

In 2011, Asiga launched the world’s first LED-based DLP 3D printer and started the affordable desktop resin printing revolution, which significantly changed digital manufacturing.

The Asiga Pro 4K has Wifi connectivity, wireless direct and ethernet connection, automatic support generation with the included Asiga Composer software, and a touchscreen interface. Available with varying minimum pixel sizes (32, 46, or 56 microns), the Pro 4K is available with either a 365 nm, 385 nm or 405 nm LED light source.

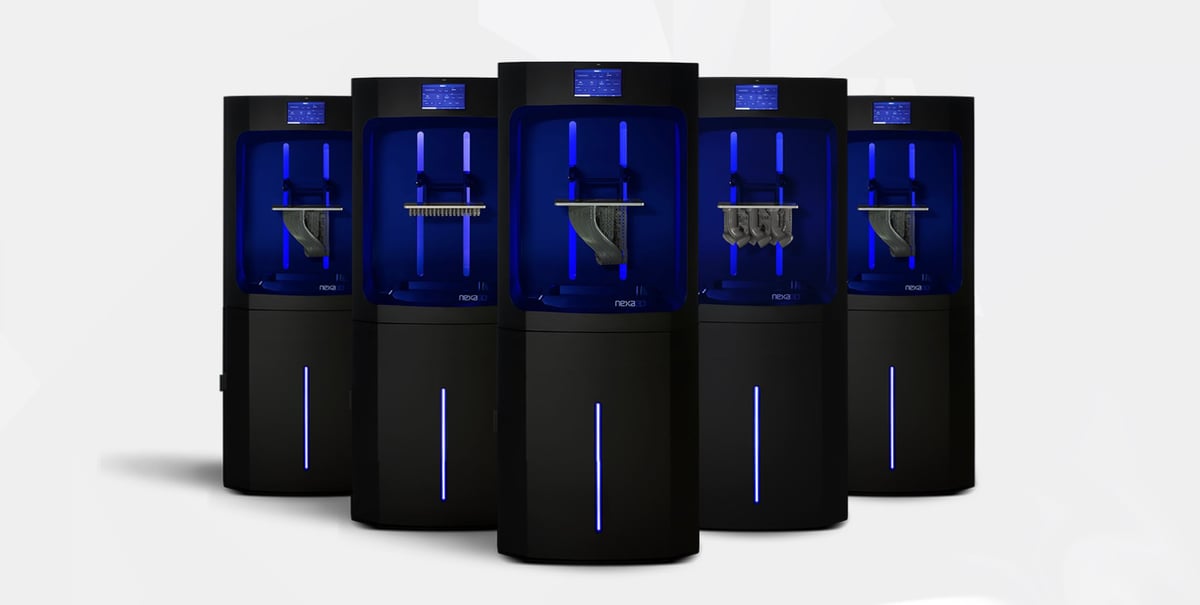

Nexa3D NXE 400Pro

Nexa3D’s NXE 400 3D printer boasts a large build volume and what the company calls its Lubricant Sublayer Photo-curing (LSPc) technology to deliver accuracy and tight tolerances with a superior surface finish. Nexa3D says LSPc technology leverages a self-lubricated, flexible membrane that resists sticking to both the printed part and the underlying LCD screen to deliver faster printing speeds.

The NXE 400 is crafted to be modular for easily interchangeable parts and technology upgrades. Nexa3D also offers post-processing wash and cure machines for large volumes. This bundle of print, wash, and cure machines makes Nexa3D a one-stop shop for resin printing production. The Nexa3D xWash and xClean and washes two full builds at once.

Nexa3D’s an open material platform but has a menu of validated materials through its partnerships with chemical giants Henkle, BASF, Covestro, Evonik, Arkema, and Keystone, a leading choice for dental labs.

Stratasys Origin One

From biocompatible medical devices to aerospace-grade components, the Origin One by Stratasys focuses on production applications. The company says the machine’s compact footprint and minimal power requirements enable manufacturers to maximize production capacity per square foot with a low per-part cost, fast time to part, affordable single component resins, minimal post-processing, low waste and high production yields.

Origin’s “P3” technology, which Stratasys says is an advancement on DLP, precisely controls light, heat, and force, among other parameters, via closed-loop feedback software.

Stratasys works with a network of chemical companies (Henkel, BASF, and DSM) to co-develop photopolymers in several categories, specifically for Origin One, boosting part consistency.

The company’s GrabCAD Print software is now available for Origin One to enable users to automatically generate supports or use advanced manual supports. Prepare files for printing based on application requirements, print time, or desired support contact points. Additional features include labeling, advanced material management, and access to open materials via the Open Material License parameter set.

Carbon M3 Max

California-based 3D printer maker Carbon launched its latest industrial resin printer, the M3 Max, in 2022. Carbon says the M3 Max provides an “advanced end-to-end idea-to-production platform” when combined with its software, Design Engine, and proprietary Carbon resin materials. Because Carbon’s DPL technology, called Digital Light Synthesis, has some unique features requiring specific resin properties, material selection was a bit of a drawback. But in just the last six months, Carbon has introduced new materials and collaborated with material makers that seem to have solved that problem and grown its material portfolio to 20 in addition to some Flexcera brand resins from Desktop Health.

Although we have our dental 3D printers in another guide, this niche has been a strong focus at Carbon. The company recently introduced new materials and new workflow software for dental labs. On the industrial front, though, there’s the new rigid material, EPX 150, and a new elastomer, EPU 46, for manufacturing.

The M3 Max and the also new M3 are the same size as Carbon’s M2 launched in 2019 but boast a simpler print experience with the help of a new touchscreen that features more printer options.

The Carbon suite includes printers, washers, and curing machines, along with software. Carbon’s software offering is more than a build prep platform, it contains design tools to customize your product, generate multi-zonal lattices, and optimize topology.

Carbon machines are available for lease, not purchase.

LuxCreo Lux 3Li+

With headquarters in China and California, LuxCreo makes a professional resin 3D printer, the Lux 3Li+ series, which aims to facilitate industrial production for what it calls 3D smart factory printers.

The company’s software, LuxFlow and LuxAlign, can enable accurate and consistent high-throughput 3D printing at a production scale across a smart factory of hundreds of printers, the company says. Like Carbon, the software is more than build prep and aids you in implementing lightweight designs.

LuxCreo is another resin printer maker heavily involved in the dental field. Its Lux 3+ dental printing solution is one of the only on the market that can directly 3D print clear aligners.

The print speed is about 40 mm per hour.

Nexa3D XiP Pro

In May 2023, industrial 3D printer maker Nexa3D launched a Pro version of the desktop resin machine it launched in early 2022. The XiP Pro is even zippier than the smaller XiP ($6,300), the company says. There are a lot of pro features in this new version aimed at enabling businesses to print more and print faster.

Boosting print speed from 18 verticle cm per hour to 24 vertical cm per hour, the ZiP Pro can produce its entire build volume (292 x 163 x 410 mm) in under two hours. But more than speed, this new Pro version offers a 7K resolution LCD screen compared to 4K on the standard XiP.

The 7K screen has a 46-micron pixel size that, with anti-aliasing technology, can achieve a surface quality that appears even finer.

Extras you won’t see on similarly sized machines are the XiP Pro’s adaptive speed control that optimizes the process parameters based on part geometry and selected resin, or the debris detection that alerts you to potentially part-ruining vat anomalies.

Both versions of the Xip have the Nexa3D proprietary lubricant sublayer photo-curing durable membrane, which is the part that ensures print quality. Nexa3D says their membrane requires less frequent replacement than other similar machines.

Although Nexa3D offers several engineering-grade resins developed in partnership with top polymer makers like Henkel, BASF, and Keystone, you’re not limited to just Nexa3D resins. The ZiP is an open material platform.

Rapid Shape I100+

The I100+ is what Rapid Shape calls its workhorse resin 3D printer. Setting it apart from some others is its automation, specifically the automatic separation module (patented) that collects your printed parts in a basket automatically so the next print job can start immediately, all without any manual intervention. There’s also an automatic resin refill unit that takes care of a constantly sufficient filling level of resin material inside the reservoir.

The fully-automated system for producing thousands of parts per day also has a cleaning process that recovers up to 15% of resin to be reused in 3D printing and avoids using any cleaning chemicals. After the printing process, the parts are transported via a conveyor directly into the post-processing, where they are spun at high speeds.

This 24/7 production unit comes with an industrial projection system and internal cooling for all system components. The I100+ is the solution for companies with high-volume needs, including multiple-shift operations.

ETEC Xtreme 8K

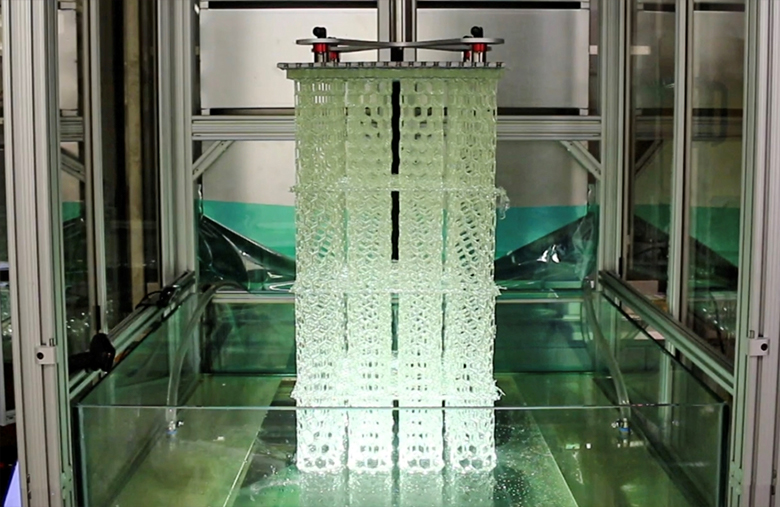

ETEC (formerly known as EnvisionTEC), a Desktop Metal company, offers the Xtreme 8K resin 3D printer for production-grade and large 3D parts. The Xtreme 8K uses dual 4K projector DLP technology offering a 12W LED light source. Top-down printing enables faster curing of each layer by eliminating the peeling step that is required for traditional DLP systems, the company says. Top-down also means the parts are fully submerged in the material during printing, which calls for fewer support structures, resulting in better surface finishes. Surface roughness can be less than 1 micron RA.

ETEC says the machine is designed to run 24/7 for volume production of 3D-printed parts. With wide material compatibility, including hard plastics, high-temperature plastics, elastomers, and rubbers, the Xtreme 8K produces a wide range of parts.

In March 2024, ETEC announced that select Evonik photopolymers and materials are now qualified to be compatible with the Xtreme 8K and the company’s Pro XL 3D printers.

The large build volume allows users to print very large parts, thousands of smaller parts, or mix and match both in one build.

Fortify Flux 3D

3D printer manufacturer Fortify’s two digital light processing (DLP) printers, the Flux Core and the Flux 3D, both feature its novel approach to resin additive manufacturing. The company’s Digital Composite Manufacturing (DCM) is a filled-photopolymer technology that introduces functional additives, such as metal and ceramic fibers, to resin. The company’s patented processing technology, Continuous Kinetic Mixing, keeps the additives homogeneous in the resin, while its magnetic alignment technology, Fluxprint, uses a magnetic field across the build area to align all fibers in the layer.

Flux Core, the company’s new baseline 3D printer is designed to process a range of viscous particle-filled resins where magnetic alignment is not required. The Flux 3D is a version of the Flux Core with the Fluxprint 3-axis magnetic field.

In addition to the hardware solutions, Fortify unveiled its Flux Developer software platform that can be used on any Flux printer. Flux Developer gives users an expanded processing window, so they can control variables, such as exposure time and intensity, material flow, resin temperature, and viscosity, and even the build plate mechanics, as they develop and onboard new materials.

Fortify’s printers range from under $100,000 to just over $200,000 depending upon options.

3D Systems SLA 750

3D Systems’ newest resin printer launched in April 2022, the SLA 750 Dual, is its fastest resin printer to date and features 15% more print volume than its ProX 800 while having a smaller overall footprint. The focus of the machine is to deliver large, production resin parts, and batch-part production for industries from transportation and motorsports to aerospace and healthcare, the company says.

The most exciting aspect of the SLA 750 is its dual synchronized 4-watt lasers that can trace out parts with high detail. Two lasers clearly double the speed of the company’s other SLA printer and, even if you opt for one laser on your SLA 750, 3D Systems says it will still be 30% faster than any of its other machines.

Tech behind the printer speed and throughput is 3D Systems’ new and proprietary scanning algorithm called Hyper-Scan. The laser control feature optimizes laser focus, power, and vector motor kinematics. The system also features a self-calibrating dual-rail recoater designed to improve print process reliability and final part mechanical properties, the company says.

3D Systems’ says the SAL 750 is “the fastest stereolithography solution available” without providing actual speed, so take that claim with a grain of salt.

In November 2023, 3D Systems previewed its new PSLA 270 resin 3D printer that won’t be out for a while and they didn’t disclose many details. It will be a “projector-based polymer 3D printing platform” so, DLP. It will diferienciate itself from 3D Systems other machines by delivering larger end-use parts more rapidly, the company said.

SoonSer Mars Pro 1600

Not yet widely available outside of China, the Mars Pro line of three large, industrial resin printers from SoonSer aim to provide both large-format 3D printing and batch production. Even though it has a huge build volume, the company says this does not affect the print speed of Mars Pro 1600 because of its proprietary variable spot system laser and in-house path planning software.

SoonSer prides itself on their machines’ ease of use with software that automates much of the process. With an easy-to-navigate interface, SoonSer software features reporting capability, provides insight into hardware usage and part traceability.

The Mars Pro 600, 850, and 1600 feature an open resin system for material flexibility, which currently contains around ten 3D printing resins, each with varying mechanical properties, colors, and applications.

SoonSer machines feature EU CE and US FCC certification for safety.

The Newest & Up-And-Coming Resin 3D Printers

Raise3D DF2 Solution

Just launched late last year with plans to start shipping in Q2 2024, the DF2 Solution (~$6,000) from Raise3D is the company’s first resin printer after having made very popular filament machines for many years. It ‘s a bold move to enter the crowded pro-desktop resin market but, as with everything Raise3D does, it approached resin with the end-user in mind and a focus on usability.

The company’s new DF2 Solution, which is a DLP 3D printer and has a 200 x 112 x 300 mm build volume, is a total “solution” for manufacturers who 3D print all day and are exhausted by the process hassles of tracking parts and loading and cleaning resin bins. Sure the DF2 DLP 3D printer has quality components and the high resolution you’d expect, but the key to this offering is the completeness of the package, which includes a washing unit, a curing unit, software, and material cartridges.

The solution boasts “traceable workflow” features, which include a “smart build plate” that integrates with both post-processing devices and has an embedded RFID tag that records the type of resin being used, in addition to washing and curing settings. This allows various operators to manage the washing and curing phases regardless of their familiarity with the products being produced.

Photocentric Liquid Crystal Titan

In 2023, Photocentric launched the Liquid Crystal Titan, a massive LCD 3D printer, with a huge 700 x 395 x 1,200 mm build volume, 8K resolution, and 32-inch LCD screen. Naturally, you’ll need the company’s equally large washing and curing machines to accommodate the size of these parts.

The company says nine years of LCD 3D printer development arrived at Liquid Crystal Titan. The machine is compatible with daylight resins, has a light output wavelength of 460nm, and comes with 4k time-lapse cameras. Print speed is 86 mm per hour print speed, but at a 350μm layer thickness, volumetric speed jumps to up to 24 liters per hour.

Asiga Max 2 & Ultra

In March 2024, 3D printer maker Asiga launched two new resin printers. The Ultra is what Asiga is calling its most advanced DLP 3D printer yet with quality of life features including touchless entry, a magnetic platform holder and an infrared material hater. There’s also a new print mode designed for transparent parts that prevents over-curing. The Ultra is an open material platform but has a small build area (192 x 108 x 147mm) because it’s intended mostly for dental applications.

Boasting many of the same features as the Ultra, the new smaller (119 × 67 × 75mm) Max 2 is a DLP 3D printer with a 62 micron resolution and a 385 nm or 405nm light engine.

Lead image source: All3DP

License: The text of "The Best Professional & Industrial Resin 3D Printers in 2024" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.