Polypropylene (PP) is everywhere around us because it’s widely available and cheap, making it the second most used plastic in the world after polyethylene. Its processing versatility, outstanding material properties, and recyclability make this polymer a favorite of the manufacturing sector, especially injection molding.

When you 3D print PP it retains all of its sought-after properties and is great for anything that needs to be light, water-tight, and durable. Hinges, for example, represent a very popular use, as PP can repeatedly bend without breaking. Printing with polypropylene is slowly catching up with traditional manufacturing industries, even though it faces unique challenges, some of which we will also offer solutions for toward the end of this article. But first, let’s take a look at the polymer itself.

The Polypropylene You Know

Material Properties

Polypropylene has become a popular choice for manufacturers because of its low cost and many favorable chemical properties with the most important ones listed below.

- Water resistance: Polypropylene is highly impermeable. This property is essential for total immersion applications in medical and industrial products.

- Transmissivity: Under the right circumstances, high transmissivity can be obtained. Aesthetics or transfer of light requires this property.

- Color variability: Adding colors is easy and does not degrade the properties of the plastic (dying process).

- High melting point: Compared to other plastics in the market, polypropylene’s high melting point makes it an excellent option for laboratory and food appliances (containers, kitchen utensils) where high temperatures are required.

- Chemical resistance: The chemical and solvent resistance of semi-crystalline polymers is usually much better than that of competing amorphous materials since their densely packed crystalline structures protect them against dissolution.

- Biological resistance: It does not mold or deteriorate by biological factors, such as bacteria or fungi (in the short term).

- Insulation: Given its high resistance to electricity it is commonly used in electronic components.

- Non-toxicity: According to the Food and Drug Administration, polypropylene is generally considered safe for food and human contact and does not include the controversial additive Bisphenol A (BPA). However, depending on the mixture used, current research suggests that endocrine-disrupting chemicals found in the plastic could still be at risk of leaching into foods and drinks under certain conditions.

- Recyclability: In theory, polypropylene is both chemically and mechanically recyclable. Concerning 3D printing, this study demonstrates that, unlike other common filaments that are susceptible to scission or crosslinking during the recycling process, recycled polypropylene demonstrates excellent material properties due to its high thermal stability.

- High flammability: This material can burn easily, but there are grades that are more flame resistant.

- UV degradation: It’s prone to sunlight damage, degrading the polymer bonds holding it together. Therefore, in its pure form, it is not an ideal choice for long-term outdoor light exposure, yet this can be improved with pigments and other additives.

- Limited high-temperature uses: Though it can handle some heat, it gets too hot for PP after a certain point. This is because it has a high-temperature expansion coefficient.

- Poor resistance to chlorinated solvents and aromatics.

- Poor bonding properties: This makes it challenging to paint and affects its compatibility with certain glues. However, the adhesive strength can be enhanced, which would allow the use of paints and ink.

- Susceptibility to oxidation. Polypropylene is susceptible to thermo-oxidative degradation, which can be remedied to an extent by adding antioxidants to the mixture.

Mechanical Properties

Another critical aspect of polypropylene’s physical attributes regards its behavior under mechanical loads. Here, it also boasts a number of favorable properties that make it attractive as a manufacturing material.

- Tensile strength: Despite being lightweight, the material is capable of withstanding heavy loads.

- Elasticity and toughness: Polypropylene is regarded as a tough material because it can deform without breaking. It’s also very flexible, making it easy to mold in different shapes and ensuring that it can take significant damage before breaking.

- Fatigue resistance: This property is the reason why your shampoo lid is made from polypropylene. It retains its shape after being bent or subjected to torsion. This makes it suitable for living hinges which are usually not achievable with more familiar 3D printing materials like PLA, ABS, or nylon.

The Polypropylene of the Future - Stronger & Sustainable

Research into enhancing the properties of PP for additive manufacturing hint has new products to come. One recent investigation into reinforcing PP with different types of glass, an eco-friendly additive, found that it significantly improved its mechanical properties.

In June, US-based PureCycle Technologies produced its first run of recycled PP pellets made from post-industrial recycled material, such as reclaimed consumer packaging and other discarded products traditionally destined for a landfill. Once fully operational, the company’s facility will produce 107 million pounds Ultra-Pure Recycled PP pellets that are easily colorable and 3D printable.

In April, researchers at the University of Sydney used two strains of fungi to successfully biodegrade polypropylene. The researchers hope their method could one day reduce the vast amount of plastic polluting the environment and lead to a greater understanding of how plastic pollution might biodegrade naturally under certain conditions.

Applications of Polypropylene

Polypropylene is one of the most common polymers you’ll find around the house. It’s excellent for its translucency as well as its resistance to chemicals and fatigue, being both food- and microwave-safe. Moreover, it can be heat-formed, shaped, welded, and even spun into fibers to produce fabric products. Applications relying on the thermoplastic include:

- Automobile parts

- Flexible and rigid packaging

- Fashion and sportswear

- Medical devices

- Housewares

- Household items

Recently, a construction equipment manufacturer needed to solve a problem in the field on existing equipment. A specific area on the truck assembly was allowing high pressure water to enter and affect vehicle performance. Unable to wait 16 weeks for the injection molded solution, the OEM turned to 3D printing service provider Peridot, which used selective laser sintering 3D printing and a polypropylene from BASF to meet the application demands.

The part (pictured above) had to meet outdoor temperature requirements of -29ºC to 49ºC well as ability to withstand direct exposure to high pressure water and vibrations. Several hundred components currently performing well in the field, according to Peridot.

Polypropylene 3D Printers

If you are looking into polypropylene 3D printers, there is a wide variety to choose from since many desktop FDM machines can, at least technically, process the material in filament form. Some manufacturers offer specialized kits like polypropylene print plates to increase the chances of printing success. Industrial machines also process polypropylene as a fine powder. The four top 3D printing methods used to produce polypropylene parts are therefore:

- fused deposition modeling (FDM)

- selective laser sintering (SLS)

- multi jet fusion (MJF)

- high-speed sintering (HSS)

SLS, MJF, and HSS are different versions of powder bed fusion. Each method has its pros and cons regarding cost, speed, and print quality, which we cover below.

3D Printing Polypropylene Filament & Pellets

Merging the versatility of FDM 3D printing with polypropylene’s material characteristics bears great potential. For example, improved patient-specific medical devices like orthoses or insoles can be quickly realized at affordable prices. That’s why printing with polypropylene becomes more and more popular, but specialty or composite mixtures are still few and far between. One exciting development in the sector is the new Caverna PP 3D printable foam material by Infinite Material Solutions. When placed in water after printing, this polypropylene-based filament dissolves some of the deposited material, leaving behind a lightweight and microporous morphology similar to a sponge.

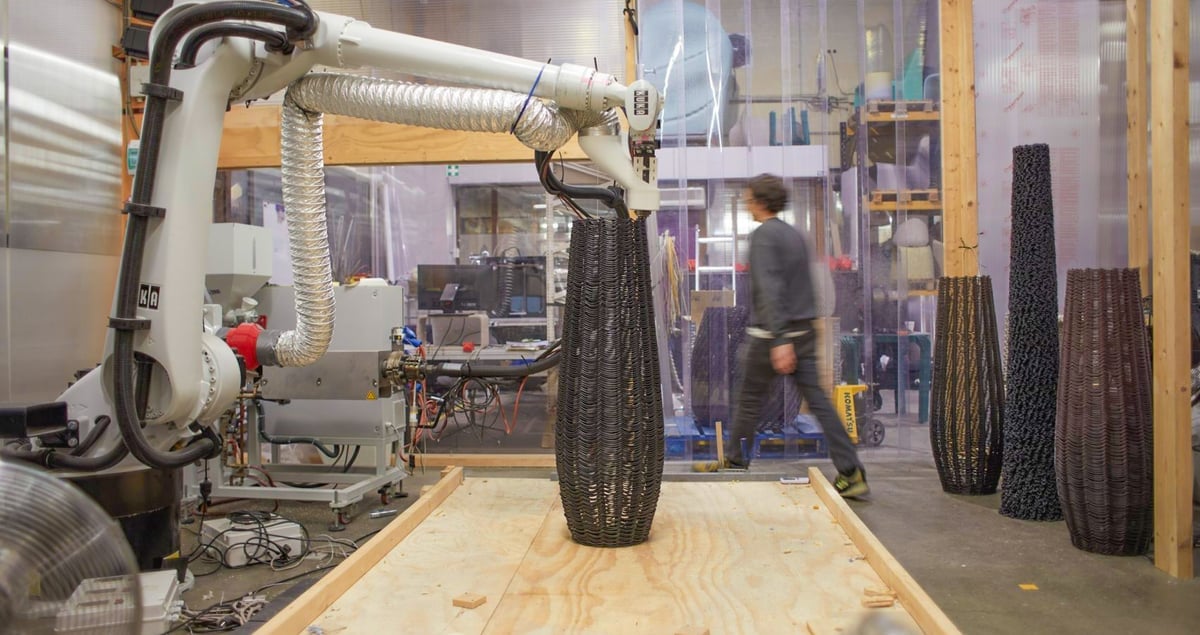

PP filament is widely available in a range of formulations, but the opportunity to 3D print with PP in pellet form is gaining traction as a far more economical alternative for larger projects. In most cases, you can 3D print with the same PP pellets used in the injection molding industry with a pellet 3D printer.

Tip #1: Use Clear Packing Tape

Tape is often used as an adhesive aid on print beds, with Kapton tape and blue painter’s tape being classic choices. Unfortunately, these classic options won’t work well here, as PP doesn’t like sticking to other materials.

Thankfully, PP loves to stick to itself, and most packing tapes are made of polypropylene. Therefore, instead of using the above tapes, try printing onto some clear packing tape. (Make sure it’s made of PP.) You’ll likely see a dramatic improvement in bed adhesion.

Tip #2: Use a Large Brim

Try printing with a large brim or raft to combat polypropylene’s high warping stresses. Both methods increase the surface area of the first layers of your prints, reducing concentrated points of warping stresses and increasing the likelihood of your prints succeeding. After printing, they simply snip or peel off.

With PP, you may have to increase the brim or raft size beyond what you might typically use for other materials. Generally, the two can be used interchangeably, though you may find yourself preferring one over another.

Tip #3: Turn Up the Heat

Another way to mitigate warping is to turn up the bed temperature. This will prevent the PP from cooling down too much, thus reducing the amount of contraction. By keeping contraction down, you can reduce the warping stresses that are generated.

A good place to start is your printer or filament manufacturer’s default settings for PP, if available. Otherwise, start at 85 °C and turn up the bed temperature 5 °C at a time until you find an optimal temperature. The sweet spot should be somewhere between 85 °C and 100 °C.

Enclosing your 3D printer to keep in additional heat and prevent temperature fluctuations may also be beneficial, though certainly not required. If your printer doesn’t have one, we have some tips for making your own enclosure.

Powder Bed Fusion Polypropylene

Powder bed fusion encompasses any technology that fuses layers of powder feedstock together. This is done either by directly melting them with a laser or selectively bonding them with an energy absorber that is jetted from nozzles and subsequently heated up to melt the powder.

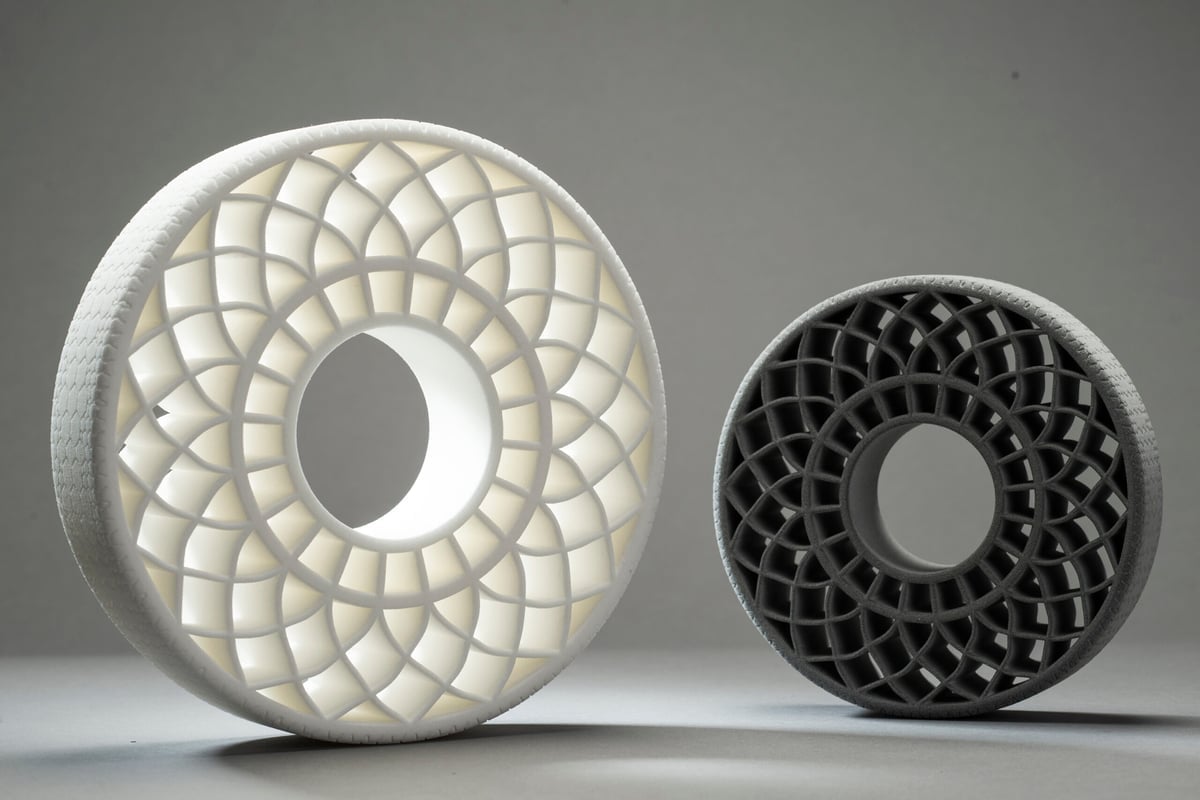

Polypropylene powder is currently available for selective laser sintering (SLS), multi jet fusion (MJF), and high-speed sintering (HSS). In all three cases a fine powder of polypropylene, created from resins via Dissolution-Precipitation Method or Cryogenic Milling, is molten layer by layer into the desired shape, leaving behind the technologies’ characteristic grainy surface. However, varying material compositions and parameters often mean these powders are restricted to a specific technology or machine.

Process-specific advantages of PP include its very high powder refresh rate and comparatively low melting temperature, which would reduce the cost of expensive lasers in SLS. Similar to FDM however, warpage is a significant concern that not only affects dimensional accuracy but may also lead to print crashes, making polypropylene a particularly difficult PBF material to work with.

Order Polypropylene 3D Printed Parts

If you’re just getting started with polypropylene 3D printing, ordering a few parts from a third-party 3D printing service is a great way to evaluate if the material fulfills your requirements.

Services, such as Craftcloud by All3DP, offer several types of materials in all the relevant technologies so you can compare. For example, upload the digital file of your factory fixture to a service provider, select one printed in polypropylene using FDM and another printed in SLS with glass-filled polypropylene, then put both to the test.

3D Print Services That Offer Polypropylene

The Environmental Impact of Polypropylene

As a last remark, polypropylene is made of oil, a finite resource with a tremendous impact on the environment both as an energy source and as a refinery product in the petrochemical industry. Polypropylene is not biodegradable and its decomposition in landfills takes anywhere between 20 and 450 years as the process depends heavily on outside environmental conditions.

On top of that, polypropylene is often used for single-use items like water bottles which are notorious polluters of the environment where they gradually break down into microplastics. To avoid these issues, polypropylene can be recycled. However, not all recycling is equal and brings with it its own set of problems.

Polypropylene Recycling

Polypropylene has the resin recycling code 5 and theoretically offers good chemical and mechanical recyclability relative to other plastics on that list, meaning products made from recycled PP have excellent mechanical qualities. Chemical or solvent-based recycling of polypropylene is known as the Dissolution / Reprecipitation Technique and yields more homogonous recyclate due to the improved capability to remove contaminants. On the downside, this technique is quite energy-intensive, resulting in higher costs and making it difficult for the recyclate to compete with the low price point of virgin material.

The bottom line when it comes to polypropylene is that even though it shows good recyclability on paper, only about 1% to 4% is currently recycled. The vast majority either ends up in the environment, landfills, or “thermal recovery”, which means burned for energy generation, releasing the bound-up carbon dioxide into the atmosphere. Therefore, the priority when it comes to using polypropylene, or any polymer for that matter, is to think before you 3D print and always keep the waste hierarchy (reduce, reuse, recycle) in mind to avoid unnecessary waste.

Lead image source: Lead image credits: HP, PPprint, Materialise, 3DFilaPrint, Fillamentum

License: The text of "Polypropylene (PP) 3D Printing – The Ultimate Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.