Metal laser cutters are a staple of machine shops and manufacturing worldwide, but newer, more compact, laser cutters are also found in smaller metalworking businesses, architecture firms, and even hobbyist garages for anyone who might need to cut multiple metal sheets, pipes, and rods, in materials from stainless steel to aluminum.

To pick the best metal laser cutter for your job, you’ll need to know a bit about the types of laser these machines feature and which metals they cut. Here, we’ll also give you tips and best practices for laser cutting metal along with the best machines on the market today at a range of price points.

Although metal laser cutters can cut other materials, the reverse is not often true, with the exception of some thin aluminum. So if you’re looking for a laser cutter for woods, plastics, papers, or other materials, check out our other guide below.

While we’re at it, let’s also differentiate between cutting metal and engraving on it. To engrave metal, you need far less powerful lasers and, typically, less expensive machines. Fortunately, we also have a guide for laser engraving metal below.

So now, let’s take a look at today’s medium-power metal laser cutting machines used with a variety of metals no thicker than 10 mm.

Know Your Lasers: CO2 vs Fiber?

Purists may say you must have a fiber laser to cut metal, but that’s not strictly true.

Yes, fiber lasers cut metal faster, the beam is smaller so it’s more precise, and it uses less electricity. Fiber lasers are also easier to work with and cheaper to maintain in the long run. However, fiber lasers are typically twice the price of CO2 lasers, and they can’t cut as wide a variety of materials.

Let’s look at the differences a little closer.

A CO₂ laser is generated by sending an electrical current through a glass tube filled with CO₂ and other gases. At the end of this airtight glass tube are two mirrors, and the electricity flowing through the tube aggravates the gases, causing them to produce light. The light bounces around some cleverly placed mirrors within the laser cutter before being focused by a lens and exiting the device, hitting the surface of the material you’re working with.

CO₂ lasers might be cheaper, but they will always require using oxygen or nitrogen as a gas assist and will be limited to cutting less-reflective metals. CO₂ lasers are also sensitive machines. With their combination of mirrors and glass tubing, they are quite fragile and need aligning perfectly to function at their best. This results in more expensive upkeep and servicing costs in terms of both time and money. Still, this is balanced by their affordability to begin with.

Fiber lasers are a newer technology in the laser cutting world. On an industrial level, they’re often deployed to cut thin sheets of metal for production components. In desktop form, they’re still expensive machines, but they do have a number of benefits including electrical efficiency and fewer moving parts.

In a fiber laser, the laser itself is generated from an optical fiber with rare-earth elements (such as erbium, ytterbium, or neodymium) added. Fiber lasers cut without a support gas. Lasers produced in this method are very stable and easy to focus.

There are other types of laser cutter out there, but for the purposes of this buyer’s guide, we’re going to focus on the two most common ones – CO₂ and Fiber.

Metal Materials for Cutting

Cutting materials like cardboard, acrylic, and wood is easily done with entry-level CO₂ cutters. This is because these materials easily burn and absorb light. On the other hand, metal is reflective and heat conductive, which means a laser has to expose a smaller area to more intense light in order to cut through.

Different metals have different properties that affect how they can be cut. High-powered CO₂ lasers can cut metals, such as steel and stainless steel, but can have difficulty with aluminum and brass because of its reflective qualities. Fiber lasers are common for cutting tasks with copper and aluminum.

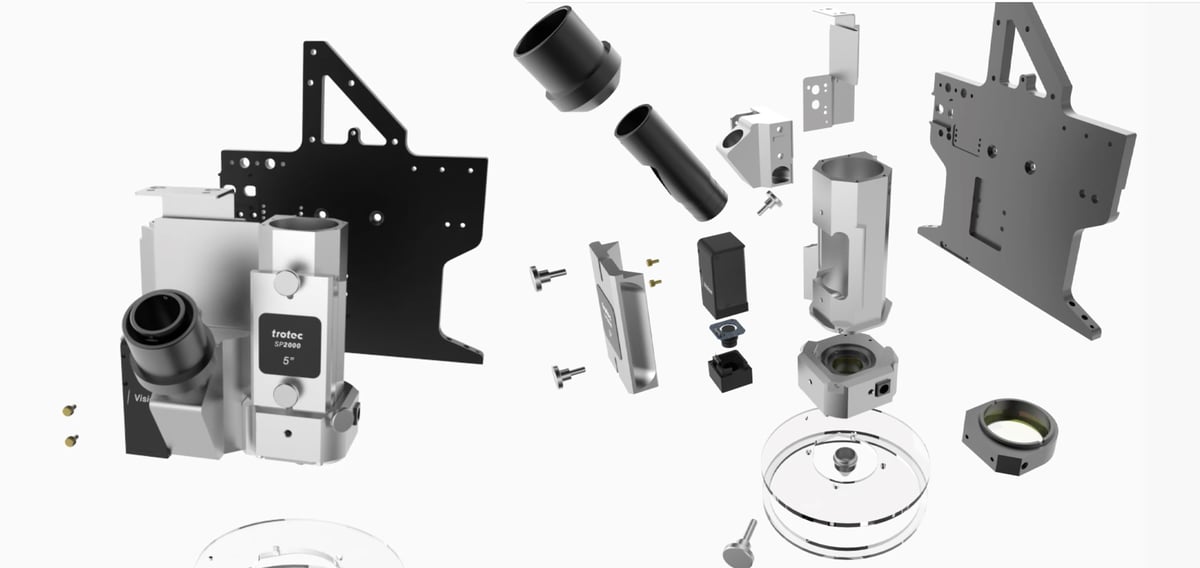

Parts of a Metal Laser Cutter

To make the best metal laser cutter purchasing decision and to get to the most our of your machine, you’ll want to understand about about how they work and how you should work with them.

The basic parts of laser metal cutting machines:

- frame or full enclosure

- laser power supply (built-in or independent)

- laser generator

- reflector path

- laser cutting head

- water chiller (if water cooled)

- the control panel

- CNC system

In order to get the best results, there are a few simple things that can help the laser cutting process go easier or faster. When using either a CO₂ or fiber laser cutter, researching how they work with different materials is key to a successful project. Once the right material is paired with the proper laser cutter and laser power, use these simple tips to get started:

- Elevate the material. When cutting materials with a laser, it’s best to have the least amount of surface area touching the work platform. Using a platform raised on spikes or a honeycombed work surface is suggested. Having a raised platform means less heat is dissipated through the machine, and less molten material will fall onto it.

- Conduct tests. Doing a test run with your software can save a lot of future hassle. Having the laser cutter run through the program without the laser running shows any mistakes that may happen and saves time and material. Doing a small test run on scrap material with the laser running allows you to learn the focus point, and how much power and speed is needed to cut through new materials.

- Separate gas from the laser. When using a CO2 laser cutter with oxygen gas assist, keep the tank as far from the machine as possible for safety. Do the same with fiber lasers that may use oxygen or nitrogen. Keeping the gas tanks in a separate, flame-proof container is often safest.

- Make good cuts. When designing, make sure that any parts to be cut are completely cut out from the stock material. This helps with post-processing and makes sure there are no cut or bend marks from trying to get a piece out.

Picking the Right Machine

Purchasing a metal laser cutter is often done through a distributor rather than directly with the manufacturer, although you can often find a list of distributors on the manufacturer’s site.

Top Metal Laser Cutting Machines

These top metal laser cutting machine manufacturers all offer a range of products from entry-level to industrial.

Cutting & Post-Processing

Once you have the proper machine and take the necessary precautions, cutting metal isn’t really that different from cutting wood or MDF (medium density fiberboard). The laser cutter emits a beam that melts or vaporizes the material, using a gas assist that either helps to heat the material and blow away debris or just expels debris.

The important difference to understand is that metal is reflective, and some lasers, including most CO₂ lasers, can’t handle the laser being reflected back into the laser emitter. That’s why CO₂ lasers in the 150- to 300-watt range primarily work on different types of steels that aren’t too reflective. Fiber lasers work on a different principle that allows them to be several times more powerful than CO₂ lasers, with nearly none of the drawbacks.

As with other lasers and materials, finding the correct focus point, power, and speed through testing is the path to successful metal laser cutting. One guideline to keep in mind is to only cut low-reflective metals like steel with a CO₂ laser. Fiber lasers can cut through most metals, but finding the correct pulse and amount of power to use for different materials is important.

After the metal has been cut, there are a few processing techniques you can use to give the material a cleaner finish. The cut edges can be sharp, so using a deburring tool or sanding down the edges is often a good idea. Depending on what metal you’re working with, you can also add a finish to the piece. This includes polishing, acid etching, painting, hydro dipping and more, all of which can add some extra character to your project.

Always check through your machine at the end of every project to make sure that any mirrors, lenses, pump systems, modules, and axis components are in good working order. Neglect will eventually lead to failure, so maintaining a well-tuned machine will keep it working for the next project.

Staying Safe

While there are a few different types of laser cutters available, in this article, we’ll be focusing on CO₂ and fiber laser cutters. These two types are very different from one another, but both of them can be very dangerous if misused.

CO₂ LASERS

In order to cut metal, these machines must have a minimum rating of 150 W and use oxygen assist. Without the proper safety precautions, the laser alone can cause lacerations, burns, and immediate blindness. Because of the oxygen assist, there’s also the possibility of combustion or explosion if the gas tank is treated improperly. Always make sure any flammable gas is used and stored safely.

FIBER LASERS

Fiber lasers are several times more powerful than CO₂ lasers. This means that, like CO₂ lasers, they can cause burns and blindness, but even indirect exposure to the laser can also cause harm. Be sure to wear the proper safety equipment and use the appropriate laser enclosures.

Some important things to have on hand when working with these lasers are properly-rated safety glasses for the laser’s frequency. Wearing gloves is also recommended when you’re adjusting components in the machine to avoid leaving oils or other residues.

Having a well-ventilated area is vital since the lasers can potentially emit noxious or even toxic fumes. And always be sure to have an ABC-rated fire extinguisher that can handle trash, liquid, and electrical fires.

Design Tips

Whether you are an engineer, an entrepreneur, or a hobbyist, laser cutting enables you to be creative and even artistic as long as you follow some basic design rules.

1. Closed contours

All cutting contours have to be closed, period. This is the most important rule, and most logical. If a contour remains open, it will be impossible to remove the part from the raw sheet metal. The only exception to this rule is if lines are meant for engraving or etching.

2. Line colors and thicknesses

This rule is different with each online service. You should check the required color and line thickness for cutting. Some services offer laser etching or engraving in addition to cutting and may use different line colors for cutting and etching. For example, red lines could be for cutting, while blue lines might be for etching.

Some services don’t care about line colors or thicknesses. Check this with your chosen service before uploading your files.

3. Round holes

If you need holes with tight tolerances, it’s wise to pierce with a laser and later drill holes with a drill bit. Piercing is making a small hole in the material, which will later guide a drill bit during drilling. A pierced hole should be around 2–3 mm in diameter, but it depends on the finished hole diameter and material thickness. As a rule of thumb, in this situation, go with the smallest possible hole (if possible, keep it as large as the material thickness) and gradually drill bigger and bigger holes until you reach the desired diameter.

4. Threaded holes

This makes sense only for material thicknesses of at least 1.5 mm. Steel, for example, melts and evaporates when it’s laser cut. After cooling down, the cut hardens and is very hard to thread. For this reason, it’s a good practice to pierce with a laser and perform some drilling, as explained in the previous tip, before thread cutting.

5. Corner fillets

Sheet metal parts may have sharp corners, but adding fillets on every corner — of at least half the material thickness — will make parts more cost-effective. Even you don’t add them, some laser cutting services will add small fillets on every corner. If you need sharp corners, you should mark them as described in the service’s guidelines.

6. Notches and tabs

The minimum width of a notch must be at least 1 mm or the material’s thickness, whichever is greater. The length should be no more than five times its width. Tabs have to be at least 3 mm thick or two times the material’s thickness, whichever is greater. As with notches, the length should be less than five times the width.

The distance between notches must be at least 3 mm, while the tabs must have a minimum distance from each other of 1 mm or the material thickness, whichever is greater.

Failing to follow this rule may result in a deformed part.

7. Multiple parts or thin features

When cutting multiple parts on the same sheet of metal, a good rule of thumb is to leave a distance of at least the material’s thickness between them. If you put parts too close to each other or cut very thin features, you risk burning away material between two cutting lines.

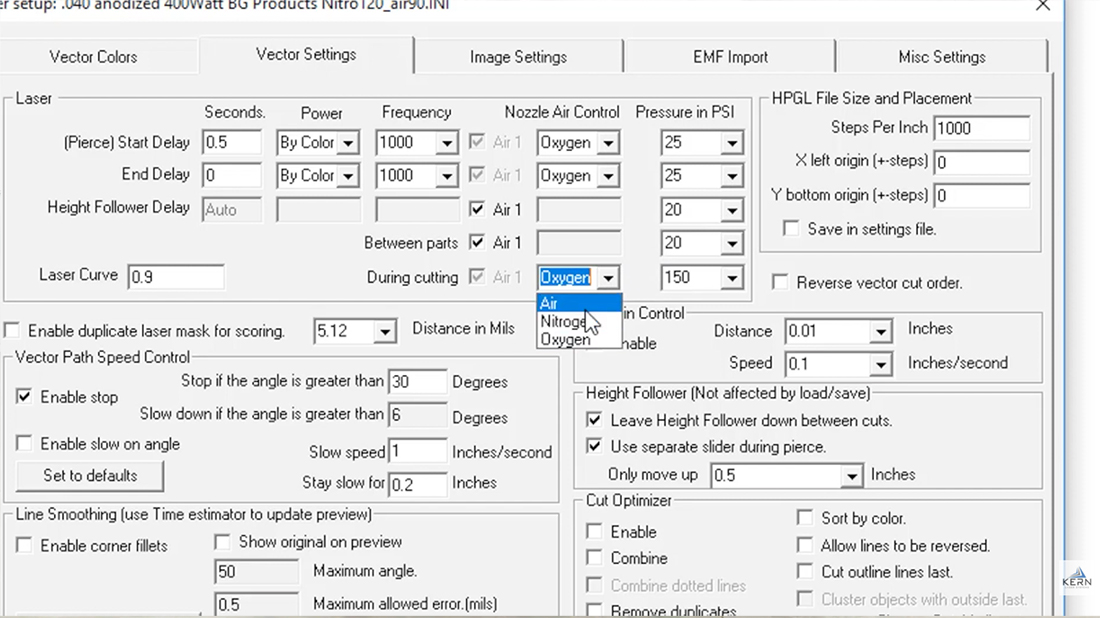

Software

Laser cutting software comes in two different flavors – design and control. Design software is the tool in which you design what it is you actually want to laser cut. Control software handles the machine and the commands it needs to get on with the job.

With some machines, the software will be provided for you. This is the case with Full Spectrum Laser, which provides a piece of browser-based control software called RetinaEngrave v3.0 with its machine. This software was developed by the company itself, so it ought to work pretty flawlessly with its own machines.

Some machines will require you to source (and pay for) your own laser software. You do have the option of using free ones, such as the popular LaserGRBL control software, but many users believe that paying for quality software is crucial in obtaining good results from your laser cutter. It’s a cost to factor into your purchasing budget.

Metal Laser Cutting On-Demand Services

Laser cutters that can cut metal are expensive, and not everyone has the time or means to work with one. Luckily, there are other ways to get metal cut that are very affordable. There are lots of services that will do it for you, and often all you need to do is upload your CAD files onto the platform for an instant price, submit a design, pay for materials and shipping, and wait!

Here are some great places to look into:

- Protolabs ships world wide and boasts custom sheet metal parts and assemblies in as fast as one day.

- Fractory offers a wide range of metal laser cutting, bending, and manufacturing.

- Xometry ships worldwide and works with materials like aluminum, copper, steel, and stainless steel. As well as laser cutting, they offer services in 3D printing, CNC machining, water jetting, plasma cutting, and casting.

- Pololu ships worldwide and laser cuts stainless steel and spring steel up to 1.5 mm.

- Lasergist ships worldwide for free and works with different types of stainless steel. They’re great for engraving, sandblasting, and polishing.

- eMachineShop ships worldwide and works with aluminum, steel, spring steel, and stainless steel. They provide all the same services as Xometry but also offer turret punching, injection molding, sheet-metal bending, and more.

Another option to consider is businesses in your local area. They will often be cheaper than the major international services but will likely focus on one machining process rather than several different ones.

Whether you’re looking to invest in your own machine or use a metal-cutting service, hopefully you now have a better understanding of what’s possible!

Lead image source: Trumpf Laser Cutters

License: The text of "Metal Laser Cutters – The Ultimate Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.