Creality promises speed with the Ender 7. Not the drive-slower-than-50mph-or-this-bus-will-explode kind of speed. Nor the out-of-control cruise ship variety. Just quality prints, fast. A simple promise that sounds easy to deliver? Right?

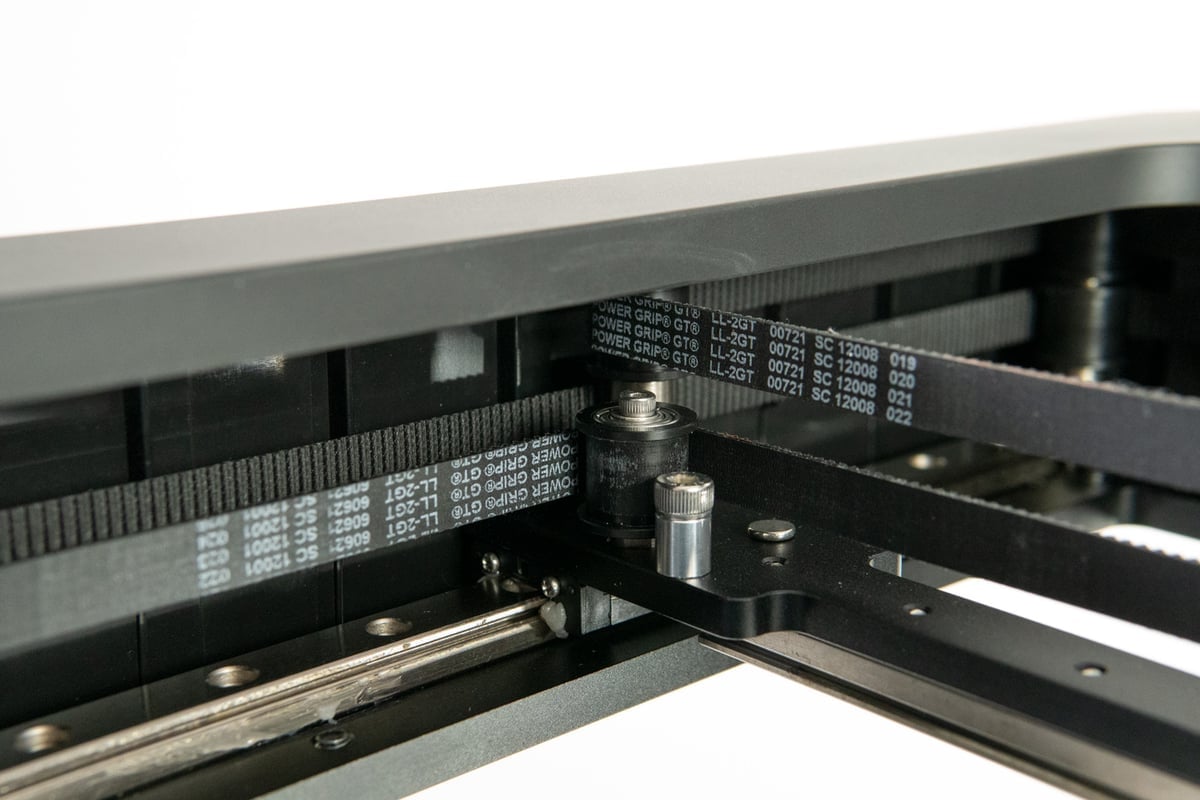

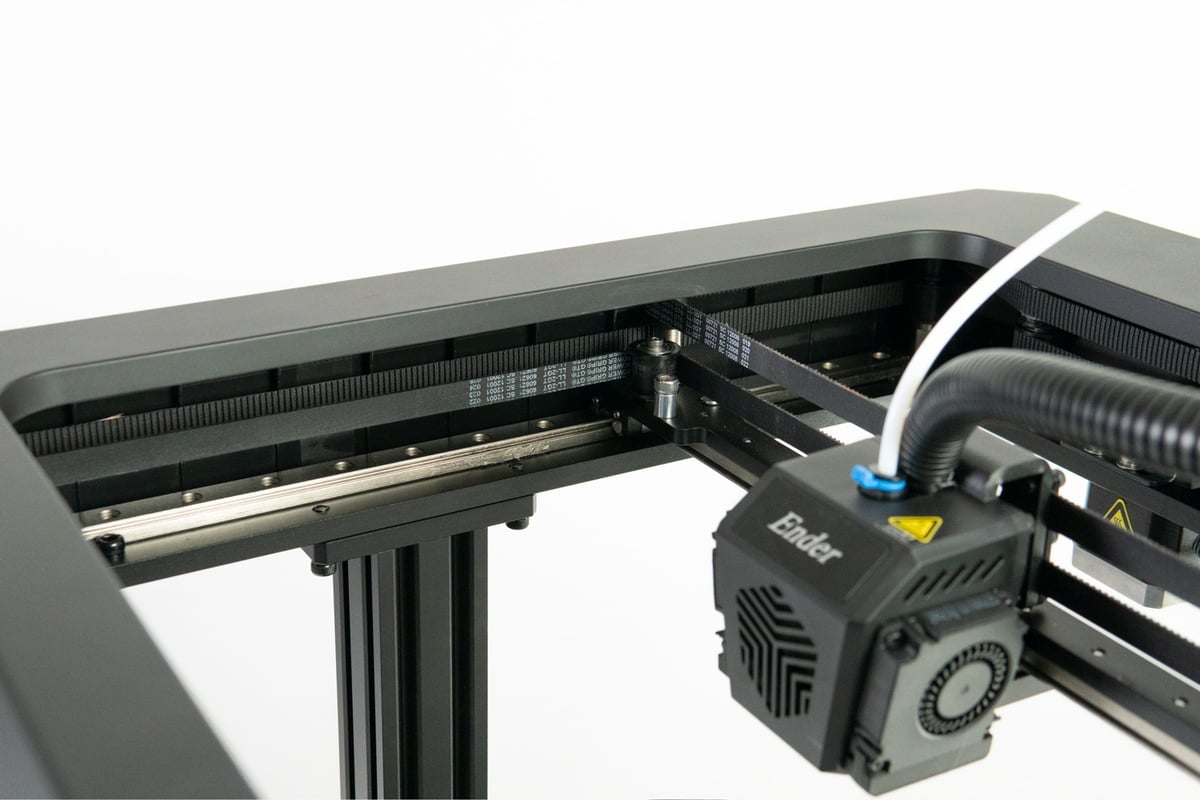

Before we get to that though, let’s whistle through the Ender 7’s vitals. It has, like the Ender 6 before it, CoreXY kinematics, meaning a complex belt-driven system for the printer’s movements in the X- and Y- axes, plus a textured glass print bed traveling along the Z-axis.

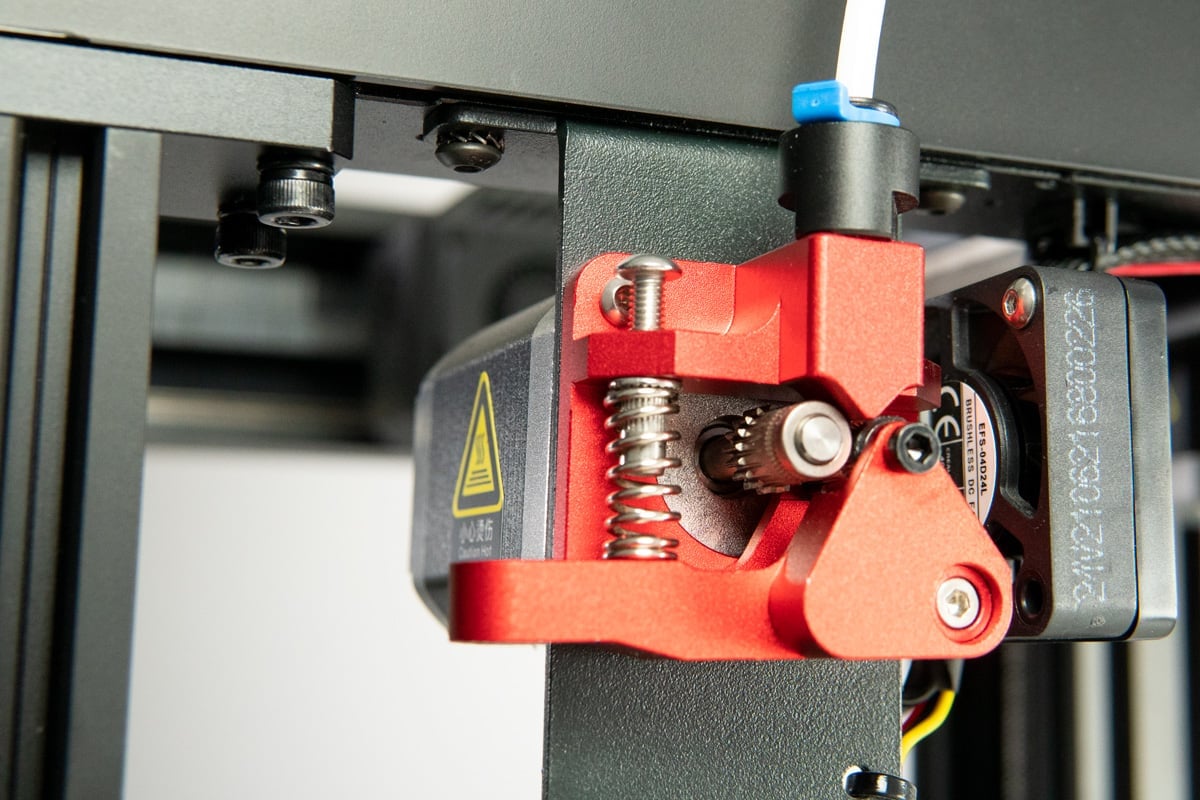

The filament is pushed by Creality’s dual-geared direct extruder and melted in a hot end with custom Creality elongated nozzles. You’ve got 250 x 250 x 300 mm of build volume to work with, and Creality Slicer (one of the lighter – and therefore better – Cura reskins) to slice your models. That is, basically, it.

The Ender 7 promises a lot, and some might see it as the printer to jump up to from the Creality’s smaller bed-slinging printers such as the Ender 3. But, at $729 – close to double the cost of the Creality’s auto-leveling CR-6 SE (or almost triple the Ender 3 V2, for that matter,) it’s not. Read on for the why.

Verdict

Pros

- Decent print quality out of the box

- Straightforward to setup and use

- Saves time on larger prints

Cons

- Expensive

- Using full print volume crashes print head

- Loud

- Rarely prints at the advertised 250 mm/s

- Default high speeds tricky to dial in for materials other than PLA

Perhaps it was the flashy video bigging up 250 mm/s and the promise of blistering fast printing, but we’re left feeling a little underwhelmed by the Creality Ender 7. Sure, it can print faster than many similar desktop 3D printers in some circumstances without completely giving up on print quality – that’s good – but for over $700 of 3D printer, it doesn’t seem like there’s all that much here. There’s pricier hardware like linear rails, beefier stepper motors with microstepping drivers, and Gates timing belts to accommodate the CoreXY motion system, but ultimately the Ender 7 is a printer of similar caliber to the company’s previous machines – not necessarily better. It can print faster than others, yes, but not necessarily at the same level of quality – the machine doesn’t quite live up to the marketing.

The Tech

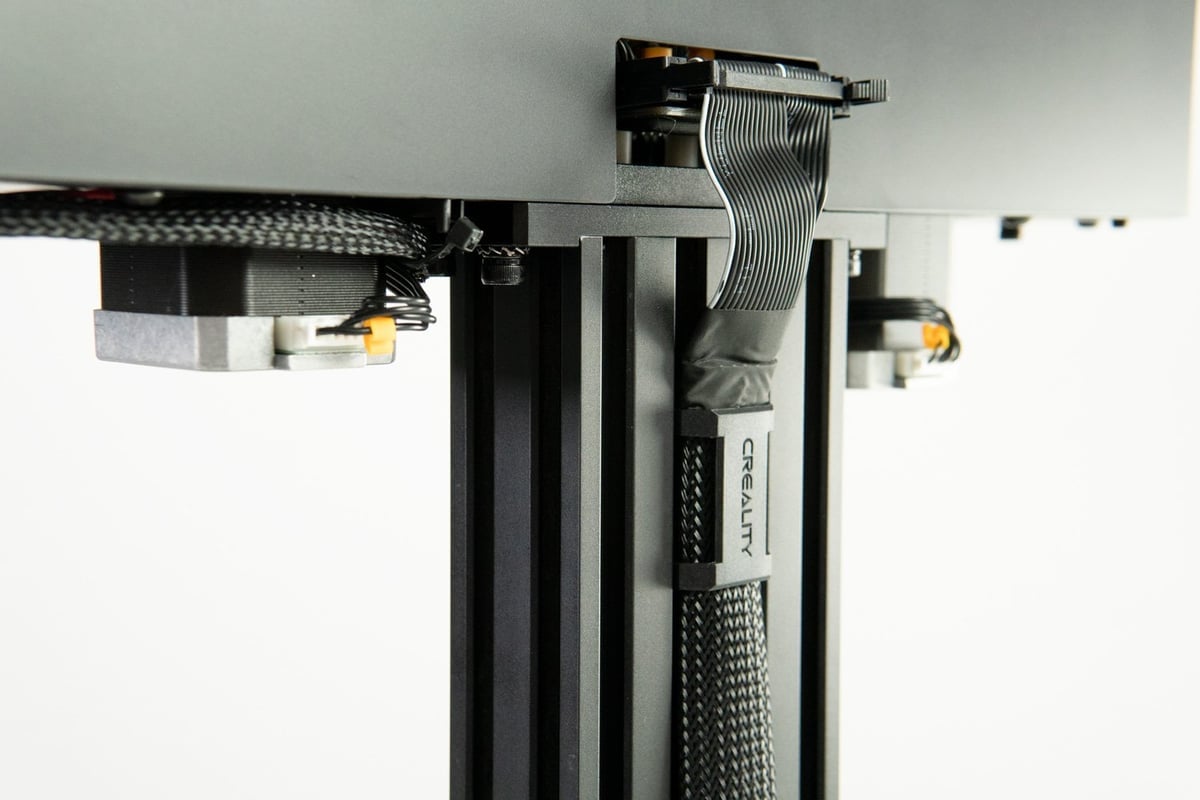

For what you might consider a typical printer, the Ender 7 has a pretty atypical design. Composed of two main units connected by three aluminum extrusion “legs”, it has a distinctly “alternate” look compared to the cubic shapes of many of Creality’s past and present machines. Also, by nature of its design and use of preassembled blocks, it ships in a relatively flat box.

The Supporting Act

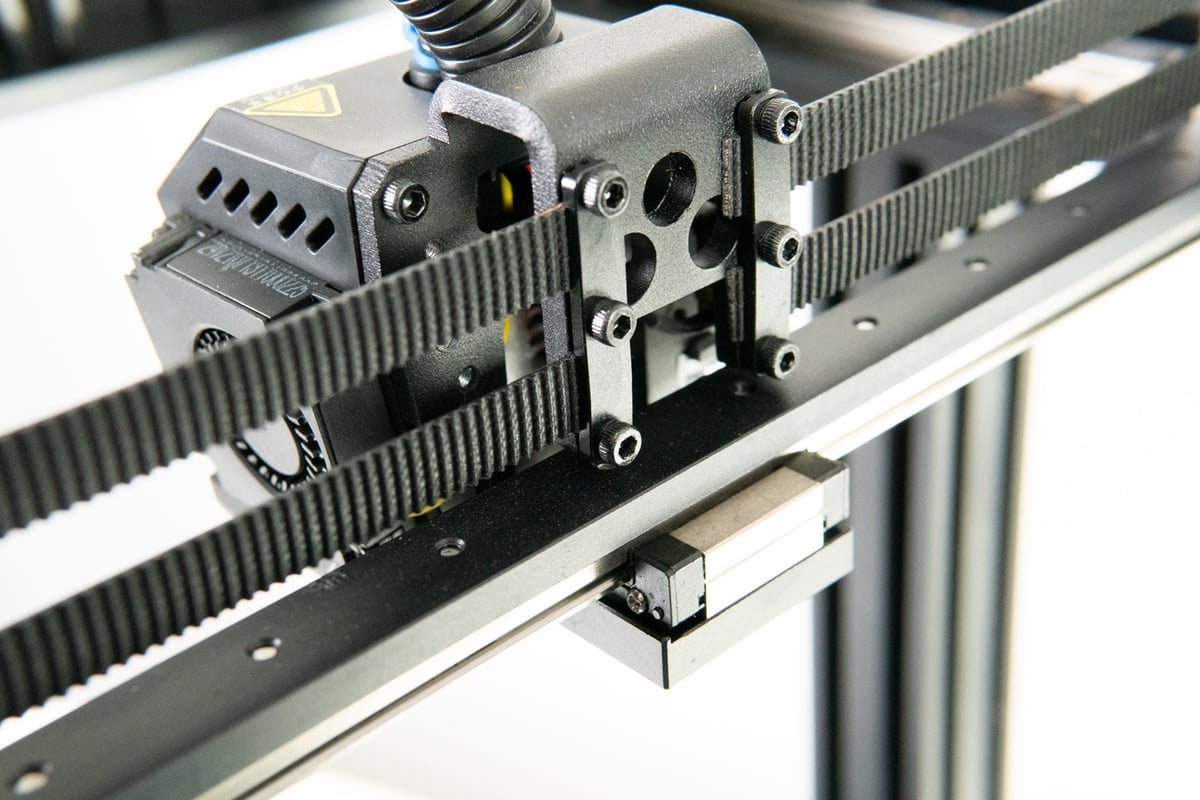

So, what is there to make you care about the Ender 7? Besides Creality’s claim to speeeeed with the Ender 7, we struggle to see much in it. It is the stereotypical Ender 3D printer: 250 x 250 x 300 mm build volume, Bowden extruder, silent stepper motor drivers, 32-bit board. The print bed and hot end reach 100 ℃ and 260 ℃ respectively, limiting you to “everyday” filaments such as PLA, ABS, PETG, and firmer TPUs. The filament is fed by a powerful dual-geared extruder. (We’ve seen this referred to as an upgraded MK8 extruder – useful to know should you need spares.) Biting into the filament from two sides, this extruder seems powerful and only came up short on some large, fast prints running at the cooler end of the material’s temperature range.

If you try to print the full 250 x 250 mm build area, the print head will crash over the metal bed clips and the print’s nozzle-priming purge line – if you want to avoid the risk of damaging the printer or first layer you’ll have to print smaller than the stated volume.

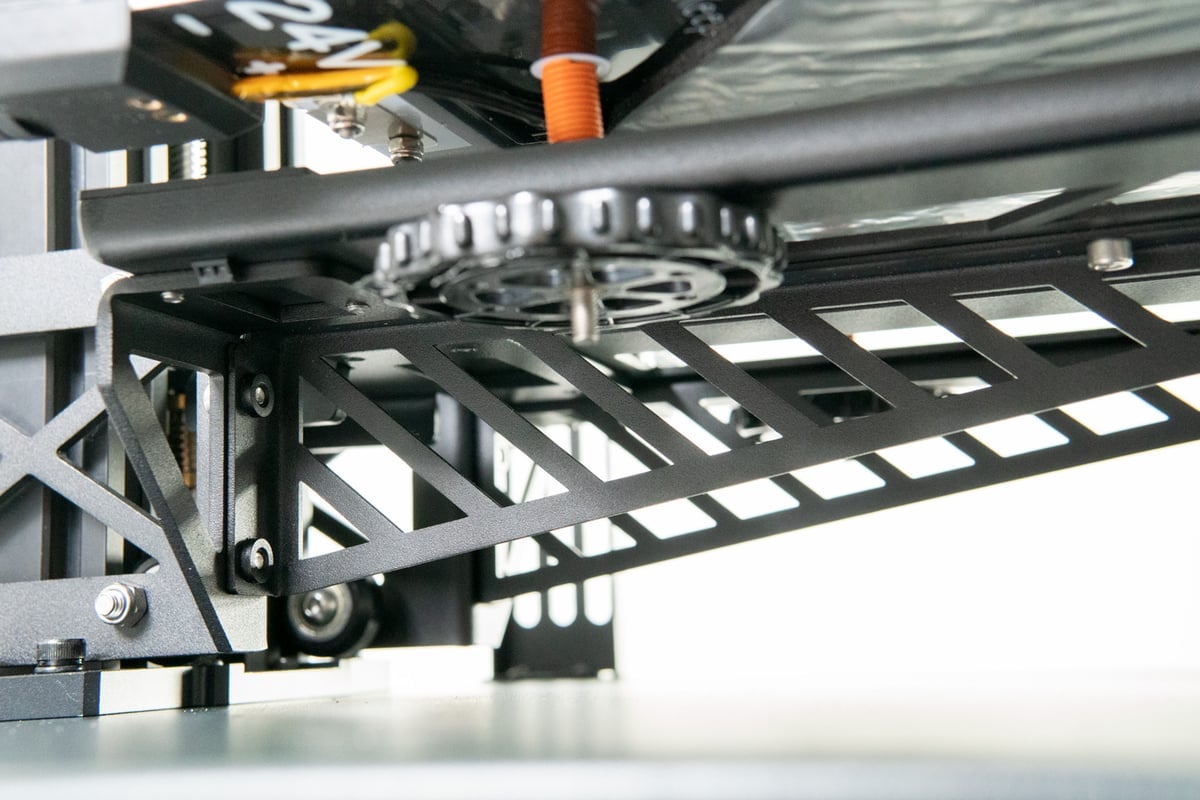

Bed leveling is handled manually via the expected four oversized bed leveling wheels. Depending on how high you place the printer, this may be tricky – the Ender 7 is quite tall – some 560 mm, not including the print head cabling and Bowden tube looming over the printer. For comparison’s sake, it occupies a similar footprint to the Ender 3 Max, which is way slower but much cheaper and has a much larger build volume.

As far as bed leveling goes, the Ender 7 is basic but functional. Get it dialed in, and you don’t really need to touch it again; through the course of our testing, we found no need to remove the glass bed for print removals – only minor universal adjustments to the Z-offset were necessary for good first layers from filament to filament.

The print bed is a glass slab with the print facing side surfaced with a print-gripping texture. On other Creality machines, this texture is smooth, with a regular pattern. For the Ender 7, though, it’s a fine, rough texture. It feels like a chalkboard, even down to the skin-crawling effect it has on some people when they touch it.

We must confess our disappointment at the lack of a tool drawer on the Ender 7. Just as we strike up a thing of putting food in them for cheap laughs, they take it away. Boo, Creality. Boo.

Out Come the Roadies

Setting the Ender 7 up is a matter of a handful of screws, connecting the base unit – containing the display, brains, and I/O of the printer – to its three “legs” to the top unit, which houses the business end of the CoreXY motion system, extruder, print head, and various cabling.

As is common with such printers, the Ender 7 has the tools – mainly hex keys – required to assemble it. While good enough to get the thing assembled, they weren’t ideal for the tight spaces in which the Ender 7’s assembly asks you to operate. A screwdriver- or ball-end-style key would’ve been much better – a minor complaint.

As far as electronics are concerned, you have one cable to snap in place. It’s pretty much foolproof. Do note that the Ender 7 uses a variable power supply though, and make sure you have it set to the appropriate voltage. This is found on the right-hand side of the machine.

Headliners

And so we reach the headline act. The reason anyone would bother coming to this flashy show; CoreXY and speeeeeeed. CoreXY kinematics have a reputation for allowing bum-clenchingly quick print speeds without a drop in quality or accuracy.

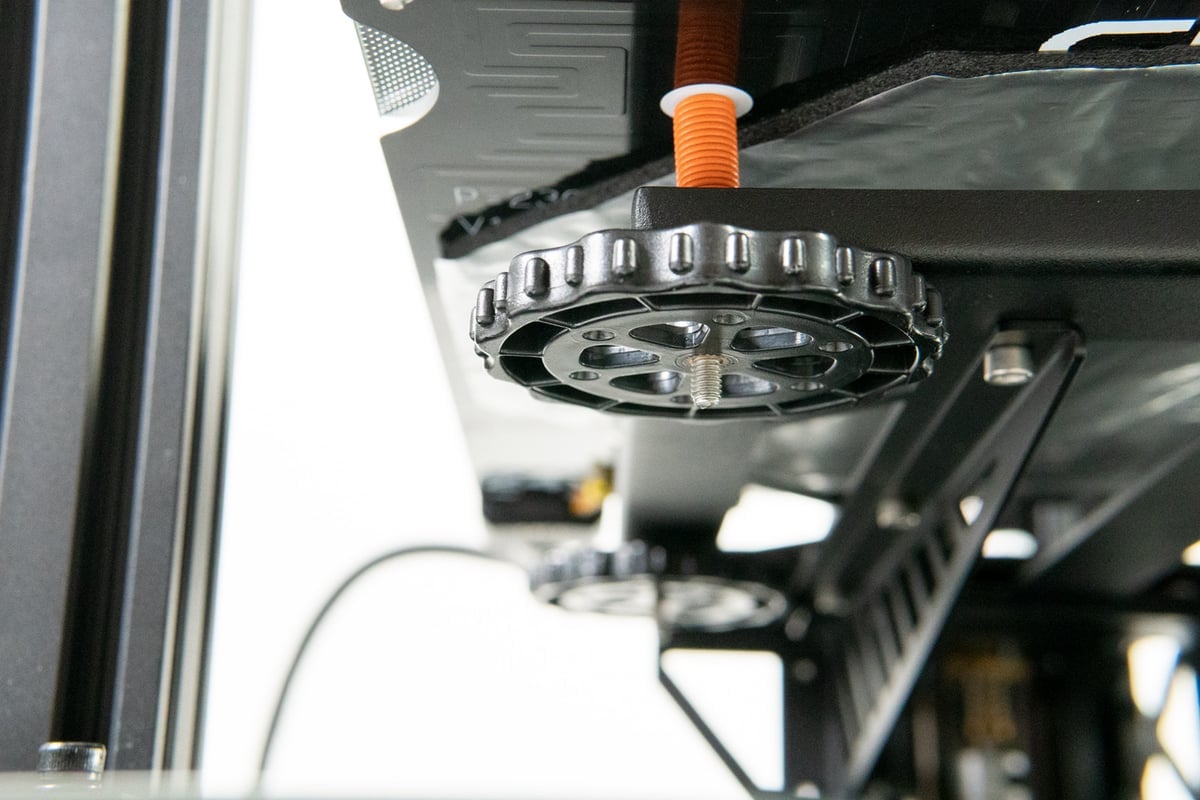

For a closer look at the whats and wherewithals of CoreXY, check out our full guide to the system. In a nutshell, CoreXY utilizes two stepper motors in tandem to position the print head in the X- and Y- axes. These stepper motors are fixed in place, away from the print head, contributing little resonance and, more crucially, no mass whatsoever to the print head’s movements. Less mass means less inertia to overcome, which means higher speeds without taxing the structural rigidity of your system. Higher speeds; upkeep in quality. Or so the theory goes.

CoreXY 3D printers are pretty complex to wrap the mind around, and until recent times have been the reserve of smart hobbyists pursuing printing perfection. (Or companies with professional customers willing to pay for the tech.) Nowadays, there are budget CoreXY options from many manufacturers.

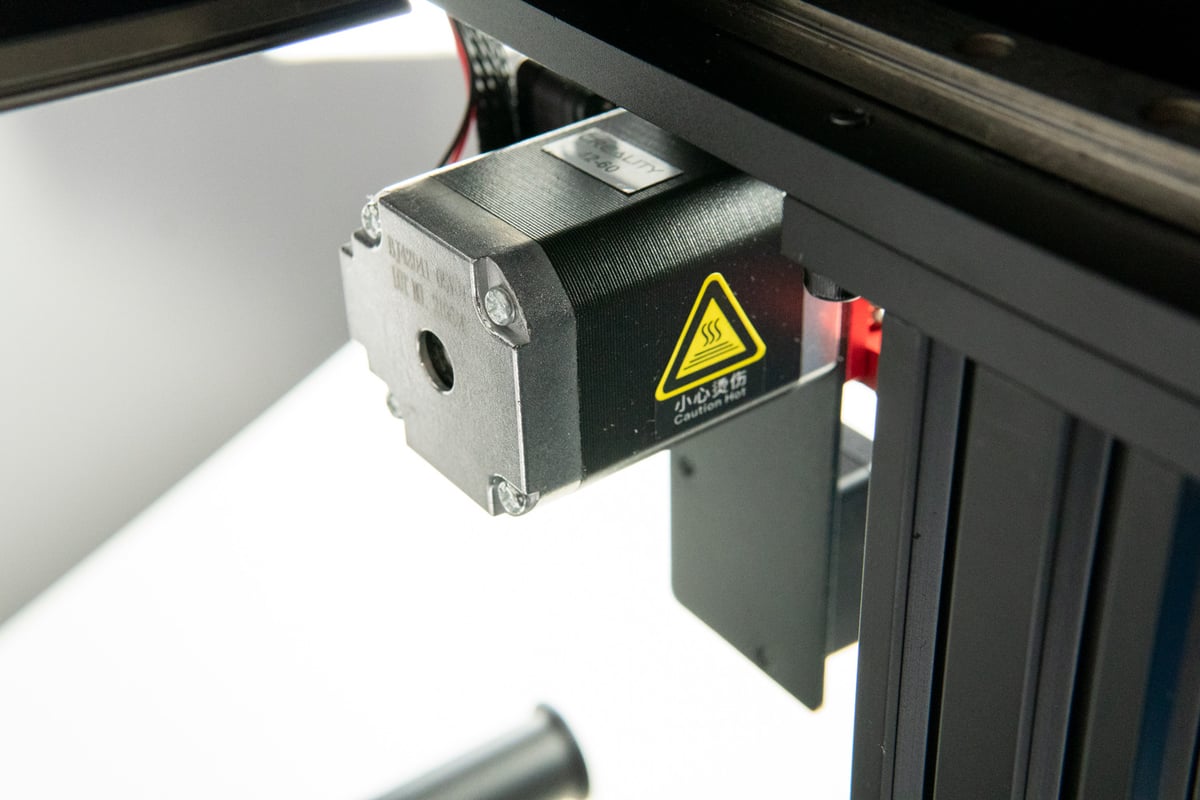

Creality has the Ender 6 and 3DPrintMill rocking CoreXY, and now the Ender 7. While we see thick gauge Gates belts and strong 42-60 stepper motors doing the heavy lifting of hurling the print head gantry and its linear rails (good), the result is loud and hot. We’re not suggesting the Ender 7 runs problematically hot, but the stepper motors do end up at a painful-to-the-touch level of heat. There’s a laborious quality to the Ender 7 in operation. It’s not subtle.

And also, goodness, is it loud. Not in the way the original Ender 3 whines – the chorus of printing days past – but just a pitchless din. We liken it to a plane idling on the runway. Constant noise. It is not quiet, and yes, you might get annoyed by it.

But Is it Fast!?

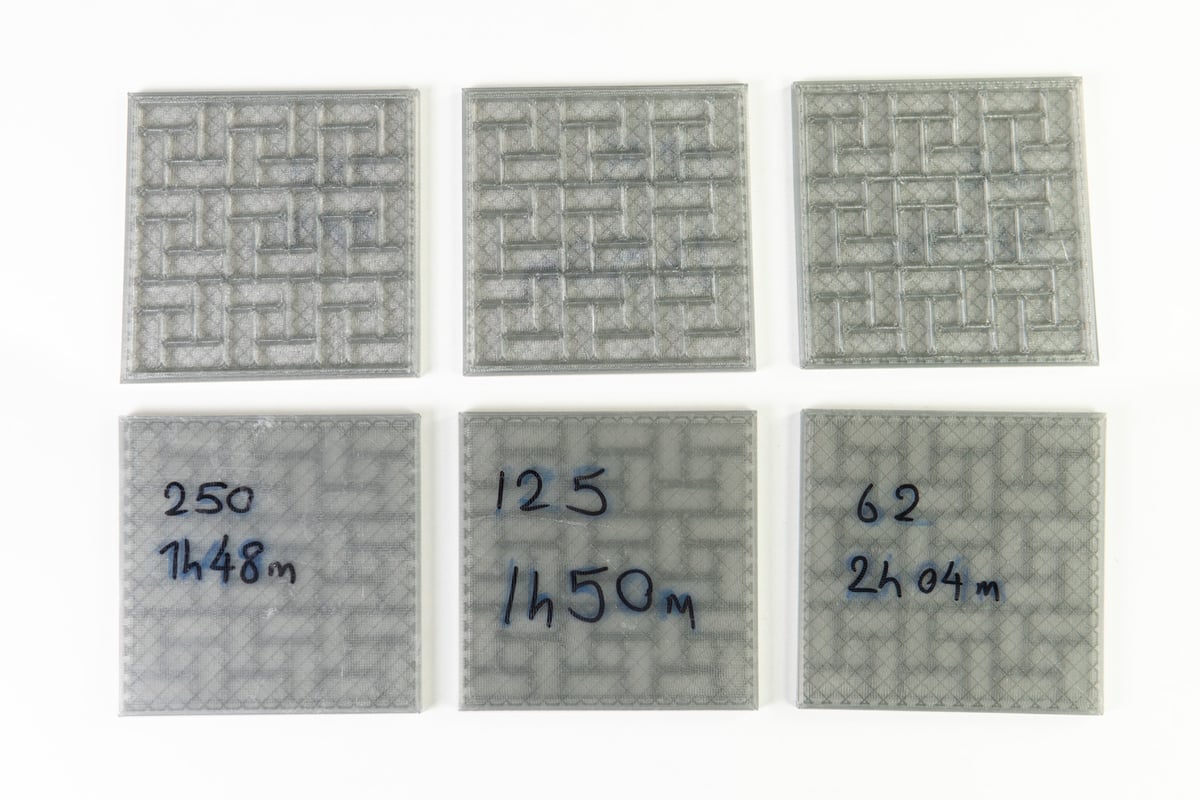

The golden question. Creality markets the Ender 7 as capable of printing at 250 mm/s with no loss in quality. It certainly is fast, but we feel the claim of 250 mm/s is a bit misleading, given there are other factors that influence the print speeds you’re achieving, and also that running at the company’s default, fast, speed yields poorer results than the company’s less expensive machines.

Print speed is a tricky subject. What you set in the slicer as your “print speed” is not necessarily what the printer will actually do. There are factors that constrain this, not only in further slicing settings that modify your desired speed for certain elements of a print, but also simply in the physics of the model you want to print. 250 mm/s is fast, but in a print the size of a Benchy, there simply aren’t any sections of the print that are long enough for the printer to reach that speed using the default acceleration settings – the print head accelerates and decelerates into direction changes, which of course takes time and distance in a given print move.

Even on a straight line covering 250 mm (coincidentally, the max printable space in the X- and Y- axes on the Ender 7), you wouldn’t complete that move in one second.

To help illustrate this we ran the same print at decreasing print speed and noted the estimated time given by the slicer, and the elapsed time logged by the 3D printer. Here’s what we found:

Further evidence of 3D printing reality crashing the Ender 7’s speed party can be found when we plug in the default values and desired print speeds into the print speed calculator hosted over on the Prusa Printers website. The desired print speed of 250 mm/s using the Ender 7’s default acceleration speed of 500 mm/s means the printer is only ever going to actually hit its targeted 250 mm/s speed approximately 60 mm into a 250 mm move, maintaining 250 mm/s for approximately 130 mm of the move before slowing down over the remaining 60 mm of the move.

With this in mind, we can divine that print moves of 130 mm have the print head hitting the targeted 250 mm/s for only a fraction of time. Ultimately, on stock settings, only prints using more than half of the Ender 7’s 250 x 250 mm build area – ideally close to the full platform – will come close to the print speeds Creality boasts about in its promotion of the printer.

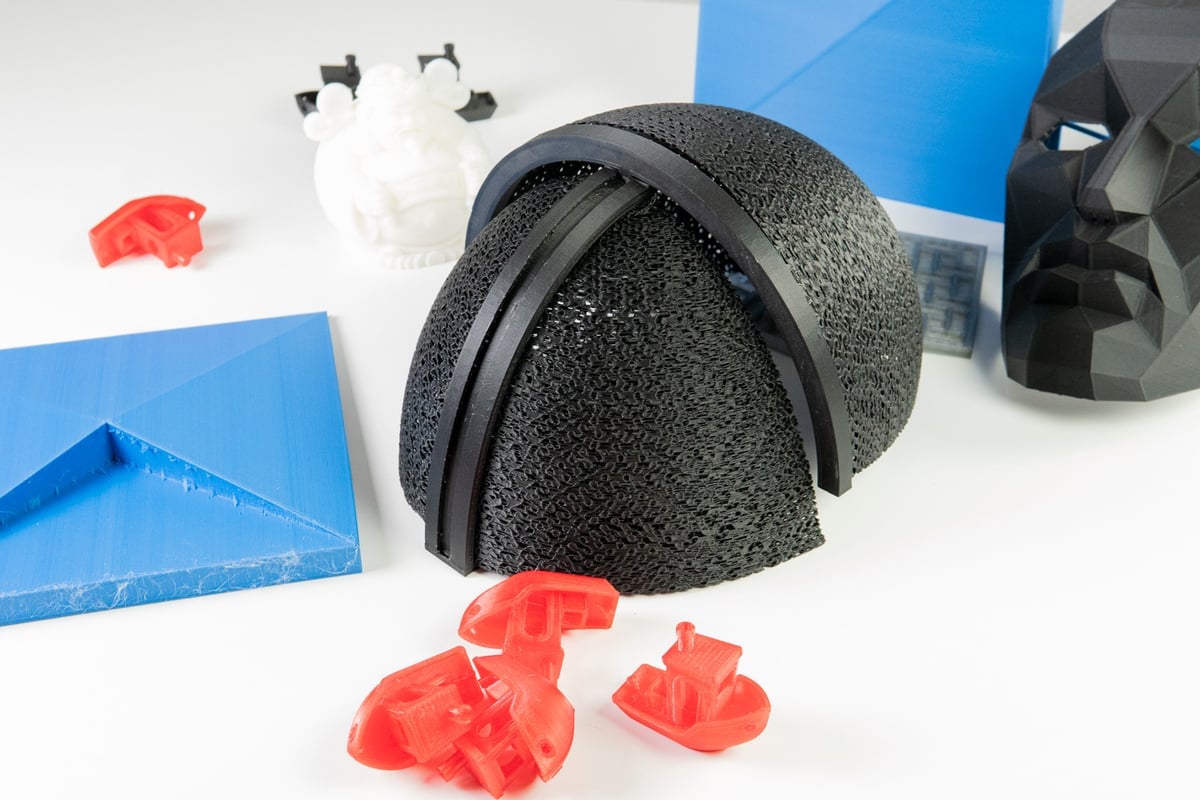

From our testing, we do notice that it’s faster than many of the machines we have sitting around the office on default settings, but this only really comes into play on larger prints that take longer.

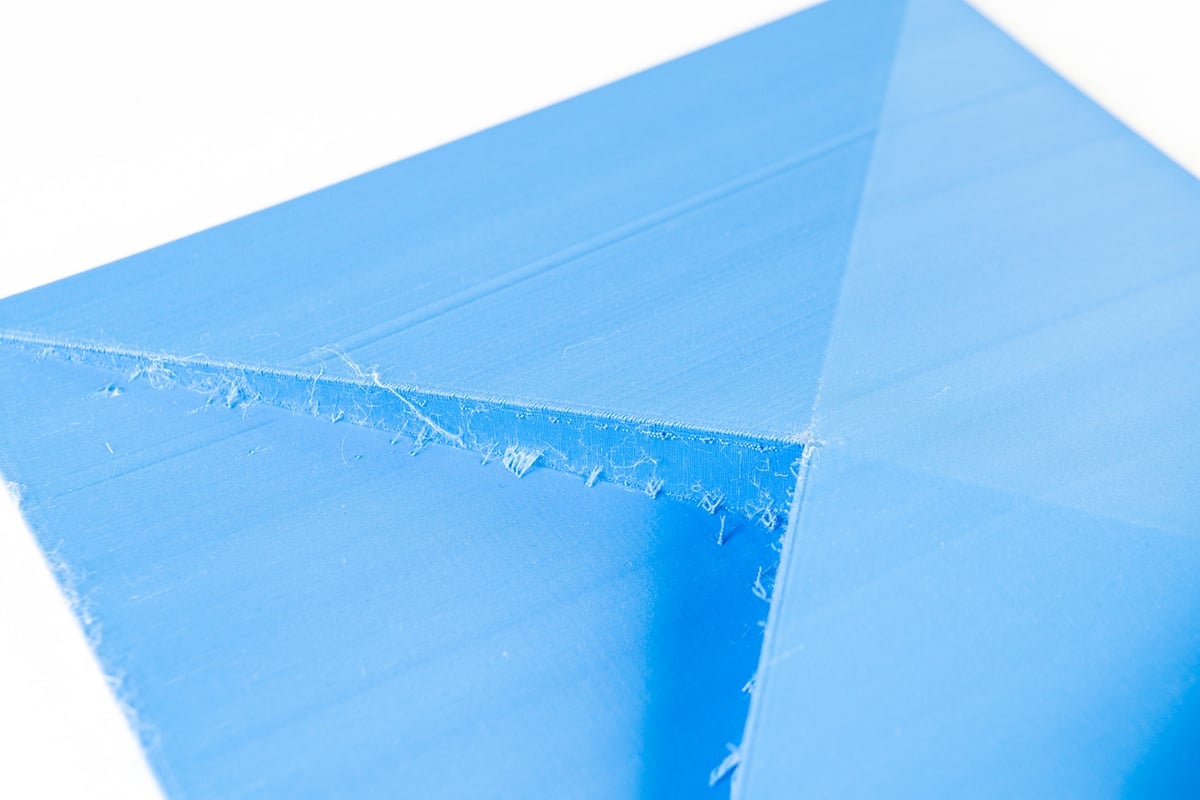

In a straight shootout with the Original Prusa i3 MK3S+ and Creality CR-6 SE, we saw print time differences that back up the assertion that for smaller prints, the Ender 7 doesn’t have much of a speed advantage, but for larger prints, it ramps right up and blitzes the rest. This is expected. But even when the Ender 7 isliving up to its promise, there are noticeable signs of a printer running fast with less-than-optimal settings.

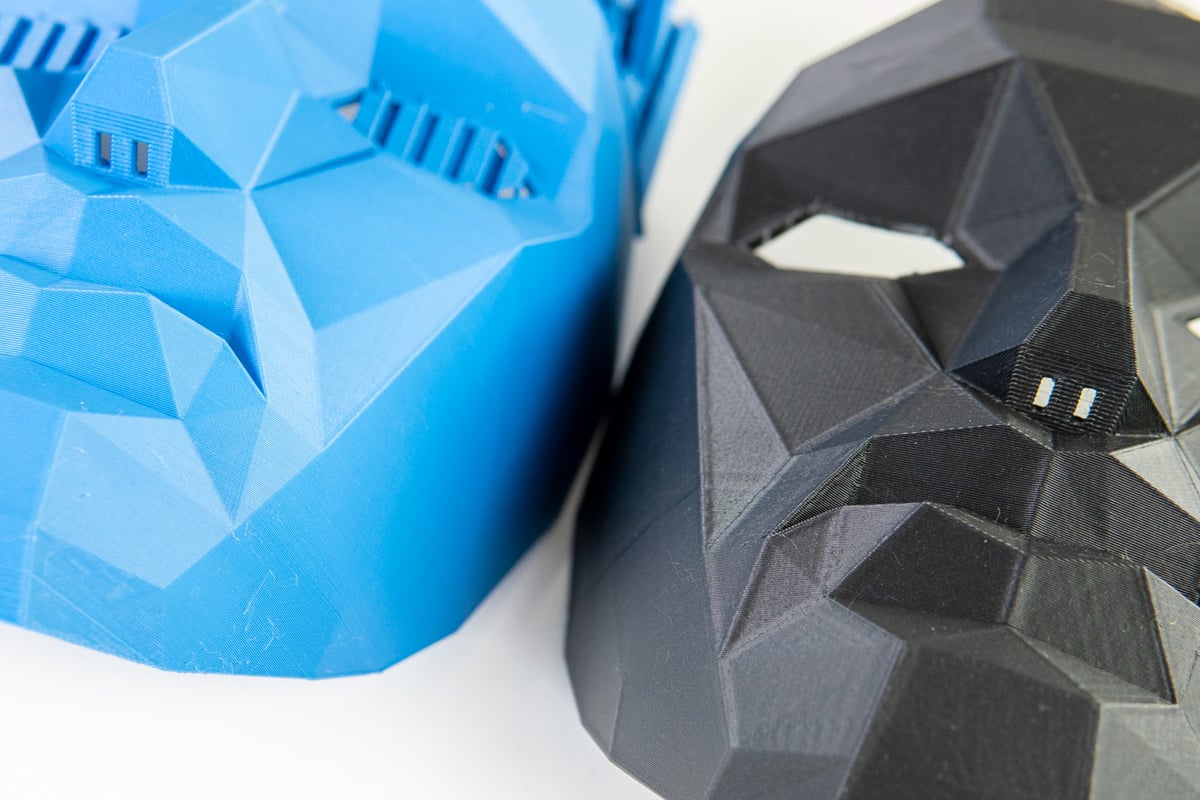

In the pic above you can see that the CR-6 SE captures the corners of this angular mask better than the Ender 7, which exhibits ringing and prominent bulging at direction changes. Both on their respective stock settings and speeds, they took almost 15 hours, and 5 hours, respectively. A huge time difference that, for some, will be valuable. But there is also a noticeable difference in the prints themselves.

Printing & Usability

So, we know that the Ender 7 feels like the typical Creality 3D printer. And in terms of the materials you can print and the size of prints you can create, it’s not all that dissimilar from the Ender 3, 5, or 6 and their respective variants. If you’re printing larger objects, it’s fast.

There are clear signs of the system having teething issues. (Or rather, were – a firmware update for the machine mid-review fixed some of the following.)

For one, the Ender 7 rebooted every time we inserted the microSD (yeah, it’s microSD – no full SD here) to queue up a new print. Not something you’d expect of a company with literally dozens of similar machines, all rocking similar firmware and hardware. As said, an update (which involves taking the baseplate off the printer to update the touchscreen’s FW, too) addresses this, so check your version info should you end up with one.

When a long-distance print runs out of filament, we are presented with an unresponsive popup dialogue asking you if you’d like to change filament; “yes,” or “no.” Nothing happens on “yes,” and hitting “no” returns you to the print-in-progress overview, with the print supposedly paused (good), but cooling (bad).

On one occasion printing fast at default print settings, the filament had advanced so far beyond the filament sensor that it was deep inside the extruder and unreachable. There’s no system-based menu to back the filament up here, so the course to change filament involved taking the Bowden tubing out of its coupler, but only after telling the printer to heat up again. A hassle.

The firmware update we mentioned above supposedly fixed the printer from cooling when the filament sensor tripped, but we haven’t found this to be the case.

Minor firmware struggles aside, the Ender 7 is also slow to heat and start printing. As part of our speed testing drag race between the Ender 7 and a Prusa i3 MK3S, the MK3S heated, completed its leveling routine, and began printing before the Ender 7 had even finished heating up.

Also, the visibility of the printing action is limited by the plastic strut at the front of the printer. It makes it tricky to see how your first layer is going down – compounded by the large dual-fan-toting print head, which already obscures much of the print.

Grumbles aside, we’ve found the Ender 7 pretty proficient in tackling PLA at its default speeds, which, as stated for long prints, saves you time. The print quality at such speeds is optically good but not as precise and crisp as you see on the slower Creality CR-6 SE or Prusa i3 MK3S.

Slowing the Ender 7 down, we see an increase in print quality. It stands to reason that this should happen – though this renders the Ender 7 rather pointless, given speed is supposed to be its thing. It could be that there’s a lot of homework to be done fine-tuning its settings, and it can maintain quality at speed. We didn’t try.

Is It Worth It?

The Creality Ender 7 is a good printer, and we can certainly see the benefit of it for long-distance prints that make use of its full build volume.

But: it’s loud, its build volume isn’t all that large (it’s only marginally larger than the Ender 3), the printer itself is very large despite the fairly average build volume, the prints still suffer from minor artifacts at high print speeds, and there are some wrinkles yet to be ironed out in the firmware. It’s not complete, and despite being a “proper” CoreXY machine, it’s not a dazzling example of the benefits such kinematics can bring. You only need to look to YouTube and speed tests of home-built CoreXY rigs to see how blisteringly fast these machines can be. The Ender 7, in our experience, is not this.

Maybe it’s possible to mod one to be like those machines, but with an initial outlay of ~$729 for the Ender 7, it seems a pretty pricey point to start from. Sorry to burst the bubble of anyone excited for Creality’s speed demon.

Perhaps when it eventually drops in price or goes on sale it’ll seem better value – especially if you’re less fussed about prints with high finish off the print bed, but need larger objects quickly. For the $729 asking price, we’d rather get a couple of similarly-sized bed-slinger printers and double the output.

Features

CoreXY Setup

Originally, CoreXY was a niche motion system primarily reserved for open-source or professional machines. A recent trend in consumer 3D printing towards this complex kinematic setup is forming as CoreXY architectures have been able to deliver high-quality printing at fast speeds.

The Ender 7 follows this trend, trying to set new benchmarks along the way, and brings up Creality’s CoreXY fleet up to three: besides the Ender 6 and the recently released 3DPrintMill CR-30 (an odd version of CoreXY).

In general CoreXY printers employ two timing belts, each connected to a stepper motor, for the X- & Y-axes (hence the name). Depending on how each motor is spinning, the print head will move in different directions, or, if only a single stepper motor is activated, diagonally. This design offers some significant benefits, namely speed and precision, as the stepper motors are stationary on the printer frame thus reducing the weight and inertia of the moving gantry, consequently allowing the print head to accelerate, travel, and print faster (without the loss of print quality).

On the downside, the belt system is more prone to wear and tear and, if not aligned correctly, can lead to more print failures. Thankfully, Creality ships the belt setup already pre-assembled, sparing you the hassle of trying to align the belts correctly yourself.

Print volume

With a 250 x 250 x 300 mm build volume, the Ender 7 offers enough space for some large-ish prints. But by today’s standards, this is not considered a very generous build volume. During the live-streamed launch, users were already inquiring about a Pro or Plus version – similar to the Ender 5 line. Although it features less Z-axis height than its predecessor, the Ender 6, it should provide enough room to work with for your day-to-day prints. It’s not size, but speed the Ender 7 is aiming for.

Dual Cooling Fans

In order to print at these speeds, proper cooling of the printed layers is essential. Otherwise, you will encounter either massive print artifacts or complete print failures.

To achieve the required cooling effectively, Creality’s new Ender 7 features a dual-fan-toting print head that constantly blows from both sides of the print head onto the nozzle. According to Creality, these butterfly-shaped wing ducts draw in 169% more air than previous models and provide the necessary cooling.

Customized high volume nozzle

Another feature tailored towards fast printing is the Ender 7’s customized high volume nozzle. With an increased melting chamber volume of 50 mm³ and a large heating block, the hotend should be able to constantly feed and smoothly extrude molten filament even when printing at near-supersonic speeds.

The Bowden style, full-metal dual gear extruder mounted onto the frame also promises to provide that hotend with stable filament feeding.

Further Features

Additional features on the Ender 7 include:

- Cantilevered print bed – Coated with Creality’s Carborundum glass, the bed moves up and down the Z-axis on a lead screw. The print surface offers superb adhesion, but the free-hanging bed could prove to be a bit wonky.

- Assisted bed leveling – Unlike some recent Creality releases, such as the CR-6 SE, the new Ender 7 does not come with an automatic bed leveling function. The printhead can be sent to five different points on the bed, though, and you will have to adjust the bed via the knobs yourself.

- Touchscreen control panel – Pretty self-explanatory; poke away at the printer’s 4.3-inch color touchscreen.

- Filament sensor and resume print function – No surprise on a printer these days, but essential if something should go sideways.

Tech Specs

General Specifications

- Technology: Fused deposition modeling (FDM)

- Year: 2021

- Assembly: Partially assembled

- Mechanical arrangement: CoreXY

- Manufacturer: Creality

3D Printer Properties

- Build volume: 250 x 250 x 300 mm

- Feeder system: Bowden drive

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 260 ℃

- Max. heated bed temperature: 100 ℃

- Print bed material: Coated glass

- Frame: Aluminum

- Bed leveling: Manual

- Connectivity: SD card, USB cable

- Print recovery: Yes

- Filament sensor: Yes

- Camera: No

Materials

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: Consumer materials (PLA, ABS, PETG, Flexibles)

Software

- Recommended slicer: Cura, Simplify3D, Repetier-Host

- Operating system: Windows, Mac OSX, Linux

- File types: STL, OBJ, AMF

Dimensions and Weight

- Frame dimensions: 430 x 460 x 570 mm

- Weight: 17.2 kg

Similar Printers

You may also be interested in the following printers:

For further information, feel free to check out our Best CoreXY Printers Guide.

Creality Ender 6

The Ender 6 looks a little different from the Ender 7, but they are both CoreXY printers at heart. The Ender 6 offers a similar suspended glass-covered 250 x 250 mm print bed but offers potentially taller prints with a 400 mm high Z-axis. What’s more, the printer is semi-enclosed with acrylic panels and can be further furnished with a removable top cover to fully enclose it — stabilizing printing temperatures and protecting parts from environmental influences.

Two Trees Sapphire Pro

The Sapphire Pro is another CoreXY printer, offering a decent 235 x 235 x 235 mm print volume and a semi-automatic bed leveling sensor. With its price tag of $300, it is one of the most affordable CoreXY 3D printers currently available, and we found the machine to work quite well once you get initial hiccups under control.

License: The text of "Creality Ender 7 Review: Fast and Forgettable" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.