Compare the features of various 3D printing technologies and one stands out as ideal for the mass production of complex parts: binder jetting. These machines typically have a larger print volume and print with higher speed and very reliable accuracy.

Metal binder jetting is the most popular because it produces metal parts in batches with the same quality as injection molding but doesn’t require molds or tools. Manufacturers from Volkswagen to Cobra golf clubs are turning to binder jetting over traditional metal fabrication methods and over other 3D printing methods for a host of reasons we’ll get into below.

Sand binder jetting is carving out a growing niche in the foundry industry for its ability to deliver highly precise and very large sand molds and cores much faster than traditional methods.

Polymer binder jetting has yet to hit its stride outside of applications requiring multiple colors because it doesn’t produce particularly strong parts. Yet, innovations that include heat in the polymer binder jetting process are adding new dimensions of strength to the technology, even though some don’t consider these new methods with heat to be binder jetting in the strictest definition. We’ll get into the distinctions below.

But first, if you’re not familiar with binder jetting, let’s summarize:

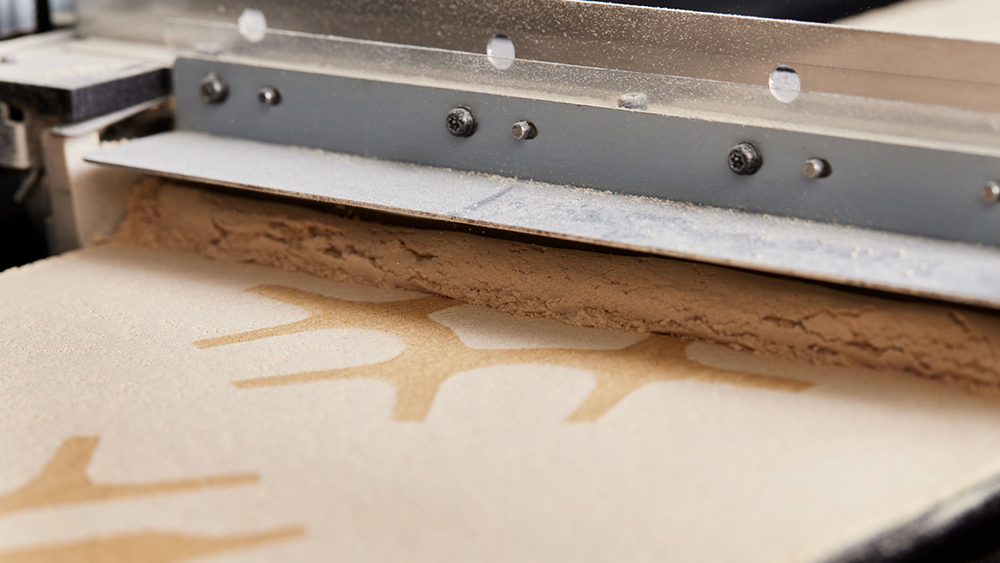

Binder jetting is a method of 3D printing that uses a liquid binding agent to bond powdered materials in layers to create solid, complex shapes. As the build progresses, the layers of the print are bonded together, resulting in a box of powder with the desired part geometry inside.

Mixing liquid and powder may sound messy, but today’s advanced 3D printer technology can precisely place millions of nanogram-sized drops of binder per second onto a fine powder to define a cross-section layer of a part about 0.01 mm thick. The technology can be applied to almost any type of powder, from metals like titanium to polymers, such as nylon, along with powdered ceramics, sand, and even sugar.

Below we look at it all along with the top binder jetting printers on the market.

What is Binder Jetting?

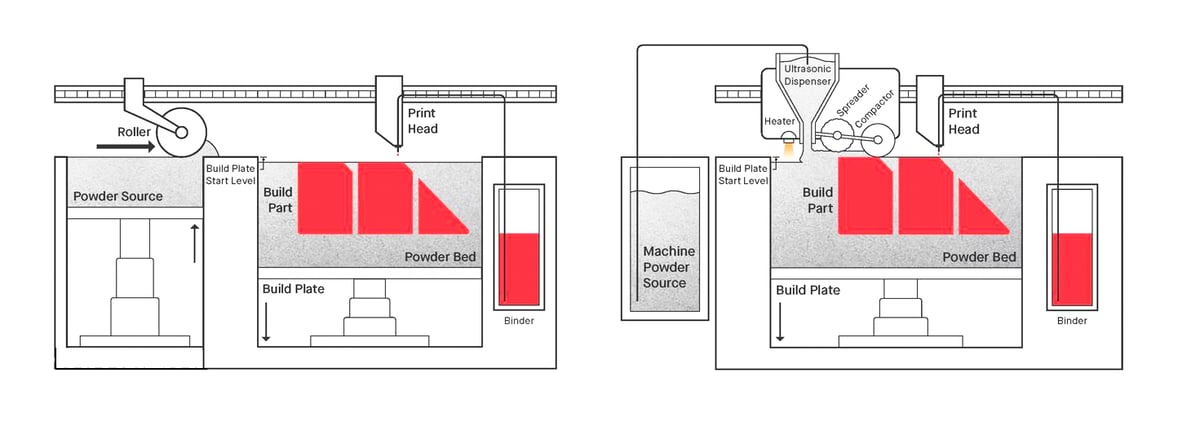

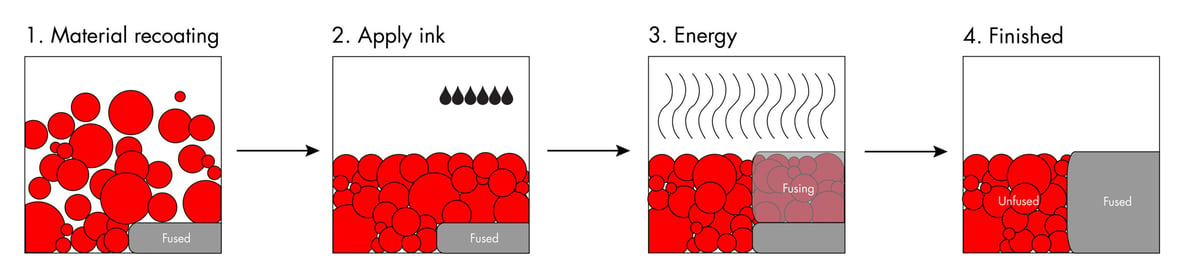

Whether metal, plastic, sand or another powdered material, the binder jetting process is the same.

First, a recoating blade or roller spreads a thin layer of powder over the build platform. Then, a printhead with inkjet nozzles passes over the bed, selectively depositing tiny droplets of a binding agent that bonds the powder particles together. When the layer is complete, the build platform moves downwards and the blade recoats the surface. The process then repeats until the whole part is complete.

Some versions of binder jetting technology incorporate heat to further fuse together the sections that received the binder liquid. There can also be colored inks introduced into the process for polymers.

After printing, the parts are encased in unused powder and often left to cure. Then the parts are removed from the powder bin and the excess powder is collected and can be reused.

From here, depending on the material, some post-processing is required.

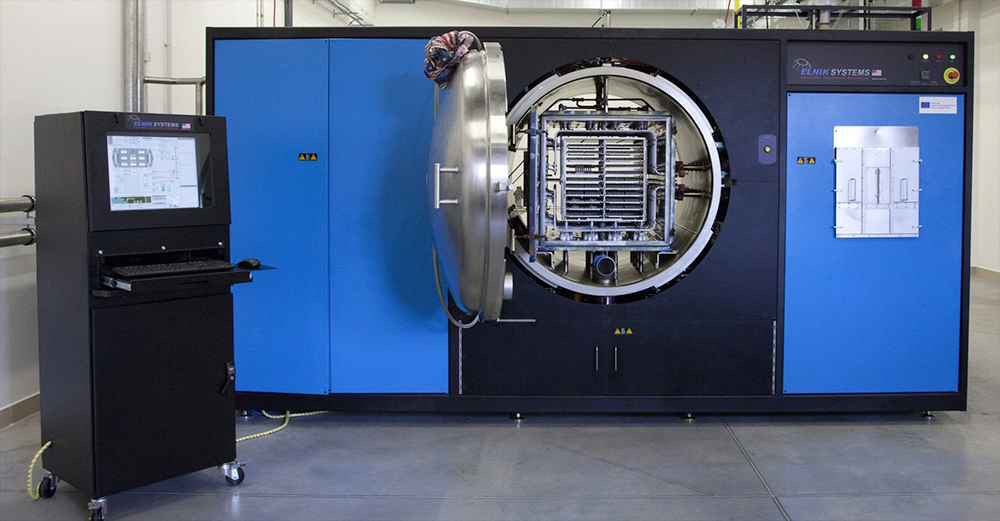

Metal part post-processing first involves heat treatment in a furnace to remove the binder, condense the part, and remove the pores or holes left behind from removing the binder. Other post-processing can include filling the pores of the metal part with another material to create a desired matrix or composite material.

Plastic part post-processing often includes a coating to improve the surface finish. You can also polish, paint, and sand polymer binder jetted parts.

Binder Jetting Pros & Cons

Binder jetting has several advantages over traditional metal injection molding and over other forms of 3D printing, depending on your requirements. The technology especially shines when it comes to speed, since printheads typically work faster than lasers, electron beams, or extrusion.

According to research by Amir Mostafaei, assistant professor in the Department of Materials, Mechanical and Aerospace Engineering at the Illinois Institute of Technology, binder jetting is poised to dominate other areas of manufacturing, specifically metal injection molding, because they share the same materials and processes, and size and geometry details, such as wall thickness.

Binder Jetting Pros:

- Materials. Binder jetting is compatible with a wide range of powdered materials currently available, and because powdered metals and ceramics are sintered to full density in many other traditional manufacturing processes, proponents of binder jetting say it has the potential to surpass powder-bed fusion in applications and has the widest selection of materials of all AM processes. In theory, binder jetting can be used with any powdered material and complementary binding liquid, although, in practice, a smaller menu of materials are “qualified” for use. Currently, some of the most unusual materials include wood powder and sugar.

- Process. Most binder jet printing processes operate at room temperature and atmosphere, avoiding issues related to oxidation, residual stress, elemental segregation, and phase changes, making the powder around the parts in the build box highly recyclable, saving on material costs, researchers say. [1]

- Size. The build volume of binder jetting 3D printers is among the largest of all 3D printing technologies while still maintaining the high resolution afforded by inkjet. [1]

- Volume. Batches of different parts are printed at once tightly nested to take advantage of every centimeter of build space. This high-volume production capacity makes it ideal for companies that want to print a lot of complex parts.

- No supports. The need for support structures is eliminated or significantly reduced for any part geometry produced by binder jetting because the powder bed provides enough support in most cases, which means greater design freedom (especially for creating internal channels), less material waste, and less time and labor to remove supports.

- Speed. Binder jetting is fast and has high production rates, so it can produce large volumes of parts more cost-effectively than other methods.

- Versatile. Binder jetting can produce various densities with controlled porosity based on the sintering temperature and time, which leads to a wide range of uses. [1]

Binder Jetting Cons:

- Multi-steps. Binder jetting is a multistep process requiring post-processing steps, which, involves additional equipment.

- Distortion risks. The process of making the binder jetted parts more dense – sintering for example – can result in distortion of the geometry. However, this should be avoidable with proper software calculations in advance.

- Manual labor. Moving parts from the printer to the post-processing machines and depowdering the printed parts is usually a manual process. Some depowdering automation is possible depending on the part geometry.

Metal Binder Jetting

Metal binder jetting is a very appealing technology for metal part production for all the reasons mentioned above, plus one very important point related specifically to metal: lightweighting.

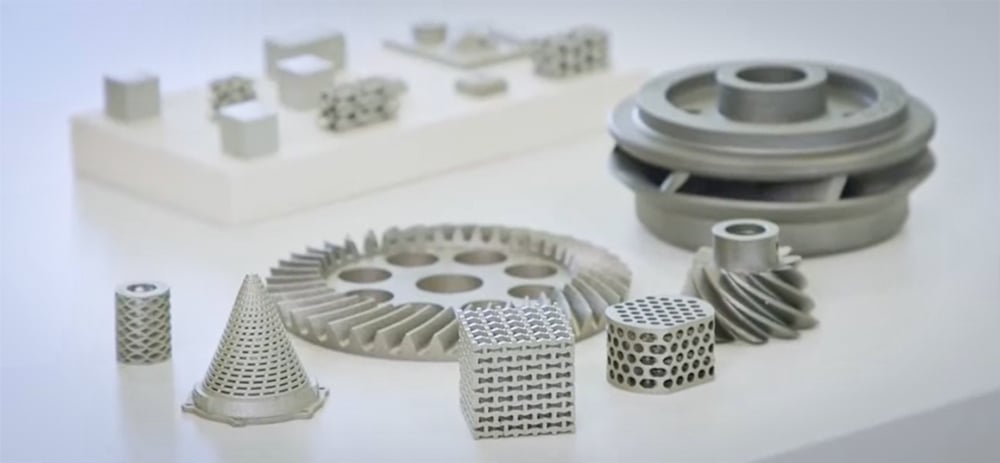

Because binder jetting can print parts with complex pattern infills instead of being solid, the resulting parts are dramatically lighter while being as strong. Binder jetting’s porosity feature can also be used to achieve lighter end parts for medical applications, such as implants.

As with other additive manufacturing processes, binder jetting can produce complex components with internal channels and structures, eliminating the need for welding and reducing the number of parts and the weight of components. Redesigning your metal parts for binder jetting can lead to a dramatic reduction in material used and wasted.

Overall, the material properties of metal binder jet parts are equivalent to metal parts produced with metal injection molding, which is one of the most widely used manufacturing methods for the mass production of metal parts. Plus, binder jet parts exhibit higher surface smoothness, especially in internal channels.

It’s a 3- to 5-Step Process

Metal binder jetting parts require secondary processes after printing to achieve their good mechanical properties. Right off the printer, parts basically consist of metal particles bound together with a polymer adhesive. These so-called “green parts” are fragile and not useable as it.

After printing and removing the parts from the bed of metal powder (a process called depowdering) they’re heat-treated in a furnace (a process called sintering). Both the printing parameters and the sintering parameters are tuned for the specific part geometry, material, and desired density.

Depending on the temperature of the furnace and the time parts are sintered, they can be 99% dense or as much as 60% porous.

Bronze or another metal is sometimes used to infiltrate the voids in a binder jetted part, resulting in zero porosity. Highly porous parts may be desired for lightweight applications or medical implants, where porosity has been shown to enable bone growth.

Metals & metal alloys for binder jetting:

- Maraging steel

- Stainless steels

- Tool steels

- Low alloy steels (4140, 4340)

- Nickel

- Cobalt

- Titanium

- Aluminum

- Copper

- Bronze

Despite its advantages, you won’t find a wide variety of metal binder jetting machines on the market. This technology is dominated by a few very large players, including HP, Desktop Metal, and Digital Metal (now owned by Markforged). GE Additive’s Series 3 binder jet machine is due out in 2023, and an interesting desktop-size metal binder jetting machine from a new company named Sinterjet was on display at the 2022 Formnext additive manufacturing trade show.

When selecting a machine, be sure to request part samples and consider the ease of use of the software; the availability of the materials (proprietary or open); the cost of consumables, such as the binder; and the integration of the complete ecosystems (printer, depowdering station, sinter oven).

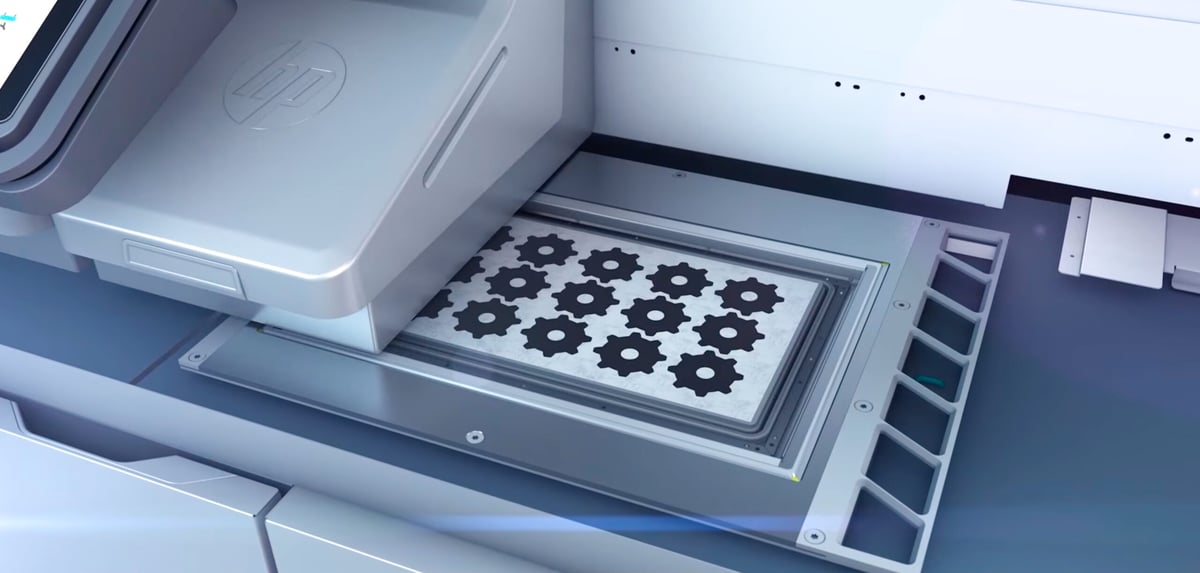

HP Metal Jet S100

HP inkjet technologies have led a broad range of printing markets for decades, so it’s no wonder that when you talk about 3D printing with inkjets, HP is a major player.

HP started off in polymer 3D printing in 2014 and adopted its binder-and-powder technology called Multi Jet Fusion to metal, called Metal Jet. HP Metal Jet is a binder jet technology that features density after sintering of more than 97%, similar to MIM, the company says. Metal Jet has been available to select manufacturers, such as Cobra Golf, for years, but the latest version, the Metal Jet S100 solution, just became available to customers in 2023.

Unique to HP is the use of a thermal element included with the inkjet heat that not only precisely delivers a binding agent to a powder metal bed, but can heat it as well to remove some of the liquid binding agent.

HP offers one model of metal 3D printer, the S100, that currently only prints with stainless steel (17-4 PH and 316L). It has a build volume of 430 x 309 x 200 mm and features a minimum layer height of 35 microns.

If you take a look at all of the equipment in the HP Metal Jet S100 photo above, it may seem like a lot, but all of these are required for the process. HP does a nice job integrating all of the parts of the process, leaving out the final sintering oven since most metal fabricators would already have one, plus there are plenty on the market.

The full solution is a metal factory package designed to scale. Key to the ease of use is software that controls each step and a rolling build unit that’s simply pushed from the printer to the curing unit to the power removal and recovery station.

HP has a strong focus on automating metal powder handeling. In fact, you won’t need to “handle” the powder at all since the unused powder is collected in the powder removal station; then you roll the build unit into the powder management station where the powder is mixed, sived, and automatically loaded into another build unit.

The final parts can undergo machining and polishing to meet dimensional and surface finish requirements.

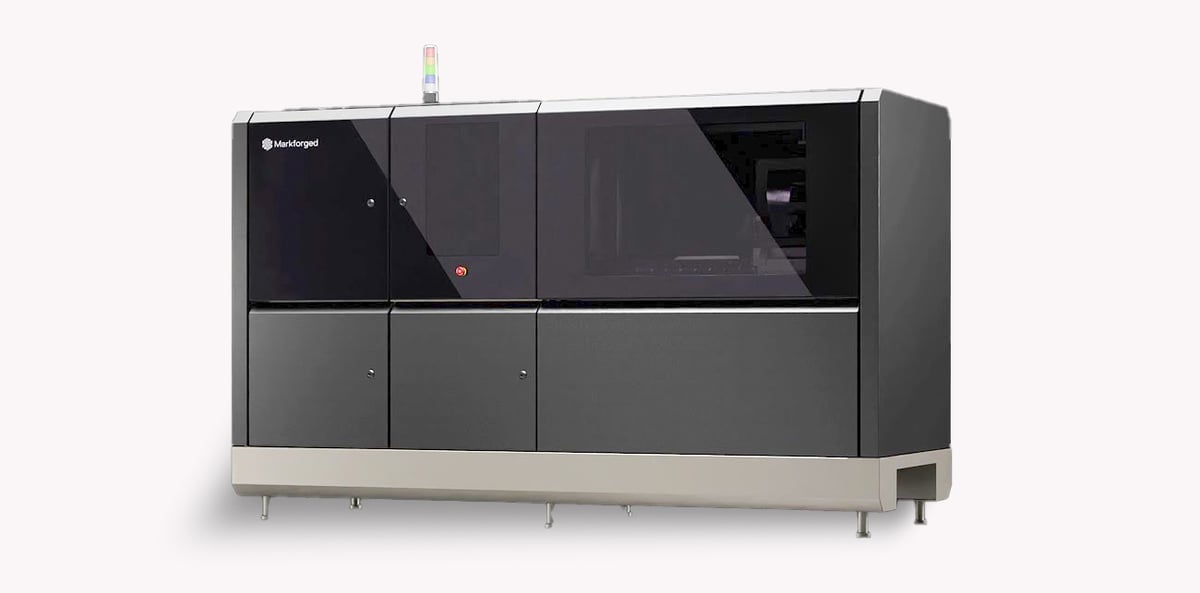

Markforged PX100

Markforged is one of the leading 3D printer makers using extrusion technology for both metal and polymers, but to expand into metal binder jetting, it acquired the Swedish metal binder jet maker Digital Metal in 2022.

In 2023, Markforged renamed the Digital Metal DMP Pro binder jet printer as the Markforged PX100, available in two sizes.

Once a part of Höganäs, one of the world’s largest and oldest makers of metal powder, Digital Metal was established in 2004 to explore technologies that would lead to the sale of more metal powder. Originally designed to prove that metal binder jetting could produce quality parts, not as a saleable piece of equipment, the PX100 was a bit overengineered, the company says. Yet that engineering has led to a precision and part quality that sets it apart, according to Markforged.

The base of the machine is a slab of granite that’s required to stabilize the unit and eliminate vibrations during printing. This is why the PX100 is nearly twice as heavy as any other metal binder jetting solution. There are also smooth linear motors and air bearings, which Markforged says leads to exacting precision and static accuracy better than 1 micron.

The company’s binder jet solution focuses on producing large batches of small and intricate metal parts. With its 250 × 217 × 186 print volume, it can make larger parts, but customers have opted for this solution for its ability to make hundreds or even thousands of small parts at a time, such as watch faces and medical instruments.

Markforged offers the full ecosystem of accessories covering depowdering and powder management with your choice or manul or automatic versions.

There’s a relatively basic downdraft table for preparing powder for the printer, a manual depowdering station or a semi-automatic depowdering station, and a fully automated powder handling system that connects to the manual or semi-automatic depowdering station and automatically dispenses new powder, mixes it with powder collected from the depowdering station, and sieves it at a capacity of 120 kg/h.

Because the method doesn’t require heat or a curing or drying step, there’s no lengthy cool down or heat up, and the time between batches can be as little as 15 minutes.

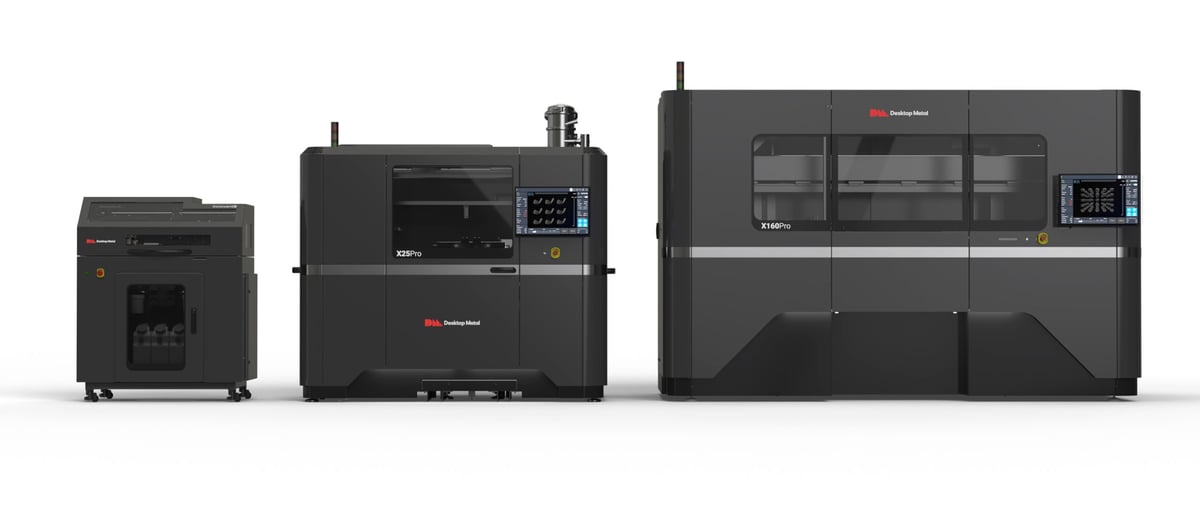

Desktop Metal Shop System, X-Series & Production System

Desktop Metal offers six distinct metal binder jetting machines: the Shop System, the X-Series in three editions, the Production System P-50, and the Production System P-1.

Designed with smaller machine shops in mind, the Shop System (available in four build volumes) produces metal parts with good surface finish and resolution in a turnkey solution that doesn’t require a dedicated engineer, the company says.

The Production System is the company’s highest throughput machine designed for high-speed mass production of metal parts. The Production System P-50 is the fastest metal binder jetting system on the market.

Desktop Metal inherited the metal binder jet technology and patented materials of its closest rival ExOne when it acquired the company in 2021. Since then, those machines have also seen some upgrades, including new names: InnoventX, X25Pro, and X160Pro. ExOne was one of the pioneers the commercialization of metal binder jetting almost two decades ago.

The X-Series differs from Desktop Metal’s Shop and Production systems in a number of ways. X-Series machines can all process ceramic powders, such as alumina and aluminum nitride, in addition to sand, “composite powders”, and metal powders.

The X-Series has what the company calls Triple ACT (Advanced Compaction Technology), which is a patent-pending way of dispensing, spreading, and compacting metal powders in the printing process. X-Series systems can achieve dimensional tolerances of less than 1%, the company says. By comparison, the Production System has ±2.0% dimensional tolerance.

Another difference between the X-Series and the Shop Systems is the print heads. The Shop System uses a less expensive thermal printhead, whereas the X-Series and Production System printers use piezo printheads. Desktop Metal says piezo printheads may have higher resolution, better durability, and more performance and material options. The X-Series printers also do not feature an inert environment like the Production System.

Polymer Binder Jetting

The process and technology for plastic binder jetting involves plastic powder and a liquid binding agent similar to the metal version, but there are several variations and patented technologies that make plastic binder jetting a difficult category to define.

We’re going to take the broadest possible view in this article and include every method that uses polymer powder and a liquid binding agent.

Polymer binder jetting begins with a polymer powder (usually a type of nylon) spread across a build platform in a thin layer. Then inkjet heads dispense a binder-like glue (and/or other fluids, including colored inks, fusible or radiation absorbing fluids, and magnetic fluids) precisely where the polymer should be joined on each layer.

In some methods, there’s a heating unit attached to the inkjet head or on a separate carriage that fuses the parts of the layer that receive the fluid. The methods that include this heating step create stronger parts than the ones that don’t because the polymer powder is essentially melted together rather than only glued together.

Binder jetting with heat, such as Multi Jet Fusion, is comparable to the technology that uses lasers to melt polymer powder — called selective laser sintering — but is faster, offers a smoother surface finish, and you’re able to reuse more of the powder left over from a printer run.

HP, the creator of the MJF, may balk at being included in the binder jet category even though its Metal Jet solution is touted as binder jetting. The company’s polymer technology, for many reasons, is unique. However, MJF involves a polymer powder and a jetted binding fluid, so we’re including it here.

In the HP Multi Jet Fusion process, a radiation-absorbing ink is introduced into a powder bed by means of a print head. Areas that are not to be printed, on the other hand, are cooled with a second printing fluid, a detailing agent. After each layer has been printed, energy is introduced via an infrared lamp.

HP is not the only 3D printer manufacturer to introduce heat to what would appear to be a binder jetting process. Voxeljet developed a technology called High Speed Sintering (HSS) where a thin layer of plastic powder, such as PA12 or TPU, is applied to a heated building platform. An inkjet print head then moves over the entire surface of the platform and moistens or infiltrates select areas of the building platform with infrared light-absorbing ink. The building platform is then irradiated with infrared light, and inked areas absorb the heat, which sinters the powder layer underneath while the unprinted powder remains loose. The parts are then cooled down in a controlled manner in the building area before they can be removed.

Stratasys has another binder-jet-like technology called Selective Absorption Fusion (SAF), again incorporating heat into the process. This polymer powder 3D printing process uses an infrared absorption fluid to fuse particles of polymer powder together in layers to build parts. This is followed by exposure to infrared energy, which causes the areas with HAF to melt and fuse together. The sequence is repeated until the parts are completed.

Once printed, plastic parts are removed from their powder bed and can often be used without any further processing. Parts can also be infilled with another material or cured to add strength, or polished and painted.

Binder jetting with polymers, like with metals, has a range of unique advantages.

Advantages of polymer binder jetting

- Superb multicolor reproduction (3D Systems only)

- Fast print speeds

- Support-free design flexibility

- High rate of material recycling

- High-quality surface finish

- Consistent mechanical properties

Disadvantages of polymer binder jetting

- Somewhat limited materials

Lastly, let’s clear up some terminology and confusion around the use of the word “jet”. There’s another 3D printing technology called material jetting, which uses UV-curable liquid polymers jetted onto a build surface and instantly cured by UV light. There are no powders or binding liquids. Several popular 3D printers have “jet” in their name, such as the MultiJet from 3D Systems and the PolyJet from Stratasys, but these are not binder jetting machines.

3D Systems CPJ 860Pro & CPJ 660Pro

3D Systems makes a wide range of 3D printers employing several types of technology. The one in the binder jetting category is called ColorJet Printing (CJP). The feature here is not the core material but rather the color binder.

As with other methods of binder jetting, the material is spread in thin layers over the build platform with a roller. After each layer is spread, color binders (in cyan, magenta, and yellow) are selectively mixed and jetted from inkjet print heads, which causes the core material to solidify. The build platform lowers with every subsequent layer, which is spread and printed, resulting in a full-color or white three-dimensional model. The unused powder can be reused. Parts can be sanded, drilled, tapped, painted, and electroplated, which further expands the options available for finished part characteristics.

CJP is a popular choice for miniatures, full-color product models or prototypes, and medical modes.

HP Jet Fusion 5420W, 5200, 4200

HP makes three series of Multi Jet Fusion 3D printers that all use the same polymer powder and binding fluid technology.

The 5420W, 5200, and 4200 all have the same build volume but vary a bit in print speed, materials, and resolution.

MJF produces stiff, functional parts widely used in the automotive industry for enclosures and housings, fixtures, and tooling. The machines can achieve up to 70% surplus powder reusability.

MJF is widely used at on-demand 3D printing services for its ease of use, flexibility and ability to produce batches of various parts at once.

More than just a printer, it’s an integrated end-to-end solution that includes a depowdering station and a material management station. There are in-printer quality checks reported via a touchscreen to help minimize errors and enable job progress tracking. HP offers remote monitoring of your HP system from anywhere.

In addition to nylon, HP MJF printers can produce parts in glass-filled nylon, TPA, and TPU.

HP used to offer its Multi Jet Fusion technology in full color but sadly discontinued its HP Jet Fusion 380 machine in 2021.

Stratasys H350

Stratasys introduced the Stratasys H350 3D printer in 2021, designed specifically for end-use parts production. Applications include end-use parts such as covers, connectors, hinges, cable holders, electronics housing, and ducting.

Powered by what the company calls Selective Absorption Fusion (SAF) technology, the H350 printer is designed to give manufacturers consistency, a competitive and predictable cost per part, and complete production control for volumes of thousands of parts. SAF uses an infrared absorption fluid to fuse particles of polymer powder together in layers to build parts. Industrial-grade piezo-electric print heads jet the fluid in prescribed areas across each layer of polymer powder to create each cross-section of the part. This is followed by exposure to infrared energy, which causes the areas with the fluid to melt and fuse together. The sequence is repeated until the parts are completed.

The H350 is designed to meet the needs of customers in industries such as commercial goods, automotive, and consumer goods and electronics that benefit from the ability to quickly produce large volumes of 3D printed nylon parts. Service bureaus and contract manufacturers also benefit from the industrial-grade performance of the system. Applications include end-use parts such as covers, connectors, hinges, cable holders, electronics housing, and ducting.

Voxeljet VX200 HSS & VX1000 HSS

Whether sand, plastic, or ceramic, Voxeljet 3D printers use powder material and binder to deliver finely detailed parts. The Voxeljet line of 3D printers is focused on the production of molds or models for metal casting applications but are also a popular choice for design samples, jewelry, art, and architecture parts.

Voxeljet’s polymer binder jet machines include the VX200 and the VX1000, which can also process sand and ceramic, along with the VX200 HSS and the VX1000 HSS, which only process polymers. The HHS versions refer to the Voxeljet technology process called High Speed Sintering. Don’t be confused by their use of the word sintering, there are no lasers or electron beams involved. Instead, Voxeljet’s HHS technology uses infrared light to irradiate the binder (or ink, as they call it) that’s been selectively distributed on the polymer powder. The ink dyes the polymer black so it can better absorb the infrared light. The company called it “laser sintering of polyamides and other polymers – only without a laser.” The end result are parts with better mechanical properties than other forms of binder jetting.

The VX1000 HSS positions itself as an economically viable alternative to conventional plastic injection molding. In fact, Voxeljet hopes its HSS tech will help establish additive manufacturing in the series production of the plastics industry. HSS material powders include PA12 nylon, PP, TPU, PEBA, and EVA.

Ceramic Binder Jetting

Binder jetting is expected to become an important process for preparing technical ceramic parts because it can overcome multiple problems that appear in the conventional ceramic preparation process, such as the difficulty of preparing complex-shaped ceramic parts and the shrinkage of the sintering process, according to researchers at China’s Northwestern Polytechnical University.

Binder jetting has inherent advantages for the additive manufacturing of ceramics (alumina, zirconia, silicore, aluminum nitride, silicon nitride, etc.), including print speed, print size, material choices, and flexibility. It isn’t the only way to 3D print technical ceramics, however. The industry also features a range of stereolithography (SLA) and digital light processing (DLP) machines.

Binder jetting is continuing to grow, and future machine enhancements for printing small particle size, and sinterable ceramic powders will continue to create broader adoption.

Voxeljet VX200 & VX1000

Voxeljet manufactures a range of flexible binder jet additive manufacturing machines that can process polymers, ceramics, and sand. The ones with ceramic capabilities are the VX200 and VX1000.

From prototyping to agile industrial series production, Voxeljet’s ceramic 3D printers can handle a spectrum of ceramic materials, such as aluminum oxide, zirconium oxide, mixed oxides and non-oxide ceramics, such as silicon nitride in advance to ensure the optimum industrial applicability in our processes. The phenolic resin-based processes (PDB) and water-based (CDB) are optimal for the production of complex and filigree cores or molds. Each printer is customized to the customer’s use case.

The VX200 offers the highest degree of flexibility in terms of material development in the Voxeljet system series. The Voxeljet open-source software allows process parameters to be adapted to individual 3D printing materials.

Desktop Metal X-Series & Production System

Capable of printing with both metal and technical ceramic powders, Desktop Metal’s X-Series are versatile machines. The technology works with a wide range of ceramics, from silicon carbide to tungsten carbide cobalt.

The company’s Production System, known for its menu of 16 metals, has one ceramic offering, tungsten carbide cobalt.

X-Series printers offer a feature called Triple Advanced Compaction Technology that Desktop Metal says compacts the ceramic powder in the print bed for part density and repeatability in line with metal injection molding.

Sand Binder Jetting

The production of large sand-casting molds, models, and cores is one of the most common uses for binder jetting. The low cost and speed of the process make it an excellent solution for the foundry industry. Elaborate pattern designs that would be very difficult or impossible to produce using traditional techniques can be printed in a matter of hours.

The future of industrial development continues to place high demands on foundries and suppliers. Sand 3D printing is at the beginning of its potential.

Desktop Metal S-Max Flex, S-Max Pro, S-Print & S-Max

Sand 3D printers from ExOne, a Desktop Metal company, support sand casting applications across various industries. The company offers three models of sand binder jetting 3D printers featuring different build sizes.

The S-Max Flex is the company’s most affordable sand 3D printer, developed to provide faster ROI and easy integration into digital casting operations. This robotic manufacturing system features an industrial robot with an end effector that dispenses a binder into a telescoping job box (1,900 x 1,000 x 1,000 mm) of sand at 115 liters per hour.

The S-Max Pro covers the full range of 3D sand printing from prototyping to serial production. It’s available as a stand-alone solution and can be connected by a network that creates a fully automated production line, to realize industrial serial production in 3D sand printing.

The S-Print and S-Max round out ExOne’s sand binder jetting options.

Voxeljet VX1300 X, VX2000 & VX4000

As mentioned above, Voxeljet VX200 and VX1000 machines can print with sand, polymers, and ceramic, but the company’s large industrial VX1300 X, VX2000, and the largest, VX4000, are dedicated to the additive mass production of highly complex sand cores for metal casting.

The printers use binder jetting technology to turn Cerabeads and classical quartz sand with different grain sizes into molds and cores.

CMET

CMET is a Japan-based company that offers two sand 3D printers using binder jet technology. The company claims its units are the fastest. The system uses dry artificial sand (G-CCS), and uncured sand can be recycled repeatedly. There’s also a room-temperature curing process, eliminating the heat treatment, so molds and cores can be used for the casting process immediately after sand removal.

The SCM-800II has a build volume of 800 x 400 x 400 mm and the SCM-1800 is nearly twice the size at 1.8 x 1 x 0.75 m.

Exotic & Other Binder Jetting

At its core, using a liquid to bind a powder into a shape can theoretically be applied to countless liquid and powder combinations from sugar to silk to sawdust. Below are two stand-out examples of just how much potential binder jetting has as a manufacturing method.

Wood Powder & Sap Binder

Desktop Metal, featured above for its metal, ceramic, and sand binder jetting machines, launched a new subsidiary in 2021 called Forust (yes, like forest) to 3D print wood from lumber and paper manufacturing waste byproducts, namely cellulose dust and lignin (a class of complex organic polymers that form key structural materials in the support tissues of most plants).

The process uses Desktop Metal’s existing binder jetting additive manufacturing technology on a wood-configured Shop System printer. The goal behind Forust, the company says, is to sustainably manufacture custom wood products, such as furniture, household objects, and architectural pieces that feature a digital grain throughout. Final parts exhibit the functionality and stiffness in line with conventional wood and can be stained with a variety of finishes, including natural, oak, ash, and walnut, the company says.

Sugar Powder & Flavoring Binder

About a decade ago Sugar Lab invented a new kind of culinary printer that used powdered sugar and water in a binder jetting technique to make fantastically shaped and colored sugar creations. They sold their invention to 3D printing giant 3D Systems, where it languished for a while until the folks at Sugar Lab bought it back.

Today, the printer is no longer for sale but the sugar creations are. Sugar Lab sells its creations across the US and makes custom pieces for restaurants and private clients.

Binder Jetting On-Demand Printing Services

If you’re not ready to invest in a binder jetting system, there are services with the machines and expertise to deliver the parts you need, whether it’s one spare part or 10,000.

Contract additive manufacturers or 3D printing services offer everything from a simple digital design upload platform where you can get your part in a few days or less to full design and engineering services to walk you through the entire process. Many of the 3D printer makers themselves offer on-demand printing, which is a great way to test out the equipment’s capabilities before you buy.

Binder Jetting Services

Special thanks to Dr. Bastian Barthel, Project Manager Metal Additive Manufacturing / Metal Binder Jetting at the Fraunhofer IFAM research institute, and Dr. Alexander Azzawi, Head of Innovation Domain Binder Jetting Applications at Evonik specialty polymers for their technical review.

Sources:

[1] “Binder jet 3D printing – Process parameters, materials, properties, and challenges” June 2020. Authors: Amir Mostafaei, Illinois Institute of Technology; and Amy M. Elliott, Oak Ridge National Laboratory; et al.

Lead Image:

Binder jet 3D printing is a versatile technology that is used to make parts in metal, plastic, ceramic, wood, and even sugar (Source clockwise: White PA12 material printed on HP Multi Jet Fusion by Weerg; red painted HP Multi Jet fusion printed by Weerg; sand 3D printing by Voxeljet, metal 3D printing by Desktop Metal, metal 3D printing by HP, SAF polymer 3D printing by Stratasys, polymer 3D printing by HP, sugar 3D printing by Sugar Lab, polymer 3D printing by Voxeljet)

Lead image source: Production metal parts by ExOne

License: The text of "Binder Jetting 3D Printing – The Ultimate Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.