Where traditional mills and routers are fixed in two dimensions or require handheld operation and, let’s be honest, skill, the CNC router simplifies things. Introducing computer control for pinpoint accuracy in three (or more) axes, a CNC machine can turn blocks of material into end-use and, more importantly, sellable objects right before your eyes.

There’s an abundance of CNC machines in all shapes, sizes, capabilities, and price points today, with a clear boundary between the consumer/prosumer level machines that emphasize ease of use, and the machines from manufacturers that cater to professional machinists. With this in mind, we’re focusing largely on the lower end of the spectrum, with budgets from the hundreds to some thousands. As much as we’re in awe of them, you won’t find the likes of Tormach or Haas in this list. We’re looking at accessible, lower-cost systems better suited to domestic budgets.

In most cases, the CNC machines we’re highlighting here can fit on a desk. Past that, they expand beyond the benchtop for accessible large-scale cutting and routing without complex controllers.

| CNC Router | Work Area (mm) | Spindle Included? | Market Price (USD, Approx.) | Check Price (Commissions Earned) | |

|---|---|---|---|---|---|

| Beginners: SainSmart Genmitsu 3020 Pro Max V2 | Sturdy inexpensive all-rounder | 300 x 205 x 78 | Yes | $549 | |

| All-Rounder: Carbide 3D Shapeoko 4 | The go-to CNC workhorse with peerless support | From 444 x 444 x 101 | No | From $1,525 | |

| Budget: SainSmart Genmitsu PROVer 3018 V2 | Low-cost, low-stakes system to experiment with | 280 x 180 x 40 | Yes | $269 | |

| Hybrid: Snapmaker Artisan | Cut, carve, laser and 3D print in one package | From 350 x 400 x 400 mm | Yes | $2,999 | |

| Metal: Carbide 3D Shapeoko HDM | Ready-to-run, with max rigidity and a VFD spindle | 690 x 535 x 145 mm | Yes | $5,400 | |

| 5-Axis: Penta Machine Co Pocket NC-V2 | Compact and capable in 5 axes | 115 x 128 x 90 mm, A: -25° - 135°, B: continuous | Yes | From $6,500 | |

| Handheld: Shaper Origin | You do the moving, it does the cutting | No maximum | Yes | From $3,799 | |

| Large-Format: MakerMade M2 | Space-efficient large-area cutting | 1219 x 2438 mm | No | $1,198 | |

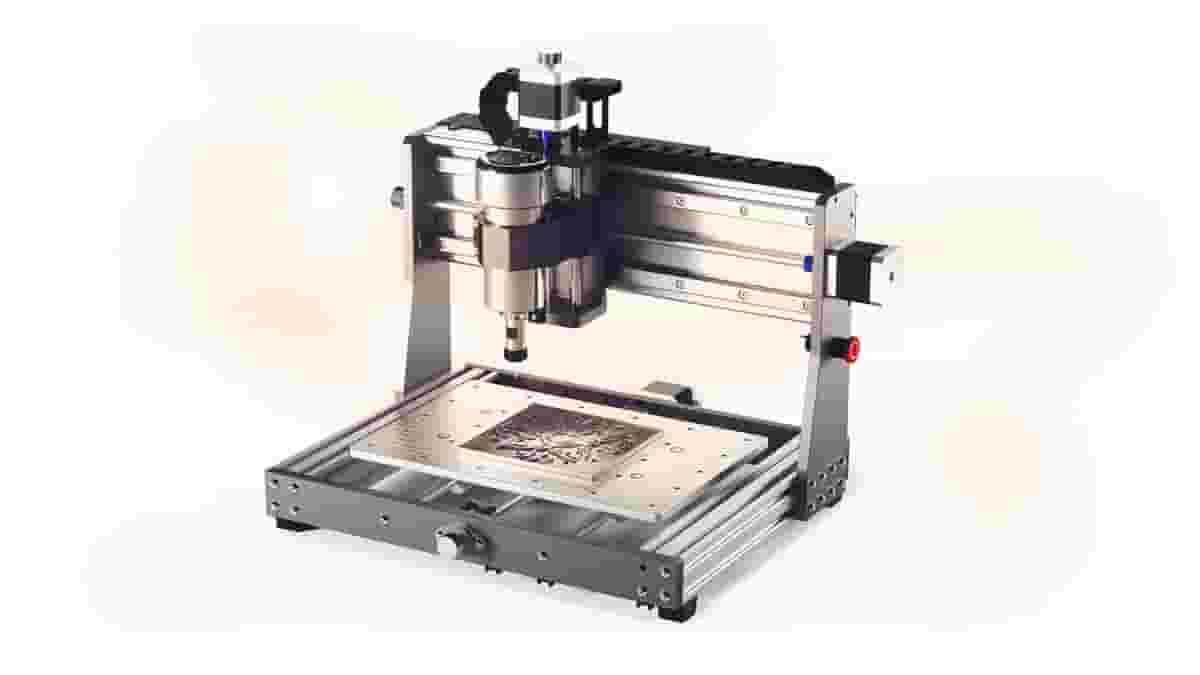

Beginners: SainSmart Genmitsu 3020 Pro Max V2

As quite possibly the foremost name in affordable CNCing, SainSmart’s Genmitsu series has quickly grown to offer all shapes and sizes below the popular Shapeoko form.

The SainSmart Genmitsu 3020 Pro Max is a touch pricier than our typical “budget=beginner” approach, coming in at ~$550, but for good reason – with its sturdy construction and powerful spindle, SainSmart says it can tackle metal, opening up possibilities beyond the usual suspects of wood, foam, and plastics.

There’s slim detail about this aspect, honestly, but we don’t doubt that at the appropriate speeds, this little powerhouse could indeed make a dent in tougher materials that many other Genmitsu series CNC machines would struggle with.

While not enclosed, side panels help to contain the mess of chips generated by the cutting and engraving process. On that subject, the 3020 Pro Max V2 features a solid aluminum work plate with diverse points to clamp your material stock down. A separate spoil board, not provided, will be necessary for full cutting.

Expandability is a feature of this CNC machine. The controller has ports for laser and air-assist add-ons, and there are kits available separately to double the work area of the machine for a total of 300 x 405 x 78 mm.

GRBL firmware ensures wide compatibility with popular control software, and an offline controller gives you convenient direct control of the machine.

It’s not foolproof, but all the pieces are there for an educational first contact with CNC.

Other Machines

We can understand the desire to spend sparingly when first setting out with a new tool or hobby. Sometimes, though, there are premium options that take the trial and error out of learning and simply offer a sophisticated, user-friendly onramp. In this context, that machine appears to be the Carvera, a now-out-of-Kickstarter desktop CNC machine that’s sturdy, fully enclosed, and includes an automatic tool changer – features virtually unseen at its $4,799 price point.

The work area is 360 x 240 x 140 mm, and the Carvera comes with software that presents multi-tool jobs in an easy-to-handle manner. An optional 4-axis module lets you carve cylindrical objects, too. It’s pricey but highly capable and one to check out if you’ve got deep pockets and plan to tackle multi-stage projects.

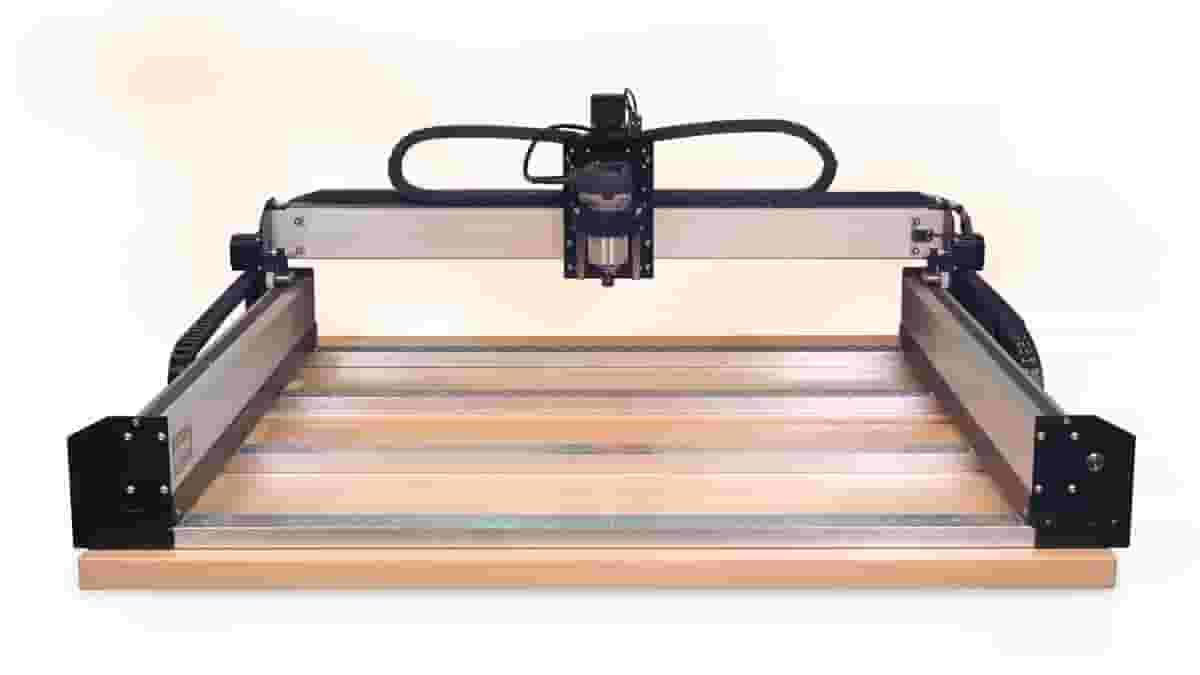

All-Rounder: Carbide 3D Shapeoko 4

Carbide 3D’s Shapeoko 4 has been around for 3 years now and continues to represent the best value to be found in the Carbide 3D range, starting at $1,700.

It comes in three different sizes – Standard, XL, and XXL. In terms of work area, it begins at 444 x 444 x 101 mm with the Standard, followed by the 838 x 444 x 101 mm XL, and with the largest XXL giving the most workspace at 838 x 838 x 101 mm. Naturally, the sizes of the machines vary too, with the largest XXL sizing up at 1270 x 1042 x 483 mm and weighing in at 75 kg.

The Shapeoko 4 has a number of key features, with the most noticeable being what Carbide 3D calls a hybrid table. This MDF waste board features integrated aluminum T-slots for work-holding and comes with Carbide 3D’s Gator Tooth and Tiger Claw clamps that the firm claims can allow almost anything to be held down securely. Elsewhere, thick belts and strong V-wheels boost stability, and a 65 mm router clamp allows for a Carbide Compact router or Makita to be equipped. DeWalt routers are not recommended.

Able to cut through a variety of materials, including woods, soft metals such as aluminum, and just about anything in between, the Shapeoko 4 is great value for money and, for us, the ideal all-rounder in CNC.

Other Machines

There are a dizzying number of machines that take a similar form to the Shapeoko; many the result of open-source efforts to produce affordable CNC hardware (the original Shapeoko and the X-Carve it inspired included). And as many variants and splinter machines as there are, there are spins on the feature set, nuts and bolts used. We highlight the Shapeoko 4 above for its maturity, approachable software and user experience, and the reputation of Carbide 3D’s customer service, but there are plenty of other machines that offer similar punch and work area.

Sienci and Onefinity are two such companies gathering steam with their respective offerings, the LongMill Benchtop MK2 and Woodworker. While they lack the squared framing of the Shapeoko, they instead present as an H-shape that, in the Woodworker’s case, can be mounted anywhere, letting you work on existing structures as well as simply mounting a spoilboard for smaller jobs. The Onefinity Woodworker includes a control tablet with CAM functionality baked into it, in addition to a Wi-Fi connection (not necessary for the machine to function).

Another machine with an excellent reputation among the CNC community, the Inventables X-Carve is a popular choice for people looking to cut all kinds of materials up to soft metals such as aluminum. Like Carbide 3D’s Shapeoko range, the Inventables X-Carve has a strong community following and a userbase that shares its tips and tricks online on forums such as Reddit.

Users outside of North America would do well to find their local flavor of the machine. In the UK, Ooznest produces the Workbee Z1+, while Portuguese manufacturer RatRig has recently opened up with its Stronghold Pro CNC machine. In researching this update, it seems to us that many countries have their own spin on this machine style.

Learn more

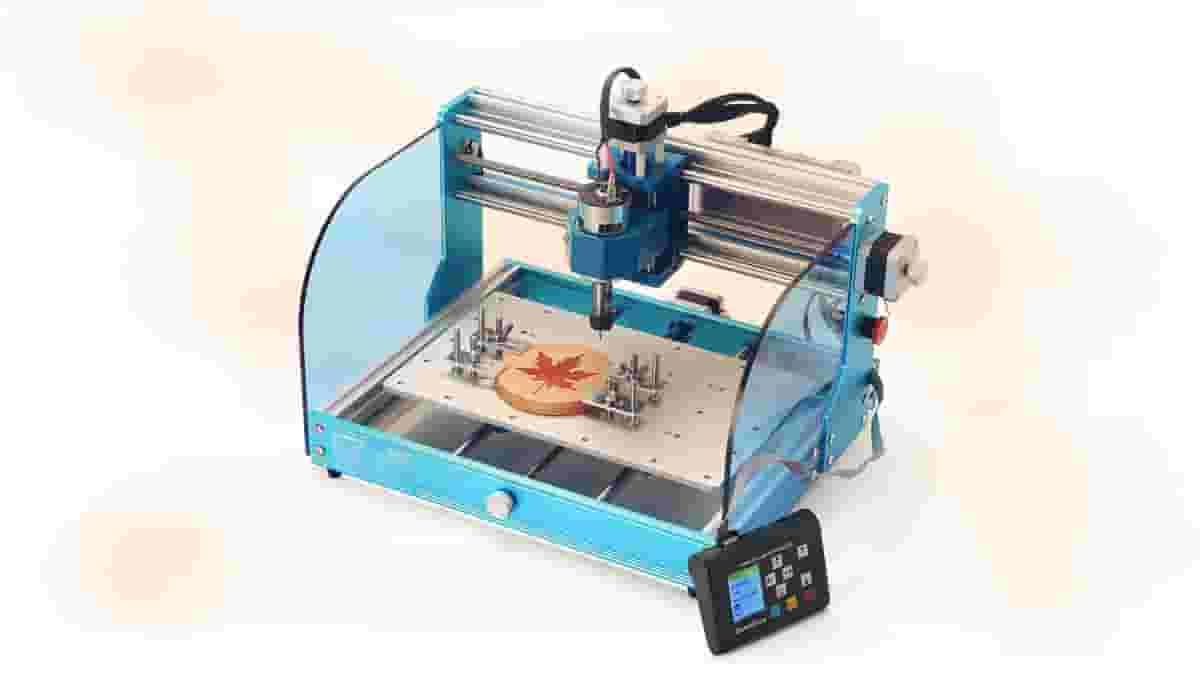

Budget: SainSmart Genmitsu PROVer 3018 V2

Those looking to dip their toes in CNC routers with the bare minimum of outlay can now do so for even less, as this SainSmart Genmitsu PROVer 3018 V2 (wow, that’s a mouthful) is cheaper than our last update. It’s basic, but not the most basic, as it doesn’t skimp on essential safety features like safety shut-off buttons, something no-name machines via dodgy retailers often do.

The SainSmart Genmitsu PROVer 3018 V2 arrives semi-assembled and features a surprising number of safety and convenience features including an offline controller, integrated safety shutoff button, plus sidewalls for chip containment.

There’s a slight hit to sturdiness, with a part bakelite construction that some criticize for the flex it can be susceptible to, but if you’re not pushing the system particularly hard, then we expect this to be easily handled.

You have options, too, with upgradeability to larger work volumes or a laser engraver possible. Overall, for the price, this is a very solid cheap CNC machine with the potential to drag you deep into the hobby.

Other Machines

There’s not a huge amount between low-cost CNC routers, with the 3018 design being the primarily-copied design. If you have slightly more to spend than the Genmitsu PROVer 3018 Pro V2, then SainSmart’s other offerings increase the quality and feature set in line. Larger work volumes, heavy-duty all-metal constructions, and flexible spindle options come with the uptick in price. There are rival companies out there offering something similar, but SainSmart offers the safest bet and most competitive machines in the budget sector, at least for now.

Hybrid: Snapmaker Artisan

A subject close to our heart. 3D printers doing cools things, such as CNC cutting and engraving. Or rather should we say CNC machines doing cool things like 3D printing? The Snapmaker Artisan attempts them all with a tough modular system that lets it swap out toolheads including powerful lasers, dual extrusion 3D printing, and a 200 W spindle for CNC work.

All of this is tied together with a tidy touchscreen-fronted control box with an emergency shutoff. An enclosure is included as standard.

For its ~$3,000 price tag, you get competent tools for three different manufacturing processes, which isn’t half bad. The work area spreads to some 400 x 400 mm, making it one of the larger machines on this list.

You’re unlikely to have a great time working extensively through aluminum with the Artisan but, given its versatility, we’re thinking varied or multi-stage work is where it shines.

Other Machines

Very few machines are capable of offering a hybrid manufacturing process. Manufacturers have to design around the most demanding process, and between CNC machining, laser engraving, and 3D printing, that’s CNC by a substantial margin. The end result might be a machine accomplished at each of those jobs, but one that stops well short of mastering any of the three. As they’re also expensive to design, build, and calibrate to a good standard, Snapmaker exists as pretty much the only horse in the race.

The firm still offers its previous generation machine, the Snapmaker 2.0. Available in a slightly smaller configuration than the Artisan, the Snapmaker 2.0 A350T is upgradeable with newer, more powerful modules and an enclosure, giving you a lite version of the Artisan for some small savings.

Alternatively, if your projects don’t demand space, but you do appreciate software that simplifies your work, the ZMorph Fab desktop “5-in-1” (they take liberties with what qualifies as a function) is a robust and compact system that can comfortably achieve small works. It’s fully enclosed and has the requisite safety features, plus a wealth of supporting educational materials, too. It commands a $5,999 premium, though – twice that of the Snapmaker Artisan.

Learn more

Metal: Carbide 3D Shapeoko HDM

Within the scope of this guide, your options for processing metals are somewhat limited, but not exhausted.

For one, there’s Carbide 3D’s Shapeoko HDM, a toughened version of the company’s venerable Shapeoko system that is comfortable chewing through aluminum from dusk ’til dawn. Such intense usage would stress and break other systems, but the HDM has something most others don’t: a water-cooled VDF spindle. A particular piece of kit designed to run cool and long, this is its core differentiator when compared to most other CNC routers that, in many cases, simply repurpose trim routers better suited to short bursts of work.

Unlike other Shapeoko products, the HDM is delivered on a pallet, ready to run. Eliminating assembly is more than just a convenience; it ensures the machine is built to a professional standard and edges out any slop in the build.

Other areas of improvement in the HDM over other machines from the company include a beefier power supply and control electronics, plus better isolation from electrical noise.

Other Machines

While many consumer-level desktop CNC routers are technically capable of chewing non-ferrous metals – even the standard Shapeoko machines are capable enough at it – you may lose some accuracy and have a finickier time from narrower margins of error from your spindle’s RPM. Some machines are built just for it, though, including the Bantam Tools Explorer. Designed to machine on the go (with an optional Pelican case accessory for secure transportation), this compact CNC machine is designed to simplify the metal machining process. It includes simple-to-use software that walks you through job setup (though note that it’s freemium software with a subscription plan to unlock advanced functionality and future features) and includes the probes for the system to identify your material’s dimensions, touch off, and machine without exhaustive manual setup.

A regular name we encountered on our mission to find solid CNC recommendations for metal work was the Penta Machine Co Pocket NC V2, a compact metal milling machine that offers the bonus of 5-axis movement. There are two versions, with the Pocket NC V2-50 capable of processing harder metals including 316 steel and titanium. We cover the Pocket NC in more detail below.

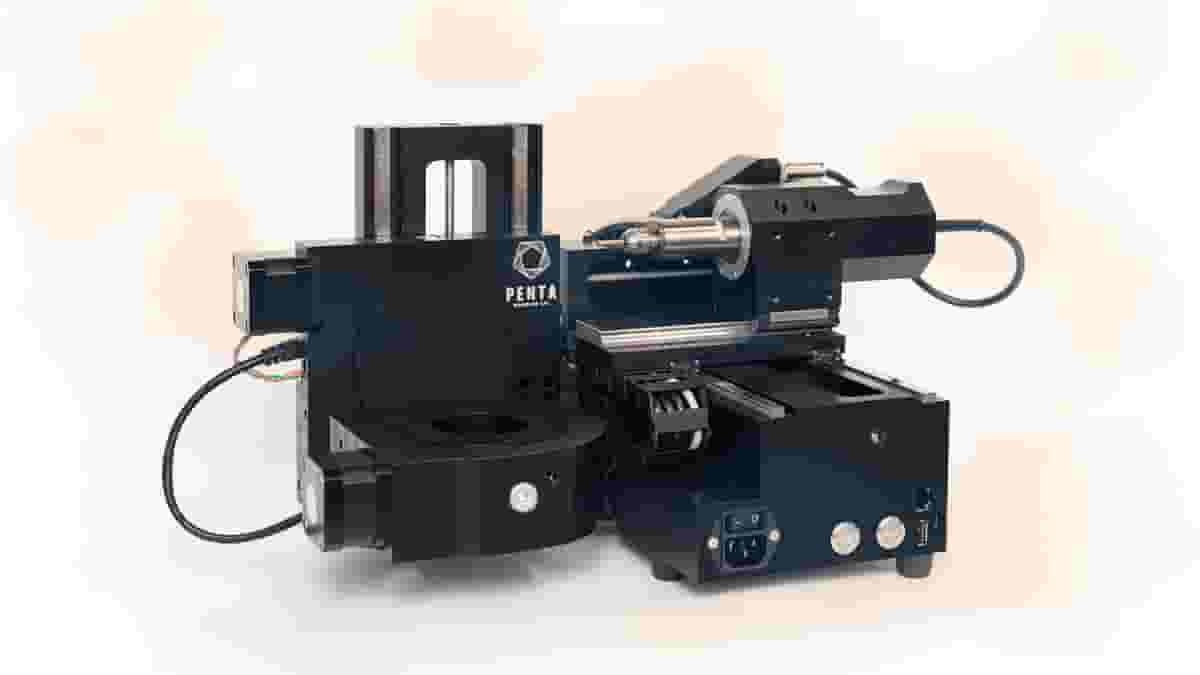

5-Axis: Penta Machine Co Pocket NC-V2

There are plenty of desktop CNC machines that offer 4-axis milling, but only through separately purchased add-ons. The Penta Machine Co Pocket NC-V2 is the only one we know of that offers 5-axis right off the bat, and handily carries a great reputation with it to boot. Designed around an educational experience, the system makes use of an industry standard for 5-axis milling, tool center point control (TCPC), which allows the machine to maintain 4- and 5-axis contouring independently from the orientation of the workpiece in your CAM.

For anyone expecting to upgrade to the larger, pricier, “professional” 5-axis tools, the skills gained with the Pocket NC carry through, making it a useful (and let’s not neglect competent – the Pocket NC V2 can comfortably chew through metals including some steel and titanium) low-cost investment to gain a lot of CNC capability.

There are a few versions of the Pocket NC, so it’s best to investigate your needs against what they offer. The primary differences between the Pocket NC V2-10, V2-50 CHB, and V2-50 CHK are the spindle speeds and the collets used (plus the baggage that goes with this – accepted tool diameters, tool change times). The V2-10 is cheaper, and could be considered more “general purpose” and optimal for working with the full build volume, whereas the V2-50 is, in Penta Machine Co’s words, ideal for “fast, narrow, and deep machining”.

There’s a further difference between the V2-10 and V2-50 in that the 50 requires an air compressor to help manage the heat and debris generated during cutting.

Other Machines

Our research tells us that it’s slim pickings for 5-axis machines in the desktop/hobbyist space. Short of spending tens of thousands on an industrial-grade machine, or building your own, the only machine we can confidently point to is the Pocket NC above.

There are plenty of 4-axis machines and upgrades out there, though, with many of the popular machines mentioned on this list capable of 4-axis work. Think hard about whether you unconditionally need the fifth axis – it could be there’s a more cost-effective solution in working with 4 axes.

Handheld: Shaper Origin

How can a CNC router be handheld? That seems paradoxical. And that’s what we thought until we saw the Shaper Origin, a frankly radical frankenmachine that puts the router back on the table, in a manner. The Shaper Origin basically offers your traditional plunge router form, slaps a computer in it, and lets you handle the general direction of travel, with the device taking over the specifics of the job.

You won’t be making 3D reliefs with the Origin, but for large-scale (or small) work, you create your job in the provided software and then follow the machine’s directions on the onboard display. Alternatively, you can use the display itself to create quick jobs using shapes and lettering and work completely independently from a computer.

Ad-hoc adjustments to the work you are doing while doing it is one of the superpowers of the Origin. On the imaginary scale of power tool to CNC machine that we’ve just conjured for the purpose of illustration, it sits squarely as a smart power tool. Without the operator, it’s useless – but there is a CNC element in that the computer is making fine adjustments and taking accuracy on your part completely out of the equation. It’s completely genre-defying.

Large-Format: MakerMade M2

When is a large-format CNC machine not a large-format CNC machine? When you stand it up and push it against a wall, naturally.

A spin-off of the open-source Maslow CNC, the M2 by MakerMade takes the unusual, chain-driven, easel-mounted CNC machine of the original and adds stability and comfort upgrades. The novelty of the design is that you can work on stock up to approximately 1200 x 2400 mm (4 x 8 ft) but with a footprint only ~600 mm (~24 inches) deep.

The system comes without a spindle and offers clamp sizes of 65 mm, 71 mm, and 91 mm for you to mount your own. Alternatively, MakerMade offers its own 65 mm spindle that includes a few design touches with the large-format nature of the system in mind – an extra-long power cable, for one thing. If you use a standard router or spindle, you may find a power cord extension necessary.

All in, the sled, spindle, bricks, and framing for it all add up to a heavy cutting unit that can power through materials at, MakerMade claims, up to 40 inches per minute. Not bad for the scale at which you’ll be cutting.

You have to build it yourself, to a degree more than many of the kits on this list, but it’s also still pretty affordable, despite a recent near-$400 price increase. Sheesh.

Other Machines

If you have the workshop space to fit it, Carbide 3D’s Shapeoko 5 Pro is the company’s largest machine yet and packs the hardware to perform across its ~1200 x 1200 mm (~4 x 4 foot) work area. It’s the premium Shapeoko experience, short of the VDF spindle (available separately), and includes the myriad of features that make the machines a worthwhile investment including a hybrid table for flexible workholding, and Carbide 3D’s BitSetter tool for simple tool changes. We particularly like that the gantry can project the spindle beyond the worktable for tackling joinery. As with all Shapeoko machines, though, it’s a “headless” experience, meaning all control comes through a connection with your computer.

A more “standalone” time could be had with the Onefinity Elite Foreman, Onefinity’s most advanced CNC machine. You get a Masso controller with a 15-inch “industrial” grade display for direct control and programming over the machine. As with the Shapeoko 5 Pro above, the work area sprawls to ~1200 x 1200 mm (~4 x 4 feet). Onefinity claims the Elite Foreman was designed around the Makita 1-1/4 HP Compact Router (RT0701C), not included, but any 65 mm or 81 mm router can be mounted.

What's Changed?

To help you keep track of past recommendations and structural changes to what we’re recommending, here’s a changelog of what’s happened to this article:

Update – February XX, 2024: Not an awful lot has changed in the chewy nom nom world of CNC machining over the last few months. Still, we’ve found time to go through this piece and check things like availability and pricing and tidied up some styling and language bits. For now, though, we stand by these picks and feel they represent the best choices currently on the market.

Update – October 19, 2023: A long, hard think about this article has us convinced that CNC machines are simply too different to present in a broad overview-style list in the way we used to. And so we’ve busied ourselves researching solid machines to highlight across a variety of types and uses instead. We’re adopting a conversational tone, too, spelling out other machines to consider beyond the primary highlight for each.

Update – February 27, 2023: We were a touch behind with updates to this article. Some machines were replaced with new models – such as BobsCNC’s Evolution 4 becoming the Quantum and Sienci’s LongMill evolving to the LongMill MK2. Prices have changed, too. But, otherwise, this list is largely the same. We have our eye on an upcoming system or two, so we might even see a fresh update soon.

Further Reading

If you’ve stumbled upon this article but aren’t too savvy with CNC technology and how it works, then we have a few links for you that might help explain things.

We’ve compiled this list containing several guides and informative pieces on the ins-and-outs of CNC technology. From the very basic ‘What Is CNC? – Simply Explained’ all the way to our list of ‘The Top 3-in-1 3D Printers’, which gives you the option of 3D printing, laser engraving and CNC machining all in one convenient package.

License: The text of "The Best CNC Routers – Buyer’s Guide" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.