Reliable, affordable, and easy-to-operate carbon fiber 3D printers, alongside innovative carbon fiber materials, are bringing the strength and durability of carbon fiber parts to the desktops of businesses and mid-size manufacturers worldwide.

Chances are, if you’re looking to buy a carbon fiber FDM (fused deposition modeling) 3D printer, you already use carbon fiber materials in your business but need a faster and cheaper way to make your carbon fiber tools and parts. Or, perhaps you’re turning to 3D printing carbon fiber to replace expensive metal parts and machined aluminum components with something just as strong but far lighter and available in hours, not days. You may also choose carbon fiber 3D printing to create stronger functional prototypes that can withstand the rigors of mechanical testing or even carbon fiber final products, such as jigs and fixtures for manufacturing.

Although 3D printers that use carbon-fiber-infused filaments are not the only way to 3D print carbon-fiber parts — there’s also selective laser sintering with carbon-fiber-infused nylon powder — FDM machines are the most economical entry point for most companies. Below we feature the top desktop- and benchtop-size printers, but we also have a guide to industrial carbon fiber 3D printers for larger volumes and more advanced features.

Carbon fiber-reinforced filaments – including chopped carbon fiber, continuous carbon fiber (CCF), and continuous fiber co-extrusion (CFC) – open up new ways to produce high-performance prototypes and end-use parts for aerospace, automotive, and manufacturing, among many other industries. 3D printed carbon fiber parts are rapidly replacing molded carbon fiber and metal components for a long list of applications. Skip down to the end for a closer look at the types of carbon fiber that could affect your purchasing decision.

In this buyer’s guide – updated for 2024 – we pull back the curtain on carbon fiber 3D printers and explore the affordable desktop and benchtop systems for professionals. While it’s true that to print with carbon fiber-infused filament, you, technically, only need a hardened steel nozzle that reaches the optimum temperature for carbon fiber filament, which is around 260°C. But you’ll need more features if you’re serious about reliably and consistently producing the highest-quality carbon fiber parts for your business, which is the inspiration behind this guide.

Carbon fiber material can be tricky to print with so many printers offer features designed to address these points. For example, since carbon-fiber-infused filament is abrasive and the carbon fibers can lead to frequent nozzle clogging, affecting the smooth flow of filament, printers that manage carbon fiber material the best have a hot end that can maintain a high temperature consistently for a long time. The higher print temperatures put additional stress on the hot end that also can be balanced with a heated bed and an enclosure to prevent temperature fluctuations. An full enclosure isn’t strictly necessary, it’s the consistent heat that’s the goal.

Bed adhesion can also be a problem requiring specialized build surfaces to help prevent warping, and features, such as precise bed leveling are important. Most critical, though, is a print profile of speed, temperature, and layer height tuned specifically to carbon fiber.

In the end, you can 3D print with carbon fiber filament on machines that cost only a few hundred dollars, but considering that the material itself is about $50 a spool and the risk of failed prints on a budget machines is likely higher, you may not be saving any money in the end.

If you’d like to know more about the technology, materials, applications, and what to look for in a carbon fiber 3D printer before you start browsing the machines, scroll down to the end. Otherwise, let’s dive into printers!

| 3D Printer | Fiber Type | Max. Build Volume (mm) | Chamber | Max. Extruder Temperature | Market Price (approx.) | Check Price Commission Earned |

|---|---|---|---|---|---|---|

| Bambu Lab X1E | Chopped | 256 x 256 x 256 | Actively heated to 60ºC | 320°C | $2,500 | |

| Raise3D E2CF | Chopped | 280 x 305 x 605 | Passively heated | 300°C | $4,500 | |

| UltiMaker Method X Carbon Fiber | Chopped | 190 x 190 x 196 | Actively heated to 110°C | 300°C | $6,000 | |

| Delta WASP 2040 Industrial X | Chopped | 200 x 200 x 400 | Actively heated to 70°C | - | $6,350 | |

| UltiMaker S7 | Chopped | 330 x 240 x 300 | Passively heated | 280°C | $8,400 | |

| Flashforge Creator 4-S | Chopped | 400 x 350 x 500 | Actively heated to 65ºC | 360°C | $13,000 | |

| Markforged Mark Two (Gen 2) | Continuous | 320 x 132 x 154 | Not heated | - | $18,500 | |

| Anisoprint Composer A3 | Continuous | 460 x 297 x 210 | Passively heated | 270ºC | $35,000 | |

| Stratasys F190CR | Chopped | 305 x 254 x 305 | Passively heated to 30ºC | - | $45,000 | |

| Markforged X7 Gen 2 | Continuous | 330 x 270 x 200 | Not heated | - | $73,000 |

Desktop & Benchtop Carbon Fiber 3D Printers

Carbon fiber printers are getting smaller. There’s a growing selection of office-friendly CF printers entering the market aimed at a wide audience of designers, engineers, and any type of businesses that can benefit from super-strong 3D printed parts, whether it’s for machines shop fixtures, prosthetics, or custom bicycle frames.

However, not every professional filament 3D printer can print with carbon fiber filament because this material requires a high extrusion temperature (at least 200ºC) and its abrasive nature can ruin brass printer nozzles so special nozzles are also required. Always compare the specs of your printer to the requirements of your carbon fiber filament.

Now, here are some of the most sought-after machines for professionals.

Bambu Lab X1E

Although the Bambu Lab X1E just launched in October 2023 it makes our list of top carbon 3D printers because we had it in our shop recently and printed part after part of impressive carbon fiber prints.

We’re featuring the X1E over the company’s X1 Carbon for two reasons. First, we experienced frequent nozzle clogs with the X1 Carbon that we were able to trouble shoot, but it was a flaw. Secondly, the X1E is only sold through qualified resellers that also offer customer support and trouble shooting, which is what a business should look for since you don’t want to spend hours reading online help Wikis or figuring out issues on your own.

The X1E has added features an actively heated chamber to 60ºC for better results with engineering-grade materials like carbon fiber PHAT, and a new hotter (320ºC) nozzle, compared to the X1 Carbon. It also sports a heavy-duty air filtration system and a higher level of network security.

To dry your carbon fiber filament before printing the X1E itself is a dryer. Just turn it on, heat it up, and put the filament in the cardboard box in the printer for about 12 hours following the temperature settings on the filament.

Raise3D E2CF

Released in 2021, the E2CF is Raise3D’s dedicated carbon fiber machine. Setting it apart from the pack are the independent dual extruders so you can print with carbon-fiber nylon and a more easily removed support material. This no only eases removing supports but saves on material costs.

The silicon carbide nozzles, which boast better wear resistance and thermal conductivity than hardened steel, can get up to 300°C and the build plate maintains a comfortable 110°C.

The company says, the E2CF aims to meet the needs of engineers in automotive, aerospace, and healthcare, who need to produce parts with a high strength-to-weight ratio and have a consistently high performance during long-term operations.

To ensure a stable printing process, the E2CF is equipped with two standalone sealed dry boxes, developed by Raise3D to deal with the high water absorption of nylon and fiber-reinforced filaments. These dry boxes are attached to the printer, allowing the materials to be kept in conditions of minimum humidity while printing. Another feature is the assisted auto-bed leveling process with a high-precision optical sensor for improved accuracy in nozzle height calibration.

The E2CF includes the features you’d expect on an industrial FDM, including a camera, robust software, auto leveling, HEPA air filter, touchscreen control, and power loss recovery.

The E2CF is compatible with fiber-reinforced PLA, ABS, nylon, PET, PPS, and others from a variety of makers.

UltiMaker Method X Carbon Fiber

Setting the Method X Carbon Fiber Edition apart on this list is its material options. With the three interchangeable extruders that come with this printer, you can print with carbon-fiber-reinforced nylon (PA12), carbon-fiber-reinforced ABS, and stainless steel 316L. I know we’re focusing on carbon fiber here, but one machine that can print CF and metal may tick some boxes for certain manufacturers.

Method X is a dual extruder machine aimed at the replacement parts market for metal parts, and jigs and fixtures for manufacturing. The company launched the larger Method XL in may (305 x 305 x 320-mm build volume, $13,000) that you can also attached a optional extruder to for carbon fiber materials.

This machine features three quick-change extruders capable of reaching 300°C to easily handle this abrasive material. The Method X has a 110°C heated chamber.

All in all, the UltiMaker Method machines are a versatile option thanks to their high customizability. Their relatively reasonable price tag also makes them good choices for your first carbon fiber 3D printer.

Delta WASP 2040 Industrial X

Stretching the limits of what might fit on your desktop, the Delta WASP 2040 Industrial X is manufactured in Italy by WASP and prints in a range of materials including carbon composites. The machine’s Hot and Cold Technology allows for controlling the chamber temperature up to 70°C and cools down the internal parts, which makes printing technical materials easier, the manufacturer says.

You can quickly switch between the dual Zen X extruder for single and multi-material printing and the Flex extruder for printing flexible materials. Delta Wasp 2040 Industrial 4.0 can be connected to WiFi networks so that you can manage your printer from a smartphone, tablet, or PC. The printer also features a camera for monitoring the print remotely.

The WASP 2040 Industrial X also features a dual gear filament driver for better material handling and a large TFT display for easier usability. WASP also manufactures the 4070 ZX model, much larger printer that’s also capable of processing carbon materials.

UltiMaker S7

UltiMaker has been a household name in FDM 3D printing for a long time and launched its most pro printer yet in Jan. 2023, the S7. Then in July it launched a carbon fiber expansion kit for the S7.

UltiMaker users have long wished the machine could manage carbon fiber materials and with the new kit, which includes two spools of UltiMaker PET CF in black and one spool each in both blue and gray. It also includes one 0.4 mm Print Core CC and one 0.6 mm Print Core CC. New print profiles in the Cura slicer ensure near one-click success.

In addition to the new PET carbon fiber, UltiMaker can also print with the company’s ABS carbon fiber and nylon carbon fiber. The carbon fiber PET is the first material by UltiMaker that is able to be enhanced for even greater mechanical performance with annealing or post-printing heat treatments.

UltiMaker says the S7 includes features that customers have requested, such as a flexible build pate, and underneath the build plate is where UltiMaker added new tech that enhances leveling and temperature consistency, both critical to achieving tight tolerances and part quality. Another design change improving temperature is the glass door. UltiMaker ditches the S5’s signature double-door design for a single door on the S7, a change that removes the cool air that could be drawn in from between the double doors.

The S7 comes with an optional material changer and an improved monitoring camera.

Flashforge Creator 4-S

Flashforge, best known for its consumer printers, launched the Creator 4 to appeal to design, engineering, and manufacturing firms.

Available in four versions, the Creator 4-S, is the one with the Extruder HS, the company’s carbon-fiber specific extruder that can reach 360℃. Creator 4-S’s enclosed build chamber offers heating capabilities of up to 65℃ and a heated print bed to 120℃.

Unlike conventional dual extruders, the Creator 4’s independent dual extruder gantry enables you to use both printheads simultaneously, doubling the throughput potential of the 3D printer, or enabling you to use a soluble support material.

On the software side, the printer comes with a filament management system that automatically sets internal temperatures according to the material being used. Additional features include a HEPA 12 air filter for safe indoor use and a built-in camera for remote build monitoring.

Flashforge materials include CF-PLA and CF-PETG.

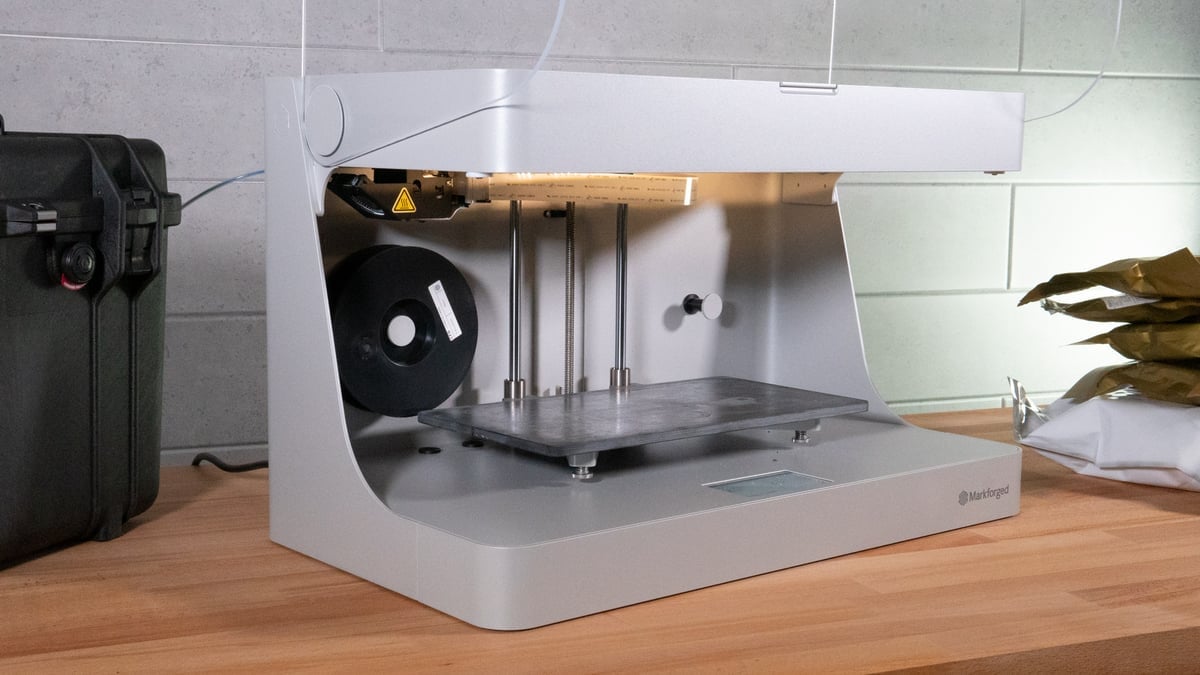

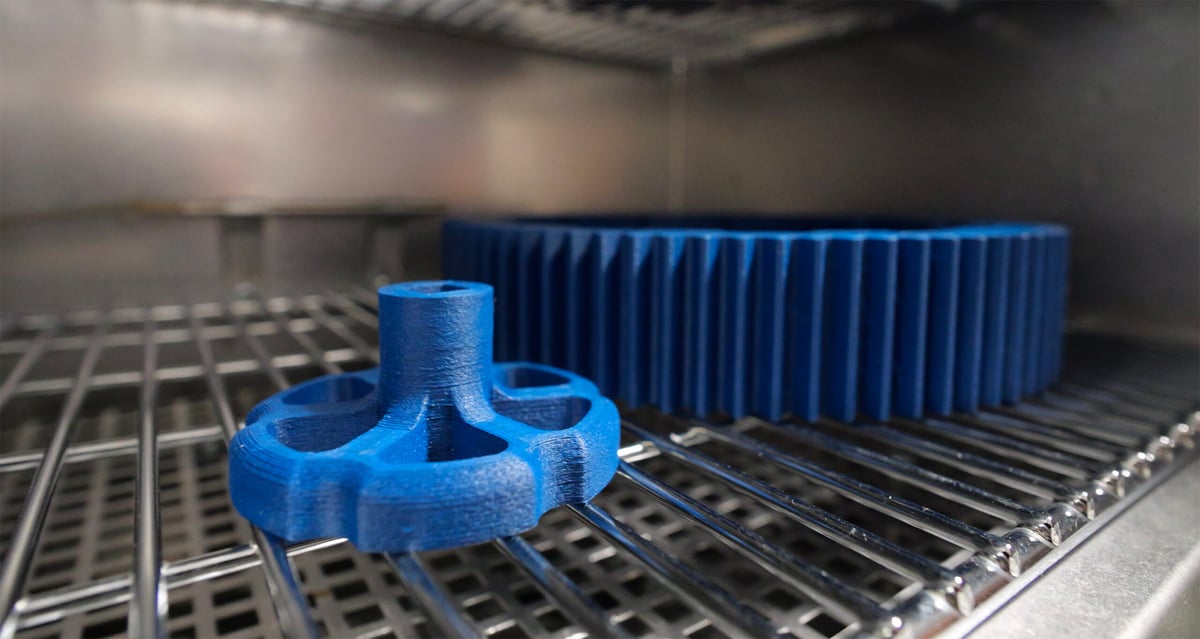

Markforged Mark Two (Gen 2)

As an industrial 3D printer in desktop form, the Markforged Mark Two, in our experience in the All3DP print lab, delivers high-performance parts, consistently, straight off the print bed.

This 3D printer has two extruders and uses continuous fiber reinforcement technology meaning that one nozzle extrudes Onyx, Markforged’s proprietary carbon-filled nylon material, while the other nozzle reinforces Onyx with a continuous strand of fiber (carbon fiber, Kevlar, or fiberglass). This fiber-on-fiber reinforcement process produces end-use parts with strength and versatility.

Prints using just the Onyx material without the reinforcement are also impressive.

We took the Markforged Mark Two for a spin in 2022, and you can read our in-depth analysis below.

To streamline the reinforced fiber production process, Markforged has developed its own software that enables you to import and slice a design to be optimized for continuous fiber 3D printing. You can select where you want and don’t want the continuous fiber. In the reinforcement view, you can configure the print’s fiber content on a per-layer basis, with a shortcut to distribute multiple isotropic areas of reinforcement evenly throughout specified ranges. You also control concentric areas of reinforcement, choosing to blanket the inner, outer, or all walls with fiber.

Neither the bed nor the chamber are heated. Markforged’s own Onyx material is specifically designed for this and you can’t use any other material (or you won’t get good results with any other material). Material handling is critical, so the filament stays in a dry box ($400) as it’s used.

In Oct. 2023, the company introduced a new simulation software so you can test the strength of your design ideas without even printing them out.

Although the Mark Two (Gen 2) has a modest 320 x 132 x 154 mm build volume, it has been widely adapted by a various industries for everything from jigs and fixtures to movie props.

Anisoprint Composer A3

Composer A3 from Anisoprint is another continuous fiber 3D printer (as opposed to using filament with chopped fibers). The technology takes carbon fiber 3D printing up a step from the chopped carbon fiber filament printers above and adds substantially more strength.

Through a complex extruder, various thermoplastic polymers can be reinforced with a continuous strand of carbon fiber as they are simultaneously extruded. This approach ensures low porosity, good adhesion of fiber to polymer, and superior mechanical properties, Anisoprint says. Unlike the Markfogres, Anisoprint says you can imbed continuous carbon fiber into your choice of polymer filaments as long as they have a processing temperatures of up to 270°C, which includs PLA, PETG, PA, and PC.

Each of the printer’s extruders comes with its own fan, which helps in cooling the printed material and prevents warping and other issues, the company says.

The Anisoprint slicer software Aura lets you select where to place the carbon fiber and where not to, like in supports or areas that don’t need the extra strength.

Stratasys F190CR

The Stratasys F190CR (and the larger version F370CR) 3D printers – CR stands for composite-ready — introduced carbon-fiber-reinforced nylon to the company’s older Stratasys F123 series.

These two extensions of its benchtop-size machines aim to give users an easier-to-print experience for advanced engineering-grade materials. Stratasys’ carbon-fiber reinforced filaments for this machine are ABS-CF10 and Nylon-CF10. The F190CR only prints with Stratasys’ proprietary materials.

The F190CR series has a heated chamber (up to 30ºC) and a heated bed, and Stratasys says it is more efficient because you can print in multiple resolutions from a single print head, avoiding print head changes.

There’s a built-in camera and two unheated material bays located in pullout drawers allow for easy accessibility and fast changes.

Markforged X7 Gen 2

Straddling the divide between benchtop and fully industrial carbon fiber printer is the X7 from Markforged. This 3D printing platform has a relatively small footprint and features continuous carbon fiber (like the company’s Mark Two above) along with Kevlar reinforced materials for producing high-performance parts.

Compared to the Mark Two, the X7 is a more advanced system overall, the company says. It streamlines the entire production ecosystem and includes premium features, such as a laser inspection process that scans parts mid-print to check the dimensional accuracy.

Using the dual material system, the Markforged X7 is able to produce composite parts where the first nozzle builds the plastic matrix of the model (out of nylon or carbon-fiber infused nylon) while the second nozzle winds fiber (carbon, Kevlar, glass, or high temp fiberglass) throughout the part or where needed.

The X7 uses the Markforge machine learning software to help the 3D printing system to adapt and account for variables so it produces parts that are accurate and precise the first time, the company says.

All Markforged materials are proprietary and the machines are not open to third-party materials.

In late 2023, Markforged launched another carbon fiber machine called the FX10. In many ways, the X7 and the FX10 address a similar need, have a similar build volume, and are both continuous carbon fiber 3D printers. But the FX10 picks up where the X7 left off, Markforged says. The FX10 is twice as fast as the X7, and what makes the FX10 really stand out from all other Markforged 3D printers is a series of new innovations covering sensors, software, and hardware for more reliable and automated operation.

Understand Carbon Fiber Properties for Better Prints

Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own to maximize the quality of your prints. Each 3D printer and carbon fiber filament is unique, so check the material requirements against your printer’s specs and experiment with different settings to achieve optimal results.

Some of the carbon fiber printers featured in this article use proprietary materials only available through the printer manufacturer. In most cases, you can only use the manufacturer-approved materials with your carbon fiber printer, but the good news is that there still is variety.

For example, the Markforged Mark Two, in addition to continuous carbon fiber (CCF), can print with its proprietary Onyx, made from nylon mixed with chopped carbon fiber, as well as fiberglass and Kevlar. The Anisoprint can print with continuous carbon fiber or basalt fiber depending on your need.

Chopped vs Continuous Carbon Fiber

Let’s take a minute here to lay out the difference between a carbon fiber 3D printer that prints with filament infused with chopped carbon fiber and a 3D printer that prints with a continuous string of carbon fiber.

Filaments containing carbon fiber particles, whether its nylon carbon fiber, PEEK carbon fiber, or some other base polymer combined with carbon fiber, work the same way. The heat from the extruder makes the filament pliable and also aligns the embedded carbon fibers in the print direction, which gives the final print its strength and stiffness. Different brands of carbon fiber filament contain different percentages of carbon fibers, usually around 20% carbon fiber by weight.

The second method of carbon fiber printing is continuous carbon fiber (CCF), which uses dual extruding nozzles. One lays down a layer of continuous carbon fiber while the other lays down a layer of another material. This method creates parts that are stronger than using chopped fibers and provides a more consistent load distribution. It’s ideal for parts that don’t require carbon fiber throughout, but, instead, reinforcement in specific areas – just on the outer wall, for example.

Another version of this approach is continuous fiber coextrusion (CFC), where a plastic material and a continuous fiber are merged inside the extruder.

Use a High Extruder Temperature

Compared to easy-to-print materials like PLA, carbon fiber-reinforced materials require a much higher extruder temperature, generally around 260°C and above. The first thing on your carbon fiber 3D printing checklist should be to check the maximum extruder temperature of your printer. If the temperature can’t get high enough, you shouldn’t try using carbon fiber filaments with your machine.

Use a Hardened Steel Nozzle

Since carbon fiber-based materials are so abrasive, they tend to wear down the printer’s brass nozzle and are more likely to clog the extruder pathway. To minimize these frustrating problems, it’s best to equip your 3D printer with a hardened steel nozzle. This hardware upgrade helps your printer handle the abrasive nature of carbon fibers. It’s worth noting that nozzles made of hardened steel are less thermally conductive than brass nozzles.

When printing with a hardened steel nozzle, it’s best to set the extruder temperature 40-50 °C higher than the filament manufacturer recommends. This will ensure the extruder remains at a high enough temperature while the carbon fiber filament is extruding. Additionally, turning the fan speed down will lessen the impact of any thermal conductivity issues.

Prevent Clogs With Large Diameter Nozzle

Another way to prevent carbon fiber filament from clogging the extruder is by using a nozzle with a larger diameter (0.5 mm or above). When filaments are reinforced with carbon fiber, they become more brittle. This increases the risk of the material snapping, especially when it’s being directed around tight corners or around the frame of the printer.

There are a couple of ways to reduce the chances of filament breakage, such as utilizing a PTFE filament guiding tube and leaving some slack so that it isn’t interacting with sharp turns or other rough areas.

Lower the Print Speed for Carbon Fiber

There are also a few adjustments you can make to the settings in your 3D printing slicer in order to improve compatibility with carbon fiber filaments. For instance, lowering the print speed by around 50 percent makes it easier for the extruder to handle the carbon fiber more effectively. Another way to fight clogging issues is by reducing or eliminating the retraction distance in your settings.

To Anneal or Not To Anneal?

Annealing is a post-printing heat treatment designed to better fuse layers and boost the overall strength of a carbon fiber 3D print. Annealing is a heat treatment process traditionally used in metal and glass industries to relieve stresses, increase ductility (the ability of a material to deform or stretch under stress before breaking), and improve material properties. The basic principle involves heating a material to a specific temperature using a type of oven and then cooling it at a controlled rate.

Printer makers don’t make these ovens, so it would be a separate equipment consideration.

Though annealing can have benefits it’s not a universal approach for 3D printed polymer parts. Some polymers, such as nylon, can be improved with an additional heat treatment, but it depends on your specific brand of filament. For example, carbon-fiber nylon from Bambu Lab and UltiMaker recommend annealing, while other manufacturers recommend against it. For this reason, the process can be complicated and may yield unexpected results if you don’t have specific guidance from the material maker, such as what temperature to heat treat and for how long.

License: The text of "The Best Carbon Fiber 3D Printers in 2024" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.