Anycubic and Creality are two of the larger predators prowling the savannah of the 3D printing landscape. Recently, you might have spotted them leaving the undergrowth to present two brand new FDM 3D printers they believe will provide them with the opportunity to pounce on a sale. On many thousands of sales, actually.

Both machines are a step up in quality and feature higher specifications than previous efforts from the brands. Compared to “last-gen” devices such as Anycubic’s Mega S and Creality’s Ender 3 V2, the specifications of the Kobra and Ender 3 S1 provide a more advanced “set and forget” level of 3D printing. That will be appealing to people willing to spend a little more cash in exchange for convenience and, theoretically, less fussing about trying to dial in settings.

In this piece, we look at the differences between these two machines in a little more depth, examining the specifications and discussing our own hands-on experiences. If you’re puzzled about one or both, this is the place to be.

At A Glance

Features

A small table of statistics just won’t cut it. We’ve got to go… deeper.

And with that, here’s a little look at the features of these machines in more detail, based on our experiences using them. We’ll see the differences much clearer by going through these machines side-by-side, feature-by-feature.

Background and Basics

Anycubic and Creality are two big guns in consumer 3D printing; both names are responsible for generating tens of thousands of sales every year. It’s undoubtedly Creality that’s the bigger of the pair, though. The Shenzhen-based manufacturer is easily the leading budget 3D printer manufacturer right now, and its Ender 3 series of FDM 3D printers is the most successful in the hobby’s history.

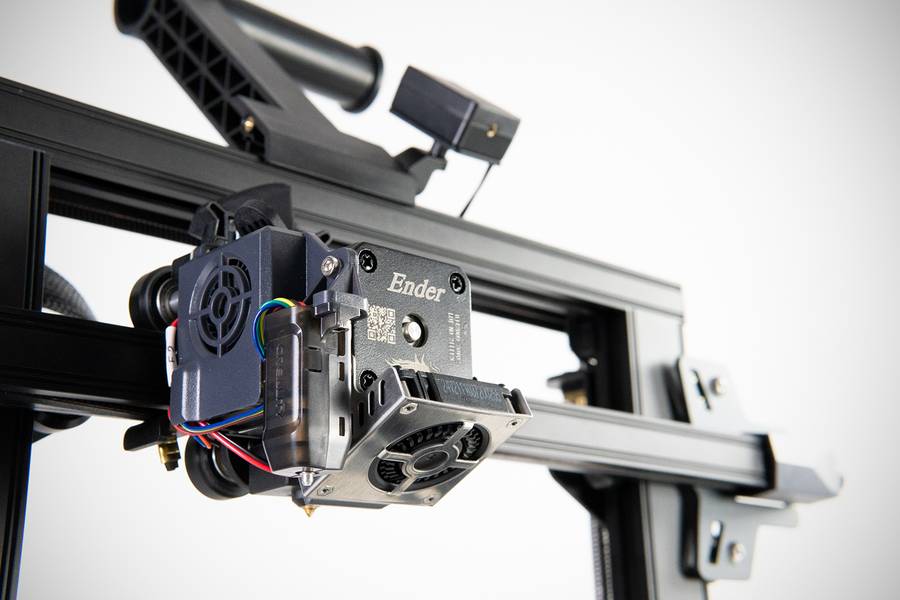

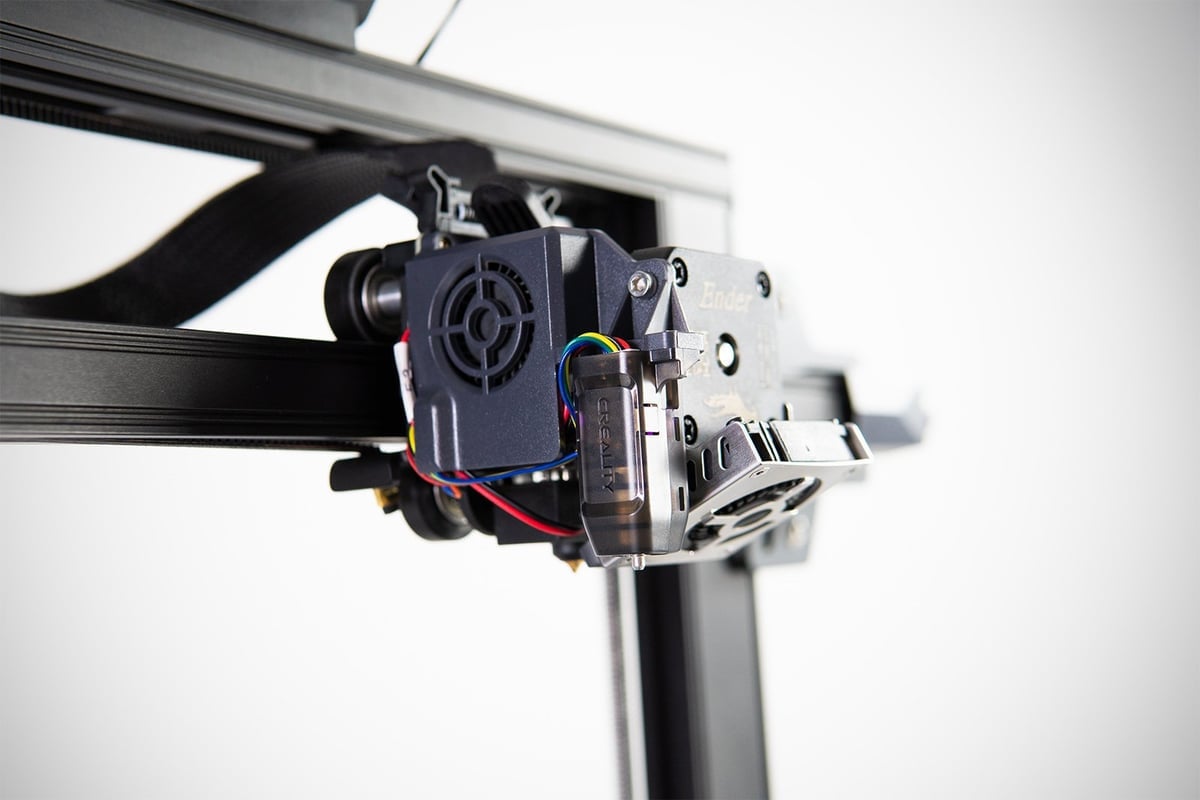

The Creality Ender 3 S1 is the latest Ender 3 series 3D printer and is a substantial upgrade on the machines that came before it. The Ender 3 S1 packs a brand new direct extruder (dubbed the Sprite), automatic bed leveling, a new magnetic spring steel PC print sheet, plus a host of other minor upgrades, making it the most advanced Ender 3 series printer to date.

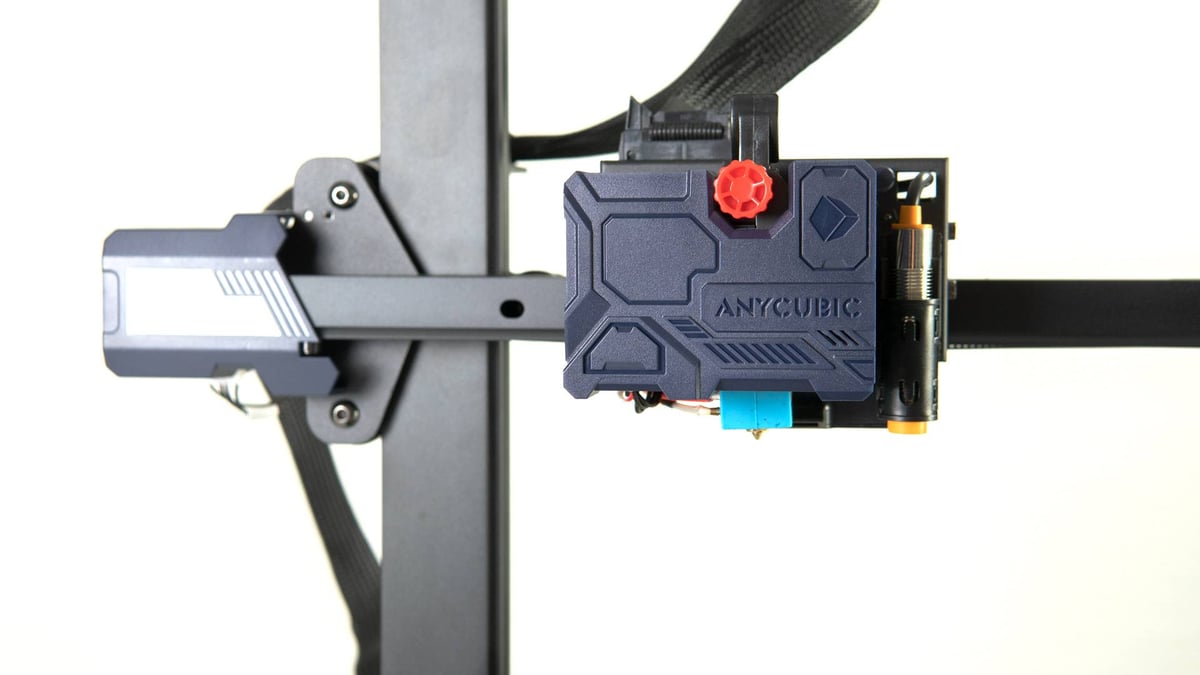

Anycubic’s Kobra is also a big step forward over previous Anycubic FDM offerings. Like the S1, it also packs a direct extruder, automatic bed leveling, a spring steel print sheet, and lots of little upgrades to improve usability and performance. Compared to previous efforts from Anycubic, it’s a far better machine for everyday users and has ensured Anycubic continues to have a foot in the budget FDM 3D printer sector that Creality so comfortably dominates.

These machines come almost entirely assembled, with only a minimal amount of effort required to get them into printing order. That’s great if you’re a newcomer, but Anycubic’s Kobra does feature better instructions than those offered by Creality, which we typically find a little thin on detail and with difficult to parse illustrations. You may as well bin them from the get-go and watch an influencer screw it together on YouTube instead.

Both machines are a “step forward” from previous generations of FDM 3D printers launched under the respective brands; they could also be described as more advanced beginner 3D printers. Both bring features to the table previously found on pricier printers, possibly a sign that some of the technology is filtering down. Or, that the manufacturers have figured out how to make them cheap? It is often a characteristic of brands based in the manufacturing powerhouse that is Shenzhen.

So, we have two machines from two big companies trying to do similar things at a similar price point. Has one managed to do it better than the other? Or are you going to be well off no matter which of these printers finds its way onto your shelf? One thing’s for sure, you’ll be seeing a lot of these machines talked about, filmed, and snapped online over the next couple of years.

Learn more

Learn more

Both manufacturers hold back when it comes to detailing their mainboards.

Despite giving its new extruder a short, catchy, even slightly fun name, Creality’s mainboard instead goes by CR-FDM-v2.4.S1_v301. It’s almost certainly a variation on the company’s 32-bit 2.4.x boards (the Ender 3 V2 uses the 4.2.2). It comes equipped with stepper-motor-silencing drivers, though it isn’t stated anywhere which drivers they are and as they’re buried under heatsinks and thermal paste, we can’t really check. We asked Creality but didn’t get a response.

Looking back over previous Creality offerings, we can see they’ve offered TMC2208, TMC2209, or TMC2225 drivers, so it’s fair to assume it’s one of a combination of these to be found in the S1. Don’t expect to do any advanced firmware controls on these without getting the tools out. Linear advance, as cool as it is, probably won’t be doable here without significant modification.

Anycubic’s mainboard is the self-developed Trigorilla Pro A V1.0.4. We reached out for specifics on this board, but Anycubic told us that most of it cannot be revealed publicly, so here’s what we know.

The stepper drivers (TMC2209s on the X-, Y- and Z-axes, and MS35775 on the E) are soldered to the board so you’ve not much hope of swapping those out, but they run in UART or SPI modes, meaning slightly more advanced features are possible. An example of that is the sensorless homing the Kobra possesses. It’s rare to see in a printer at this point in the market. You won’t find one single physical, optical, or any other kind of endstop along the X- and Y-axes. Instead, it registers the resistance against the printhead when they reach their physical limits and cut the motion. It’s clever.

We discovered during testing that right out of the box, basic values such as eSteps and flow needed tweaking. Linear advance is also not currently doable, you’ll need customized or updated firmware for that to happen. Anycubic’s default UI and options are limited to only the basics; filament loading, temperature control, movement, leveling, and Z offset. For anything more advanced, you’ll need a host and control platform like OctoPrint or Pronterface.

Learn more

Learn more

Build Volume

Both of these machines come in wearing very similar build volumes that both lie in the “bang average” sector of printable space.

Creality’s Ender 3 S1 has a 220 x 220 x 270 mm build volume, which differs from previous Ender 3’s by delivering an extra 20 mm in the Z. No big deal.

Over on the Anycubic Kobra, you’ll find a slightly unusual build volume of 222 x 222 x 252 mm, 2 mm larger in every axis than the Creality Ender 3 V2 and absolutely infuriating to anyone who loves round numbers. It’s a build volume that reeks of one-upmanship (or two-upmanship perhaps, in this case), but if you need a lot more space, Anycubic offers the Kobra Max, a printer with a whopping 400 x 400 x 450 mm build volume. It’s important to note that the Kobra Max has little in common with the Kobra. Confusing.

Both printers should provide you with enough space to get going on your 3D printing journey. A print rarely fills up a bed of this size. Anyone just setting off in 3D printing is unlikely to need more than these printers provide.

Learn more

Learn more

Build Plate

We’ve two similar but noticeably different build plates in these two machines, which one is better could well come down to personal preference. What we’ve got are two spring steel sheets that magnetically attach to the heated bed that you can pop off very simply and flex to remove prints. In theory, you should never need a scraper again with this sort of setup.

Anycubic’s plate differs by being a grain-textured PEI sheet. PLA and TPU love it and will stick together like teenagers and TikTok. PETG can prove a little trickier though, remaining unhealthily attached to the print bed, which might require more forceful separation, much like teenagers and TikTok. Sigh.

Handling PETG can be made a little easier by putting down a little layer of glue prior to printing, but you may find that the print surface leaves a distinctive and, actually, rather annoying texture on your first layers due to that grainy texture. We had this bed during our testing with the Anycubic Vyper, and it wound us up royally.

Creality’s spring steel plate is PC coated and far less grainy in texture. It still has a texture, but it isn’t as harsh and so probably won’t leave your first layers with a surface texture on par with a neglected parking lot. It’s the best Ender 3 build plate so far in our book and offers excellent adhesion across all materials we tested it with. It’s also easy to flip on and off the bed, and prints generally just pop off with a simple flex. The only annoying thing about it really is the lack of guides to align the bed. Apart from that, all good.

Learn more

Learn more

Bed Leveling

Both printers here utilize automatic bed leveling, albeit with different sensors.

Creality uses its CR Touch system, a non-branded branded (if you like) version of BL Touch. The system makes use of a metal touch probe. Its job is to give a soft poke to 16 different points across the print bed, just like a BL Touch system. The idea is that it accounts for inconsistencies in the flatness of the print bed and gives you a lovely flat surface on which to produce your prints.

By the way, with the Ender 3 S1, you still get large hand-leveling knobs under the bed to get yourself to a certain level of levelness. However, they do not appear on the Anycubic Kobra, a machine that relies solely on its automatic bed leveling for even first layers.

Anycubic uses the name LeviQ, which applies to any of the auto-bed leveling systems on its modern printers. It differs from Creality’s touchy-pokey probe by being an inductive probe instead. This type of sensor produces a magnetic field, and when it gets close enough to something metal that interferes with the field, it reacts.

Naturally, this doesn’t work very well with non-metallic build plates. The sensing distance is short, often mere millimeters, so a thick, non-metal surface such as glass doesn’t work well. Anycubic uses a spring steel sheet here. It’s nothing all that unique or special, but it worked well during our test, and all in all, it’s just nice not to have to manually level something, isn’t it?

Learn more

Learn more

UI

For the UIs, we’ve a pair of 4.3-inch LCDs. One is touchable, and one is untouchable – in the poking won’t do anything sense.

Anycubic is the one that’s gone with the touchscreen system in this case, and we found it to be two things we most certainly aren’t in a Monday morning meeting – bright, and responsive. Some people might get a little frustrated with its inconsistencies. For example, to set the temperature, you type in the number. But, to raise the print head to work on the machine, repeated taps on values 0.1, 1, or 10 mm figures are required, which is annoying.

Creality has gone with a rotary knob instead of the touchscreen. A safe choice that’s easy to use, with clear graphics and options to choose from. There’s little else to report.

Both of these UIs do what you want them to do, it really just comes down to what you prefer, but you certainly won’t be disappointed with either. The Anycubic just might have the potential to frustrate you more.

While not technically “UI”, we want to point out the SD card situation. Creality only accepts the full-size SD card in the S1, which is welcome. The Anycubic Kobra only takes MicroSD, which is an item so small and fiddly it can vanish in an instant if you drop it. If it slips down the back or side of a cabinet, you’ve more chance of finding El Dorado than seeing that card ever again. What a colossal pain they are. When it comes to SD cards, full-size is the way to go.

Learn more

Learn more

Extrusion

There are two direct extruders on the menu here, both strong performers.

Creality’s new Sprite direct extruder really impressed us during our test earlier this year. It’s a geared extruder with a reduction ratio of 3.5:1, with dual gears that grip the filament and push it through. It weighs in at a pretty low 210 grams, only around 60 more than the Bowden extruder found on the Ender 3 V2, a pretty impressive achievement. Being able to heat to 260 ℃, it can handle filaments like PLA, ABS, PETG, TPU, and anything else considered ‘basic’ consumer filament.

During our time testing the S1, the Sprite impressed us with its simple filament loading and unloading and its consistency. Not once did we suffer from a clog, which is lucky, because taking apart a direct extruder like this can be a real chore. Reliability and consistency here are very desirable characteristics.

Anycubic’s direct extruder has some shortcomings, but it’s far from a bad apple. The extruder here reminds us a bit of the E3D Titan Aero, though differences like the larger heater block and Bondtech-esque filament release lever make it clear it’s its own thing. The big disappointment here is the basic toothed gears, which chew up the filament too much and can lead to filament collecting between the teeth. This will reduce the effectiveness of the extruder over time, meaning you’ll need to get in close with a brush or compressed air to clean it. Not ideal at all.

We had our Kobra clog one day, a moment of dread flashing before us as we realized we’d have some work to do dismantling the direct extruder, but thankfully, all was well. The Kobra is actually pretty tinker-friendly, proving simple and easy to take apart. We found ours had some below-par PTFE tubing that wasn’t quite the right length. With a new nozzle, and new PTFE lining (a spare is provided), hassle-free printing resumed.

Learn more

Learn more

Z-Axis

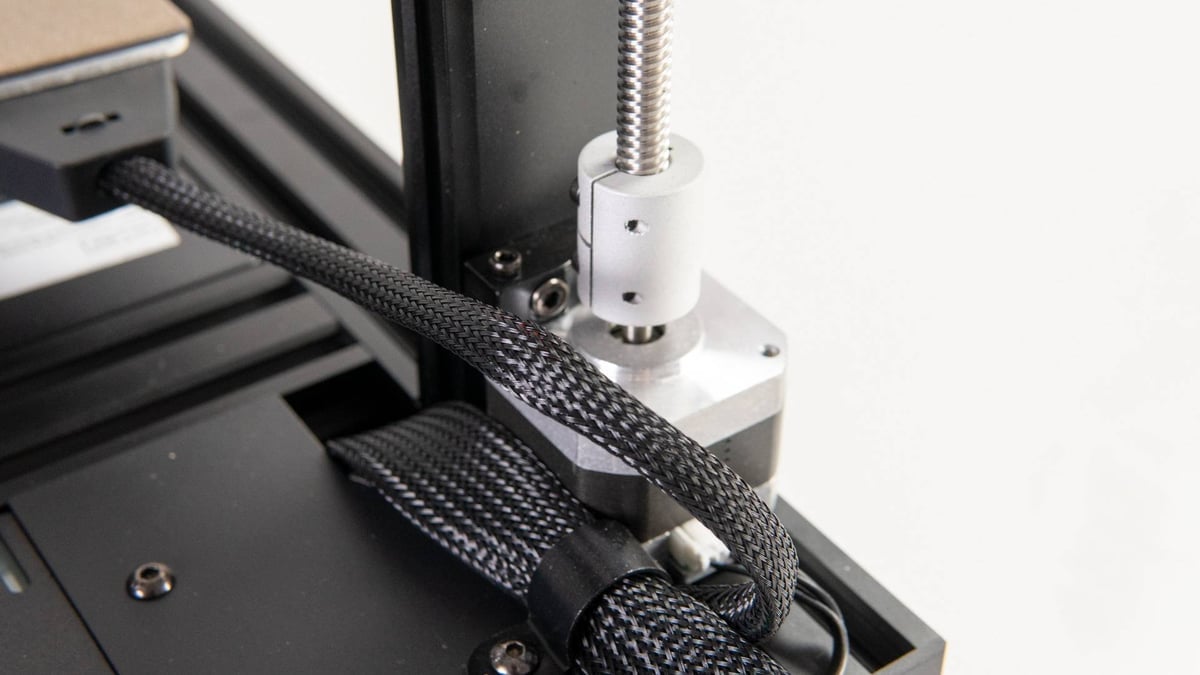

A key difference between these two printers lies in the Z.

Creality’s Ender 3 S1 makes use of a dual-driven Z-axis that should improve stability and accuracy in taller prints. It’s a popular modification in older Ender 3 series machines, and you could say it’s far more important to have in a machine using a direct extruder, as the extra weight on the print head can have some side effects. Needless to say, during our time using the S1 we saw no signs of issues, which suggests Creality has got it right.

Mind you, we didn’t really see any issues in the Z-axis over on the Anycubic Kobra either. Which is curious, as it packs a single leadscrew-driven Z-axis. We’d prefer it to feature the synchronized dual-driven setup found on the S1. While our testing found no signs that the single Z caused any issues, we can’t be sure that these issues won’t start cropping up the older the machine gets. Unfortunately, users will only be able to discover if Anycubic made the right call here after an extended period of use.

At the end of the day, a dual-Z axis is something of a luxury item and certainly not a promise of superior print quality. No problems with vibration-related print quality issues were experienced during our time with the Kobra, but should you run into some, you might benefit from reducing your print speed a little. This would likely reduce vibrations enough for the single-Z to handle comfortably. Really, that dual-Z axis and the extra stability it brings might not bring any noticable effects to your printing. That doesn’t mean it isn’t a nice thing to have though.

Learn more

Learn more

Software

With both of these machines, you’ll likely be relying on the old favorite Cura to be your primary slicer. Besides being the provided default slicer for both (albeit reskinned in Creality colors for said printer), it’s recently been refreshed, and there’s currently a Beta version of the exciting new Cura 5.0 to play around with. Whether it’s the latest version or older, Cura is a solid, dependable piece of slicer software that serves you well from being a beginner to veteran 3D printer status. Anycubic doesn’t have a proprietary slicer for its Kobra, so it’s Cura that the company recommends.

Being G-code munching machines, the Kobra and Ender 3 S1 are compatible with popular alternatives such as PrusaSlicer.

Learn more

Learn more

Price

Despite having pretty similar specs there’s actually a $100 price difference between these two machines.

Creality’s Ender 3 S1 comes in at $399 (though we’ve seen it being sold for more elsewhere) and Anycubic’s Kobra costs just $299.

A direct-extruder-toting automatic-bed leveling 3D printer for $299 is a fabulous price. Anycubic has managed to really put together a good package here and it’s done so without asking for the world from its customers. Credit where credit is due. However, you can see where the savings have been made in a few cases.

For a start, the whole printer looks and feels a bit low rent. You can feel the cheapness in its plasticky shell and feels like some corners have been cut here and there that could have made it a much more attractive machine. A single Z-axis also isn’t ideal, and it remains to be seen if that decision will come back to bite in the future. However, for what you do get and the printing experience it offers, $299 is really pretty impressive.

The S1 will set you back $100 more, but feels a little better finished and has the advantage of printing a bit better. It also doesn’t require the tweaks that the Kobra does. Is that worth $100 more? That’s for individuals to decide.

Learn more

Learn more

Verdict

It’s a close run between these two, but if we had to take one home, we’d be taking the S1. We like its build plate a bit more, and the Sprite extruder is excellent. Overall, it’s slightly easier to use in everyday situations, and it doesn’t need any babying or adjusting to get high-quality prints. It just works.

$400 is a lot of money in 2022 though, and in a world ravaged by inflation issues, there’s certainly a lot to be said for keeping an extra $100 in your pocket. Turning to the Anycubic Kobra, it is a top 3D printer for a buck under $300, and it will leave a lot of people very happy indeed. It might be a bit cheap feeling and need a little extra help to get the best out of it, but many of its drawbacks compared to the Ender 3 S1 are more than forgivable for an extra three figures in the bank.

License: The text of "Anycubic Kobra vs Creality Ender 3 S1: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.