3D printing is widely used for parts that can come in contact with electricity and electric wires, potentially sparking flame. Making sure that your 3D printed parts and components aren’t prone to catching fire easily or propagating flames is critical for various applications. Therefore, using materials that can prevent the spread of fire is wise and it’s often mandated by regulatory bodies.

Flame-retardant polymers are particularly important in the aerospace and automotive industries. But even small businesses that print housings for electronics or designer studios that 3D print lamps can benefit from offering flame-resistant products.

If your part or product needs to meet an industry standard for self-extinguishing, several certified products on the market meet international requirements (we’ve listed many below). Yet many polymers, such as PEEK and ULTEM, are flame-retardant by nature and may not carry specific certifications. The manufacturers of these polymers may have carried out their own tests on the material to ensure that they are flame-retardant, but have not gone through the certification process.

ULTEM blended with another polymer, however may no longer be flame-retardant. In this case, the manufacturer may add a flame-retardant chemical to the material. Anytime a 3D printing material is a blend of polymers, there’s no way to determine its flame-retardancy without lab testing. Don’t assume every ULTEM- or PEEK-based filament is flame-retardant.

Here, we explore your options for 3D printing with certified flame-retardant materials in filament and polymer powders for selective laser sintering, as well as resins for SLA printing. If you’re not sure your application needs to be printed in flame-retardant materials or what the certifications mean, skip down to the end.

Flame-Retardant (FR) Materials

Flame Retardant Polymer Powder for SLS

Flame Retardant Polymer Resin for SLA & DLP

What Flame-Retardant Means & Why You Need It

Flame-retardant materials slow down the spread of fire because they are more resistant to catching fire and staying on fire, but they are not fire-proof. They are designed to minimize the risk of a fire starting when in contact with a small heat source, such as a small flame or an electrical fault.

There are a few ways that materials can achieve being flame-retardant:

- Using chemicals that react endothermically when heated. This means the chemicals involved in the reaction essentially absorb heat, reducing temperatures and slowing fires.

- Releasing an inert gas when heated, which acts to stifle the flames by cutting them off from oxygen.

- Having burning layers shield unburnt layers through the process of charring.

In general, any plastic components close to electrical current require some form of fire resistance or retardancy. Wire nuts, junction boxes, and internal cable supports are all examples of components at risk of catching fire if an electrical issue occurs. In addition, industrial machines, DIY tools, and household equipment, such as microwaves, toasters, and dishwashers all contain flame-retardant components.

In automative and aerospace industries, the insides of vehicles, such as the interior of a plane or the cockpit of a race car, also need to prevent the spread of fire to protect the human occupants.

Certifications & Standards for Flame-Retardant Materials

In the product chart above, you’ll notice a range of certification standards to indicate a material is flame-retardant, but what do these really mean? Let’s take a look.

Underwriters Laboratories UL 94

UL 94 is probably the most common flame-retardant standard. This standard defines how flame retardant a material is by subjecting it to specific testing. The testing process involved to gain this certification includes having a part set alight repeatedly with an external flame.

To achieve the coveted 94 V-0 rating, the part must exhibit the following properties:

- Burning for less than 10 seconds after the first and second burn. This demonstrates how quickly parts made with the material would stop burning.

- Afterglow after the second flame needed to last less than 30 seconds. This is a good guide on how quickly the part cools after being set on fire. The longer a part remains hot enough to glow, the more likely it will reignite another part nearby.

- After being set on fire ten times, no material was allowed to drip that would ignite cotton batting. Dripping material that can ignite other material is a sign that a component could ignite further fires in its immediate surroundings.

- The combustion could not consume the whole sample. This is a useful measure of how difficult it is for a flame to travel along the material.

With 94-V.0 burning stops within 10 seconds on a vertical specimen, 94-V.1, and 94-V.2 means burning stops within 30 seconds, and so forth to 94-5VA and 94-5VB, which indicate a specimen will flame but stop burning within 60 seconds.

FAR 25.853

The US FAA (United States Federal Aviation Administration) designed a vertical Bunsen burner test to determine the flammability of materials used in airplane interiors including both cabin and cargo compartments. It’s called FAR 25.853, and it’s not uncommon to see a “FAR 25.853 – approved” stamp on some plastic products. To meet the standard, specimens are held vertically inside an enclosure and a Bunsen burner flame is applied from below for either 60 seconds or 12 seconds. After the flame application time has expired, the material is observed. Flame time, ignition time, burn length, and material drip flame time are documented.

About the Author: Alejandro Auerbach is a mechanical engineer specializing in additive manufacturing at Solid Print3D.

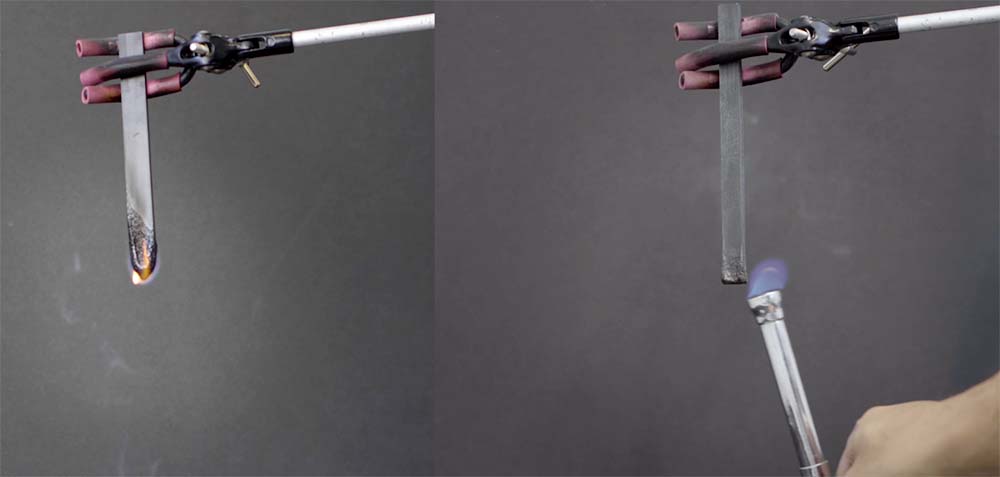

Lead image source: From the Maker's Muse YouTube channel video "Do 3D Prints Catch Fire? ABS / PLA / PETG Burn Test - Episode 1."

License: The text of "Flame-Retardant Filament & 3D Printing Materials" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.