How does 3D printing benefit the armed forces? Apparently, quite a lot. Here are 10 future applications for the soliders of tomorrow.

The U.S. Department of Defense, together with several other defence ministries in the Western world, are probably heavily invested in industrial additive manufacturing technology.

We say “probably” because the military doesn’t usually disclose its current and real capabilities. On the other hand, they do like to talk about future possibilities and the research they’re conducting on long-term projects.

In a presentation last month at the Intelligence and National Security Alliance summit, Larry Holmes, principal investigator for materials and technology development in additive manufacturing at the US Army Research Laboratory (ARL) in Maryland, sketched out a variety of potential uses for 3D printing for the military.

These range from intelligence to communications, and even to terraforming the battlefield. We’ve summarised his presentation below, along with a few other future applications for the army of tomorrow.

1) 3D Printed Antennas

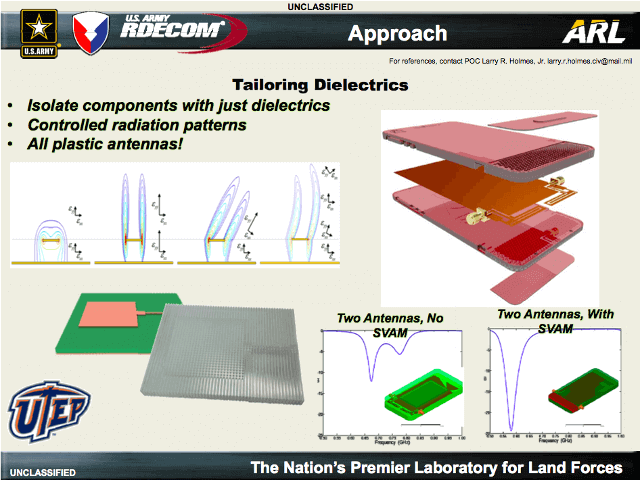

Rather than trucking or airlifting in antennas for the growing number of Internet of Things (IoT) connected devices that are appearing on the battlefield, the Army is studying ways to print dielectric antennas, even from non-conductive materials like ceramic or plastic, directly on location. EM Lab Researchers at the University of Texas at El Paso are working on several different approaches for 3D printing high-frequency circuits and electromagnetic devices.

2) 3D Printing Composites for In-Field Use

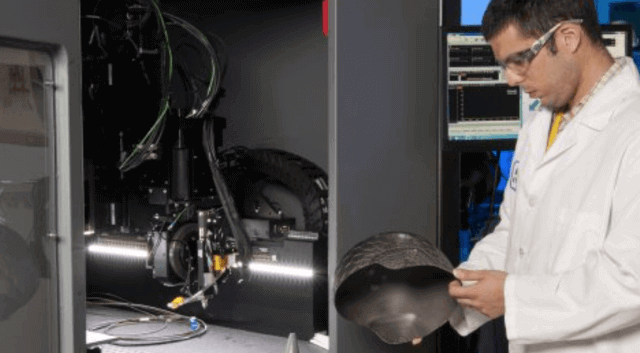

FALCom is a 3D printing process being developed by Larry Holmes at the US ARL in Maryland. It’s based on the use of composites, where scientists can engineer advanced composite cement, fiber-reinforced polymers, metal composites and composite ceramic and metal matrices: all of which can be tailored for use in the field.

3) Biometric Sensors

Like 3D printing antennas, being able to 3D print multi-material electronic circuits opens up the potential for several different applications for “future warfighters”. Researchers at Picatinny Arsenal have long envisioned the potential to embed a radio antenna on the side of a soldier’s helmet, or 3D print sensors that monitor status directly onto a weapon or an article of clothing, such as a combat boot.

4) 3D Printed Beachheads with Local Materials

One idea that Holmes suggested is a robot capable of 3D printing objects independently, from materials found on location:

“We drop a black box in a place where you wouldn’t want to send your soldiers. It could be a biohazard area, a radioactive area, dense jungle, the top of a mountain, a dangerous extreme environment, etc. Through a suite of sensors, this manufacturing unit senses what’s around it, what minerals are in the sand, and what trees are around it. It then prints robots to go collect those materials, to collect sap from trees, mud and straw to make bricks. These robots bring those materials back.”

5) Micro Assembly Robots

The Defense Advanced Research Projects Agency (DARPA) has a program called Magnetically Actuated Micro-Robots for Advanced Manipulation Applications, in collaboration with SRI International.

The MicroFactory platform technology by SRI will be used to build smart structures with high-performance mechanics. Thousands of micro-robots manufacture high-quality macro-scale products while providing millimeter-scale structural control.

For example, some micro-robots will carry components (electronic as well as mechanical, such as truss elements), some micro-robots will deposit liquids, and others will perform in-situ quality analysis.

Mounted to a mobile robotic base, a micro-factory will be able to build parts of practically any size. The micro-robots themselves could also be 3D printed.

6) 3D Printers at Sea

Last year, the U.S. Navy permanently installed a 3D printer on a warship for the first time. However, the printer aboard the USS Essex amphibious warship is not used for building replacement parts. The crew has been making everything from disposable medical supplies, to a new cap they designed for an oil tank, to model planes to move around their mock-up of the flight deck.

7) Open Additive Manufacturing

DARPA’s Open Manufacturing program seeks to speed up adoption of metal additive manufacturing for end-use components. While Sciaky and Lockheed Martin have already produced test parts for jets (not yet approved for in-flight use), DARPA has been working with a panel composed of experts from the US Army Manufacturing Technology Program, the Federal Aviation Administration, the National Aeronautics and Space Administration, and the US Army Evaluation Center.

8) Army CoCreativity and 3D Printing

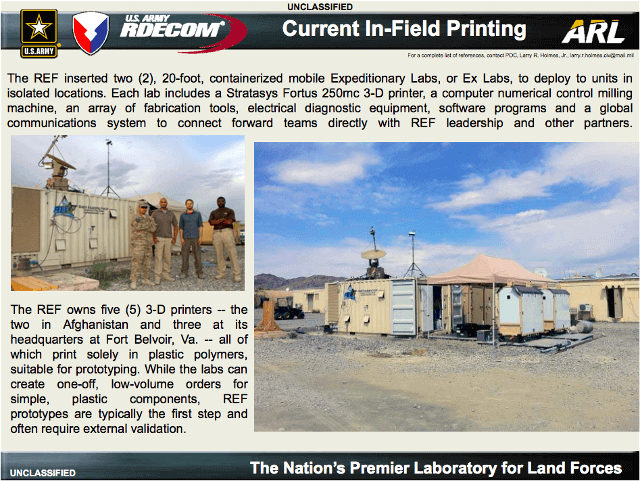

The U.S. Army’s Rapid Equipping Force (REF) created a crowdsourcing website, called Army CoCreate, where anyone can identify problems facing the Army, design a prototype solution and upload it. Army CoCreate is a proof-of-concept effort exploring the utility of crowdsourcing for army requirements and solutions.

One goal of this platform is to provide the inspiration for two workshops called “Make-a-Thons,” where Soldiers from the Maneuver Center of Excellence (MCoE) Capabilities Development and Integration Directorate (CDID) will bring virtual blueprints to life by manufacturing 3D prototypes using REF Expeditionary Lab (Ex Lab) equipment.

9) 3D Printed Uniforms

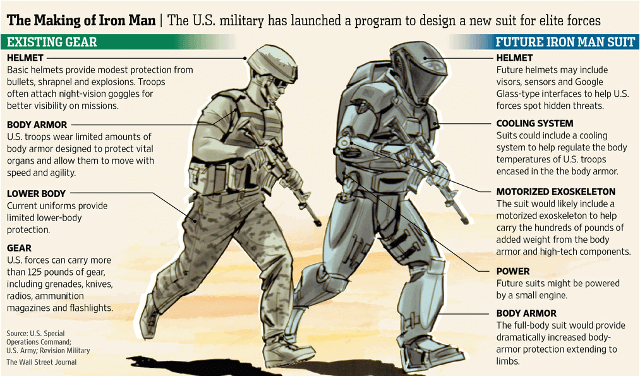

Through 3D printing, the U.S. Army is studying ways to combine different advanced materials, reduce the number of seams for added comfort and durability, and even create embedded ballistic sections into a single piece of clothing. One alternative and futuristic approach is the Tactical Assault Light Operator Suit, or TALOS.

In 2014, the military commissioned Hollywood FX studio Legacy to help them design and 3D print prototype components for TALOS, an advanced suit and exoskeleton to augment soldiers’ physical capabilities on the battlefield.

10) 3D Printed Food

The U.S. Army is also considering using a 3D printer to make the soldiers’ chow.

The Army’s Natick Soldier Research, Development and Engineering Center, (NSRDEC), a division of the Natick Soldier Systems Center (NSSC), is responsible for researching, developing, fielding and managing many soldier support systems and items, including food.

Since 2014, food technologist Lauren Oleksyk has been investigating 3D printing applications for food processing and development, as head of a research team within the Combat Feeding Directorate (CFD). Sample dishes include pizza and pasta.

License: The text of "You’re in the Army Now: 10 Future Applications for 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.