Desktop Metal unveils the “Studio System” and “Production System,” two metal 3D printers that may revolutionize the industry.

The potential advantages that metal 3D printing can offer to the industrial world are almost limitless. Unfortunately, this advanced technology is contained within expensive, bulky, and inefficient machines. That is, until now…

On Tuesday, the Massachusetts startup Desktop Metal pulled the curtain to showcase two of their highly anticipated 3D printing systems.

The company’s journey, headed by CEO Ric Fulop, started off in 2015. With a team that also includes four MIT professors, Desktop Metal set out to revolutionize metal 3D printing technology.

Their aim was to make a metal printer that is exceptionally cheaper, smaller, safer to operate, and capable of producing parts much more quickly than the bulky industrial counterpart. After two years, the result of their endeavors have surfaced in the form of the “Studio System” and “Production System.”

The “Studio System”: A Revolutionary Feat in Desktop 3D Printing

The new desktop 3D printer is an office-friendly printer that can produce metal parts. Small enough to fit on a table, the “Studio System” is for offices or factories looking to optimize their prototyping.

“The machine literally arrives, rolls through any standard door, and all it needs is power, and you’re printing parts in an office. If you’re an engineer, you can print parts next to where you design them,” says Fulop.

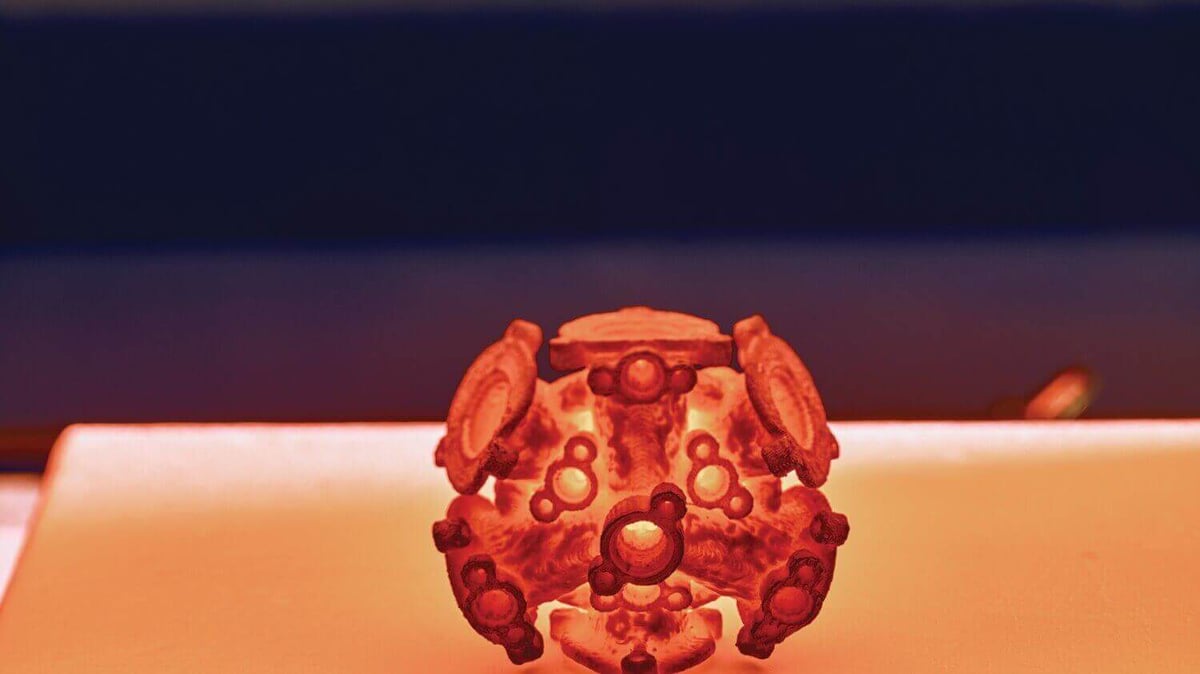

The Studio System uses their patented Bound Metal Deposition (BMD) extrusion process, similar to FDM 3D printing. Using Desktop Metal’s collection of MIM metal powders, which are bound by a polymer mix, the printer quickly produces accurate and also repeatable parts. It has a 50-micron layer resolution, automated bed leveling, and also a heated build area.

After the Studio System is finished printing, Desktop Metal’s office-safe furnace blasts the 3D printed parts at a temperature of up to 1,400 degrees Celsius. this is done without the need for a water cooling system or ventilator. In a matter of hours, the post-processing machine melts away the polymer binding agents to leave behind a metal object.

In addition to the faster production times and post-processing, Desktop Metal’s printer also allows support structure to be removed by hand. The Studio System will cost around $120,000, including the furnace and also access to their cloud-based software. It will begin shipping to customers this September.

The “Production System”: Revolutionizing Industrial Manufacturing

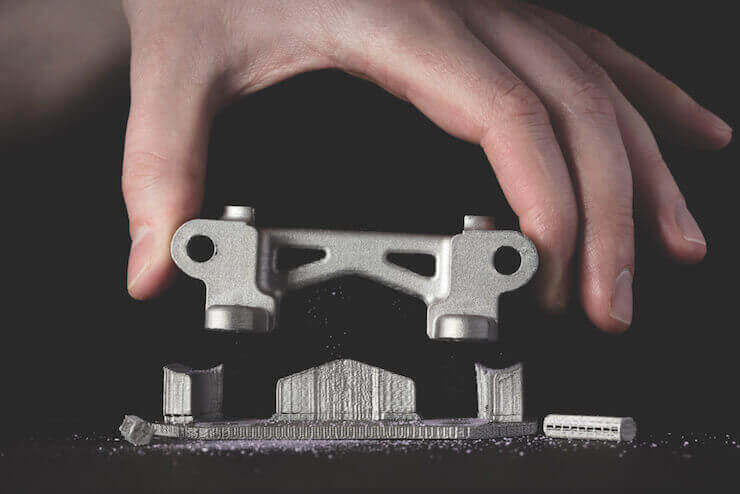

In addition to the desktop-sized “Studio System,” Desktop Metal also revealed the industrial-sized “Production System” too. Using a process called “single pass jetting,” this machine takes less than three seconds to print a single layer.

First, the printer deposits metal powder, followed by binding agent droplets that are “jetted” onto the powder. After heat is applied to bind the layer, the process quickly repeats itself. The machine is equipped with multiple bars that hold over 32,000 jets, which spray millions of droplets per second across the the build area.

The industrial-sized machine also utilizes the same furnace to finish the object as the desktop model. The larger printer will cost around $360,000 (without the furnace), and will likely start shipping to pilot customers next year. These two machines may seem pricey, but their much more affordable than conventional metal printers. These can easily run you over $800,000.

With their first products ready to hit the market, the next step will be to prove just how well this metal printer works. If the Studio System and Production System operate as advertised, we may finally be witnessing the 3D printing revolution before our very eyes.

License: The text of "Desktop Metal Debuts Two Revolutionary 3D Printers" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.