Founded by Massimo Moretti, who describes himself as a “dreamer”, WASP is an Italian 3D printer manufacturer. It’s name stands for “World’s Advanced Saving Project”, which clearly indicates the organization’s ambitious goals. Using 3D printing technologies, WASP seeks to find the most efficient and cost-effective ways to produce buildings for people who live in the desert areas of Africa and other developing parts of the World.

Traditionally, these people use low-cost, clay-based materials to build houses that can withstand the excessive heat and sudden rain pouring with success. For this reason, WASP has based its approach on clay, experimenting with shapes and designs that encapsulate the spirit of Central Africa.

Delta Construction Workers

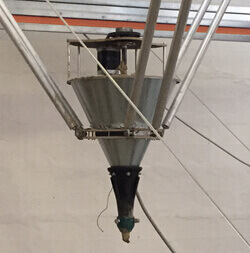

Contrary to most 3D printer manufacturers, who tend to implement a “Cartesian” architecture (that is one with the extruder moving along the two cartesian axes, X and Y) WASP chose to develop its newer machines using a delta movement architecture. That is with an inverted “delta robot” moving the extruder in a cylindrical print volume.

Small scale, high-quality printers with Delta heads was what funded the company’s goal of creating clay houses goal, since their very first humble steps in the 3D printing area. This choice was made for the huge benefits of Delta over Cartesian that would play a crucial role in the building of clay houses. Delta heads can be significantly more accurate without the need for precise calibration or low-level tolerances that would be impossible to meet in the context of a huge 3D printer with modular assembled parts.

Based on several basic requirements (easy to assemble, us self-cleaning heads and rotating nozzles, low-cost, highly-accurate, transportable) WASP has slowly developed its printer from small sized prototype to an 8 meter tall machine. The next goal, which they are currently working feverishly on, is a 12 meter tall 3D printer that will be the first big milestone of the project.

Big Enough for a House

This size will be enough to create and entire clay buildings that can house people, while previous experimental models would only have been good for pets, or for clay pottery. Of course, doubling the size doubles the deviation of the head movement, increases the tolerances and raises the weight of the whole structure. So the scaling up process is not as simple as just making everything larger and expecting it to work similarly to the small-scale models.

One of the WASP printer most advanced feature is its extruder. The team used a pressurized push approach in the beginning, but this proved to be quite demanding energy-wise. The solution that WASP’s “dreamer engineers” (everyone in the company has the title of “dreamer” on their business cards) came up with was to control the material fall rate instead of pushing it.

If You Build It…

As the machine is now 12 meters high, the moist clay mixture can use gravity as the main driving force through the extruder, using much less energy for the process. By rotating the nozzle, the clay gets properly mixed with water while the head gets constantly cleaned. This makes the printing of clay layers more cohesive and tenacious.

As WASP moves forward and perfects their printer, more and more institutions, and organizations will hop on to help speed up the development and test various implementations in all kinds of conditions. After the demonstration of the large clay 3D printer during the latest 3D print Hub in Milan, the Sardinia Research institution and the Inglesias municipality openly showed their sincere interest in the project, willing to contribute as real-world testers of the system. The road to a more sustainable housing, available to all throughout the world is wide open. A race is on between WASP and other ventures active in this field, but this is a competition where everyone wins in the end.

License: The text of "3D Printed Houses: Sustainable and inexpensive" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.