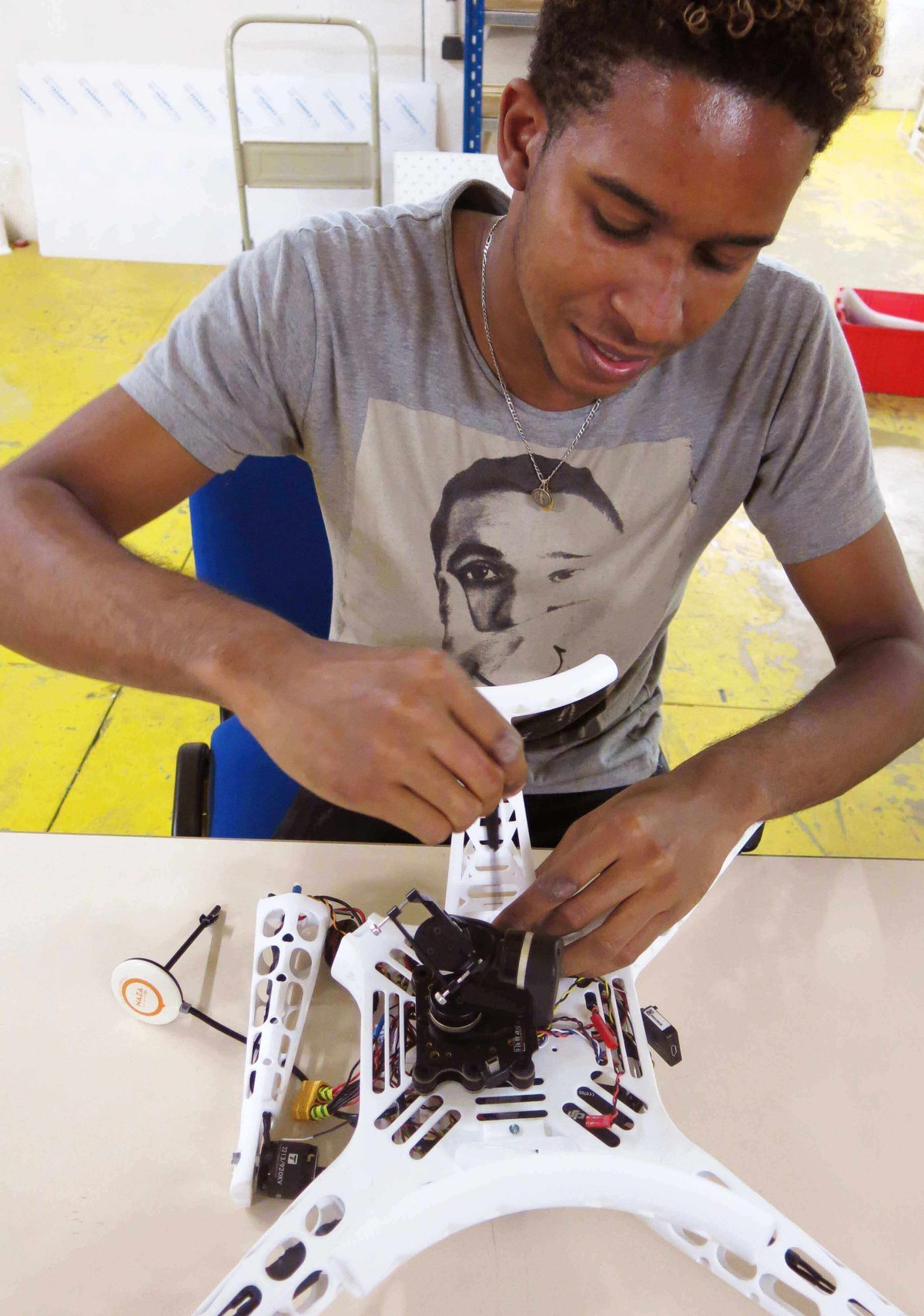

An intern at Sculpteo built a drone of his own by teaching himself design software and 3D printing, plus a little help from his employers.

Alexis Massol first dreamt of building his own drone when he was in charge of his school’s Fablab, where he was studying mechanical engineering.

Over the course of five months, he managed to build a 1.5 kg fully functioning drone. He then started an internship at Sculpteo. It was here that he revised his drone’s model to 3D print a lighter, more efficient version.

Alexis said: “I had bought a drone before, and wasn’t satisfied with it: it wasn’t stable enough, and I needed to connect it to my phone to pilot it. It lost connection frequently, which wasn’t safe.”

This led Alexis to build his own drone which he could pilot with a controller and his laptop, meaning double safety.

How was the drone made?

The process for Alexis began by looking up plans on the internet. He made notes on what a drone needed and could do, and then began learning how to design.

He said: “I had no experience at all: I taught myself how to use SolidWorks, thanks to online 3D design tutorials, like the ones you can find on Sculpteo’s website. It took me a few months to design the first version and three weeks for the second version.”

For his first drone, he used his school’s FDM (Fused Deposition Modeling) machine. He chose a PLA (polylactic acid) filament, made from corn starch.

Alexis added: “I liked the idea of 3D printing a fully biodegradable frame for my drone. It was good, but the finish didn’t match my expectations. I had in mind a very professional looking drone, like the Phantom 4 drone, to give an example.”

He then decided to try a different design and material. He used Sculpteo’s service and the SLS (Selective Laser Sintering) machines. The material he used was Sculpteo’s white polyamide (PA 12), which is strong and light.

Thanks to 3D printing, Alexis was able to choose the components and options that he wanted. While also customizing it at will. He said: “This gives me the opportunity to make my drone evolve in the future without having to pay for everything every time.”

Overall, the drone cost Alexis €1,600, which is the price of a retail drone. But the results and the hard work paid off and Alexis is happy with his finished product.

He said: “The drone functions well, it is equipped with an object detecting system, a compass, GPS, and a GoPro camera, and has a wide range: it can move as far as 1km from the command.”

Source: Sculpteo

License: The text of "How a Sculpteo Intern 3D Printed a Drone from Scratch" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.