Researchers at Purdue University develop RevoMaker, a new system to create 3D prints with fully enclosed electronic and motorized components.

“Toys work right out of the printer,” claims Karthik Ramani, Purdue University’s Donald W. Feddersen Professor of Mechanical Engineering and a professor of electrical and computer engineering.

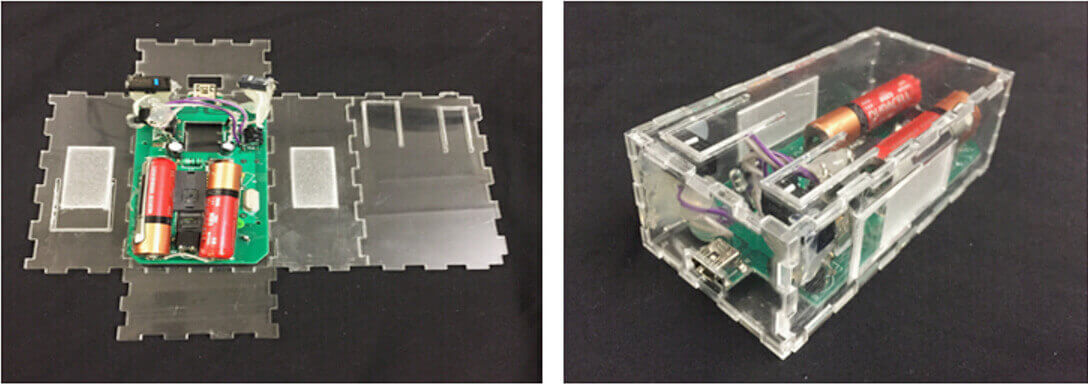

Based on current 3D printing standards, such promises might seem far-fetched, but the method is remarkably simple. Taking an off-the-shelf Ultimaker 2, Ramani’s team modified the printer by removing the print bed and replacing it with a multi-axis apparatus. Models are then split into six separate planes, and printed around a central, rotating core that contains motors and circuitry.

Another benefit of this technique; less build material is used to create supporting structures for overhanging or protruding features.

Making a Wind Up Toy with Revomaker

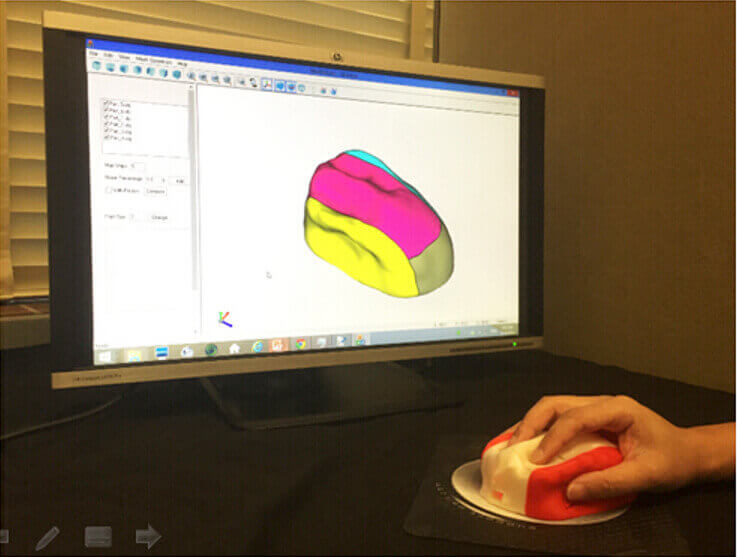

The team have demonstrated the RevoMaker printing a variety of customized product prototypes, such as computer mice and toys. “Using our methods we will soon be able to make things that actually walk out of the printer by themselves,” enthuses Ramani.

These potential applications are demonstrated in the video below, including a wind-up toy with flashing lights and moving parts, and a working computer mouse customized the shape of an individual hand.

Raymond Cipra, professor of mechanical engineering, explains the principle in greater detail:

“With a traditional 3D printer you print on a planar print bed and the platform is fixed. Our strategy is to replace the print bed with a laser-cut cuboid which can be rotated about an axis to provide orthogonal printing surfaces on each side of the volume. This cuboidal volume is also the space into which the electronics, motors, batteries are embedded before the printing process begins. Perhaps you could have multiple cuboids that you snap together in a customisable fashion.”

The RevoMaker team are presenting their findings this week at the Association for Computing Machinery’s Symposium on User Interface Software and Technology (UIST), Nov. 8 to 11 in Charlotte, North Carolina. The paper was authored by doctoral student Wei Gao; postdoctoral research associate Yunbo Zhang; graduate student Diogo C. Nazzetta; Ramani; and Cipra.

Currently, they have no plans to commercialixe the system. Instead, they hope to see the project amass a community of contributors to develop it further. How do you think this exciting technology could evolve?

https://www.youtube.com/watch?v=G5qpuDyczMM&feature=youtu.be

License: The text of "RevoMaker: Working Products, Straight from the 3D Printer" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.