Using the technology called electrospinning, the team of Penn State University demonstrated a low-cost and effective technology to create tissue-like fibers.

3D printing technologies continue to push the boundaries of what is possible within healthcare and the biomedical sciences. Within tissue engineering, researchers have previously suggested various strategies to assemble fibers into 3D layers that could potentially resemble human skin or organs. If successful, this would find widespread application within regenerative medicine to help repair damaged organs and tissues.

However, experimentation has been limited due to the costs involved as well as the complexity of the task at hand.

Now, a team of engineers at Penn State University has created a framework to grow living tissue by using a commercial 3D printer.

How Electrospinning Can Help to 3D Print Living Tissues

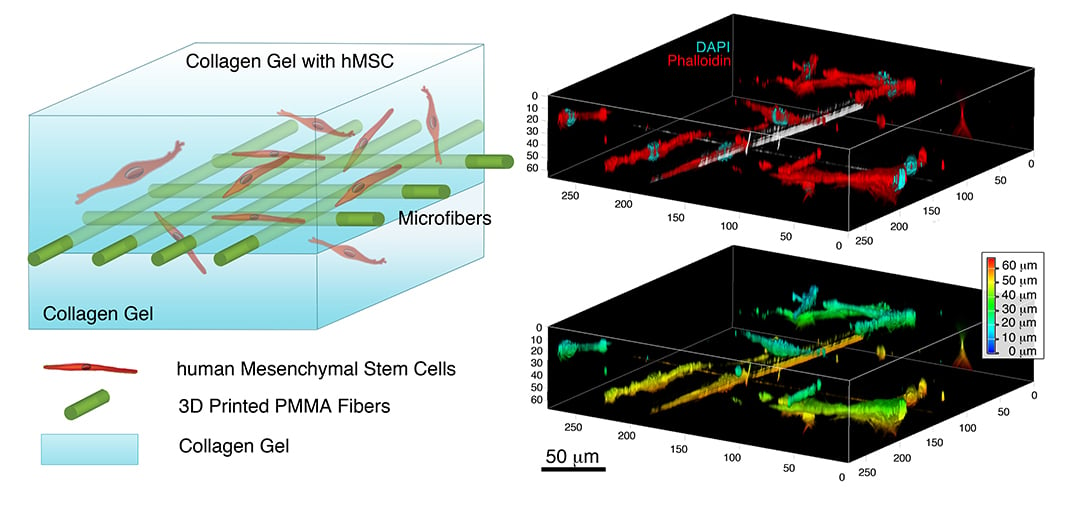

The team employed a technology called electrospinning, which already has seen widespread usage to deploy fibers in tissue engineering. Though traditional electrospinning, which has been around since the late 16th century, fails to deposit fibers at exact angles, the new 3D near-field electrospinning printer is capable of spinning fibers seeded with cells to create fiber layers. As part of the process, cells are seeded uniformly into the collagen-based 3D scaffold to create the tissues.

The new method provides an opportunity to spin polymer fibers such as collagen layers whilst offering added precision and more control over the patterns created. Material consumption is also minimized. By utilizing hydrogels, the method is also a more cost-efficient way to create polymer fibers.

Justin Brown, Associate Professor of Biomedical Engineering at Penn State, explained: “We are trying to make stem-cell-loaded hydrogels reinforced with fibers like the rebar in cement. If we can lend some structure to the gel, we can grow living cells in defined patterns and eventually the fibers will dissolve and go away.”

The ultimate goal is to allow medical units to more effectively provide tissue and organ samples to patients. Right now, organ transplant tissues are still coming from donors and every 10 minutes a new patient is added to a waiting list for an organ in the US. However, an average 20 patients die each day waiting for a transplant.

The 3D printer has the potential to steamroll a new field within tissue engineering. Whilst microextrusion bioprinters have already been used to print tissue and bones separately, the aim of the new 3D printer is to create more complex structures altogether, mimicking the body’s own way of growing bone and cartilage together.

Source: Penn State University

License: The text of "Researchers Find New Low-Cost Ways to 3D Print Living Tissues and Organs" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.