Researchers in additive manufacturing materials have developed a group of extremely stretchy, UV-curable, and 3D printable elastomers.

Elastomer materials have great electrical and thermal insulation, elasticity, and resilience. This makes them a useful material for emerging fields like soft robotics, flexible electronics or smart biomedical devices. Unfortunately their uses remain limited because of the thermal curing process necessary for their treatment.

3D printable elastomer materials are one potential solution. Many are already commercially available for UV light 3D printing, but they can’t stretch beyond 200% after they are cured. This is still too limited for professional applications.

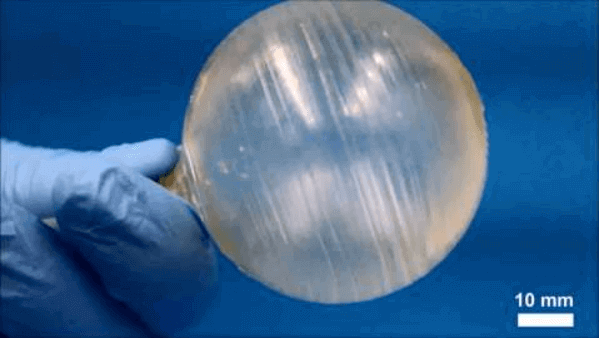

Recently, however, a researchers made a breakthrough. They’ve developed a new elastomer material that can stretch up to 1,100%. It is perhaps the most stretchable 3D printing material ever made.

Working together are researchers from the Singapore University of Technology and Design’s Digital Manufacturing and Design Centre (DManD), the Campus for Research Excellence and Technological Enterprise (CREATE), and the Hebrew University of Jerusalem (HUJI).

Co-leader in developing the SUV elastomers is assistant professor Qi (Kevin) Ge from the SUTD’s DManD Centre. ”We have developed the most stretchable 3D printable elastomer in the world,” he said. “Our new elastomers can be stretched by up to 1100% which is more than five times the elongation at break of any commercially available elastomer that is suitable for UV curing based 3D printing techniques.”

Benefits of Stretchable Elastomers for 3D Printing

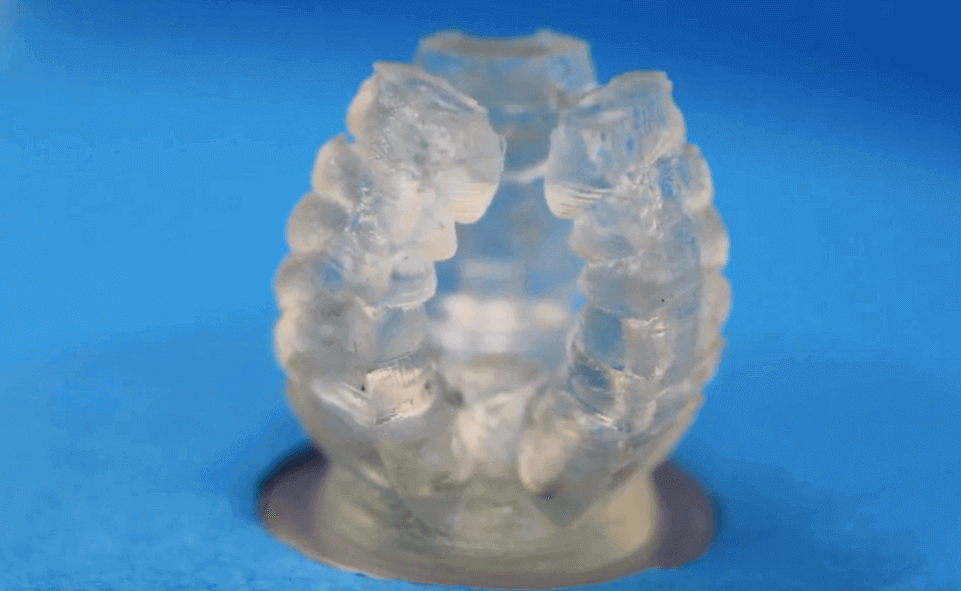

Benefits of the new SUV elastomers are that they can take the form of complicated geometric structures. Using high resolution 3D printing with the materials, complex shapes or hollow structures can be made quickly and without deformation.

Ge continues:

“Compared to traditional molding and casting methods, using UV curing based 3D printing with the SUV elastomers significantly reduces the fabrication time from many hours, even days, to a few minutes or hours as the complicated and time-consuming fabrication steps such as mold-building, molding/demolding, and part assembly are replaced by a single 3D printing step.”

The SUV elastomers can help fabricate flexible electronics with good mechanical repeatability. In addition, they have the ability to sustain large elastic deformation.

In demonstrate this, the researchers fabricated a buckyball light switch. Remarkably, it still works after pressing more than 1,000 times.

Professor Shlomo Magdassi is another co-leader of this project at HUJI and CREATE. He said:

“Overall, we believe the SUV elastomers, together with the UV curing based 3D printing techniques, will significantly enhance the capability of fabricating soft and deformable 3D structures and devices including soft actuators and robots, flexible electronics, acoustic metamaterials, and many other applications.”

Interested in finding out more? Read the paper on “Highly Stretchable and UV Curable Elastomers for Digital Light Processing Based 3D Printing”

License: The text of "Researchers Develop Stretchable Elastomers for 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.