Researchers at Waseda University have developed the 3D Chemical Melting Finishing (3D-CMF) process to improve the quality of resin-based FDM prints.

Are you tired of spending hours polishing and perfecting your rugged 3D print? Researchers from Waseda University in Japan have developed a quick way to drastically improve the surface finish of resin 3D prints. They’ve named this technique the 3D Chemical Melting Finishing (3D-CMF) process.

Kensuke Takagishi and Professor Shinjiro Umezu are behind this breakthrough work. They both hail from the Waseda University’s Faculty of Science and Engineering, Department of Modern Mechanical Engineering.

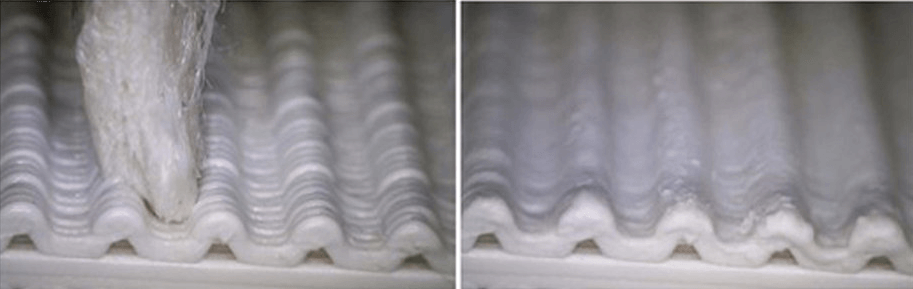

Together, the two have been working to solve a problem they call “surface ribbing”. This issue occurs when the appearance of a resin print is rough due to grooves in the layers.

The 3D-CMF process offers both structural rigidity, as well as an improved outer texture. Additionally, they claim that the 3D-CMF process has a lower price point and is less complex than other post-processing techniques. The solvent chemicals used by the researchers are completely safe to handle, and no hazardous waste is produced.

The researchers used Fused Deposition Modeling (FDM) 3D printing to conduct their experimentation. They decided on this style of printing because it is the most suitable for in-home use and is relatively affordable.

Could This Method Replace Other Post-Processing Techniques?

You may already be familiar with some of the other post-processing methods that smooth down the surface of your print. Polishing and grinding are two of the most popular finishing techniques used to repair rougher areas.

Another option is using vaporized solvents to melt down and smooth out surfaces. However, this technique involves using large amounts of flammable solvents, which could be dangerous if proper precautions aren’t taken.

The 3D-CMF process was developed and tested to make these processes easier and safer. The tool used by the Waseda University research team resembles a pen. A touch of the solvent-coated tip will smooth out the rough sections of your 3D print.

Using this method, it’s possible to remove only the necessary areas, rather than processing your entire print. This equals improved surface quality and also less waste. You also don’t have to worry about breathing in hazardous chemicals, as it uses less solvent than other common techniques.

The researchers have ensured that the pen tip is completely adaptable. This allows the user to shape their print in an extremely precise fashion. Takagishi and Professor Umezu hope that their post-processing improvements will help 3D printing technology become more commercially viable.

If you want to learn more about the findings, you can read the research study recently published in Nature’s Scientific Reports.

License: The text of "Researchers Develop “3D-CMF” to Offer Higher Quality Surface Finishing for 3D Prints" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.