This team of volunteers from Reddit are crowdsourcing the development of the world’s first medical-grade open source prosthesis – all to get the recent amputee brother of a fellow Redditor back in the gym.

Guest Post: This article originally appeared on Wevolver Blog and was written by Cameron Norris. Text and images reproduced with the author’s permission.

In June, Reddit user /u/DrSpaceMann made a post to r/fitness asking for workout regimes to help his older brother, Ryan. Two days before, Ryan lost both his hands in an oil rig accident and was worried he’d never lift again. While Ryan recovered in the hospital, his younger brother (Matt) searched for ways to help him get back to the gym.

Matt (aka DrSpaceMann) turned to Reddit – and Reddit (with the help of exiii and Wevolver) began working on creating a new prosthesis for Ryan.

The initial plan was to build a custom HACKberry printed from materials that focus on lightness, strength and durability – and RepRapper Tech’s new aluminum-filled PLA (around 30% aluminum) looked like an obvious choice.

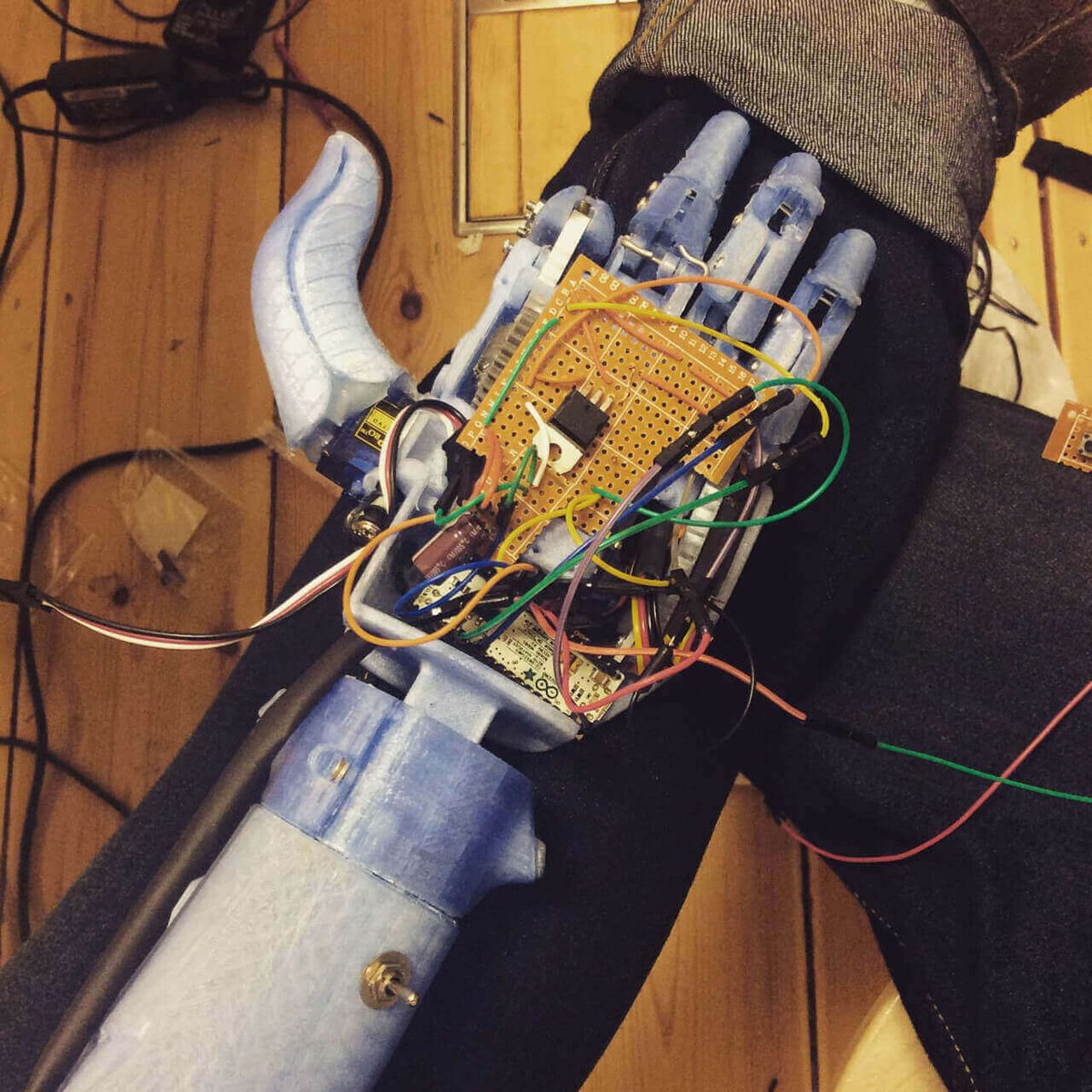

The HACKberry is an open source 3D printable myoelectric prosthetic arm created by Genta Kondo, Hiroshi Yamaura and Tetsuya Konishi of exiii Inc, a Japanese robotics company based in Tokyo that specializes in bionic arms.

One of the first Redditors to join the project team was Neela Janakiramanan, a hand surgeon from Melbourne, Australia. Neela works at the unit responsible for the first successful hand transplant in Australia; her interest in prosthetics arose from direct medical experience and the realization of the limitations on what hand surgeons could actually achieve.

Neela’s aim is to objectively assess the patient rated outcomes of this project as an official study. Neela explained to me that many health interventions are founded with good intent but ultimately fail to have a health impact because they’re not implemented systematically – or with a pre-planned assessment methodology. With Neela’s guidance, we’re working to refine the HACKberry into the world’s first medical-grade open source prosthesis – enabling everyone to benefit from its use, including double amputee, Rosa Moreno, who lost both her arms in a factory accident in Mexico.

Redditor, Michael Kane, along with his Spanish-speaking friend Andres Blank, contacted Rosa through Christine Ruddy, the director of the non-profit Partners For Responsible Trade, who has been helping Rosa since her accident.

We also entered talks with a Researcher from Oak Ridge National Laboratory, hoping to collaborate on the project with the Summer interns at Oak Ridge’s Manufacturing Demonstration Facility in Tennessee.

We organised a Skype call with the researcher to elaborate on the details of the project and were joined by seven interns, each specializing in a specific field of engineering – encompassing everything from chemistry to robotics.

After confirming their contribution to the project following the call, everyone was excited to get started. The plan was for the interns to explore how we could use 3D printers to make HACKberry parts that could withstand the demands of weight lifting. To do this, they would use the facilities impressive resources in order to identify the areas of highest stress during operation – enabling them to strengthen those areas using alternative additive manufacturing techniques. By the end of their research, the aim was to have at least the 3D printed parts of a reinforced HACKberry for Ryan’s prosthesis.

The following day, I received an email from the Director of Oak Ridge’s Manufacturing Demonstration Facility – Lonnie Love, PhD.

Lonnie worked on DARPA’s Revolutionizing Prosthetics Program, making him a hero of pretty much anyone interested in bionics.

Lonnie had written to tell me that the researcher I had been speaking with hadn’t gained authorization to use Oak Ridge resources to help with the HACKberry project; and while he clearly sympathised with our goal, Lonnie’s overall message was that Oak Ridge could not legally carry out the research that had been suggested. Shortly after, the researcher who we had made the arrangements with sent a very apologetic email for his mistake and wished us all the best of luck with the project.

However, not wanting the project to lose momentum, we decided to build a plastic prototype of the HACKberry using the 3D printers here at Wevolver – just liked had been planned in the beginning before speaking with Oak Ridge.

I barely slept for a week (it took me seven days to build it) – in fact, on the final night I didn’t sleep at all. But by Wednesday morning on 8th July, I’d hacked together a working bionic arm. exiii even emailed me to say they had seen a video of my new HACKberry on Facebook – it was the first time in the world that someone had actually built one from their designs and they were as excited about it as I was.

It had definitely been an interesting week, but we needed help fast. I decided to post an update to Reddit asking engineers and designers to contribute to the project to help Ryan and the response was amazing.

With so much support, we quickly realized we were able to go much further that we had even planned with Oak Ridge.

Reddit user, Andrew Sourk, volunteered to bring his in-depth knowledge of Carbon Fiber and Kevlar molding; Matt Miller introduced the idea of selective laser sintering; and Maxwell Emerald Perham brought his knowledge and enthusiasm of 3D design and mechanical engineering. The list of highly qualified volunteers wanting to support the project just kept on growing.

One of our most important contributors has been BULL amputee (bilateral upper limb loss) David Worley, who has been using prosthetics for 15 years since his own accident. David joined the team to offer support to Ryan and to provide the team with a decade and a half of experience as a prosthetics user.

The days following the Reddit update our team of volunteers got to work sharing designs and ideas. We also decided that in addition to refining the HACKberry under Neela’s guidance, we would build Ryan a dedicated weightlifting prosthetics using Kevlar and Carbon Fiber – including a built-in digital rep counter capable of linking to Ryan’s smartphone via BlueTooth to record his workout performance.

During our research, we discovered the i-limb ultra revolution and i-limb digits – smartphone operated hand prosthesis, perfect for Ryan’s needs. The problem is the i-limb costs anywhere from $38,000 to more than $120,000 depending on the level of customization required, and Ryan would need two of them. This discovery set a benchmark and we decided to crowd-source the development of a prosthesis with the same level of quality and functionality as the i-limb to release as open source – making the technology available to everybody.

If you think you can help please get in touch.

To join the project and find out more about the members involved, click here.

Sharing open source technology makes collaboration possible and gives anyone access to the knowledge they need to take their ideas further.