After a successful Kickstarter for the print+ DIY headphone kits, Patrick Schuur speaks to ALL3DP about the ideas behind his unique concept.

It’s a stunningly simple idea, and it’s captured the imagination of 572 backers on Kickstarter. Print off your own set of quality headphones, and customize them however you like with your choice of colors and materials. All you need is a kit containing the electronic components, fabrics, and the STL files for printing.

print+ founder Patrick Schuur is a busy man, working in a small team of three to prepare a large shipment of the headphone kits to their eager customers. But he took time from his hectic schedule to answer some questions from ALL3DP about this innovative — and exciting — concept of localized manufacturing.

Q: What was the inspiration for the print+ DIY concept?

I discussed this idea all the way back in 2004 with coaches at the design school I was attending. Questions like, “how great would it be one day when we’d be able to 3D print a mobile phone?” Back than I was hooked on this idea. At first I’d envision that only the plastic shell would be printed, where a PCB would be dropped in during printing, and then later in the future complete cellphones straight out of the printer.

print+ was inspired by using CAD software for the first time, and then 3D printing for the first time, during an internship at Griffin Technology. I fell in love with CAD and how it could be used to design parts easily. I was amazed how fast and how precise the 3D printed parts were. At the time the 3D printed prototypes were very, very, expensive.

Since I graduated I got to use 3D printing off and on. What I find really interesting is that the prices of professional 3D printing services have come down greatly, and the availability of these services are constantly on the rise. print+ is a project by my design studio form + function, where 3D printing is often used when working on client projects. Two examples spring to mind where professional 3D printed parts were used as end products.

In 2009, I designed a iPhone case that was originally intended to be manufactured by injection molding. I was shopping this case design around, until I got into contact with the guys at Freshfiber / 3D systems. They were selling 3D printed phone cases at prices comparable to mass produced phone cases. This meant the production cost was quite low. Until then, professional 3D printing was always really expensive. So for me to be able to use 3D printing as final product for something like an iPhone case, cost effectively, was a game changer.

In 2014, I helped a online bicycle retailer who wanted a simple Point Of Sale (POS) system. They originally wanted to screw a few layers of laser cut acrylic together. I offered them to make something more refined. Using the same printing technology as phone cases, we 3D printed the POS housings — that were quite large — at quite a reasonable price. Again, the fact that it was possible to print such big things, cost effectively, blew my mind.

Both of these examples were printed on professional machines.

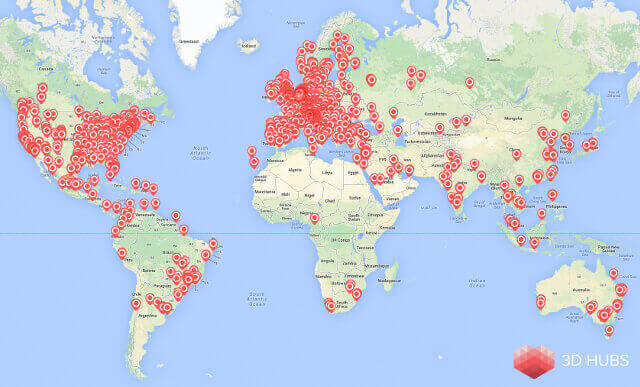

What has changed in recent years is that affordable high quality desktop 3D printers are within arm’s length — both in your home and office. As a product designer this is a dream come true. And for those who don’t have direct access to a 3D printer, the printers are still available via services like 3D Hubs.

When you look at the bigger picture, that such printers are basically everywhere now, this could actually make the concept we were discussing at design school a reality. When we look at desktop printers we see a lot of untapped potential. Because local production on a large scale isn’t really happening yet. Everything is in place to start local, distributed, production. With kits that are easy to assemble and well designed 3D printed parts we try expand the possibilities of 3D printing and increase the content quality.

Q: Tell us a bit more about the team, and their background and experience.

We are all industrial designers who have studied/study at Industrial Design department at the Technical University of Eindhoven. Alex started working at form + function and on the print+ after recently graduating. He also worked on the print+ concept during an internship at form + function earlier. Nikka is currently doing an internship, and is mainly working on a product that will show where print+ could go well into the future — but also helping out in communication with our China based suppliers (Nikka is from China).

Q: Why did you choose headphones as the launch product?

The relative simple electronics, the relatively small print size, and it’s a perfect example to show people the power of 3D printing. With print+ we want to give 3D printer owners something nice to print, and we want people without a 3D printer to become interested in using a 3D printer — because they now understand that it can be used for actual end products.

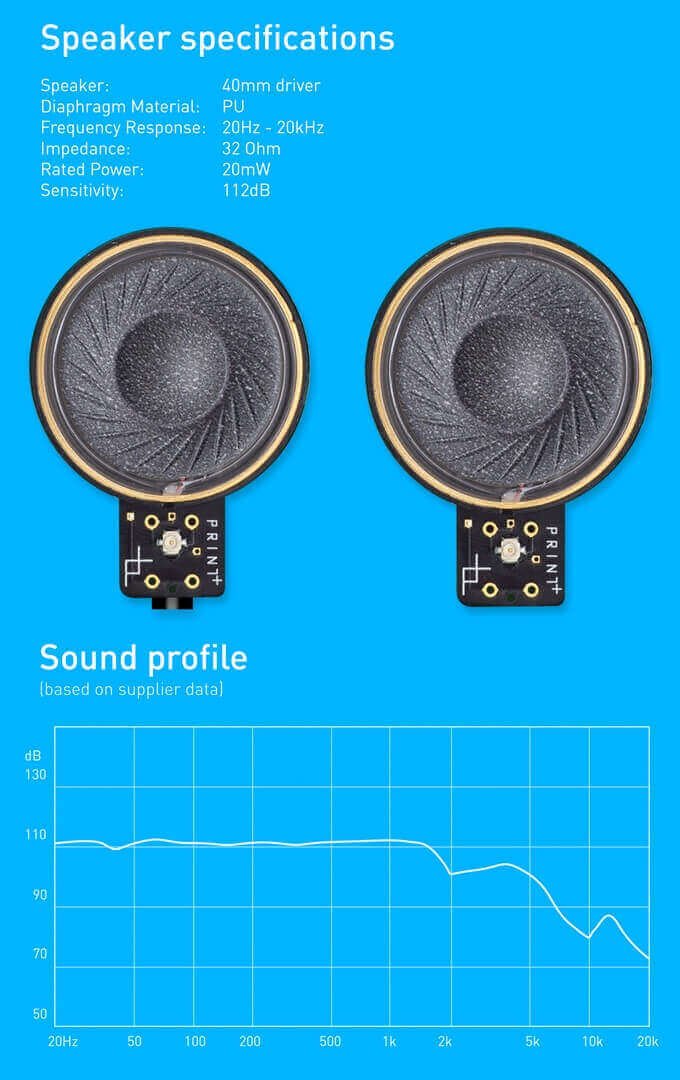

Q: Can you share some details about the audio specifications of the headphones?

They are high quality 40mm speaker drivers, with a with a PU membrane and an impedance of 32 ohm. See the specs here:

Q: Will the audio quality of the headphones be impacted by using a particular type of filament?

What we did notice is the way a part is printed has a great impact on audio quality. We currently print headphones with a shell thickness of 1.2mm ~ 1.6mm and with an infill of 50%. This has great effect on the sound quality. At the moment we are testing different variations of vents and bass tunnels — this will impact sound more than the type of filament. Other than that, the type of filament will also have great effect on comfort and durability of the headphone. In the coming months we will be doing a lot of tests to see what materials can be used best.

Q: Shipping dates are for March 2015. Why will it take so long to deliver the final product to backers?

Speaking from experience of owning a product design studio — building hardware will always take longer than you expect. It is a relatively simple project, but we are going to make most of the components in 22 different colors, which creates some challenges in production. We originally wanted to be able to deliver in December / January. But if one thing in the process goes wrong, we will be overshooting this delivery date pretty easy. So March is a more realistic date and will enable us to get everything right. And if we get everything right, faster, we will deliver before that — but we don’t want to get anyone’s hope up. At the moment we are focused on improvements of the existing components and design as well as gearing up to start production.

Q: Presumably, if this campaign is a success, you’d like to expand the range of print+ DIY products. What’s next on the slate?

That’s a good question! Out of the gate we could offer some simple products such as a handsaw and a flashlight. We have them quite far along in development, but I’m not sure if those will actually see the light of day. We are still debating what products to do next. We hopefully get to develop more complex products in the future.

Q: Tell us about your partnership with 3D Hubs. What was the origin of this collaboration?

I have been close with the guys from 3D Hubs since the beginning — Brian Garret is my brother. Years ago, Brian and Bram, 3D Hubs’ founders, worked at Janne Kyttänen’s Freedom Of Creation (FOC) — a pioneering company in creating high-end 3D printed products and developing visions of the future with regards to 3D printing. At one point I was working on the iPhone cases with Freshfiber. Both FOC and Freshfiber were also working closely together. Both became part of 3D Systems through separate takeovers. I experienced those mergers from a distance.

After FOC was absorbed into 3D Systems, at some point Brian and Bram were thinking about starting 3D Hubs, and actually went forward and registered the domain name. Not long after — I must have been one of the first people to ever send them an email — I sent them a half joking proposal to form a partnership for a brand called ‘print-o-tronics’ to ship people flat circuit boards so they can print housings around it themselves. Bram replied with ‘that a partnership would cost one million a month, with no guarantees’ — haha. This email conversation was in 2012. It took quite some time and resources to develop the first print+ product. 3D Hubs started somewhere in 2013. It is 2015 now. There are 23.000+ printers on 3D Hub’s network. The name ‘print-o-tronics’ has been changed to ‘print+’ as we will do more products than just electronics.

Q: Any plans to tie up with any other printing services in the future?

I think we will certainly explore this in the future, right now our focus is mainly on getting the print+ kits into production. Also, for most 3D print services we will have to adapt our design to be suitable for SLA/SLS.

Q: Finally, what’s the most useful thing you’ve ever 3D printed?

Apart from dozens of headphones? A replacement part for a friend’s IKEA roll up curtain. it was considered trash until he figured “hej — Patrick could print a replacement part!” So I modelled it quickly and printed it. Worked like a charm.

License: The text of "Q&A with Patrick Schuur, Inventor of print+ DIY Headphones" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.