How one social enterprise in Yangon, Proximity Designs, is teaching Myanmar’s farmers to 3D print their own agricultural tools.

“Farming is backbreaking work” says Taiei Harimoto, designer at Proximity Designs. “And farming in Myanmar can be especially hard due to the country’s low annual incomes (around $600 USD), poor infrastructure and access to quality tools.”

This is where Proximity Designs is trying to make a diffierence. This Yangon-based social enterprise is innovating with locally designed, income generating agricultural equipment for rural smallholder farmers.

Founded in 2004, their products and services have enabled the generation of over $276 million in revenue for more than 102,000 rural households.

But like farming, the task isn’t easy. Proximity Designs must keep manufacturing costs low, and until recently had to rely extensively on slow, expensive metal machining for prototyping.

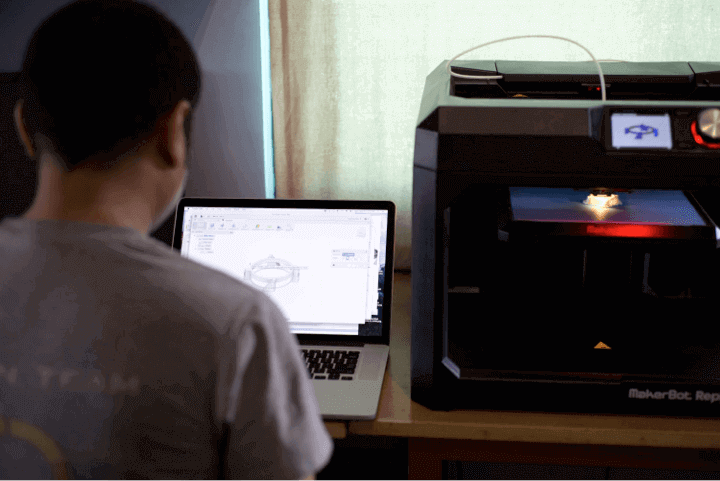

Things changed in late 2015 when they learned about MakerBot and 3D printing. Proximity Designs made inquiries with the company about whether a 3D printer could address some of the bottlenecks in their product development cycle.

MakerBot responded by donating a printer to the social enterprise, to observe the impact it could have on engineering challenges in the field.

Proximity Designs Teaches Farmers to 3D Print Their Own Tools

“Having the Replicator changed a lot of fundamental things about the research and development process,” says mechanical engineer and former Proximity Designs fellow Zachary Gould.

For example, the printer played an important role “when we needed to nail down the dimensions of specific components of a project, especially crucial parts that affected the overall alignment of the product such as spacing rings.”

And because the majority of the vendors they work with have little-to-no experience using computer assisted design (CAD) software, conversations over 2D drawings about yet-to-be-created parts were not always easy. But with printed parts in hand, conversations with vendors became much simpler.

The capability to adapt and prototype faster with a 3D printer increased their ability to address the needs of rural households across Myanmar. As Taiei Harimoto explains:

“In the past, we would have done our best in CAD, ordered machined samples from abroad, shipped them back to Myanmar to test and iterate. Completing one cycle would have taken a month, with high machining and shipping costs. The 3D printed parts helped us to physically try the assembly processes and refine designs before committing to orders of thousands of aluminum parts from abroad — resulting in huge time and cost savings.”

Moving forward, Proximity Designs plans to continue to incorporate 3D printing in their future prototyping work.

Having access to the speed, reliability, and versatility of a 3D printer has enabled them to grow and evolve alongside dynamic shifts in technology. In turn, that allows them to continue designing life-changing products for the future farmers of Myanmar.

Source: MAKE

License: The text of "3D Printing Yields Big Harvest for Proximity Designs" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.