Researchers at Cornell University have developed an ‘on-the-fly’ print system that 3D prints what you design, while you design it.

You love 3D printing, we love 3D printing, everybody loves 3D printing. But you know what nobody loves? The waste that piles up from a series of failed printing jobs. Every time you make something that doesn’t quite work, a bunch of plastic is dumped in the trash.

But a new 3D printing system from Cornell University proposes a neat solution. Researchers have developed a way to print as you design in real-time, so that changes can be made with an on-the-fly print instead of having to scrap it and start over.

The interactive printing system allows users to print simultaneously while they’re designing a prototype, and they can hit the pause button at any point to evaluate, test, and make revisions that will be added to the object being fabricated.

“We are going from human-computer interaction to human-machine interaction,” said graduate student Huaishu Peng, who described the On-the-Fly Print system in a paper presented at the 2016 ACM Conference for Human Computer Interaction.

On-the-Fly Print based on WirePrint Tech

The software powering the On-the-Fly Print system is a plugin for a Computer Aided Design (CAD) program that can send instructions to the 3D printer as changes are made, and allow for interruptions to the fabrication process.

The system has even more benefits over the traditional layer-by-layer approach of fused filament fabrication (FFF). While the nozzle only works vertically, the print-bed is replaced with a staging platform that can rotate to place any side of the object facing up, so the printer can add to it.

It also has a cutting tool for removing parts of the print, or carving out spaces in the design. The platform can also be removed from the printer so that the object can be measured and tested at any point, and then returned for additional printing.

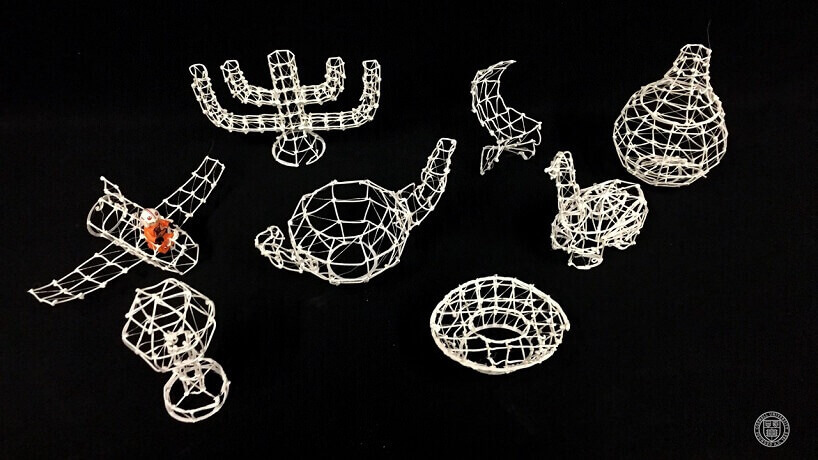

The system uses WirePrint technology, developed in collaboration with the Hasso Platner Institute in Potsdam, Germany, where the printer extrudes a thick outline of quick-hardening resin to create a wire frame of the object being prototyped. This allows for an extensive design and testing process before a solid version is built.

As a proof of concept, the team designed and printed an airplane to add to a LEGO set. It required the addition of wings, the carving out of a cockpit, and multiple checks to make sure the wingspan would fit a LEGO airport set as it printed. The whole process only took 10 minutes.

(Source: Cornell University)

License: The text of "On-the-Fly Print: Incremental Printing While Modeling" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.