Startup NVBots has brought to market a fully automated commercial 3D printer equipped with cloud-based queuing and automatic part removal.

Don’t Miss: Batch Works use Ultimaker 2+ as a Perpetual Printing Machine

The biggest hurdle to mainstream acceptance of 3D printing is easy to understand. It’s just not fully automated in the same way as a conventional 2D printer.

The workflow can be laborious. First you have to slice a 3D model and then upload it to a machine. Then you must wait for the print job to finish. Finally, you have to manually remove it from the bed before starting a new print. Compare that to printing with paper; users queue documents over a network, and their item is already waiting for them when they go to collect it. It’s stupidly easy.

In our exclusive story about Batch Works, we wrote about the search for open source solutions to better automate the 3D printing process with fused filament fabrication. A perpetual printing machine, if you will. In tandem with that, another company in the US has developed the same idea.

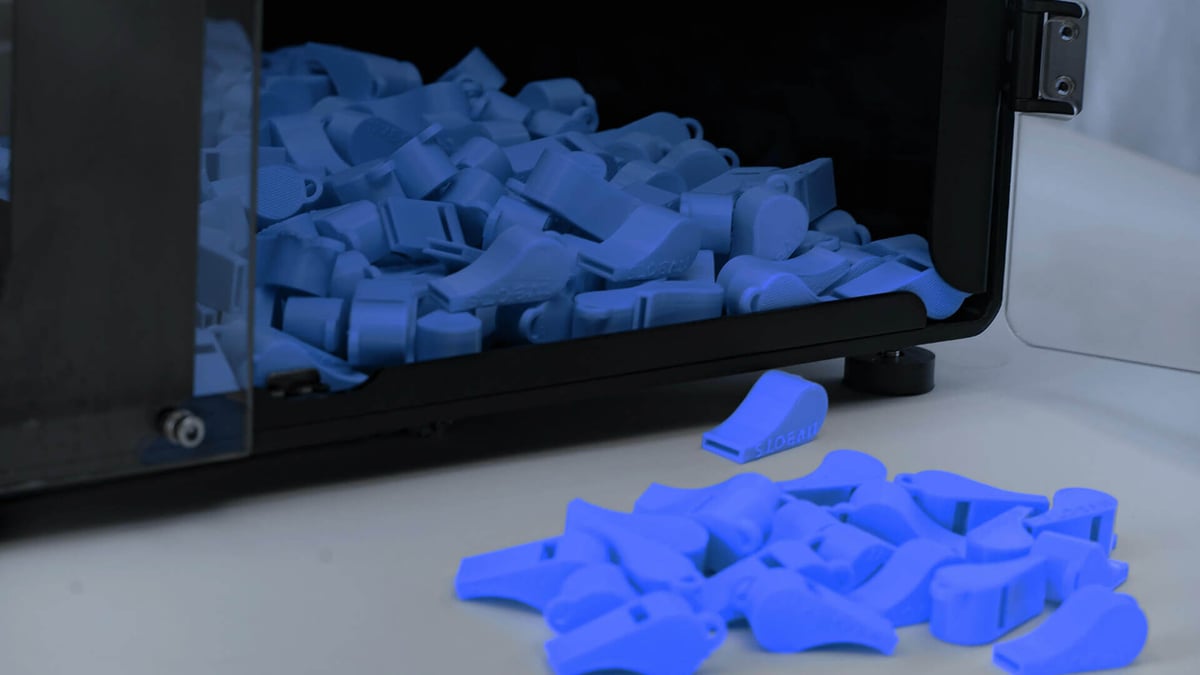

NVBots is a spinout company from MIT which has brought to market a fully automated commercial 3D printer that’s equipped with cloud-based queuing and automatic part removal. In video demonstrations we see how it makes print jobs quicker and easier through large batch printing.

The name of the printer is the NVPro. To use it, a user submits a project from any device, which queues up in the NVCloud software. When a part is finished printing, a retractable blade slides under the item out and moves it into a bin, and the next project begins automatically. Projects can be monitored remotely via webcam.

See the NVPro in action in the timelapse video below.

NVBots Leveraging the Cloud to Improve Performance

In the past year, NVBots has sold their groundbreaking machine to a diverse range of to customers, ranging from educational institutions to companies in the automotive, construction, medica, aerospace and architecture sectors.

Where it might typically require days or weeks to 3D print a model of a building or a part for a medical device, the workflow from NVBots allows clients to upload a design to the cloud and then collect the item themselves within a day.

And without the need for dedicated personnel to oversee the printing process, the reduced cost of ownership and saved labor significantly lowers the price per part compared to traditional 3D printers.

Another benefit of using cloud software is that NVBots are harvesting data on their printers to improve performance. Every time a user prints an object, the startup gathers data on things like the job’s success, quality, length, and material.

Since launch, the startup has generated 3.8 terabytes of data related to the manufacturing process. NVBots also plans to use it to tackle security issues, improve human-machine interfaces, and enable 3D printing with advanced filaments.

Source: MIT

License: The text of "NVBots 3D Printer has Project Queuing and Auto Part Removal" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.