Swiss researchers at the École Polytechnique Fédérale de Lausanne have developed a way to 3D print microscopic structures with an optical fiber as thin as a human hair.

Most likely you’re familiar with stereolithography (SLA) and DLP 3D printers. These machines produce structures by selectively shining light on liquid photopolymers, which in turn become solid.

Don’t Miss: The Best Resin 3D Printers in 2024 – Buyer's Guide

And while resin-based 3D printing is certainly more precise than fused deposition modeling (FDM), it’s no way near as fine as the technique recently coming out of École Polytechnique Fédérale de Lausanne.

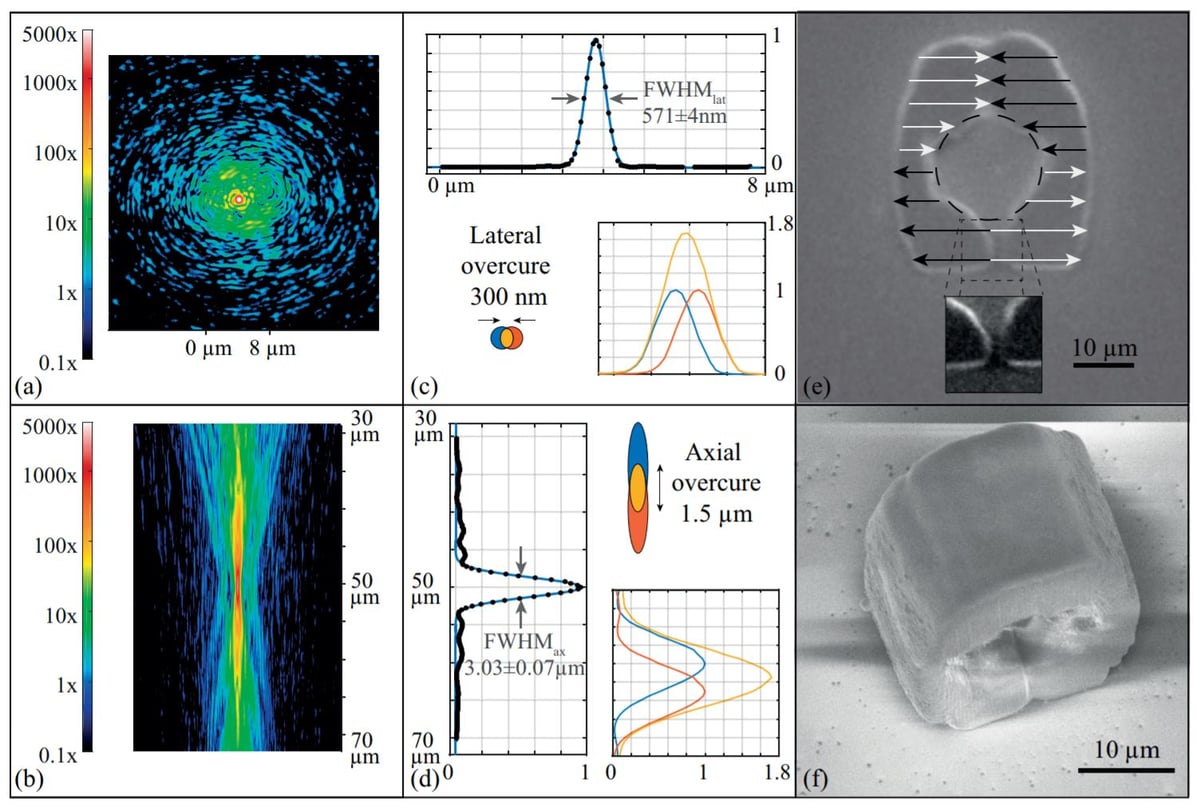

Like SLA, their method uses a laser and photopolymers. The difference is, instead of shining light on the photopolymers directly, its delivered via an ultra-thin optical fiber. How thin? No wider than a human hair.

That means the group of researchers are able to print structures with resolutions down to 1 micron in width and 21.5 microns in height. Such tiny components, combined with a compact printing system, have huge potential in both additive manufacturing and medicine. Paul Delrot, the research team’s leader, elaborates:

“With further development our technique could enable endoscopic microfabrication tools that would be valuable during surgery. These tools could be used to print micro- or nano-scale 3D structures that facilitate the adhesion and growth of cells to create engineered tissue that restores damaged tissues.”

Potential Application Areas of Microfabrication

Other laser-based microfabrication techniques do exist, but are slightly different. They typically make use of a phenomonen called two-photon polymerization, which requires complex lasers and bulky delivery systems.

In contrast, the Swiss team’s apparatus is compact enough to be easily added to a normal 3D printer’s rig, for example. “By using one printer head with a low resolution for the bulk parts and our device as a secondary printer head for the fine details, multi-resolution additive manufacturing could be achieved,” says Delrot.

Yet far larger potential lies in the area of non-invasive surgery. Installing the fiber optic cable inside an endoscope could allow for microscopic elements to be printed inside the body.

Apart from the ultra-thin delivery mechanism, this is made possible thanks to the specific photopolymer used. Delrot explains:

“We took advantage of a photopolymer with a nonlinear dose response. This can work with a simple continuous-wave laser, so expensive pulsed lasers were not required.”

This laser, unlike those normally used in microfabrication, emits light within the visible sectrum of light, which is potentially safe for human cells.

More work is required to bring the technology to clinical trials. Of particular importance is the need for a biocompatible photopolymer and a means to deliver it in a non-invasive way.

If you’re interested in the more technical aspects of the work, check out the group’s paper, published in Optics Express.

Source: The Optical Society of America

License: The text of "New Microfabrication Technique Using Fiber Optics" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.