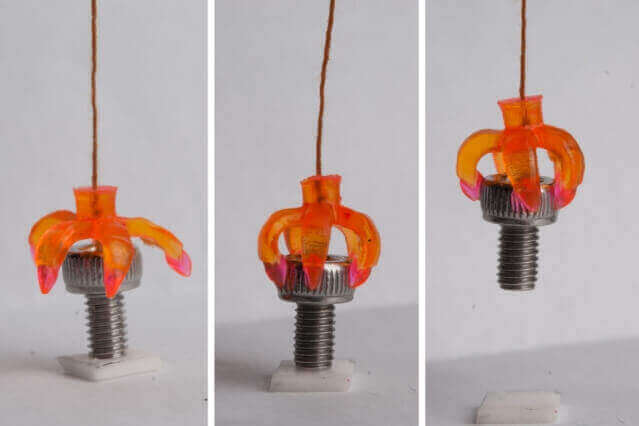

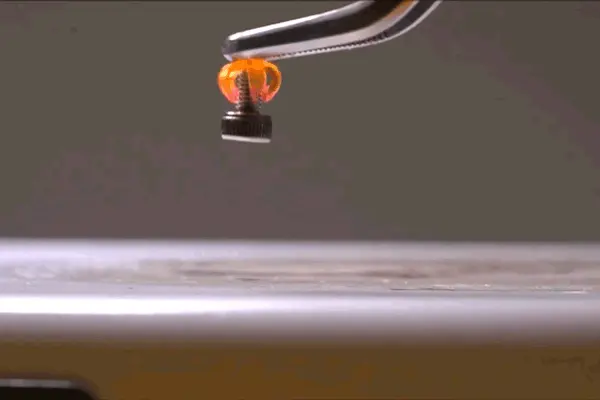

MIT researchers used 3D printing to make flexible devices which “remember” their original shapes and can transform accordingly.

Researchers from MIT and Singapore University of Technology and Design (SUTD) have created 3D printer technique which can be used to print micron-scale features. Structures the researchers have printed so far include small coils and multi-material flowers, and a miniature replica of the Eiffel tower.

These printed structures can be twisted and stretched, but will always “remember” their shape – this is called 4D printing. All that is required for this to happen is a certain temperature “sweet spot”.

The benefit of shape-memory polymers is that they can be used i.e. for drug capsules which open at the beginning of an infection.

Nicholas X. Fang, associate professor of mechanical engineering at MIT, said: “We ultimately want to use body temperature as a trigger. If we can design these polymers properly, we may be able to form a drug delivery device that will only release medicine at the sign of a fever.”

How Does this Work?

Fang and his colleagues pioneered a 3D printing process which can print shape-memory structures in impressive detail. They called it microstereolithography.

It works by using a projector light to print patterns on layers of resin. Firstly, researchers create a model using CAD software. They then slice the model and each layer is sent through the projector as a bitmap. The projector is set to work and shines the light of the pattern onto a liquid resin or polymer solution. The pattern is etched into the resin and it then solidifies to create the structure.

“We’re printing with light, layer by layer,” Fang says. “It’s almost like how dentists form replicas of teeth and fill cavities, except that we’re doing it with high-resolution lenses that come from the semiconductor industry, which give us intricate parts, with dimensions comparable to the diameter of a human hair.”

In order to make sure the material stretches and twists without breaking, the researchers picked two polymers which, when mixed together and cured, can bounce back to the original form at a specific temperature.

The researchers hope that in future they can find polymers which react to temperatures closer to those in the human body. Only then could drug delivery capsules be produced.

What do you think this technology could be used for? Let us know in the comments or read more about 4D printing here.

(Source: MIT News)

License: The text of "MIT’s 3D Printed Structures “Remember” their Shape" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.