Advancing “lab-on-a-chip” microfluidics devices, Cardiff University researchers open their designs up to rapidly prototype new developments.

Researchers at Cardiff University in Wales are making great use of 3D printing in the advancement of microfluidics. In short, microfluidics is the field covering the behavior of fluids in minuscule amounts and it applications as a testing ground for other research.

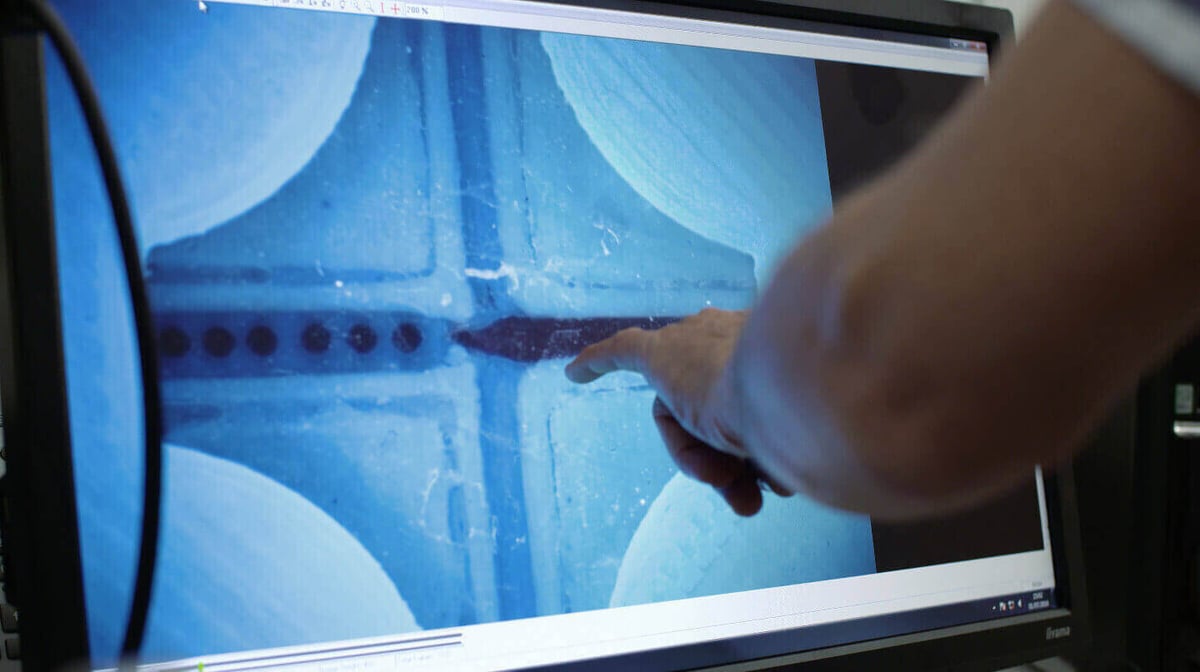

The devices created and used by the folks working on microfluidics can be referred to as a “lab-on-a-chip”. A network of tubes, sensors and actuators in a circuit, they are capable of complex functions.

By nature of their small interior volumes — we’re talking sub-millimeter — and surface tension dynamics at such scales, the researchers can manipulate the liquid. A good analogy would be the plumbing of an entire building shrunk down to microscopic scale.

The uses of such devices range from stem cell research and attempts to repair damaged spinal cords, to the creation of artificial cells used in pharmaceutical development. Even the modelling of nuclear fusion targets are possible.

3D Printing and Microfluidics

In the past such microfluidic devices have relied on production methods that are both costly and time consuming. But once again the rapid prototyping abilities of 3D printing has shown a cheap and efficient alternative is viable.

The team in Cardiff use Ultimaker machines to fabricate the Lego-like building blocks of the devices used in their research. Other studies determined 3D printing as ineffective for this purpose, claiming leakages and prints’ lack of transparency as issues. In the video above, Research Associate Alex Morgan explains that with a little tinkering, they overcame these issues.

But they aren’t the only ones using 3D printing in their research. A number of academic papers published in recent years detail microfluidic processes that use 3D printing. Interestingly, different from Cardiff University’s fused deposition modeling printer system — layering line after line of melted and extruded plastic — a team from Brigham Young University in Utah have outlined a method using stereolithography – light-solidified prints formed in a vat of polymer.

Regardless of the printing method, one universal benefit comes in the shareability of their microfluidics 3D printing. Because of this, the Cardiff University team are able to open up their designs for collaboration with other labs with 3D printers to iterate and develop microfluidics devices themselves.

Source: Ultimaker

License: The text of "Microfluidics Team at Cardiff University Democratizing Research With 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.