Need a new door handle? These “metamaterial mechanisms” developed at the Hasso-Plattner-Institut are functional objects without moving parts.

In desktop 3D printing, we spend more time preoccupied with the outer shape of an object rather than the internal structure. Something like infill — the percentage of material used to provide internal strength to a model — is about as complicated as it gets.

So what happens when you model not just the outer shape of an object, but also the internal microstructure? Try this on for size; 3D printed objects with no moving parts that can function as door handles and hinges.

Explained in an academic paper published by the Hasso-Plattner-Institut, the starting point is metamaterials; artificial objects with an internal grid of cells that have been aligned in specific patterns.

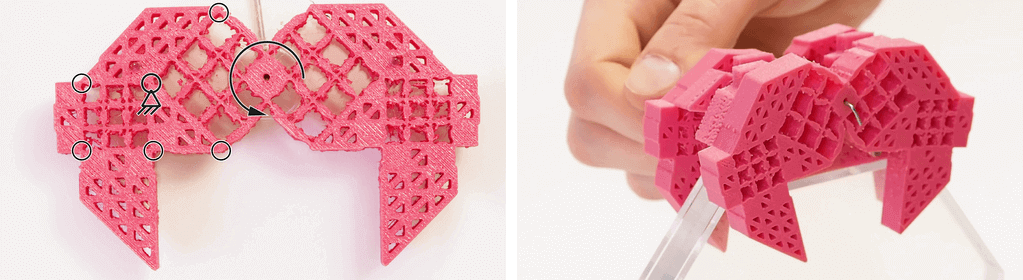

The team of researchers developed things further with something they call “metamaterial mechanisms”; the cell grids are designed for mechanical applications with repetitive and controlled directional movement in specific motions.

The project was made possible thanks to an educational grant from 3D printing service provider Shapeways.

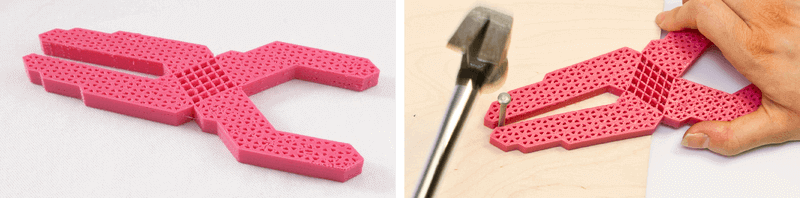

See the 3D printed metamaterial mechanisms in action in the video below, with a door latch, a pair of pliers, a hexapod robot, and other examples:

Metamaterial Mechanisms Based on Shearing Cells

The impressive thing about metamaterial mechanisms is it’s efficiency. 3D printing a door handle and latch isn’t outside the realms of possibility, but you’d first have to prepare and print the individual components and then assemble them into the final object.

With metamaterials, the door handle and latch are 3D printed together as a single object, saving time, money and materials in the process.

Once positioned, turning the handle causes the inner cell structure to shear and collapse, when in turn causes the latch to retract, and the door can be opened or closed as normal.

Granted, perhaps a 3D printed plastic door handle is not something you’d use to secure your home, but it’s a solid demonstration of the concept.

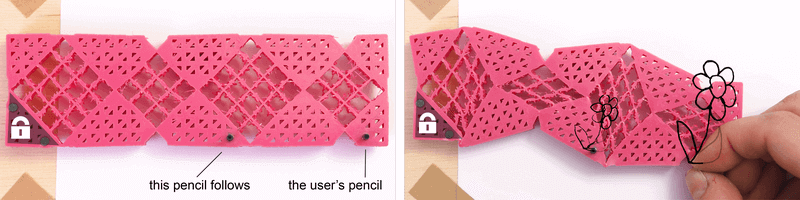

The team have also developed 3D modelling software that allows users to create their own metamaterial mechanisms. Users can place different types of cells, including the shear cell, and add functionality to their designs. To help users verify the integrity of the model before 3D printing, the sofware allows users to apply forces and simulate how the object will deform in response.

Pretty exciting stuff, eh? Unfortunately, there’s no word yet on when these models and software will be shared with the general public. Stay tuned for a future update.

License: The text of "Metamaterial Mechanisms: 3D Printed Door Handle & No Moving Parts" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.