Why should you read this: to find out the world will need to address the issue of animal farming.

If 3D printers are the early ancestors of Star Trek’s “replicator”, using them to somehow produce food is likely to be one humanity’s objectives. After all, that is mainly what the “replicator” is used for on the Enterprise. How that will happen is still unclear: We already have machines that can assemble edible substances such as chocolate, sugar and several kinds of pastes, however the final objective would be to use them not just to prepare food, but to make complex foods, such as meat, as well. If not from molecules and atoms, then, at least, from lab grown cells.

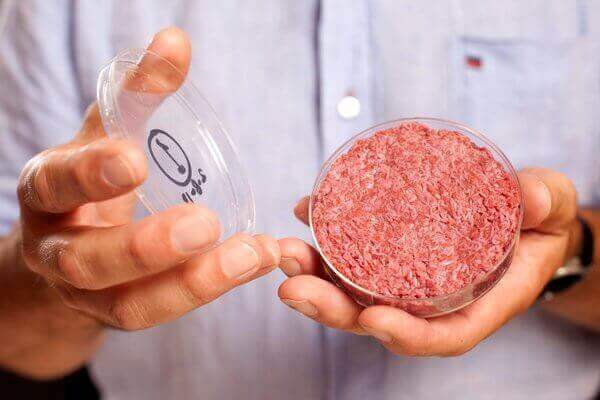

That is the goal of a company called Modern Meadow, which wants to use already available bioprinting technologies to to commercially produce in-vitro edible meat. It has already achieved quite a few results, among which tons of media coverage and even a fully 3D bioprinted edible hamburger, made with 20.000 cellular filaments “grown” from bovine stem cells.

To meat or not to meat

The reason why the entire world is so fascinated by the possibly of 3D printing artificial (actually, we should call it “bioficial”) meat is that, simply put, in a few years it will no longer be possible to obtain it from animals as we do today. Intensive animal farming is increasingly perceived as a cruel and inhumane practice (and research seems to point out that, in fact, it is) and that it is one of the largest contributors to global warming and to the depletion of the world’s water resources. According to an association called FutureFood, about 55 billion animals are slaughtered every year to fill the world’s current demand for meat and that number – which already puts a serious strain on the world today – is going to increase over the next decades to the point where it will simply no longer be sustainable.

By applying the lastest advances in the field of bioengineering of tissues, Modern Meadow is working on the development of new biomaterials that have the potential to address some of these issues. The company has developed products based on meat and tissues without having to resort to the slaughter of animals and, it says, with far more limited requirements in terms of the use and consumption of land, water, energy and even chemical agents.

Founded by a father and son team, Gabor and Andras Forgacs, this start-up is already producing artificial meat using a 3D bioprinter. The scientists first collect stem cells (that is the cells that are at the base of regenerative medicine, since they can be “programmed” to turn into any type of cell) from the animals through a common procedure known as a biopsy. The cells are then fed and cared for so that they will grow and filaments or strands. These are inserted into a bio-cartridge to be printed in the desired shape and combined to form an organic fabric which has exactly the same biological composition of the meat from a real cow. About 20,000 of these filaments – produced at a cost of more than $300.000 – is what it took for Dutch scientist Mark Post of Maastricht University to create the first lab-grown burger.

The project, which was financially supported by Google’s founder Sergey Brin, has several implications. While its exterior appearance is not so far from traditional chopped beef, many people are put off by the idea of lab grown edible meat. However that should be put into perspective and compared to the barbaric act of slaughtering an animal and the even more barbaric practice of intensive farming, which causes the animal to suffer. The lab produced meat is actually transparent so it has to be colored red with natural food colorants. It is also completely fat free, so it does not taste as good when grilled, however that can also be addressed in the future by factoring in-vitro cultured fat cells. According Mr Post, Jewish rabbis have already asserted that artificial meat could be compatible with kosher rules.

You eat with your eyes

That of external appearance and taste are certainly to of the biggest determining factors in the wide scale adoption of bioficial meat, even more than its cost, which is bound to be drastically reduced through scale economy and technological advancements. To make 3D printed meat (and other foods) more pleasing to the eye, future scientists may follow the reserch conducted by the German biozoon food innovation group. For the EU funded PERFORMANCE (PERsonalized FOod unsing Rapid MAnufacturing for the Nutrition of elderly ConsumErs) proejct, the German team of scientists worked to rebuild portions of blended food into an easily digestible form which also integrates a special system for “texturing” which makes it more attractive to the eye. For example, a chicken fillet could be cooked, blended and used to produce a portion of “gelled” chicken, in the shape of a chicken wing or breast, that can be swallowed and digested without dangers.

The biozoon printer works like a traditional inkjet system, using capsules filled with liquid foods: one for vegetables, one for meat and one for carbohydrates. It creates the initial layer, for example the two-dimensional shape of a chicken wing, with the liquid from the cartridge, extruded through the 48 nozzles inside the printhead. A jellifying agent, currently under development, is then added to the liquid in the cartridges to allow the the food to be molded into the desired shape, which may be that of a chicken wing and, at the same time, have any flavor desired.

Bespoke nutrition

Assembling foods means that it can also be tailored for specific nutritional requirements. That is what Nestlé’s Institute of Health Sciences wants to do in its Iron Man program. The Swiss food giant wants to create a machine – a “Nespresso machine of the future” – capable of creating tailored dietary supplements or even entire tailored foods and meals. The system will implement current in-development technology to track the nutrients present in the body to then combine these results with a 3D printing-like digital fabrication method, which will create the foods and insert the capsulses with the necessary nutrients. These foods may be as far as five to ten years away but the company is already investing heavily into the program.

To help us understand what possibilities are on the horizon, Next Nature published a volume entitled the “In Vitro Meat Cookbook“. Using the familiar format of a recipe book, the text will visually explore the new food cultures that artifical meat may be used for. The issue is studied both by the prospect of food design and that of bioengineering, while considering social and ethical implications. Think, for example, “painting edible meat” or eating artificially reproduced “wings of Dodo”, “flesh ice cream” or “cannibals snacks”, “woven steaks” and “transparent sushi”. People around the world eat some amazing things, it is just a matter of habit. Can we get into the habit of lab-grown meat? If we ever do a lot of animals will thank us.

License: The text of "I’m the Future of 3D Printing, Nice to “Meat” You" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.