Engineers from the defense company Lockheed Martin are using MakerBot 3D printing to develop new designs for SPIDER imaging technology.

Known as one of the pioneering aerospace and defense enterprises, Lockheed Martin is constantly on the forefront of scientific innovation. Over the last couple of years, the military-driven company has utilized hundreds of 3D printers to create prototypes, tooling, and use-end parts.

While you might expect a manufacturer of that size and stature to stick to industrial-grade 3D printing, Lockheed Martin also utilizes desktop printers. A recent case study shows how the company’s scientists and engineers are using MakerBot 3D printing to develop revolutionary space technology.

SPIDER Imaging Technology: Smaller, Lighter, More Powerful

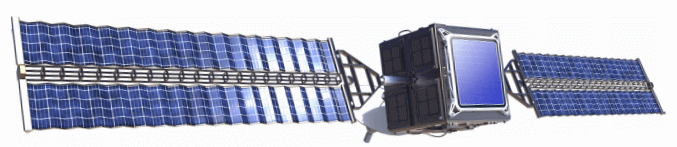

Looking to develop new telescopes, the U.S. Defense Advanced Research Projects Agency (DARPA) turned to scientists and engineers from Lockheed Martin’s Advanced Technology Center (ATC). Their goal is to redesign traditionally used telescopes, which are heavy, bulky, and extraordinarily expensive.

Working with experts at University of California-Davis, Lockheed Martin recently developed SPIDER imaging technology. This is a special silicon chip that channels light fed through tiny lenses. Compared to modern telescopes, ATC’s technology could reduce the required size, weight, and power from 10 to 100 times. On top of that, SPIDER is cheaper and faster to produce, making it an ideal alternative for space exploration.

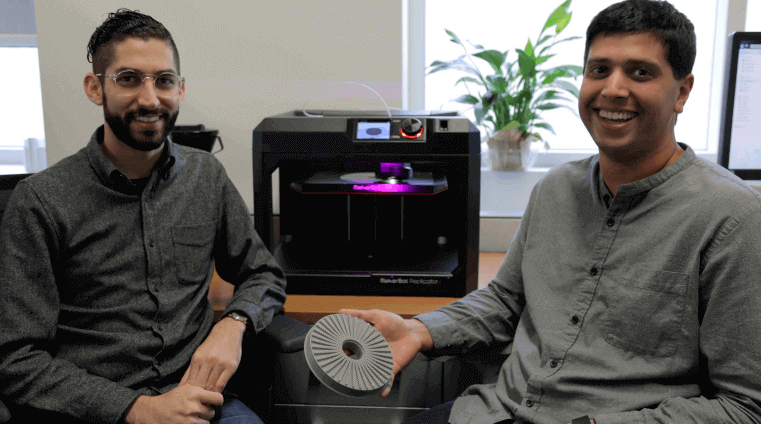

In order to create fittings for this SPIDER technology, ATC designed various arrays in Solidworks and prototyped them using MakerBot 3D printers.

How MakerBot Technology Helps Develop SPIDER Technology

Using MakerBot 3D printing technology, the engineers have been able to produce new SPIDER designs in a matter of hours. This has enabled them to perform more tests and create successful iterations at a faster rate.

The ATC team essentially owns the entire family of MakerBot printers, including a Replicator (5th Gen), Mini, Z18, Replicator+, and a Replicator Mini+. According to Guy Chriqui, Senior Research Engineer at the ATC, this range of printers are “basically running non-stop, all day long.”

When testing small rockets, the nose cone explodes off and is usually unrecoverable. But by bringing a Mini directly to the launch site, the engineers can quickly print different cones on the spot. The ATC team is also using MakerBot Tough PLA to produce functional snapping joints, known as flextures.

Lockheed Martin discovered that True Black PLA at 100 percent infill is ideal for absorbing light, preventing light leakage that can negatively affect optical tests. Lastly, neon MakerBot PLA is used to highlight specific parts, making the telescope build process much easier.

By integrating desktop printing into the development of new telescopes, Lockheed Martin is saving both time as well as money. With MakerBot technology by their side, the ATC engineers can continue developing and testing their ideas at a rapid pace. The development of this powerful SPIDER technology may someday stretch our knowledge of outer space further than it’s ever before.

License: The text of "Lockheed Martin Uses MakerBot 3D Printing To Design New Space Telescopes" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.