Lawrence Livermore National Laboratory researchers claim to be the first to 3D print aerospace-grade carbon fiber composites, possibly paving the way for complex new prints.

Don’t Miss: Carbon Fiber 3D Printer: Markforged Mark Two Review

Carbon fiber is a material which is stronger than steel and yet very lightweight. Because of this, it is ideal for making parts for the aerospace and automotive industries. However, when creating complex forms from the material using traditional methods, it is extremely difficult to control.

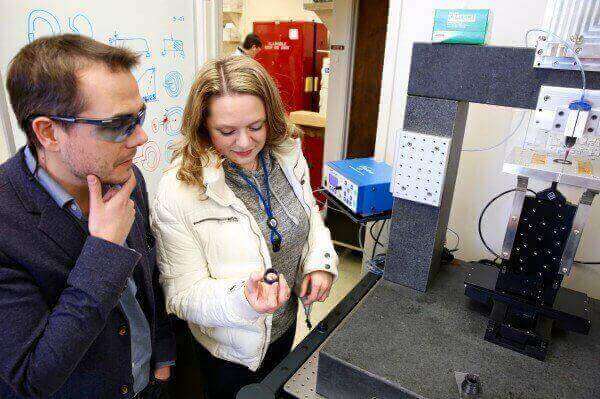

Researchers at Lawrence Livermore National Laboratory (LLNL) may have found a way to change this. The researchers are the first to 3D print aerospace-grade carbon fiber composites. And believe that because of this work, they will be able to control and optimize useage of the high-spec material.

It’s not the first time carbon fiber has been 3D printed. There are many PLA derivatives that can do the same on a regular household printer. However, it important to note the difference is that LLNL have printed aerospace-grade composites.

Jim Lewicki is the principal investigator and the paper’s lead author. He explains: “The mantra is ‘if you could make everything out of carbon fiber, you would’ — it’s potentially the ultimate material. It’s been waiting in the wings for years because it’s so difficult to make in complex shapes.” Lewicki continues: “But with 3D printing, you could potentially make anything out of carbon fiber.”

Previous problems with using carbon fiber composites included complicated methods required to create parts and an overcompensation of material due to “performance concerns”. However, researchers at LLNL were able to achieve the same material properties from two-thirds less material thanks to their new 3D printing method.

Going Beyond Carbon Fiber Filled PLA

To achieve this feat, LLNL created a custom Direct Ink Writing (DIW) printer, using their own composite carbon fiber “ink”. The researchers have also patented a method to cure the extruded material in mere seconds, rather than hours.

They relied on a computational model — visualized in the video above — in order to develop models of the flow of carbon fiber filaments in their ink. Yuliya Kanarska, fluid analyst, explains:

“We developed a numerical code to simulate a non-Newtonian liquid polymer resin with a dispersion of carbon fibers. With this code, we can simulate evolution of the fiber orientations in 3D under different printing conditions. We were able to find the optimal fiber length and optimal performance, but it’s still a work in progress. Ongoing efforts are related to achieving even better alignment of the fibers by applying magnetic forces to stabilize them.”

Because the material is conductive, it allows for a control of thermal channeling. A use could be in the production of satellite components that — printed into their design — are insulated on one side. Meaning they then do not require rotating in space.

The next challenge for the research team is to optimize the process. They have demonstrated the gains made possible with the method. But to take it further this will mean determining the best way to lay down the carbon fiber ink.

Source: Lawrence Livermore National Laboratory

License: The text of "LLNL Team Pioneer 3D Printing Aerospace-Grade Carbon Fiber" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.