The 3D Print Canal House is the first project that aims to explore the possibilities, limitations and possible implications of a full-size 3D printed house in eco compatible plastic material. Based in the city of Amsterdam, the project at Tolhuisweg focuses on the development of a canal house that should be able to interact with the various stimuli of its surrounding environment. The research and development team wants to rip the countless benefits of 3D printed houses that include the ability for personal customization, better seismic behavior, no construction wastes and no material transport costs.

Size Matters

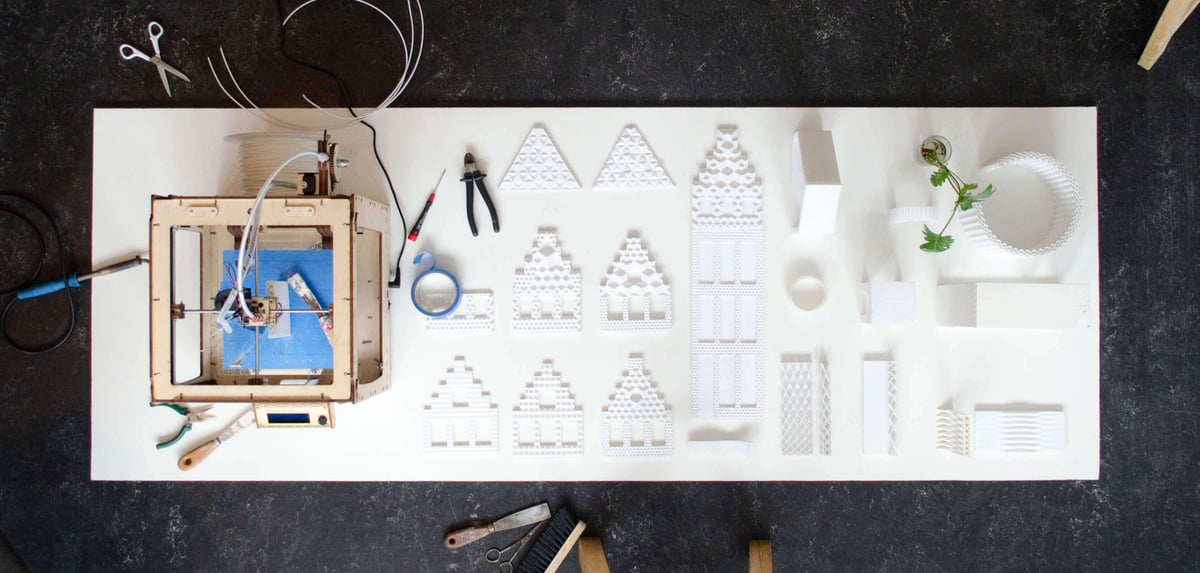

DUS Architect, the studio behind this project, has the support of Amsterdam’s major, authorities and technology partners that help with the testing and provision of special equipment. The house is built in small printers following a modular approach, designing each room individually. Taking the same designs up to scale, the team uses a custom-built 3D printer called KamerMaker (which is Dutch for “Room Builder”) that can print large parts using exactly the same principles and model files as any filament based 3D printer.

The material used for the concept house was developed by Henkel and it is a type of industrial glue combined with vegetable oil! Henkel has experimented with several biodegradable materials, as one of the goals of this project is for the building to be sustainable and recyclable. The KamerMaker printer has already undergone several improvements. It’s able to print three times faster than the initial mode at the temperature of 170°C. A second printer of the same specifications is currently in the works with the hope to further accelerate the project’s progress. Here is a quick video overview of the Canal House project.

Complexity Is Free with 3D Printing

Engineers and Architects of the Canal House project have to take into account a whole set of factors for each piece that gets printed. The parts include different inner and outer facades with extensive use of ornament elements (since “complexity is free in 3D printing”), connection points and inner meshes that add to the structural rigidness of the bodies. Inclined structural shafts of particular design are added in certain points to give more robustness and increase the safety.

The best part of the 3D Print Canal House project though is the collateral goal of the team to make the house “smart” by adding several sensors in key positions that could monitor changes in the environment and trigger corresponding actions. If temperature, light and moisture sensors are embedded into the printed material, the house could detect changes in the weather and activate heating or cooling systems inside it. This would increase its energy efficiency and automate its microclimate adjustments in real-time.

As this three-year project is mainly focused on research, it is impossible to estimate the final cost of the canal house just yet. When the building is finished and more 3D printed structures start popping up around the world, we may have a more streamlined and stable production of the raw materials used, so the cost may fall to large scale use levels. As we are going to see over the next few articles on this subject, there are already several projects that explore diffrent approaces to 3D building with several different materials. You can expect exciting news in this sector soon, in the meantime, why not take a trip to the beautiful Venice of the North to see the Canal House in the making?

License: The text of "Going to Amsterdam? Visit the 3D printed house" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.