A team of scientists from Brigham Young University have developed a custom SLA 3D printer and specialist resin that allow them to create what is thought to be the smallest viable microfluidics device.

Microfluidics is the study and manipulation of liquids on a microscopic scale. Lately, it is also the subject of much research involving 3D printing.

A team of researchers based in Cardiff, Wales, recently made great strides in 3D printing devices to allow such study using FFF. An accomplishment in itself, given the complications of layer bonding and other possible gaps.

But the Cardiff team’s device, while small, is positively rotund compared to a microfluidics device coming out of Brigham Young University. Detailed in academic journal Lab On A Chip, the team’s work achieves cross section channels as small as 18 x 20 micrometers.

For reference, that’s about the width of a human hair. We’re talking 3D printed channels with the cross-section of a hair, that are watertight. It’s a magnificent showcase of how far 3D printing tech has come.

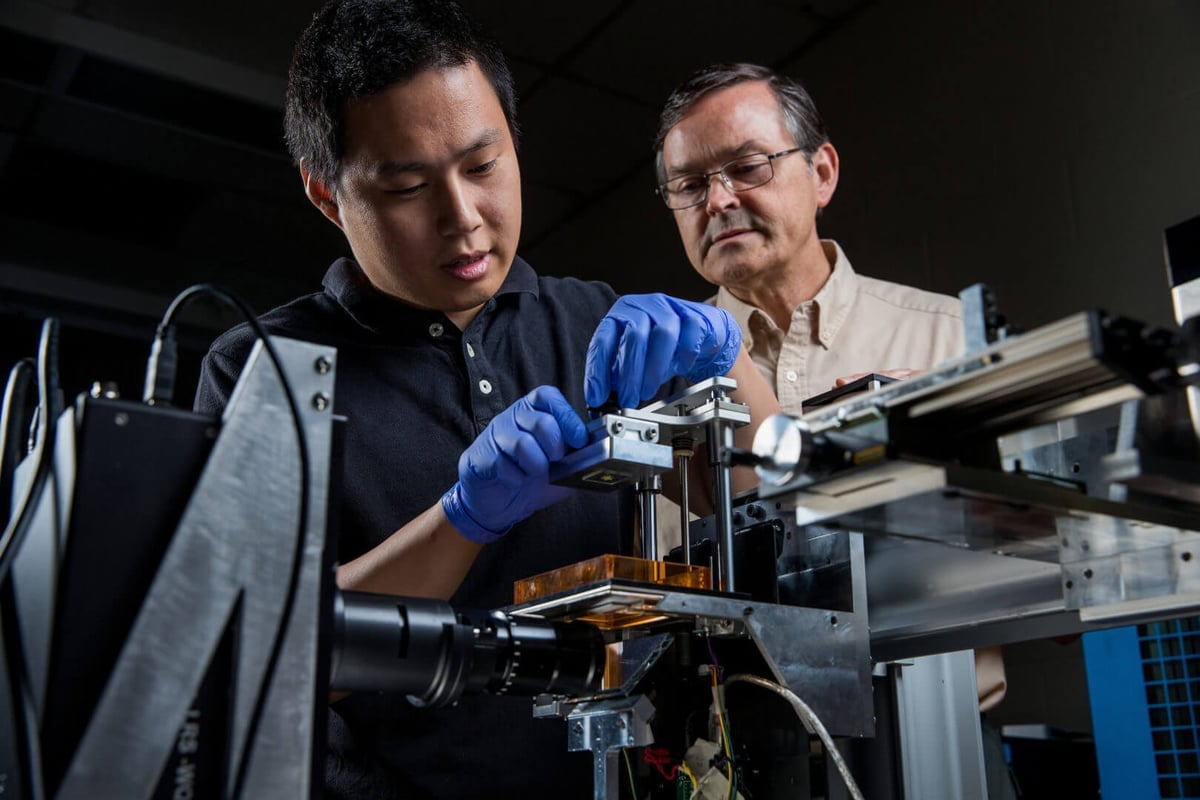

To do it, the researchers developed their own SLA 3D printer and a custom formulated resin. BYU Professor Adam Wooley commented “It’s not just a little step; it’s a huge leap from one size regime to a previously inaccessible size regime for 3D printing… It opens up a lot of doors for making microfluidics more easily and inexpensively.”

Build It Yourself: 3D Printed Microfluidics Devices

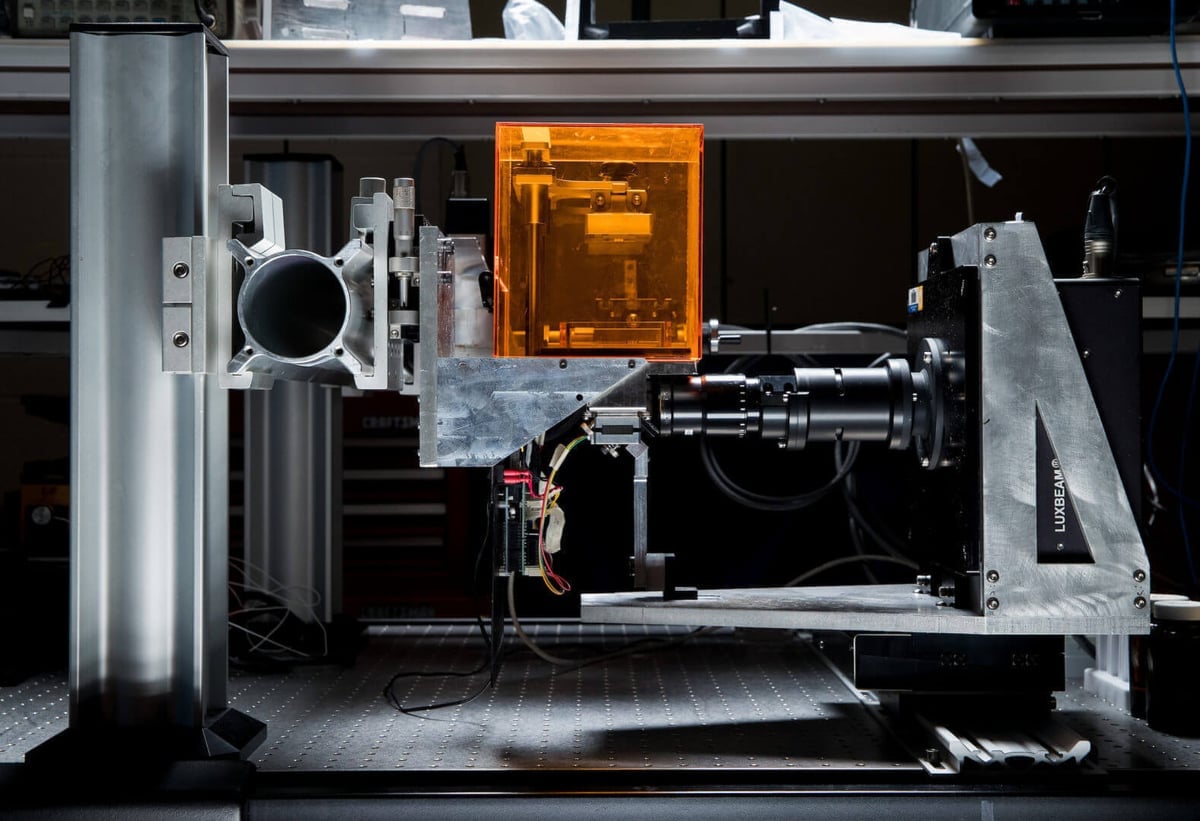

During their research, the BYU team found that the available technology couldn’t deliver the results they were seeking. And so with that in mind, they built their own SLA printer and custom resin instead.

Traditional techniques for the construction of microfluidic devices reign for their tried and tested reliability. In the spirit of pushing the envelope and innovation, the BYU team claim they are “deliberately trying to start a revolution”. And the key to this revolution is extreme resolution at reasonable costs.

With engineering know how from the university faculty taking care of the SLA printer, the chemical side of the equation required some old fashioned research.

The answer lay within the BYU library. Specifically, in a huge series of books on resin components. The researchers settled on 2-nitrophenyl phenyl sulfide as the UV absorber for their custom high-res resin concoction.

To get this new resin formulation to take, the custom 3D printer makes use of a 385 nm LED (typical SLA 3D printers use 405 nm). This two-fold approach of resin and printer means the BYU team can create 3D printed microfluidic devices on a scale previously not possible.

The team claims that this breakthrough demonstrates 3D printing can effectively challenge the traditional methods used to produce microfluidic devices.

Source: BYUNews

License: The text of "Custom SLA Solution Makes Innovative Microfluidics Devices Possible" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.