Aah, metals! One of the finest additions to 3D printable materials. As you know, your can order them through professional 3D printing services in steel, titanium, gold, silver, bronze… and now in copper.

Starting today, i.materialise offers this material on their website. Typical use cases are small robust and decorative models like coins, medals, keys, connectors, statues, freshly made artifacts.

Copper is an interesting and versatile material. The affordable metal offers high thermal and great electrical conductivity. Typically wires, cables and parts of electronic items are made of copper since the material is such a great conductor. Also, it is also often used for tubes, door knobs, handles and coins since it does not attract bacteria. Besides, copper is known to be found in architecture, household items, art, medals, and jewelry.

Be aware that this is no PLA filament enriched with copper particles – we’re talking the real thing here.

Colors and Finishes for 3D Printable Copper

Copper has a reddish color by nature. According to i.Materialise, the 3D printed copper models will be polished magnetically and by hand. You have the option of coating your copper model against scratches with a clear PU coat. This coat will also slow down corrosion, but it won’t prevent oxidation in the long run as the material is very sensitive.

Visually, there shouldn’t be real difference between uncoated and PU-coated parts at first. When corrosion starts, the difference will become apparent and a greenish verdigris or tarnish will become visible. The patina, as you know.

i.Materialise’s copper material has the same design specifications for copper as with gold, silver, bronze and brass materials. The minimum wall thickness (0.5 mm), minimum details (0.3 mm), and maximum printing size (88 x 63 x 125 mm) won’t change.

The Technology behind a Copper 3D Print

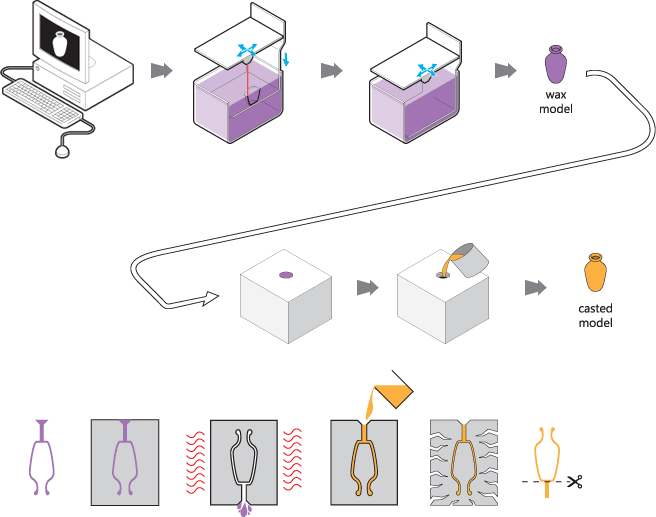

The technology for printing in gold, silver, bronze, brass, and copper is the same: a mix of lost wax casting and 3D printing. First, a wax cast of your item is 3D printed and then covered in fine plaster. When the plaster solidifies, it is placed in an oven and heated to a point where the wax is completely melted out. The metal is then poured into the empty cast and a real 3D printed metal item is created. In the final step, the item is finished manually.

License: The text of "Conductive & Thermal: iMaterialise Offers 3D Printable Copper" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.