The brains over at Makefast Workshop have pieced together a foolproof single string harp design. All you need to make your own is a 3D printer, a guitar string, tuner, bearings, nuts and bolts.

It may not quite have the range to serenade your sweet come Valentine’s Day, but why not throw musical caution to the wind and give this simple diatonic harp build a go? Dubbed the TuneFast Harp, it’s the result of Makefast Workshop’s experiment to create a stringed musical instrument that requires minimal tuning.

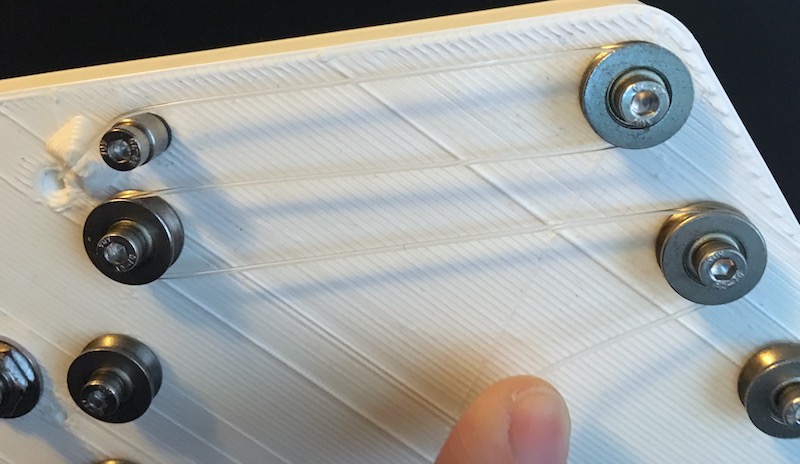

With just a single guitar string strung back and forth between fixed bearings on a 3D printed board, this harp covers an 8-note diatonic scale (think the white keys on a piano — the ones you’ll most likely use to play simple tunes).

Makefast Workshop reason that many multi-string instruments suffer a laborious tuning process, with the tuning of individual strings distorting the instrument itself, leading to yet more tuning to adjust to the deformations. In short, it can be a tedious balancing act.

For the TuneFast Harp, with each “string” under uniform tension and controlled by a single guitar tuner (bear in mind it’s in actuality a single string running back and forth), a simple equation is all that’s needed to determine the required lengths between points.

Harp-to-Heart: 3D Print Your Way to Silky Tunes

In all this little project will set you back about $7 dollars in materials. Besides the filament to run through a 3D printer (Makefast Workshop recommends PLA over ABS for its stiffness), you’ll need the following:

- Right-handed guitar tuner

- 9x M3x20mm nuts and bolts

- 9x M3 Belleville washers

- 8x 3124mm V-groove bearings

- M3 6×4 spacer

- Nylon guitar string

The 3D printable file for the board to attach all the bits mentioned above can be downloaded from Thingiverse. It’s recommended to print with at least 30% infill for strength, otherwise the harp could distort and buckle from the tension you’ll apply to the string.

Once printed, assemble the nuts and bolts with the bearings, with the washers going between the bearings and printed piece (to prevent friction and allow the bearing to rotate freely). Be mindful not to over tighten. There are eight bearings for nine pegs by design, with the ‘missing’ bearing found (or rather, not found), on the last peg where the string runs through the printed part and is secured.

Next up is to secure the tuner into the last remaining hole. Following this, it’s a simple case of threading the string onto the bearings, weaving back and forth and into the tuner. Tightening the tuner, nudge the strings to ensure it tensions uniformly across all of the notes. And that’s pretty much it — just trim the excess string and you’re set.

We’ll admit, the resulting instrument sounds nothing like an actual harp. With a plucky plink plonk, it’s unlikely to serenade the metaphorical pants off anyone come February 14th. But for a fun afternoon killing project though, its just the ticket.

Source: Hackaday

License: The text of "Make Your Own 3D Printed Single String Harp" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.