In Burghausen, Germany, silicone 3D print specialist ACEO opens the doors to its innovative tech with workshops and a new 3D print service.

For the past three years, German chemicals company WACKER has made great strides in the development of specialist silicones and 3D printing processes. In fact, the company even expanded its scope with the establishment of a team dedicated to the research. Dubbed ACEO, this new group has just launched its Open Print Lab.

Located at its own campus facility in Burghausen, Bavaria, the Open Print Lab offer small groups of customers workshops using the company’s elastomer printing solution.

More than a research group testing out new theories and processes, ACEO has a viable and proven product to flog. The company’s first silicone 3D printing system solution debuted last year at the K 2016 trade fair.

Hailed as a breakthrough in “real” elastic material printing, ACEO’s technology yields 3D printed silicones that maintain their chemical characteristics, such as bio compatibility and resistance to radiation.

Interested parties can have their own designs 3D printed using the new tech, too. A web-shop lets prospective customers upload their own designs for printing.

But this new material and method for additive manufacturing is not without its challenged. Dr. Bernd Pachaly, Head of Project 3D Printing at WACKER SILICONES, explains:

“Information and education across industries are key to understanding the variety of opportunities and applications offered by the ACEO® technology. We want customers to understand how our solution matches their needs. There is no better way than learning by first-hand experience. This is why we created our Open Print Lab.”

https://www.youtube.com/watch?v=x66yrACVXGE

How ACEO 3D Prints in Silicone

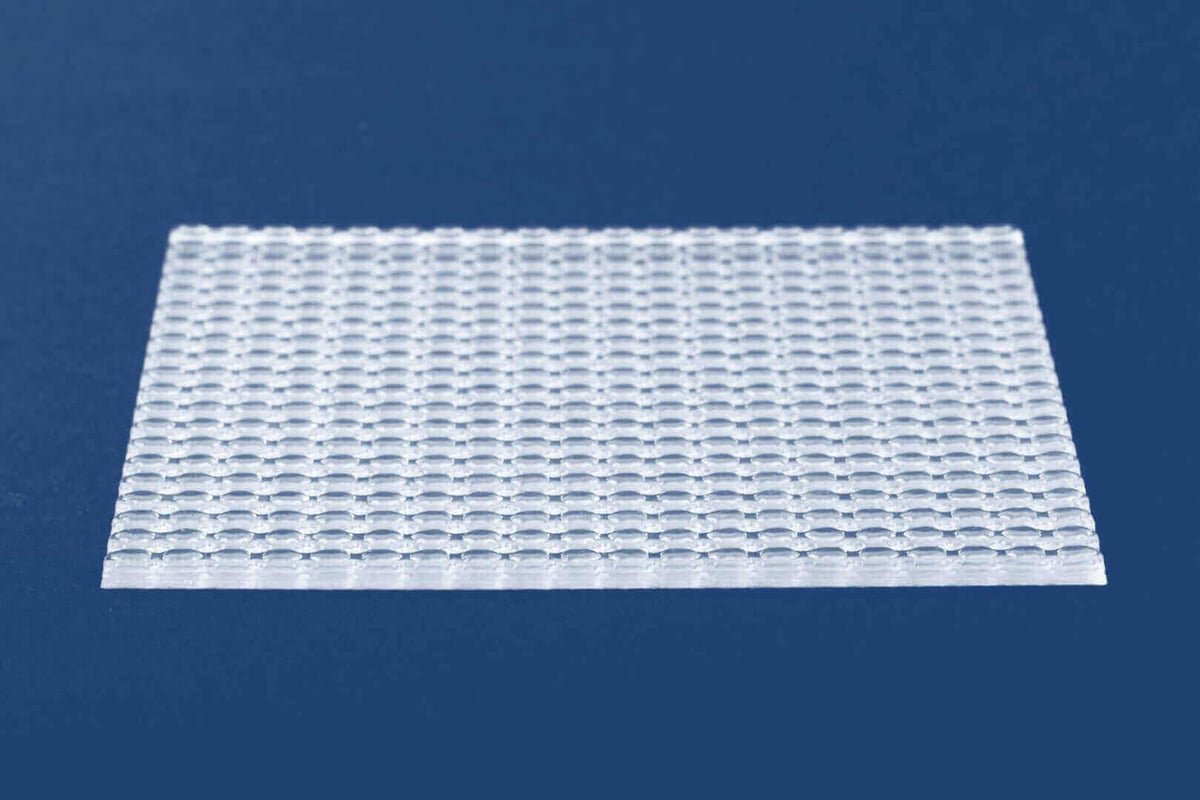

Unlike the continuous extrusion systems used to print other viscous liquids, ACEO’s silicone method lays a series of blobs of the material. Treated as voxels in the design, these dots build up layer by layer, like any other FFF 3D print. However, these silicone voxels flow together, smoothing out and forming a solid object. Each layer is cured under UV light.

In many ways, ACEO’s technology will be familiar to frequenters of 3D printing. Even complex shapes require water soluble support material, a tried and true FFF process.

If you live near Burghausen or are willing to go on a 3D printing pilgrimage, you can can join a tailor-made program that ACEO offers. Taking place at the Open Print Lab, these workshops accommodate up to four people at a time and teach both theory and practical lessons.

Source: Press Release

License: The text of "ACEO Opens Specialist Silicone Print Lab in Germany" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.